Professional Documents

Culture Documents

The Perfect Cylinder Program For Hydraulic Seals

Uploaded by

Rodrigo Jechéla BarriosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Perfect Cylinder Program For Hydraulic Seals

Uploaded by

Rodrigo Jechéla BarriosCopyright:

Available Formats

The PERFECT CYLINDER program

for hydraulic seals

THE PERFECT CYLINDER

PROGRAM FOR

HYDRAULIC SEALS

The Freudenberg-NOK PERFECT CYLINDER program for hydraulic VALUE FOR THE CUSTOMER

seals optimizes sealing technology to help customers reduce their

costs and improve the performance of their machinery. yy Leading-edge materials allow manufacturers to use non-honed,

rougher surface finishes that eliminate steps in the machining

The PERFECT CYLINDER program: process

yy Uses a unique "seal first" approach to reduce material and com- yy The number of seals and components required in a system is

ponent costs by as much as 40% reduced while performance is maximized

yy Changes the way standard cylinders are designed and man- yy Larger extrusion gaps up to twice normal design standards are

ufactured to accommodate specific application requirements tolerated, thus reducing manufacturing time

yy Incorporates three world-class materials as the pillars of its yy Reduced gland width saves space and material

success

yy Freudenberg experts evaluate and collaborate with customers'

Three pillars of success engineering teams to optimize cylinder design while maintaining

maximum application performance

Scientists at Freudenberg-NOK have developed some of the most

advanced materials and processes in existence to meet ever increas-

ing customer performance requirements. The PERFECT CYLINDER

program relies on three innovative products to deliver results:

1. HDP330 Nylon Piston Seal

2. 94AU30000 Polyurethane

3. ISG Guivex® Guidebands

What really drives costs down

Seals typically make up only

2-5% of total cylinder costs

The PERFECT CYLINDER program

for hydraulic seals

3 pillars of the PERFECT CYLINDER program

HDP330 Nylon Piston Seal 94AU30000 Polyurethane ISG Guivex® Guidebands

Features Features Features

yy Extreme high extrusion resistance yy Extreme high extrusion resistance yy Higher radial load capacity (40%)

yy Good sealing function drift yy Broad Chemical resistance yy Quieter operation

resistance yy Wide temperature range yy Excellent for short stroke

yy Dynamic sealing function similar (-40°C to +120°C) applications (inadequate

yy Hydrolysis resistance lubrication)

to or better than PTFE

yy Strong compression set yy Broad temperature range and

yy Allows for running across ports

use in mineral and synthetic oils

yy High abrasion resistance with low performance

friction design

Benefits Benefits Benefits

yy High pressure yy Larger extrusion gaps or pressure yy Improve side load performance or

yy Use in no drift applications and limit increase by 25% allow a 40-45% reduction in guide-

average pressures yy For use in wide range of oils band width in standard applications

yy High efficiency and improved (mineral and synthetic) and yy Reduced gland and piston widths

cylinder performance additives for material savings

yy Use in a wide ranging applications yy Use in biodegradable oils for yy Reduced equipment noise (db)

(including telescoping cylinders environmentally sensitive

and overhead applications) applications

yy Use in burnished or cold drawn yy Optimum design for low friction

tubes, with Ra > 15 micro inch performance (no energizers needed)

yy High abrasion resistance with yy Elimination of buffers in some

low friction design applications

The information contained herein is believed to be reliable, but no representation, guarantees or warranties of any kind are made to its accuracy or suitability

for any purpose. The information presented herein is based on laboratory testing and does not necessarily indicate end product performance. Full scale testing

and end product performance are the responsibility of the user.

www.fnst.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Reaction Paper On The Impossible DreamDocument2 pagesReaction Paper On The Impossible DreamJoshua Pantaleon Valiente100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

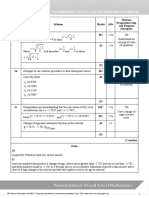

- Mark Scheme: Q Scheme Marks Aos Pearson Progression Step and Progress Descriptor 1A M1Document7 pagesMark Scheme: Q Scheme Marks Aos Pearson Progression Step and Progress Descriptor 1A M1Arthur LongwardNo ratings yet

- NSK Cat E728g 1Document6 pagesNSK Cat E728g 1shukhanNo ratings yet

- Syracuse Vision Plan After Removal of I-81Document57 pagesSyracuse Vision Plan After Removal of I-81jlammersNo ratings yet

- Granulation Machines Used For Dry Granulation and Wet GranulationDocument18 pagesGranulation Machines Used For Dry Granulation and Wet GranulationShaban Danish100% (1)

- DLP For UCSPDocument6 pagesDLP For UCSPruth taccadNo ratings yet

- Spherical Roller Bearings for Vibrating EquipmentDocument2 pagesSpherical Roller Bearings for Vibrating EquipmentRodrigo Jechéla Barrios100% (1)

- AddinolDocument18 pagesAddinolRodrigo Jechéla BarriosNo ratings yet

- Beka LubricadoresDocument2 pagesBeka LubricadoresRodrigo Jechéla BarriosNo ratings yet

- RODAC - CFW-ENG-FST - Conductive MaterialDocument2 pagesRODAC - CFW-ENG-FST - Conductive MaterialRodrigo Jechéla BarriosNo ratings yet

- PDFDocument1 pagePDFRodrigo Jechéla BarriosNo ratings yet

- Lubricant Application - Grease Volumes and Frequencies - TLT Article - April09Document76 pagesLubricant Application - Grease Volumes and Frequencies - TLT Article - April09Rodrigo Jechéla BarriosNo ratings yet

- Optibelt TT - Frequency Tension TesterDocument2 pagesOptibelt TT - Frequency Tension TesterRodrigo Jechéla BarriosNo ratings yet

- FYH ZlockDocument2 pagesFYH ZlockRodrigo Jechéla BarriosNo ratings yet

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosNo ratings yet

- KUKKODocument1 pageKUKKORodrigo Jechéla BarriosNo ratings yet

- Tabla Compatibilidad Quimica RetenedoresDocument36 pagesTabla Compatibilidad Quimica RetenedoresadolfoadolfoavilaNo ratings yet

- Cat5952 PDFDocument12 pagesCat5952 PDFRodrigo Jechéla BarriosNo ratings yet

- KUKKODocument1 pageKUKKORodrigo Jechéla BarriosNo ratings yet

- PBB de enDocument8 pagesPBB de enRodrigo Jechéla BarriosNo ratings yet

- RFN 7012-In: Ringfeder Locking AssembliesDocument6 pagesRFN 7012-In: Ringfeder Locking AssembliesRodrigo Jechéla BarriosNo ratings yet

- Bearing Load CalculationDocument9 pagesBearing Load CalculationwahyoesoemantriNo ratings yet

- Beka LubricadoresDocument2 pagesBeka LubricadoresRodrigo Jechéla BarriosNo ratings yet

- GLXXMobil SHC Gear SeriesDocument8 pagesGLXXMobil SHC Gear SeriesMarcelo GuarachiNo ratings yet

- PARKERDocument141 pagesPARKERRodrigo Jechéla BarriosNo ratings yet

- Sensors: Low-Cost Oil Quality Sensor Based On Changes in Complex PermittivityDocument16 pagesSensors: Low-Cost Oil Quality Sensor Based On Changes in Complex PermittivityRodrigo Jechéla BarriosNo ratings yet

- Tpi 252 de en Lubricators PDFDocument94 pagesTpi 252 de en Lubricators PDFRodrigo Jechéla BarriosNo ratings yet

- Bolas NSKDocument16 pagesBolas NSKRodrigo Jechéla BarriosNo ratings yet

- Bearing Load CalculationDocument9 pagesBearing Load CalculationwahyoesoemantriNo ratings yet

- PT5 007 FaqDocument26 pagesPT5 007 FaqRodrigo Jechéla BarriosNo ratings yet

- Flyer - Rodac Descase Eng Drum TopperDocument5 pagesFlyer - Rodac Descase Eng Drum TopperRodrigo Jechéla BarriosNo ratings yet

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosNo ratings yet

- 15 TollokDocument4 pages15 TollokRodrigo Jechéla BarriosNo ratings yet

- Iso 4582 1980Document8 pagesIso 4582 1980Ruwan Sampath WickramathilakaNo ratings yet

- Small Sewage Treatment Plant PDFDocument44 pagesSmall Sewage Treatment Plant PDFNGUYEN EthanNo ratings yet

- 2 Way Poppet Type Bi-Directional Solenoid ValveDocument16 pages2 Way Poppet Type Bi-Directional Solenoid ValveJonathan GiraldoNo ratings yet

- KNH 413 - Case Study 14Document17 pagesKNH 413 - Case Study 14api-301118772No ratings yet

- Overview of Medicine - Its Importance and ImpactDocument9 pagesOverview of Medicine - Its Importance and ImpactDuffosNo ratings yet

- Concrete WorkDocument3 pagesConcrete WorkAbdul Ghaffar100% (1)

- How To Prepare For The CFA Exam - QuoraDocument10 pagesHow To Prepare For The CFA Exam - QuoraaduragbeNo ratings yet

- PSS CAPE CoordinationGraphics DataSheetDocument4 pagesPSS CAPE CoordinationGraphics DataSheetMiguel Alfredo Perez OrtizNo ratings yet

- J1 - Today 1 - First Test 2022 (KEY)Document3 pagesJ1 - Today 1 - First Test 2022 (KEY)EmanuelBriosoNo ratings yet

- Grade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsDocument4 pagesGrade 10 Biology Week 8 Lesson 2 Worksheet 1 and SolutionsAva HoNo ratings yet

- SDT Pipedrive Sales Dashboard TemplateDocument10 pagesSDT Pipedrive Sales Dashboard TemplateMANEESH SINGHNo ratings yet

- Ba Etamatic Dlt2001 16 Aen 195Document156 pagesBa Etamatic Dlt2001 16 Aen 195Banu EdoNo ratings yet

- Jeann A. Gildo Bsed-Math IiiDocument3 pagesJeann A. Gildo Bsed-Math IiiJeann GildoNo ratings yet

- DashaDocument2 pagesDashaSrini VasanNo ratings yet

- Perret Mahindra SeminarDocument32 pagesPerret Mahindra SeminarBeowulf StarkNo ratings yet

- MS 2015-1-2017 - Public Toilets Part 1 Design Criteria (First Revision)Document77 pagesMS 2015-1-2017 - Public Toilets Part 1 Design Criteria (First Revision)qwertypepeheheNo ratings yet

- Auveco HNI 490Document1 pageAuveco HNI 490BillNo ratings yet

- Learning Process Focus of EducationDocument2 pagesLearning Process Focus of EducationMellani Gusdian100% (1)

- DRRMQ 3 W1Document44 pagesDRRMQ 3 W1Edelmar BenosaNo ratings yet

- BSBADM502 Assessment Task 1 Global V1.1 Jan 21Document5 pagesBSBADM502 Assessment Task 1 Global V1.1 Jan 21Gorkhali GamingNo ratings yet

- The De-Urbanisation of Bihar: by Mohan Guruswamy Jeevan Prakash MohantyDocument20 pagesThe De-Urbanisation of Bihar: by Mohan Guruswamy Jeevan Prakash MohantyD KNo ratings yet

- Plant Floor Safety: Summer EditionDocument72 pagesPlant Floor Safety: Summer EditionStefanos DiamantisNo ratings yet

- Attractive Celebrity and Peer Images On Instagram. Effect On Women's Mood and Body ImageDocument7 pagesAttractive Celebrity and Peer Images On Instagram. Effect On Women's Mood and Body ImageDesiré Abrante RodríguezNo ratings yet

- Hiwin Gen Ballscrew Catalogue EngDocument178 pagesHiwin Gen Ballscrew Catalogue EngValeriy KobaNo ratings yet

- Percorso Ii: The Led Roadway Lighting..Document2 pagesPercorso Ii: The Led Roadway Lighting..ChangKhenNo ratings yet