Professional Documents

Culture Documents

Saltfromhotair

Uploaded by

RASHED ALGANMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saltfromhotair

Uploaded by

RASHED ALGANMCopyright:

Available Formats

Salt fr o m hot air

A new technology that turns waste heat into salt

by V.M. Sedivy*

Hot brine evaporating from a THERMOSAL pond

(Peter Chromec)

Thermal salt production processes need heat at pipeline supplying the north of Spain with natural

temperatures well above 100°C. As an economic

measure this valuable heat has to be recycled several

times in multiple effect evaporators. Evaporating plants

are expensive and so is the salt that they produce. The

A gas crosses a large diapiric salt formation underlying

the area of Castejon del Puente in the province of

Huesca. In 1992, Sales Monzon SA was

established for the purpose of dissolving large cavities in the

salt deposits to be used for the storage of natural gas. In the

middle of an agricultural area, far from the sea, the resulting

new THERMOSAL® process utilises the residual waste brine could not be just discharged to the river – the brine had

heat available at much below 100°C. This low cost heat to be evaporated and the crystalline salt recovered.

magnifies the evaporation rate of brines in open ponds At first, the brine was evaporated by solar evaporation in a

and accelerates salt crystallisation. The heat can be series of plastic lined ponds. Soon it became apparent that

the evaporation rate was insufficient for the purpose. The

obtained from the cooling systems of power generators, idea of using the heat from the natural gas to enhance the

from chemical or electrolytic plants or from incinerators. evaporation rate was obvious. It resulted in examination of

Salt produced by the THERMOSAL® process can co-generation of electricity combined with salt production.

In 1993, the first 2 MW power plant and an experimental

reach vacuum salt quality at significantly lower cost. concrete salt crystallising pond were built. Subsequently,

some 120,000 tpa of pure sodium chloride is now being

produced at Sales Monzon, utilising the residual heat from

production of 17 MW of electricity, adding some 60,000m3

*Product Line Manager, Krebs Swiss Salt Technologies, VA TECH WABAG, Winterthur, of natural gas storage space per annum.

Switzerland

40 Industrial Minerals September 2000

Salt

Sales Monzon

The operation of Sales

Monzon consists of two brine

cavities, one approx. 1,000

metres, the other approx.

1,400 metres deep. Water is

injected into the salt deposit

at a rate of approx. 50m3/h.

ASR (Anhydrite Solubility

Reduction) reagent is added

into the injection water to

reduce the sulphate content

in the brine. The saturated

brine is purified by addition of

caustic soda and exhaust gas

containing carbon dioxide

from the engines of the co-

generation plant. The purified

brine is then transferred to

the crystallisation pond

through a heat exchanger The salt plant at Sales Monzon: in the foreground is the co-generation

where it is heated up by the building and brine purification; in the background are the THERMOSAL

cooling water from the co- crystallisation ponds (Vladimir Sedivy).

generation plant.

The hot brine is discharged

to a series of concrete

crystallisation ponds having a total area of 34,000m2. There particularly competitive.

the water evaporates assisted by sun and wind and the brine The design of the power co-generation plant at Sales

cools to the temperature of the environment. Depending on Monzon is modular for high efficiency at partial load. It

the climatic conditions, the hot brine is sprayed in the air consists of a series of Jenbacher turbo-charged, 16 and 20

through a series of nozzles to enhance the evaporation. cylinder, 4 stroke, spark ignition, natural gas driven engines.

The salt crystallises at the bottom of the ponds forming a The Jenbacher equipment features a highly ecological lean-

layer up to two metres deep in just one year of operation. The burn combustion system with catalytic oxidation converter,

cold brine is recirculated to the heat exchangers. A small microprocessor controlled engine management system,

stream of brine is re-injected to the cavities in order to control synchronisation with automatic power line isolation in case of

accumulation of sulphates in the circulating brine. failure and automatic reverse synchronisation when the line is

Salt is harvested as required by a mechanical shovel from recovered. The system includes a cooling water make-up unit

the bypassed and drained sections of the crystallising ponds. and a cold cooling water reserve

The purity of the salt at this stage is approx. 99-99.5% NaCl. At Sales Monzon all the installations are located outdoors,

In order to satisfy the most strict quality requirements, a salt only the power generators and electrical equipment are

purification plant based on the SALEX-C process is required. inside closed buildings. The cost of civil construction was

The SALEX-C process can upgrade the salt to approx. low because the engines work with very low vibration.

99.95% purity. A SALEX-RT salt refining process can The total utilisation of primary fuel energy is approximately

produce table salt of a quality equal to PDV (pure dry 90%. The high degree of utilisation of primary energy makes

vacuum) salt. For the drying of the salt, exhaust gas from the Spanish co-generation regulations applicable to this

co-generation engines can be used, making the process operation.

Economy of Sales Monzon operation Emissions from Jenbacher engines based on

Revenues US$11m.

5% O2 in exhaust gas

Profit US$4m. NOx 500 mg/Nm3

Investment US$12m. CO 650 mg/Nm3

Payback 3 years HC (non CH4) 150 mg/Nm3

Jenbacher engines at Sales Monzon Utilisation of primary energy in Jenbacher

engines at Sales Monzon

Number Type Power

3 JMS 316 GS-N.L 1,977 kVA Electrical power 40%

3 JMS 320 GS-N.L 2,766 kVA Utilised waste heat 50%

8 JMS 616 GS-N.LC 12,440 kVA Exhaust and radiation 10%

Industrial Minerals September 2000 41

Salt

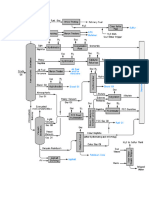

Figure 1. THERMOSAL process at Sales Monzon

Consumption figures of Sales Monzon Sources of raw salt and brine for the

THERMOSAL plant THERMOSAL process

Natural gas 0.25 Nm3/kW electricity

Residual heat 1.3 - 1.6 MWh/t salt ❖ Mined rock salt. Dissolution with or without ASR

Water 2.8 - 3 m3/t salt ❖ Brine from cavity mining. Mining with or without ASR

El. power 15 - 20 kWh/t salt

❖ Well brine, brine springs

ASR reagent 20 - 50 g/t salt

❖ Sea water (diluted or preconcentrated)

NaOH (100%) 10 - 20 kg/t salt

Polyelectrolyte 30 - 50 g/t salt ❖ Waste brines, by-product brines

Comparison of vacuum salt

and THERMOSAL salt Salt purities achievable with the THERMOSAL

Vacuum THERMOSAL and SALEX processes

salt salt Salt use Process Purity

Ca 5 ppm 10 ppm General use SALEX-B 99.8%

Mg 1 ppm 2 ppm Electrolysis SALEX-C 99.9%

SO4 400 ppm 200 ppm Refined salt SALEX-M 99.95%+

Insolubles <50 ppm 100 ppm

The unconventional, innovative and, above all, most THERMOSAL technology

economical concept of salt production at Sales Monzon Evaporation of water from brine in open ponds is the original,

appealed to Krebs Swiss Salt Technologies of VA TECH natural method of salt crystallisation. Weather conditions and

WABAG so much that they agreed to collaborate with Sales area requirements dictate that this method is mainly

Monzon and develop the concept into a commercially employed in warm and dry climatic zones. However, the use

marketable technology. This is how the THERMOSAL of residual waste heat to enhance the natural evaporation

technology was born. considerably reduces the area requirements and

VA TECH WABAG Ltd is a 100% owned subsidiary of VA compensates the climatic disadvantages of some locations.

Technologie, Linz. VA TECH WABAG acquired Krebs Swiss Combined with the highly efficient SALEX salt purification

activities in the field of salt processing in 1999. The process, THERMOSAL is the economic alternative to

innovative Krebs Swiss Salt Technologies ideally supplement conventional vacuum crystallisation for the production of top

the VA TECH WABAG’s renowned salt evaporation Systems quality industrial and food grade salt. The main physical

Escher Wyss. Through the acquisition, VA TECH WABAG principle of the THERMOSAL process is the utilisation of

strengthened its leading position in the field of salt exponentially rising water vapour pressure with rising

processing. temperature.

Industrial Minerals September 2000 43

Salt

Figure 2. Operating ranges of salt production processes

For example, at the average temperature in solar saltworks, product must fulfil a range of quality requirements. Under the

ie. at 30°C, the water vapour pressure is 0.042 bar. At 77°C, variety of conditions, a marketable, commercially viable

the water vapour pressure is 0.42 bar, ie. ten times higher. process must offer adequate processing options for any such

Consequently, the evaporation rate at 77°C is ten times combination.

higher than at 30°C. As a result, evaporation ponds required Generally, the THERMOSAL process is applicable

by the THERMOSAL process are much smaller than the whenever the raw salt is available as brine. However, it can

solar evaporation ponds and the salt layer is much thicker. also be applied if crystalline raw salt is not sufficiently

Because of the faster growth rate of the salt crystals, the upgradable in a mechanical process. For example, the raw

deposition of airborne impurities in the salt is much less per salt may be available as dark, coloured rock salt that should

weight unit of salt than in the solar saltworks. be made white. In such case, the salt can be recrystallised

Compared to vacuum crystallisation, the THERMOSAL using the THERMOSAL process.

plant is substantially cheaper to build and operate. If the raw Brines originating from dissolution of rock salts are nearly

brine is purified, the quality of the THERMOSAL salt is saturated with respect to calcium sulphate. If the brine is

comparable to the vacuum salt: the calcium and magnesium not purified, the calcium sulphate precipitates on the

levels are almost the same, the insolubles are somewhat surfaces of heat exchangers. It also precipitates together

higher but the sulphate levels are lower. with the salt so that only approx. 97-98% NaCl purity of the

salt crystallised in the ponds can be achieved. The

upgradability of such recrystallised salt is somewhat lower

THERMOSAL processing options than the upgradability of solar salt. After processing in the

Worldwide, salt is produced from a great variety of raw SALEX process, purity of 99.5-99.7% NaCl can be

materials, using all kinds of energy sources. The final salt obtained.

Figure 3: The THERMOSAL process

44 Industrial Minerals September 2000

Salt

● Precipitation with milk of lime, soda ash and carbon dioxide from

Anhydrite Solubility Reduction (ASR) the exhaust gas of the co-generation plant

● Precipitation with calcium chloride, soda ash and caustic soda

The ASR technology is based on the ability of certain chemicals

● Continuous or batch brine purification process

in ppm concentrations to reduce the solubility of anhydrite in

brine. The optimised blend of the chemicals and additives is

supplied as the ASR reagent. The final selection of the combination of the brine purification

The ASR technology is applicable for dissolution of rock salt process and the SALEX upgrading process depends on

in brine caverns for salt crystallisation or to be used as feedstock economic considerations such as the cost of brine purification

in chloralkali plants with diaphragm cells. It is also applicable for chemicals, the cost of SALEX salt processing and the end use

dissolution of rock salt in saturators and for heating of liquids of the produced salt.

containing calcium sulphate in solution. The ASR technology is For example, when SALEX-M refined salt is used as

not applicable to salts containing gypsum or polyhalite. feedstock in membrane cell chloralkali electrolysis, the primary

electrolytic brine purification can be omitted and the treatment

reduced to secondary brine purification only.

Brine purification The THERMOSAL technology is capable of producing high

The scaling problem can be completely eliminated if the raw brine quality salt from any brine and from any co-generation plant or

is chemically purified. The partial purification process removes only other residual heat source.

calcium and magnesium from the brine. The purified brine is

circulated in the THERMOSAL evaporating ponds until saturation

with respect to sodium sulphate. The sulphate concentration is Sources of prime energy

maintained below the crystallisation point of sodium sulphate by It can be that as a source of prime energy, only diesel oil, heavy

purging the brine. With this system, the salt in the ponds will be bunker oil or coal may be available. Sometimes, an incinerator

approximately 99% pure. The SALEX process will refine this salt or a process plant may supply the heat. For larger pants,

to approximately 99.8-99.95% NaCl purity. turbines may be the more economical alternative than piston

engines. Today, VA TECH WABAG, Krebs Swiss Salt

Brine purification processes applicable with the THERMOSAL Technologies offer co-generation plants 4 stoke engines; gas

process: turbines; combined cycle turbines; steam generators and

turbines combined with the SALEX process as a very attractive

● Precipitation with caustic soda and carbon dioxide from the alternative to conventional vacuum crystallisation for the

exhaust gas of the co-generation plant (partial purification) production of top quality industrial and food grade salt.

Industrial Minerals September 2000 45

You might also like

- Eudragit l100 55 PDFDocument2 pagesEudragit l100 55 PDFJohnNo ratings yet

- Elvacite Brochure 06 02Document40 pagesElvacite Brochure 06 02manox007No ratings yet

- Experiment - Phase Diagram - Three Component Liquid SystemDocument12 pagesExperiment - Phase Diagram - Three Component Liquid SystemEric K50% (2)

- Solutions and Solubility NotesDocument15 pagesSolutions and Solubility NotesForeverDirectioner100% (1)

- The Production of Ferromanganese: Rex HooperDocument2 pagesThe Production of Ferromanganese: Rex HooperNathali QuinteroNo ratings yet

- Recent Operation and Environmental Control in The Kennecott SmelterDocument17 pagesRecent Operation and Environmental Control in The Kennecott SmelterHat CopterNo ratings yet

- Nitrogen IndustriesDocument22 pagesNitrogen IndustriesKarla Joy P. SucgangNo ratings yet

- Acetylene Production-2023 4Document31 pagesAcetylene Production-2023 4Divyansh NagarNo ratings yet

- Ahp TheryDocument10 pagesAhp TheryRajendra PrasadNo ratings yet

- By Product PlantDocument6 pagesBy Product PlantRajan BhandariNo ratings yet

- Kalinga Nagar - Part3Document10 pagesKalinga Nagar - Part3cet.ranchi7024No ratings yet

- Long An Net Power StationDocument4 pagesLong An Net Power Stationdjc49No ratings yet

- 1620 Ammonia Only REDUCEDDocument32 pages1620 Ammonia Only REDUCEDAhmed KadimNo ratings yet

- AmmoniaDocument49 pagesAmmoniaAnonymous fhKOhG6No ratings yet

- Aiche-36-021Equipment Performance of AmmoniaDocument9 pagesAiche-36-021Equipment Performance of AmmoniaHsein Wang100% (1)

- 080 BergmanDocument10 pages080 BergmanYogesh LadNo ratings yet

- CHE 206 - LECTURE-3 - Bulk Chemicals and Synthetic Fuels DerivedDocument139 pagesCHE 206 - LECTURE-3 - Bulk Chemicals and Synthetic Fuels DerivedShoilayee ChaudhuriNo ratings yet

- NTPC Badarpur PPT 2012Document33 pagesNTPC Badarpur PPT 2012Anonymous 9kzuGaY100% (1)

- 1.5 Case Studies On Thermal Power PlantsDocument29 pages1.5 Case Studies On Thermal Power Plantskarthikeyan S0% (1)

- Industrial Gases WordDocument26 pagesIndustrial Gases WordFullmetal GunneNo ratings yet

- Coal and Energy Scenario in IndiaDocument30 pagesCoal and Energy Scenario in IndiaSamuelNeelamNo ratings yet

- News 2013 12Document12 pagesNews 2013 12leekiangyen100% (1)

- Flanges RequiredDocument2 pagesFlanges RequiredRojan PradhanNo ratings yet

- Sept. 25, 1951 L. A. Stenge 2,568,901: Eles. 44tagedDocument4 pagesSept. 25, 1951 L. A. Stenge 2,568,901: Eles. 44tagedwakanda foreverNo ratings yet

- 697 RoddDocument12 pages697 RoddAan SupriyantoNo ratings yet

- Tata PowerDocument9 pagesTata PowerAnkita SinghNo ratings yet

- AmmoniaDocument59 pagesAmmoniavcoolkrazy0% (3)

- Plant Layout PDFDocument19 pagesPlant Layout PDFazzatul amiraNo ratings yet

- Andrussow HCN Process With Ammonia RecycleDocument5 pagesAndrussow HCN Process With Ammonia RecycleKarolina Wieszczycka100% (1)

- Production of AmmoniaDocument29 pagesProduction of AmmoniaBhavna Bajpai83% (6)

- Lime Kiln Control Using Simple Advanced Pid Control PDFDocument4 pagesLime Kiln Control Using Simple Advanced Pid Control PDFIwan TirtaNo ratings yet

- International Process Plants: 1,100 Metric Tons/Day U PLT Urea PlantDocument17 pagesInternational Process Plants: 1,100 Metric Tons/Day U PLT Urea PlantRawagNo ratings yet

- Watertreatmentproceeding SMALLSIZE PDFDocument565 pagesWatertreatmentproceeding SMALLSIZE PDFmarc ugoyNo ratings yet

- Sulphur: Heat Recovery in Acid PlantsDocument8 pagesSulphur: Heat Recovery in Acid PlantsGajendra MehtaNo ratings yet

- The New Anglo Platinum Converting Project: P Viviers and K HinesDocument8 pagesThe New Anglo Platinum Converting Project: P Viviers and K HinesHabram Miranda AlcantaraNo ratings yet

- Iron Making TechnologyDocument53 pagesIron Making TechnologyAwas Ada UdinNo ratings yet

- Investigation of Effect of Different Drying TechniquesDocument9 pagesInvestigation of Effect of Different Drying TechniquesGanesh SamdaniNo ratings yet

- Doris HiamDocument43 pagesDoris Hiamrichard gutierrezNo ratings yet

- Bindura Nickel Corporation Smelter Operations: E. DzingayiDocument16 pagesBindura Nickel Corporation Smelter Operations: E. DzingayiLorraineNo ratings yet

- KilnDocument20 pagesKilnzabira50% (2)

- Challenge:: Improving Productivity and Reducing Dross Production A T Reynolds Metals CompanyDocument2 pagesChallenge:: Improving Productivity and Reducing Dross Production A T Reynolds Metals CompanyDebashis DashNo ratings yet

- Internship ReportDocument21 pagesInternship Reportthewebseries17thNo ratings yet

- Geothermal Plant SystemsDocument13 pagesGeothermal Plant SystemsKant KanyarusokeNo ratings yet

- Tata Steel ProjectDocument12 pagesTata Steel Projectsp32483No ratings yet

- Viv BoilerDocument40 pagesViv BoilerVivekNo ratings yet

- Legionella Pneumophila in An Ammonia Plant Cooling Tower: W. D. VerduijnDocument15 pagesLegionella Pneumophila in An Ammonia Plant Cooling Tower: W. D. Verduijnvaratharajan g rNo ratings yet

- Lechner StephanDocument9 pagesLechner StephanleekiangyenNo ratings yet

- Power PlantDocument15 pagesPower PlantBeatricia Bonaventure LimNo ratings yet

- Boiler: - IBR Boiler 22.75 Liters in CapacityDocument23 pagesBoiler: - IBR Boiler 22.75 Liters in CapacitySachin ParasharNo ratings yet

- NFL PPTDocument46 pagesNFL PPTvipin6kumar-718654No ratings yet

- An ISO 9001:2008 Certified InstitutionDocument55 pagesAn ISO 9001:2008 Certified InstitutionA AswinNo ratings yet

- W VishDocument52 pagesW VishVikram Kumar VishNo ratings yet

- Snox Pet Coke BoilersDocument14 pagesSnox Pet Coke BoilersФранческо ЛеньямеNo ratings yet

- CPTMod 3Document25 pagesCPTMod 3daddarioalexander01No ratings yet

- Chemistry in The Coal Industry: VII-Energy-E-Coal-1Document4 pagesChemistry in The Coal Industry: VII-Energy-E-Coal-1Pushp DuttNo ratings yet

- Thermal P0Wer PlantDocument24 pagesThermal P0Wer PlanttoshaliNo ratings yet

- Topsoe Methanol Coal Gasification Paper - AshxDocument3 pagesTopsoe Methanol Coal Gasification Paper - AshxAde RahmadiNo ratings yet

- Appunti AlbaneseDocument192 pagesAppunti Albanesej77wn7j9yvNo ratings yet

- Recarburant Agents For Induction Furnace in SmeltingDocument19 pagesRecarburant Agents For Induction Furnace in SmeltingashokjkhannaNo ratings yet

- Boilers and Steam Lines Chemical CleaningDocument10 pagesBoilers and Steam Lines Chemical CleaningZaheer Ahmad RazaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- 1721 6632 1 PBDocument6 pages1721 6632 1 PBAthikNo ratings yet

- Cleaning Validation Master PlanDocument9 pagesCleaning Validation Master PlanBREWSKI100% (9)

- Periodic PropertiesDocument11 pagesPeriodic PropertiesAchinthya PereraNo ratings yet

- Jackson, 1957Document12 pagesJackson, 1957diogoneNo ratings yet

- Chemical Bonding and Mot SynopsisDocument21 pagesChemical Bonding and Mot Synopsispochireddy revathiNo ratings yet

- Physical Science: Quarter 3 - Module 3: Polarity of Molecules and Its PropertiesDocument16 pagesPhysical Science: Quarter 3 - Module 3: Polarity of Molecules and Its PropertiesDelson Son100% (1)

- Aerosol 120730040104 Phpapp01Document77 pagesAerosol 120730040104 Phpapp01Rassel KabirNo ratings yet

- Sodium Silicate Corrosion Inhibitors - Issues of Effectiveness and Mechanism PDFDocument19 pagesSodium Silicate Corrosion Inhibitors - Issues of Effectiveness and Mechanism PDFPeterNo ratings yet

- 00-Cálculo de Dosis H2S PDFDocument23 pages00-Cálculo de Dosis H2S PDFamazo_14No ratings yet

- Experimental Techniques in Chemistry Ist YearDocument5 pagesExperimental Techniques in Chemistry Ist YearAish PayariNo ratings yet

- Physical & Chemical PropertiesDocument10 pagesPhysical & Chemical PropertiesJohnree A. Evangelista100% (1)

- Iso TR 8502 1 1991Document9 pagesIso TR 8502 1 1991Somak DuariNo ratings yet

- Equilibrium PractDocument2 pagesEquilibrium PractrainyNo ratings yet

- Chemistry Notes Chapter No 2 Experimental Techniques in ChemistryDocument4 pagesChemistry Notes Chapter No 2 Experimental Techniques in ChemistryHaider Jalal100% (1)

- Rate of ReactionDocument7 pagesRate of ReactionMr KilloNo ratings yet

- Classify Me! Am I Solute or SolventDocument5 pagesClassify Me! Am I Solute or SolventLara Lyn PabloNo ratings yet

- Excipient Performance - General Chapter USP 38Document19 pagesExcipient Performance - General Chapter USP 38Anonymous SDUIPeqXNo ratings yet

- Appendix 5 Proposal For A An Extraction Plant in The WakatobiDocument28 pagesAppendix 5 Proposal For A An Extraction Plant in The WakatobiMoko NugrohoNo ratings yet

- LEARNING-PLAN-IN-SCIENCE-7-4TH Quarter-WeekDocument3 pagesLEARNING-PLAN-IN-SCIENCE-7-4TH Quarter-WeekRhodeliza TiotangcoNo ratings yet

- Pharmaceutical Inorganic ChemistryDocument61 pagesPharmaceutical Inorganic Chemistryujib ujanNo ratings yet

- HazMat IAP PlanDocument12 pagesHazMat IAP PlanVanitta RangsitananNo ratings yet

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnNo ratings yet

- Trisodium CitrateDocument2 pagesTrisodium CitrateAqmar Aqeem Bin AzharNo ratings yet

- Ecosoljet YellowDocument11 pagesEcosoljet YellowShree ManjuNo ratings yet

- Lab Tests For Stimulation PDFDocument14 pagesLab Tests For Stimulation PDFizzybjNo ratings yet

- 121ferrous GluconateDocument3 pages121ferrous GluconateAira Jherese MarcosNo ratings yet