Professional Documents

Culture Documents

Holcim OH S Policy

Uploaded by

kmas1612Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Holcim OH S Policy

Uploaded by

kmas1612Copyright:

Available Formats

Policy

Holcim Group Occupational Health and Safety (OH&S) Policy

“Zero Harm to People” The most important principles of the OH&S Policy and

The overall goal of OH&S at Holcim is “Zero Harm to People”. associated management system that contribute to

We believe that injuries, occupational illnesses and diseases improvements of the OH&S performance in the Holcim

are preventable. Group are:

We apply OH&S standards and directives, define organizational Responsibility

accountabilities, provide necessary resources and training, Everyone is responsible for her/his own health and safety.

manage performance and minimize risk to employees, Managers have to provide the right management systems

contractors, visitors and the community. and are accountable for managing OH&S performance.

Five Cardinal Rules OH&S commitment and performance

The following five Corporate Cardinal Rules aim to prevent Every employee and contractor is responsible for working

the most critical incidents in our industry. No compromise safely, for knowing and following OH&S rules and procedures,

or shortcuts are tolerated. These Cardinal Rules are part and for being attentive to the health and safety of others.

of “Passion for Safety”, the Corporate OH&S Action Plan: Nobody may undertake or allow any other person to undertake

1. Do not override or interfere with any safety provision any unsafe act or work in an unsafe condition. Demonstrated

or allow anyone else to override or interfere with them. OH&S commitment and performance are key criteria for good

2. Adhere to Personal Protective Equipment (PPE) rules leadership in Holcim.

applicable to a given task at all times.

3. Always follow Isolation and Lock Out Procedures. Complying with OH&S rules

4. Do not work if under the influence of alcohol or drugs. Complying with OH&S rules and directives is a condition

5. Report all injuries and incidents. of employment in Holcim.

Policy Principles Injuries/incidents/unsafe acts

All injuries, incidents and unsafe acts must be investigated. The

1. The OH&S management root causes must be found and corrected. Those with potential

In general for serious harm must be shared between Group companies so

In order to achieve the requirements of the Holcim OH&S that corrective or preventative measures are implemented

Policy, the Holcim Group requires Group companies to have throughout the Holcim Group.

an OH&S management system.

Safety observations, inspections and audits

The definition, application and practical implementation of the All levels in the organization carry out safety observations.

key elements of the OH&S management system are detailed Specialists carry out periodic inspections and audits.

in the Holcim OH&S Handbook. Managers must ensure that all issues recorded or identified

get corrected.

© Holcim Group Support Ltd 2008 1/2

Training “Passion for Safety” must be implemented throughout

Training is essential to have healthy and safe workplaces: the Holcim Group via local OH&S action plans at each

• All employees must know the general and their task-specific Group company.

OH&S rules and procedures. They must recognize, report

and correct all unsafe acts/conditions in their workplace. The OH&S management system

• Contractors must be trained in the OH&S rules and The OH&S management system is described in the OH&S

procedures applicable to their job. They are required to always Handbook, which documents the minimum requirements that

conform to those OH&S rules and procedures. must be implemented throughout the Holcim Group to reach

“accepted good practice” in OH&S management. Nevertheless,

2. Structure and processes

it is left to individual Group companies to determine what

A. Structure

methodologies, systems and processes they adopt to achieve

Corporate OH&S is a function of HGRS and develops the OH&S

the Group’s OH&S goals and targets.

Policy, its directives, standards and rules, which are approved

by the EXCO. Corporate OH&S also provides auditing, training,

The OH&S pyramid

support and consulting to the Group companies.

The OH&S pyramid is a visual representation of the Holcim

OH&S management system. Each block contains separate

Each Group company manages their own OH&S performance.

minimum requirements that must be met. The “Green Pyramid”

It has an OH&S organization, lead by an OH&S coordinator.

audit protocol specifies the various criteria which need to be

OH&S officers operate at a plant/unit level.

fulfilled per block.

B. Processes

Local policies and procedures

There is a systematic approach to managing OH&S in Holcim.

Every Group company has in place a formal OH&S policy,

rules and procedures to govern its own OH&S function and

CSR

approach. Compliance with the policy and procedures is key

OH&S is one of the focus areas of Corporate Social Responsibility.

and therefore will be verified/certified and reviewed through

periodic auditing.

“Passion for Safety”

“Passion for Safety” is a process to develop and implement

Each Group company shall establish its annual OH&S plan and

a strong and sustainable OH&S culture allowing Holcim to

set OH&S targets as an integral part of its local business plan.

achieve their goal of “Zero Harm to People”. It is based on

This local OH&S plan must be aligned with “Passion for Safety”,

strong management commitment and well-defined line

the Corporate OH&S Action Plan.

accountability for OH&S.

OH&S performance measurement

“Passion for Safety”, the Corporate OH&S Action Plan,

In order to monitor, benchmark and improve the performance,

outlines the various OH&S objectives, activities and tasks to

reporting and control tools are in place. The GMR includes a

continuously improve our safety performance. The various

monthly report with OH&S performance data from all Holcim

activities and tasks are structured into four work streams:

Group companies.

• Set the Culture

• Drive Accountability

• Mobilize People

• Manage Performance

© Holcim Group Support Ltd 2008 2/2

You might also like

- DESIGNING LPG SYSTEMSDocument35 pagesDESIGNING LPG SYSTEMSkmas1612No ratings yet

- Old School Bulking 101Document52 pagesOld School Bulking 101Vladimir Filciu80% (5)

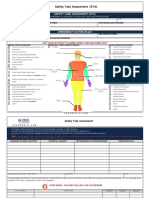

- Safety Task Assessment FormDocument2 pagesSafety Task Assessment FormRajkumsr VNo ratings yet

- Nen-En 1825-1 2004Document30 pagesNen-En 1825-1 2004Alexandros TountasNo ratings yet

- Electrical Project DesignDocument225 pagesElectrical Project DesignMoideen Thashreef78% (9)

- Good Morning, I Love You Mindfulness and Self-Compassion Practices To Rewire Your Brain For Calm, Clarity, and Joy by Shauna ShapiroDocument163 pagesGood Morning, I Love You Mindfulness and Self-Compassion Practices To Rewire Your Brain For Calm, Clarity, and Joy by Shauna ShapiropimpamtomalacasitosNo ratings yet

- EHS Committee ExampleDocument11 pagesEHS Committee ExampleJonathanNo ratings yet

- HSE Committee Meeting AgendaDocument1 pageHSE Committee Meeting AgendaNurul JannatiNo ratings yet

- HSE Manual NRC GroupDocument65 pagesHSE Manual NRC GroupPurnomo JarodNo ratings yet

- Daily Site Inspection ChecklistDocument2 pagesDaily Site Inspection ChecklistRavi thokalNo ratings yet

- Oman LPG Fire Safety RequirementsDocument47 pagesOman LPG Fire Safety Requirementsadnan amal yusfarNo ratings yet

- Safety Violation Notice1Document1 pageSafety Violation Notice1rahul kavirajNo ratings yet

- Safety AlertDocument1 pageSafety Alertindrak1978No ratings yet

- Hse Monthly ReportDocument2 pagesHse Monthly Reportshubham dabasNo ratings yet

- 8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseDocument14 pages8.8 5 Respiratory Protection Management Measures (At HSSE P 8 43V0 2022) ReleaseGeyko RuslanNo ratings yet

- 14-F02 Ppe Hazard AssessmentDocument3 pages14-F02 Ppe Hazard AssessmentZaheer AhmedNo ratings yet

- 04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectDocument5 pages04weekly Statistics Report (July) : Técnicas Reunidas Petrokemya Abs ProjectAviects Avie JaroNo ratings yet

- National Safety Week Program AgendaDocument3 pagesNational Safety Week Program AgendaDJadee Anuppur AmlaiNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- HSE STATSDocument1 pageHSE STATSPT. ANUGRAH MIRAN MANDIRINo ratings yet

- Environment, Health & Safety Policy: Revision No.: 00 DateDocument1 pageEnvironment, Health & Safety Policy: Revision No.: 00 Dateanand shankarNo ratings yet

- Job Safety Analysis (Rms Project)Document9 pagesJob Safety Analysis (Rms Project)Ahmad MensaNo ratings yet

- Contact NoDocument3 pagesContact NovictorNo ratings yet

- EHS Calendar September 2019 Training Fire Safety PPE AuditsDocument1 pageEHS Calendar September 2019 Training Fire Safety PPE AuditsSiddharth RanaNo ratings yet

- How To Run Toolbox TalksDocument2 pagesHow To Run Toolbox TalksRoshin99No ratings yet

- SHE Committee Meeting Minutes ReviewDocument4 pagesSHE Committee Meeting Minutes ReviewCHETAN WANKHADE100% (2)

- 12 Ways To Boost Workplace SafetyDocument6 pages12 Ways To Boost Workplace Safetymuhammadarifh4486No ratings yet

- HSE Auditing HSE ProfessionlasDocument20 pagesHSE Auditing HSE ProfessionlasSantanu DasNo ratings yet

- Incident ReportDocument5 pagesIncident Reportrizal azizanNo ratings yet

- Daily Safety Inspection ChecklistDocument3 pagesDaily Safety Inspection ChecklistBALJIT singhNo ratings yet

- Alnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Document12 pagesAlnajim Alzahir Co. - Emergency Evacuation Drill On 10-May-2022Abdullah TwfeeqNo ratings yet

- On-Site Emergency Plan and Reporting FlowchartDocument4 pagesOn-Site Emergency Plan and Reporting FlowchartMd Nurul IslamNo ratings yet

- Incident Accident ProceduresDocument3 pagesIncident Accident ProceduresmpriceatccusaNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- HSE Plan and Transport Emergency ResponseDocument8 pagesHSE Plan and Transport Emergency ResponseAllocation ResourceNo ratings yet

- Job Safety Observation Form Template - JotFormDocument4 pagesJob Safety Observation Form Template - JotFormGonzalo MazaNo ratings yet

- Note Emshe - Hazard Identification ControlDocument38 pagesNote Emshe - Hazard Identification ControlMel Yusoff100% (1)

- Office - Safety - Training-Trident Hydrojetting Philippines Inc.Document40 pagesOffice - Safety - Training-Trident Hydrojetting Philippines Inc.Dlraje DlrajeNo ratings yet

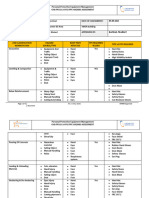

- Task Risk Assessment TableDocument10 pagesTask Risk Assessment TableakhmadbayNo ratings yet

- Initial & Re-CertificationDocument107 pagesInitial & Re-CertificationSatya PrabhatNo ratings yet

- Weekly Hse ReportDocument2 pagesWeekly Hse Reportengrabbas75100% (1)

- Life Saving Rules Engagement Final Pack June - 2022Document40 pagesLife Saving Rules Engagement Final Pack June - 2022vinil radhakrishnaNo ratings yet

- Tiling Lesson 1.5.17Document7 pagesTiling Lesson 1.5.17Daryl MurrayNo ratings yet

- AsdssssDocument1 pageAsdssssAviects Avie JaroNo ratings yet

- Risk Assessment For Stone WorkDocument17 pagesRisk Assessment For Stone WorkKhuda BukshNo ratings yet

- Example COSHH Risk Assessment - Warehouse - COSHHDocument2 pagesExample COSHH Risk Assessment - Warehouse - COSHHWisnu KertaningnagoroNo ratings yet

- Maraba Al Iraq Al Khadraa: Emergency Drill ReportDocument3 pagesMaraba Al Iraq Al Khadraa: Emergency Drill Reportfdfddf dfsdfNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

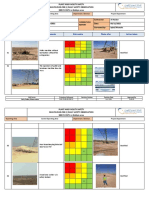

- 45 Safety Observation Report. 380 KV OHTL - Qiddyia Area 07-11-2021Document4 pages45 Safety Observation Report. 380 KV OHTL - Qiddyia Area 07-11-2021Shafie ZubierNo ratings yet

- Evaluation of Camp OHS Risks AssessmentDocument3 pagesEvaluation of Camp OHS Risks Assessmenthasanhse640No ratings yet

- Intel Construction EHS: Processes and Procedures ManualDocument127 pagesIntel Construction EHS: Processes and Procedures ManualRanjan BhaumikNo ratings yet

- HSEQ Questionaire For Contractor EvaluationDocument6 pagesHSEQ Questionaire For Contractor EvaluationNasih Tr100% (1)

- Jurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Document3 pagesJurong Island Cargo Tec RA Alignment of Cover Belt BC1 & BC2Anonymous kWfNFb100% (1)

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Mechanism 8 0 - AD EHS Practitioner Registration - Ver 2.2 (March 2014)Document48 pagesMechanism 8 0 - AD EHS Practitioner Registration - Ver 2.2 (March 2014)prabhu_amtNo ratings yet

- December 2019 EHS Calendar with Daily Safety ActivitiesDocument1 pageDecember 2019 EHS Calendar with Daily Safety ActivitiesSiddharth RanaNo ratings yet

- Halliburton: Job Safety AnalysisDocument2 pagesHalliburton: Job Safety Analysisaneshse100% (1)

- SAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XDocument13 pagesSAFETY CAMPAIGN On Student of Islamic Boarding School As Electric Al Technician in Pondok XWhina R AymaNo ratings yet

- Sharjah Waterfront City-Sector 2 & Sun IslandDocument2 pagesSharjah Waterfront City-Sector 2 & Sun IslandCaptainNo ratings yet

- EHS is Everyone’s ResponsibilityDocument88 pagesEHS is Everyone’s ResponsibilityMarthaNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- Minutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftDocument5 pagesMinutes of Meeting-RC Safety Staff Meeting 6 23SEP15-Final DraftMohammed Jai Sujiya KhanNo ratings yet

- Safety BoardDocument1 pageSafety BoardsunilNo ratings yet

- F 5.3 C Star-Safety-Inspection-JULYDocument4 pagesF 5.3 C Star-Safety-Inspection-JULYSn Ahsan100% (1)

- Day 04 Design of LPG System Part 04Document14 pagesDay 04 Design of LPG System Part 04kmas1612No ratings yet

- ISOLATORDocument1 pageISOLATORkmas1612No ratings yet

- How Is Lamp Light Output Measured - Lights by H&HDocument3 pagesHow Is Lamp Light Output Measured - Lights by H&Hkmas1612No ratings yet

- Design CalculationDocument1 pageDesign Calculationkmas1612No ratings yet

- Day 04 Maintenance of LPG SystemDocument11 pagesDay 04 Maintenance of LPG Systemkmas1612No ratings yet

- Type MV Directional Spray Nozzles, Open Medium Velocity General DescriptionDocument14 pagesType MV Directional Spray Nozzles, Open Medium Velocity General Descriptionkmas1612No ratings yet

- Design Calculation For Sprinkler For Shell Cooling: Friction Loss Per Meter of Riser LineDocument4 pagesDesign Calculation For Sprinkler For Shell Cooling: Friction Loss Per Meter of Riser Linekmas1612No ratings yet

- RCCBDocument1 pageRCCBkmas1612No ratings yet

- Day 02 Component of LPG System - Part 01Document31 pagesDay 02 Component of LPG System - Part 01kmas1612No ratings yet

- Fire Exting Insp Maint PDFDocument2 pagesFire Exting Insp Maint PDFNeelesh AnkolaNo ratings yet

- Day 02 Design of LPG System Part 01Document28 pagesDay 02 Design of LPG System Part 01kmas1612100% (1)

- The Role of Hydrofluorocarbons in Global Fire Protection: An UpdateDocument11 pagesThe Role of Hydrofluorocarbons in Global Fire Protection: An Updatekmas1612No ratings yet

- Holcim OH S PolicyDocument2 pagesHolcim OH S Policykmas1612No ratings yet

- FSL GasesComparisonDocument13 pagesFSL GasesComparisonkmas1612No ratings yet

- Inspection, Maintenance, Testing, and Recharging Periods For Portable Fire ExtingishersDocument3 pagesInspection, Maintenance, Testing, and Recharging Periods For Portable Fire Extingisherskmas1612No ratings yet

- Inspection, Maintenance, Testing, and Recharging Periods For Portable Fire ExtingishersDocument3 pagesInspection, Maintenance, Testing, and Recharging Periods For Portable Fire Extingisherskmas1612No ratings yet

- Cooper Ls Brochure Lighting Design GuideDocument32 pagesCooper Ls Brochure Lighting Design GuideMeenal SwarnakarNo ratings yet

- Halon vs. NovacDocument7 pagesHalon vs. Novackmas1612No ratings yet

- NFPA 13 PresentationDocument4 pagesNFPA 13 PresentationRaoofNo ratings yet

- SmokeDetector InspectionTesting WhitePaper A05 0407Document4 pagesSmokeDetector InspectionTesting WhitePaper A05 0407Eddi Pelaez SalinasNo ratings yet

- LT-894SEC MMX Installation ManualDocument148 pagesLT-894SEC MMX Installation ManualEddi Pelaez Salinas100% (1)

- Clean Agent Fire Suppression AlternativesDocument13 pagesClean Agent Fire Suppression Alternativeskmas1612No ratings yet

- Is 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersDocument26 pagesIs 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersShivakumara ArehalliNo ratings yet

- Introduction To Our Lux, Lumens & Watts GuideDocument5 pagesIntroduction To Our Lux, Lumens & Watts Guidekmas1612No ratings yet

- The Role of Hydrofluorocarbons in Global Fire Protection: An UpdateDocument11 pagesThe Role of Hydrofluorocarbons in Global Fire Protection: An Updatekmas1612No ratings yet

- For Any Storey With A Floor Area Less Than or Equal To 400 MDocument2 pagesFor Any Storey With A Floor Area Less Than or Equal To 400 Mkmas1612No ratings yet

- Chronic Lymphocytic Leukemia Present StatusDocument18 pagesChronic Lymphocytic Leukemia Present StatusLhOi ParagasNo ratings yet

- E4 SubtypesDocument26 pagesE4 SubtypesJuliaNo ratings yet

- Sensory Integration Therapy and Auditory Integration TrainingDocument10 pagesSensory Integration Therapy and Auditory Integration TrainingMuskaan KhannaNo ratings yet

- CHN - Community Health Nursing - Lecture 1 (Prelim)Document4 pagesCHN - Community Health Nursing - Lecture 1 (Prelim)Akasha FrostmourneNo ratings yet

- Research Lecture 1 by Ma'am Jasmen PasiaDocument79 pagesResearch Lecture 1 by Ma'am Jasmen PasiaSteph VeeNo ratings yet

- Dialog Patient AdmissionDocument3 pagesDialog Patient AdmissionYunita TriscaNo ratings yet

- Kudori Therapy - Updated 9th Dec17Document32 pagesKudori Therapy - Updated 9th Dec17Manickavasagam RengarajuNo ratings yet

- Bulletin: Schema TherapyDocument16 pagesBulletin: Schema TherapyRafael CalpenaNo ratings yet

- End Stage Renal DiseaseDocument9 pagesEnd Stage Renal DiseaseShantanu DixitNo ratings yet

- The Mental Status Exam (MSE)Document5 pagesThe Mental Status Exam (MSE)Huma IshtiaqNo ratings yet

- Supplier Audit ChecklistDocument11 pagesSupplier Audit ChecklistOlexei Smart100% (1)

- Cardiocap 5 Manual UsuarioDocument228 pagesCardiocap 5 Manual UsuarioJonathan Scott100% (1)

- Safety Data Sheet (SDS) Anysol-D100Document11 pagesSafety Data Sheet (SDS) Anysol-D100U.s. Ezhil ArivudainambiNo ratings yet

- List of Health Care Organizations Empanelled under CGHS DelhiDocument94 pagesList of Health Care Organizations Empanelled under CGHS Delhinishita groverNo ratings yet

- HA-RLE-WS # 6 Assessing PainDocument3 pagesHA-RLE-WS # 6 Assessing PainJULIE ANNE CORTEZNo ratings yet

- Return To Work After Work Related Injury in The Construction Sector: A Scoping ReviewDocument21 pagesReturn To Work After Work Related Injury in The Construction Sector: A Scoping ReviewchizitarankwoparaNo ratings yet

- BEAP Candidate Guidebook 9820Document43 pagesBEAP Candidate Guidebook 9820Hakkı YılmazNo ratings yet

- Seminar ReportDocument31 pagesSeminar ReportBitNo ratings yet

- Unsafe Acts and Unsafe ConditionsDocument47 pagesUnsafe Acts and Unsafe ConditionsGabriel Flores100% (1)

- Project BHDocument41 pagesProject BHBinsha ShyjanNo ratings yet

- Sommers 2021Document8 pagesSommers 2021Maira Machado Frota PinheiroNo ratings yet

- Cancer Incidence and Mortality Among Fighter.12Document8 pagesCancer Incidence and Mortality Among Fighter.12Adi AndoneNo ratings yet

- THEORIES OF ADDICTIONDocument24 pagesTHEORIES OF ADDICTIONManali NaphadeNo ratings yet

- MAS110 - Week 1 - Infection Control Worksheet 2Document4 pagesMAS110 - Week 1 - Infection Control Worksheet 2geonikawilliamsNo ratings yet

- Name: Mendones, Aldritz John Class Code: NSTP 1 7005B Date Submitted: December 08, 2022Document3 pagesName: Mendones, Aldritz John Class Code: NSTP 1 7005B Date Submitted: December 08, 2022RenzNo ratings yet

- Class II Correction With The Cantilever Bite Jumper: Original ArticleDocument9 pagesClass II Correction With The Cantilever Bite Jumper: Original ArticleNaveenNo ratings yet

- Diabetics PrescriptionDocument1 pageDiabetics PrescriptionSunil HNo ratings yet

- Sensors BMS PDFDocument45 pagesSensors BMS PDFPearl BaskarNo ratings yet