Professional Documents

Culture Documents

Minh

Uploaded by

Khanh Minh LuuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minh

Uploaded by

Khanh Minh LuuCopyright:

Available Formats

BACKGROUND

The Industrial Revolution: The drastic and wide-reaching change in conditions of the society and

industry , the transformation from an agricultural economy to a manufacturing economy in England

from the late 18th to the middle of 19th century. It implies a once and for all occurrence, and not a

steady and gradual transformation

- Smelting is the act of extracting metal from its ore through heating and melting processes.

The iron and steel industry was further developed due to the advancement in technology

and entrepreneurial initiative. Due the limited amount of forests, the British iron industry

could not develop as they relied heavily on charcoal, which was made of hardwood, for

smelting purposes.

Abraham Darby found the alternative material for smelting, which made the process became

much more economical and efficient. In the middle of the 17 th century, his foundries were

producing pig iron, smelted with small quantities of coke.

The next man to experiment with iron smelting was Benjamin Huntsman, who added

charcoal and ground glass to aid the extraction of metal. After that, with the invention of

Bessemer process, the removal of impurities from iron became much cheaper.

In the 1720's, an important breakthrough occurred in rolling the iron. Grooves were added

to the rolling cylinders, allowing manufacturers to roll iron into different shapes, instead of

simply into thin sheets.In 1783, Henny Cort, a Fareharm iron-maker improved grooved

rollers and puddling furnace, which helped to produce high quality iron wih desired

shapes.This was called wrought iron or “puddled iron” and was used to make machine parts

and even iron rails, which required a high level of accuracy and uniformity in their

manufacture.

In the late 1700s, cast iron was produced by re-melting pig iron and adding other elements

into the melt before being casted.

ECONOMIC GROWTH:

In 1788, for example, British ironmakers produced about 76,000 short tons (68,900 metric tons) of

iron. In 1806, they produced over three times that amount.

PAST AND PRESENT:

Before the revolution, Br had to mainly import iron from other countries, such as Sweeden and

Russia. But from 1785, imports decreased and Br exported iron and produce wrong iron consumer

goods. During the mid-1700's, most machines were made of wood. Cast iron, which required

charcoal as a fuel, used to be too expensive to be used as a building material. After the discovery of

coke-smelted iron, iron was then the most common material used for building machinery. By the

early 1800's, manufacturers used iron to make a wide variety of products, including machine frames,

rails, steam engine parts, and water pipes.

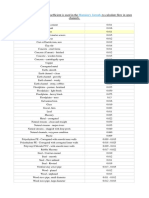

You might also like

- History of Steel MakingDocument3 pagesHistory of Steel MakingAb Wajid FarukiNo ratings yet

- The Importance of Steel PDFDocument3 pagesThe Importance of Steel PDFahmedd55No ratings yet

- Steel AsiaDocument19 pagesSteel AsiamalynNo ratings yet

- Aluminco Crystal-Line-Product-Brochure en FR Rev072017Document74 pagesAluminco Crystal-Line-Product-Brochure en FR Rev072017irena34No ratings yet

- Copper-Nickel - Seawater System Design - GuidelinesDocument15 pagesCopper-Nickel - Seawater System Design - GuidelinesVidyasenNo ratings yet

- Sheet Metal and TinsmithryDocument22 pagesSheet Metal and TinsmithryVictor EvangelioNo ratings yet

- History of SteelDocument79 pagesHistory of SteelChrissa100% (2)

- Industrial RevolutionDocument24 pagesIndustrial RevolutionHafsah SiddiquaNo ratings yet

- Cast IronDocument1 pageCast Ironabhimanyureddy146No ratings yet

- 117 Section 8 Brief History of BrassDocument1 page117 Section 8 Brief History of Brasssonnyoneand2No ratings yet

- Technology of Iron and SteelDocument29 pagesTechnology of Iron and SteelTanya SirohiNo ratings yet

- Bessemer ProcessDocument22 pagesBessemer ProcessJosua Aditya PratamaNo ratings yet

- BrassDocument5 pagesBrassbilly124billy456No ratings yet

- VISLDocument78 pagesVISLKshama Asha SunderNo ratings yet

- Steel Age: By: Kuo Garol SarongDocument14 pagesSteel Age: By: Kuo Garol SarongKuo SarongNo ratings yet

- Why Britain?: Towns, Trade and FinanceDocument5 pagesWhy Britain?: Towns, Trade and FinanceAnushka RaghuwanshiNo ratings yet

- Industrial RevolutionDocument125 pagesIndustrial RevolutionDexiz BellenNo ratings yet

- Historical DevelopmentDocument3 pagesHistorical DevelopmentShakil AkhterNo ratings yet

- 1E7 Rehabilitation AD 2Document111 pages1E7 Rehabilitation AD 2alexrodriguezabcNo ratings yet

- Cottrell - MetallurgyDocument1 pageCottrell - MetallurgyLuis OliveiraNo ratings yet

- 1 Historical Development and Characteristics of Structural SteelsDocument30 pages1 Historical Development and Characteristics of Structural Steelsron_dany100% (1)

- Unit 2: Begining of A New Era Industrial RevolutionDocument27 pagesUnit 2: Begining of A New Era Industrial RevolutionManoj KumarNo ratings yet

- Engineering in The Industrial RevolutionDocument18 pagesEngineering in The Industrial RevolutionbalingbinglorieanneNo ratings yet

- Background: MeteoritesDocument16 pagesBackground: MeteoritesAwadhesh SharmaNo ratings yet

- Sssssssss DsDocument5 pagesSssssssss DsAsia VelascoNo ratings yet

- Color Difference Between Cast and White IronDocument13 pagesColor Difference Between Cast and White IronStainless steel FoundryNo ratings yet

- The Bessemer ProcessDocument3 pagesThe Bessemer ProcessSaurabh PatelNo ratings yet

- Steel History: Mild Steels Are The Steels With The Lowest Carbon Ratio, Less Than 0,02%. They Are HighlyDocument2 pagesSteel History: Mild Steels Are The Steels With The Lowest Carbon Ratio, Less Than 0,02%. They Are HighlyMarius MariusNo ratings yet

- Iron Processing: Iron Processing, Use of A Smelting Process To Turn The Ore Into A Form From Which ProductsDocument9 pagesIron Processing: Iron Processing, Use of A Smelting Process To Turn The Ore Into A Form From Which ProductsDevina DianmahendraNo ratings yet

- Industrial Process Steel Pig Iron Henry Bessemer William Kelly Removal of Impurities Iron OxidationDocument12 pagesIndustrial Process Steel Pig Iron Henry Bessemer William Kelly Removal of Impurities Iron OxidationjayaprabhalNo ratings yet

- Puddling (Metallurgy)Document33 pagesPuddling (Metallurgy)asha200920102012No ratings yet

- Steelworks Products and Tinsmithing ToolsDocument39 pagesSteelworks Products and Tinsmithing ToolsEli SuarezNo ratings yet

- Cast Iron Soil Pipe History, Uses, and PerformanceDocument16 pagesCast Iron Soil Pipe History, Uses, and PerformancelalalalandNo ratings yet

- History of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Document584 pagesHistory of The Manufacture of Iron in All Ages, and Particularly in The United States From Colonial Times To 1891.Artisan Ideas75% (4)

- History ProjectDocument14 pagesHistory Projectvaghelashweta92No ratings yet

- The Steel StoryDocument48 pagesThe Steel StoryChen Hsiang-ChunNo ratings yet

- Pig Iron Blast Furnace Coke: Processes Starting From Bar IronDocument1 pagePig Iron Blast Furnace Coke: Processes Starting From Bar IronA-ReaderNo ratings yet

- Industrial RevolutionDocument49 pagesIndustrial Revolutionhuongleung100% (1)

- MME 449 Ferrous Metallurgy 4.00 Credit Hours/Week 400 January 2018 TermDocument13 pagesMME 449 Ferrous Metallurgy 4.00 Credit Hours/Week 400 January 2018 TermAbdul AuwalNo ratings yet

- History of Stainless SteelDocument65 pagesHistory of Stainless SteelMayank100% (1)

- Jurna MetalurgiDocument13 pagesJurna MetalurgiIsfan Satriyo PramudaniNo ratings yet

- Steel Making - Open-Hearth TehniqueDocument5 pagesSteel Making - Open-Hearth TehniqueMarcelo Rodriguez FujimotoNo ratings yet

- HMS News 71Document8 pagesHMS News 71btdolanNo ratings yet

- On The Role of Ferroalloys in SteelmakingDocument8 pagesOn The Role of Ferroalloys in SteelmakingJavo GarciaNo ratings yet

- Department of Mining Engineering (NITK)Document26 pagesDepartment of Mining Engineering (NITK)ankeshNo ratings yet

- Timeline CastingDocument5 pagesTimeline CastingCam Miller100% (1)

- Passage 3Document1 pagePassage 3retno pideksoNo ratings yet

- The Process of Steel HistoryDocument22 pagesThe Process of Steel HistorydaveNo ratings yet

- Barrow Steelworks: An Illustrated History of the Haematite Steel CompanyFrom EverandBarrow Steelworks: An Illustrated History of the Haematite Steel CompanyNo ratings yet

- Steam, Steel and Spark: The People and Power Behind the Industrial RevolutionFrom EverandSteam, Steel and Spark: The People and Power Behind the Industrial RevolutionNo ratings yet

- Steel MillDocument6 pagesSteel MillRenato Gigliotti MPhNo ratings yet

- Industrial Revolution CompilationDocument122 pagesIndustrial Revolution CompilationveriNo ratings yet

- Second Industrial RevolutionDocument4 pagesSecond Industrial RevolutionFrancesco PaceNo ratings yet

- Iron Steel Princip - OberrichDocument56 pagesIron Steel Princip - OberrichKTRINNYNo ratings yet

- History of SteelmakingDocument1 pageHistory of SteelmakingMark Anthony Asañez BrianNo ratings yet

- 2.iron MakingDocument13 pages2.iron MakingOecoeps SvaertatforstaNo ratings yet

- Oswego Iron FurnaceDocument2 pagesOswego Iron FurnaceFrank SmithNo ratings yet

- RSC Iron and Steel IntroductionDocument1 pageRSC Iron and Steel IntroductionHoney AliNo ratings yet

- Bending Guidelines - 247TailorSteelDocument44 pagesBending Guidelines - 247TailorSteelhrcozgNo ratings yet

- Catalogue Khớp Nối Mềm Rắc CoDocument2 pagesCatalogue Khớp Nối Mềm Rắc CoVietHienNo ratings yet

- Railroad GlossaryDocument29 pagesRailroad Glossarypeponis100% (1)

- PB Orvar Supreme EnglishDocument12 pagesPB Orvar Supreme EnglishTrexa GyreueNo ratings yet

- Bayer Material Science Thermoplastic Joining TechniquesDocument38 pagesBayer Material Science Thermoplastic Joining TechniquesdlstoneNo ratings yet

- VX SAK Catalogue 2017 enDocument80 pagesVX SAK Catalogue 2017 enIng. Roberto MoncayoNo ratings yet

- 347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Document4 pages347 Stainless Steel: 1.4541 1.4543/1.4561/1.4550 1.4552 (Cast)Prem NautiyalNo ratings yet

- Our Stainless Steels Solutions, The Most Complete Range Available On The MarketDocument7 pagesOur Stainless Steels Solutions, The Most Complete Range Available On The MarketKalpesh JainNo ratings yet

- c09 Aeb D Sta B ST Al Az 0001Document1 pagec09 Aeb D Sta B ST Al Az 0001Ryan De Vera PagalNo ratings yet

- Asme2a Sa-36Document7 pagesAsme2a Sa-36asjkhjshdjkashdashNo ratings yet

- Stainless Steel Grade 304 Vs 304LDocument3 pagesStainless Steel Grade 304 Vs 304Lrudi setiawanNo ratings yet

- Manning's Roughness CoefficientDocument2 pagesManning's Roughness Coefficientdjuka15No ratings yet

- Aisi 1020 Carbon Steel (Uns g10200)Document5 pagesAisi 1020 Carbon Steel (Uns g10200)Dimas Dwi HNo ratings yet

- Dental Amalgam: Pustaka: Anusavice: Phillps' Science of Dental Materials Combe E.C.: Notes On Dental MaterialsDocument19 pagesDental Amalgam: Pustaka: Anusavice: Phillps' Science of Dental Materials Combe E.C.: Notes On Dental MaterialsshelyjelNo ratings yet

- Gco 2000 Professional Manual 192110 PDFDocument227 pagesGco 2000 Professional Manual 192110 PDFburak_umutNo ratings yet

- ETS-50-06-12-E1 High-Voltage Components - Surge Arrester, Metal Oxide 170 KV PDFDocument5 pagesETS-50-06-12-E1 High-Voltage Components - Surge Arrester, Metal Oxide 170 KV PDFraghavendran raghuNo ratings yet

- Connection Design - Its Role in Steel DetailingDocument9 pagesConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.No ratings yet

- StockbridgeDocument1 pageStockbridgekariboo karibooxNo ratings yet

- UNIT-3 NotesDocument15 pagesUNIT-3 NotesDarbhalaPavanKumarNo ratings yet

- Stoichiometrey II Which Copper Sulfide?Document3 pagesStoichiometrey II Which Copper Sulfide?Iris CastroNo ratings yet

- Limit Switches: Severe Duty Mill and FoundryDocument40 pagesLimit Switches: Severe Duty Mill and FoundryBgd FadliNo ratings yet

- Rock and Mineral Identification For Engineer PDFDocument57 pagesRock and Mineral Identification For Engineer PDFAwang ❾❾ Putra100% (2)

- Astm A 691 .98Document6 pagesAstm A 691 .98FrengkiNo ratings yet

- EN9 Technical Data: Print Friendly Text Only Site MapDocument1 pageEN9 Technical Data: Print Friendly Text Only Site MapMari selvamNo ratings yet

- Hbi Use in FoundryDocument3 pagesHbi Use in Foundryravikataria02No ratings yet

- 1.2 Milling Machine:: Introduction To MachiningDocument13 pages1.2 Milling Machine:: Introduction To MachiningHukulele99No ratings yet

- 04-Rfittings.50 2002 200603Document44 pages04-Rfittings.50 2002 200603mkpqNo ratings yet