Professional Documents

Culture Documents

Dpi Operating Instructions

Uploaded by

Natane AlvesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dpi Operating Instructions

Uploaded by

Natane AlvesCopyright:

Available Formats

Digital Pressure Indicator DPI

Operating Instructions

Cylinder pressure monitoring

The DPI Digital Pressure Indicator measures dynamic pressures. It is

designed to analyze the internal combustion curve of large two and

four stroke diesel engines. The measurement is performed via an

indicator valve.

Digital Pressure Indicator DPI - Bedienungsanleitung

Content

1 Safety instructions..............................................................................4

2 Product description.............................................................................5

2.1 Application and function...........................................................5

2.2 Handheld device........................................................................6

2.2.1 Design...........................................................................6

2.2.2 Technical data...............................................................7

2.3 Pressure sensor..........................................................................8

2.3.1 Design...........................................................................8

2.3.2 Technical data...............................................................8

2.4 Software...................................................................................9

2.4.1 Description....................................................................9

2.4.2 Requirements for the PC...............................................9

3 Prepare the DPI system for use.......................................................... 10

3.1 Software installation................................................................ 10

3.2 Prepare the handheld device for the measurement................... 12

3.2.1 Enter motor parameters............................................... 12

3.2.2 Transfer motor parameters to the handheld device...... 14

3.3 Set date and time of the handheld device................................ 16

4 Perform measurement on the motor................................................. 17

5 Display measurement results............................................................. 21

5.1 Transfer data records from the handheld device to the PC........ 21

5.2 Analyzing measurement data with the DPI software................23

5.2.1 Pressure Plot................................................................24

5.2.2 TDC Correction...........................................................28

5.2.3 PV Plot........................................................................30

5.2.4 Bar Graph...................................................................32

5.2.5 Data Info.....................................................................34

5.2.6 Raw Data....................................................................35

5.3 Sending and receiving measurement data by email..................36

6 Organize measurement data in the handheld device.........................38

6.1 View data records on the handheld device...............................38

6.2 Delete data records in the handheld device..............................39

7 Maintenance.....................................................................................40

7.1 Maintenance of the pressure sensor.........................................40

7.2 Cleaning the pressure sensor...................................................40

7.3 Charging the handheld batteries.............................................. 41

7.4 Changing batteries..................................................................42

7.5 Setting the contrast, background lighting of the handheld device.. 43

2 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

General

The operating instructions serve to ensure that the product is used properly,

effectively and safely. Please read all instructions and warnings carefully.

Follow all safety precautions to avoid personal injury or property damage

during the workflow. For damage or injuries caused by non-compliance

with the requirements, the manufacturer assumes no liability. The manu-

facturer also takes over no liability if other than original manufacturer spare

parts and consumables are used.

This operating manual is directed mainly at technically trained personnel.

In case of doubt regarding safety or operational aspects, please do not

hesitate to contact the manufacturer for assistance. Should you notice a

faulty description or depiction or if you would like to suggest points for

improvement, we are looking forward to hearing from you.

Please keep the operating manual near the product to have it available if

needed. Make sure that the manual is protected from dirt and moisture.

Explanation of symbols:

DANGER

Immediate danger is possible causing severe injury or death if you do

not follow the instructions given.

WARNING

If you do not heed the warning, dangerous situations may occur leading

to severe injury or death.

CAUTION

Follow the instructions carefully, otherwise dangerous situations may

occur leading to injury or damage to property.

NOTICE

Please follow the recommendations and instructions for a correct and

flawless operation of the device or measuring system.

Friedrich Leutert GmbH & Co. KG 3

Digital Pressure Indicator DPI - Bedienungsanleitung

1 Safety instructions

The DPI may only be operated by trained personnel with the utmost cau-

tion and in compliance with the safety regulations for measuring large die-

sel and gas engines.

DANGER

Wear protective glasses during the measurement as hot gas or par-

ticles come out of the engine and could injure you. Wear hearing

protection during the measuring process as it can get very loud in

the engine room.

WARNUNG

Put on protective gloves before measuring because the surface of

the indicator valve and the sensor can get very hot during the indi-

cation process.

Do not operate the DPI hand-held device and the pressure sensor

above the allowed pressure and temperature ranges.

Remove the pressure sensor from the indicator connection immedi-

ately after each measurement to avoid overheating.

Use the hollow key provided.

NOTICE

Protect the DPI from moisture to prevent corrosion damage.

Do not insert any tools into the sensor bore.

Cooling the sensor with liquids is not permitted.

If the BAT indicator light on the handheld device is red this indicates

a low battery charge. There remains a measuring time of about 20

minutes. End the measurement within this time and charge the bat-

teries.

Charge the batteries via the USB connection of the handheld device

by the PC or with the associated USB charger.

When replacing the battery only use identical types.

4 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

2 Product description

2.1 Application and function

The DPI (Digital Pressure Indicator) measures dynamic pressures. It serves

for Analysis of combustion processes in 2- and 4-stroke large diesel engi-

nes. The measurement is carried out via an indicator valve. This electronic

indicator is the consistent further development of the successful digital in-

dicators of the DPI range and replaces all mechanical indicators.

In order to be able to measure pressure profiles with the DPI each cylinder

of the engine must be equipped with a standard indicator valve. By means

of the Thompson adapter the DPI pressure sensor is temporarily mounted

to the corresponding indicator valve. The construction of the Thompson

adapter minimizes the risk of overheating since the heat is dissipated quick-

ly.

By using a high-resolution sensor and a very high query rate of the hand-

held device the DPI can assign a crank angle performance and create a

power calculation without the use of a TDC sensor.

The electronics of the battery-operated DPI handheld device is installed in a

robust splash-proof plastic housing. The low mass display is not pulled out

of its seat in the event of impacts as it is often the case with larger displays.

Menu texts and measurement data are shown on the LC display of the DPI

hand-held device. The menu structure is easy to grasp and enables you to

operate measuring system intuitively. The menu-driven control enables you

to use the DPI effectively after a short time.

The DPI is operated with standard AA batteries which can be replaced by

releasing a single screw.

The measurement results are displayed during the respective cylinder me-

asurement on the display of the DPI handheld device and are saved on the

device‘s internal SD card.

A data set consists of several measurements (cylinder numbers) that

amongst other things contain the following values:

– Place of measurement (ship name)

– Engine name

– Date / time

– Number of measuring cycles (cycles)

– Highest cylinder pressure (Max. Press.)

– Average cylinder pressure (Avg. Press.)

– Lowest cylinder pressure (min. Press.)

– Engine speed (RPM)

– Boost pressure

Friedrich Leutert GmbH & Co. KG 5

Digital Pressure Indicator DPI - Bedienungsanleitung

All representations and mathematical calculations in the DPI software are

based on this data.

The saved measurement data can be transferred to a PC / laptop by the DPI

software to be visualized, evaluated or to be sent electronically.

The measurement data evaluation using Windows-based software gives

the ability to make complex diagnostic statements about the quality of the

combustion processes.

Every product is manufactured according to the ISO 9001 quality standard,

tested and shipped with a calibration certificate which guarantees a high

device accuracy.

2.2 Handheld device

2.2.1 Design

4-pin connection socket for pressure sensor

LC display with backlight,

4 lines x 20 alphanumeric characters

LED for status display of the batteries

and of the measuring process

ON / OFF button

Control buttons

USB socket type B

ACT display:

BAT ACT

– flashes blue during the measurement

BAT battery charge displays:

– lights up red: low battery charge

– flashes red: the automatic shutdown will take place shortly

– flashes green: active charging of the batteries

– glows green: batteries fully charged

6 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

Shoulder strap

Battery compartment for 4 x 1.5 V

batteries

Type label with CE marking

Plastic housing

2.2.2 Technical data

Storage capacity : 50 engines with up to 24 cylinders each

Interface : USB 2.0

Power supply : rechargeable standard AA

NiMH batteries 1.2 V / 2000 mAh

Battery life : > 6 h for sensor 0 to 300 bar

Battery charging : via USB

Display : 20 x 4 alphanumeric characters, with

backlight, high contrast

Degree of protection : IP 65

Temperature range : 0 bis 55 °C

Dimensions : 211 x 100 (81) x 45 (26) mm

Weight : 430 g incl. batteries

Friedrich Leutert GmbH & Co. KG 7

Digital Pressure Indicator DPI - Bedienungsanleitung

2.3 Pressure sensor

2.3.1 Design

The DPI is supplied with a pressure sensor and connection cable. By the

armored cable with plug the sensor is connected with the DPI hand-held

device.

The pressure sensor is suitable for temporary measurements on indicator

valves only (gas pressure measurements on internal combustion engines).

Measurements on hydraulic systems must not be carried out.

The quartz sensor is characterized by high accuracy, robust construction

and durability. Its calibration interval is 8000 operating hours. The cali-

bration check can only be carried out by the manufacturer. In this regard

please contact the manufacturer.

Connection cable

Piezoelectric sensor

(inside)

Connection thread W27 x 1/10 ”

NOTE

The screw of the pressure sensor is sealed to prevent improper use

or handling. Breaking the seal will lead to loss of warranty.

2.3.2 Technical data

Pressure range : 0 to 300 bar

Speed range : 50 to 5000 rpm

Accuracy : < 0.5%

A/D resolution : 16 bit (0,0092 bar/sample)

Degree of protection : IP 65

Connection thread : W 27 x 1/10”

Temperature range : 0 to 350 °C

Dimensions : Ø = 60 mm, L = 180 mm

Weight : approx. 490 g

8 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

2.4 Software

2.4.1 Description

After measuring the engine the measuring values saved in the handheld

device are transferred to the PC and can be displayed with the DPI soft-

ware and evaluated in detail. To analyze the engine data different visu-

alization modes are available (pressure diagram, PV diagram, bar graphs,

tabular information).

To operate the DPI software you can use the commands in the menu bar,

the four tabs for selecting the display mode and various buttons.

Menu commands

Tabs to select the display mode

Display area

Command buttons

LED shows connection of

handheld device on the PC

The software enables data export, report generation or sending of the

data by email with just a few clicks.

In addition the software is used for comfortable configuration of the hand-

held device.

Since the software is in English language basic knowledge of English is fa-

vorable but not a requirement. In the manual you get a detailed description

for each command which enables you to work with the program without

any foreign language skills.

Friedrich Leutert GmbH & Co. KG 9

Digital Pressure Indicator DPI - Bedienungsanleitung

Menu commands

Menu “File”

Opens a data record from the PC’s hard drive

Data export as a dpz file on a PC or by email Imports a

dpz file from the PC hard drive

Exports the opened data record to an xls file Create a

report for printing or as a PDF file

Exit the program, also with Alt + F4

*) A dpz file is a measurement data record in DPI for-

mat and to be read with the DPI software only.

Menu „Handheld”

Imports a data record from the handheld device into the PC

Exports the engine data

Synchronize the date/time of the handheld device with the

PC

Menu „Settings”

Selection of the display colors for the 24 cylinders

Enter the company name, address and logo for the report

Menu „About”

Display of software version and manufacturer

Find and install updates available online

Link to the manufacturer’s homepage

2.4.2 Requirements for the PC

In order to be able to run the DPI software, your PC should meet the fol-

lowing requirements:

– A free USB port for data transfer between the handheld device

– and PC

– approx. 15 MB free space for the installation of the software and the

– documentation

– Windows 7 and higher

– minimum screen resolution 1024 x 768, recommended 1280 x 1024

– Color 16 bit or higher

– Printer, color printer recommended

This manual was created for software users who have basic knowledge

of computer skills. You should be familiar with the typical Windows fea-

tures like menus and command buttons since these elements are not ex-

plained here.

10 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

3 Preparation of the DPI system for use

3.1 Software installation

The software is stored in the handheld device’s memory upon delivery

and must be copied and installed on the PC before use.

1) Connect the DPI handheld device with a Windows PC using the sup-

plied USB cable. The DPI automatically turns on and is recognized by

the computer as a drive. Additional device drivers do not need to be

installed.

2) Open the newly recognized drive ‘DPI’. Select the file ’Installer DPI

(version no.). Exe’ and copy it to the PC, for example on the desktop.

NOTICE

DO NOT start the installation directly from the DPI drive!

3) Start the software installation on the PC by double-clicking to the

file ‘Installer DPI (version no.). exe’.

4) Confirm the license conditions and continue with [Next>].

Friedrich Leutert GmbH & Co. KG 11

Digital Pressure Indicator DPI - Bedienungsanleitung

5) Follow the further installation instructions. Finally the DPI and a pro-

gram group appears in the Windows start menu and Desktop icon

for the DPI software.

If a previous version of the DPI software is already set up on your PC,

you can update it. You will receive updates e.g. electronically..

Start the installation of the new software as described above. Here the

installation program searches for existing versions and automatically selects

their installation path.

During the update the program files are updated as well.

The directory with the measurement data remains unaffected.

NOTICE

The measurement data and program settings are saved on the

System drive C under your user name \ My Documents \ DPI. Please

back up this data regularly. Please be aware that a reinstallation of

Windows will overwrite the directory `My Documents` and the data

could be lost.

12 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

3.2 Prepare the handheld device for the measurement

3.2.1 Enter engine parameters

At first use of the device you have to enter the engine parameters once for

each engine.

NOTICE

Pay attention to correct entries so that the DPI gives you correct

measurement results.

1) Start the DPI software on the PC. Open the command [Open Data-

base] in the menu [File].

2) Select [Create Ship]. Place the mouse pointer on the line ‘ANewS-

hip’ and enter the name of the ship / power plant or similar. Under

‘Description’ you can write down additional information. Save the

entries with [Save].

3) Mark the ship’s name and click on [Create Engine] to set up an en-

gine for this ship.

Friedrich Leutert GmbH & Co. KG 13

Digital Pressure Indicator DPI - Bedienungsanleitung

4) Enter the engine-specific parameters in the ‘Create new Engine’

window.

Dataset

Engine name : Name of the engine

Stroke length : stroke length

Correction rod length : length of the connecting rod

Piston diameter : piston diameter

Engines : engine manufacturer / type

Handheld

Default boost pressure : charge air pressure (standard)

Default meas. cycles : measuring cycles (standard)

Default meas. cylinder : no. of cylinders (standard)

Default strokes : 2- or 4-stroke engine

NOTICE

When determining the length of the connecting rod the dis-

tance between the large end and the small end has to be

considered and not the total length of the connecting rod.

The DPI is able to measure the TDC based on the pressure curve

showing the course of combustion. This is the basis of the power

calculation. For engines with premature combustion for reduction

of nitrogen oxide emissions some peculiarities result regarding the

automatic detection of the TDC. In these cases the check box [NOx]

can be ticked to determine the TDC.

Use the DPI‘s ability to prevent interfering influences on the mea-

surement result by selecting certain measurement settings, e.g. the

number of measurement cycles as basis for averaging. This gives you

results which enable you to compare the measurement data of the

individual cylinders to each other.

5) Save the entries with [OK]. Repeat this step for more engines if nec-

essary.

During the indication process the DPI uses the current measuring settings

for each engine. These will be saved until they are redefined.

14 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

3.2.2 Transfer engine parameters to the handheld device

1) Connect the handheld device to the PC by means of the USB ca-

ble. The handheld device switches on automatically and the battery

charging process begins.

2) A green LED symbol in the status bar of the DPI software indicates

that the handheld device is connected to the PC.

NOTICE

If the handheld device is connected to the PC or the battery

charger via USB button operation is not possible.

3) Open the [Export Engines Data] command in the [Handheld] menu.

In the upper ‘Setup’ area the datasets are displayed which are al-

ready stored in the handheld device. If you mark an engine with the

mouse you will see the assigned “parameters” in the lower window

area. If no engine data has been saved yet in the handheld device

the following window would be empty.

4) Click the [Add Engine from Database] button.

Friedrich Leutert GmbH & Co. KG 15

Digital Pressure Indicator DPI - Bedienungsanleitung

5) Mark the desired engine and click on [To Handheld]. After success-

fully transferring the engine parameters to the connected hand-held

device the new engine appears in the list. The handheld device is

now ready for the measurement.

NOTICE

You can enter and save the parameters of a maximum of 50 engines

in the DPI.

6) Close the window with [Close] and disconnect the handheld device

from the PC.

16 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

3.3 Set the date and time of the handheld device

The correct value of time and date is necessary to ensure an exact temporal

assignment of the measurement results.

The date format is month / day / year, the time is displayed in

hours:Minutes:seconds.

The date / time setting of the handheld device is done in the DPI software

by synchronization with the PC settings, provided the PC is set up correctly.

1) Connect the handheld device to the PC using the USB cable. The

P MI handheld device switches on automatically and the battery charging

Connected to USB

R e c h a r gi n g . . . process begins.

- - -} - - - - - - - - - - - - - - - -

2) Start the DPI software on the PC.

3) Open the menu [Handheld] and [Sync. Time].

4) Click the button [Synchronize Time to Handheld] button. The date

and time settings of the PC are transferred to in the handheld device

and saved there.

5) If necessary, disconnect the handheld device and PC. The handheld

device switches off automatically.

Friedrich Leutert GmbH & Co. KG 17

Digital Pressure Indicator DPI - Bedienungsanleitung

4 Perform measurement on the engine

DANGER

Wear protective glasses during the measurement as hot gas or parti-

cles come out of the engine and could injure you.

Wear hearing protection during the indication process as it can get

very loud in the engine room.

WARNING

Put on protective gloves before indicating because the surface tem-

perature of the indicator valve and the sensor can get very high

during the indication process.

Do not operate the DPI handheld device and the pressure sensor

above the allowed pressure and temperature ranges.

NOTICE

Ensure that the load and the speed is as constant as possible during

the measurement in order to get comparable results.

If the sensor cable is not connected to the sensor, insert the orange contact

into the pressure sensor and secure the contact by screwing on the knurled

nut. Pull it hand tight. The plugs of the connection cable have a “nose /

slot” connection identifier. Please pay attention to correct insertion.

Plug the sensor cable into the 4-pin connection socket of the handheld

device. Please make sure that the red marking point shows towards the

display of the handheld device and the plug is not turned.

1) Before installing the pressure sensor, clean the relevant indication

channel by fully opening the indicator valve briefly while the engine

is running in order to blow out the channel. You thus avoid the sen-

sor membrane being contaminated or damaged.

2) After blowing out close the indicator valve completely.

3) Then attach the pressure sensor to the indicator connection of the

Engine.

NOTICE

First hand-tighten the cold sensor to prevent it from seizing.

18 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

P MI 4) Press the button for 1 second to switch on the handheld device.

The serial number and the firmware version appear on the display

SN: 9757 for a short time.

V e r si o n : 1 . 0 3 . 3 1

» M ai n m e n u « 5) In the main menu you can now use the arrow keys or to

change the lines. Confirm with the button if the line `Measure

M e a s u r e e n gi n e } engine` is marked by the } arrow.

Show data

» M e a s u r e e n gi n e « 6) Scroll with the vertical arrow keys or , until the motor to be

measured is marked on the display with the } arrow.

M ai n E n gi n e }

A U X E n gi n e 1

» M e a s u r e e n gi n e «

M ai n E n gi n e

A U X E n gi n e 1 }

A U X E n gi n e 2

7) Open the indicator valve completely.

Sensor warm up 8) Start with . The sensor warm-up phase begins. A cancellation is

Ti m e l ef t : 0 0 : 4 8 possible with the button , the display changes back to the main

menu.

} C a n c el

NOTICE: Do not turn off the DPI before the measurement is

terminated otherwise you would have to wait for the pres-

sure sensor to warm up again before each measurement.

M e a s u r e e n gi n e 9) The engine to be measured appears after the warm-up phase. Below

A U X E n gi n e 1 that the cylinder number appears as a flashing digit. If necessary change

C yli n d e r n o : 0 1

} No Ye s } the cylinder number with the arrow keys or . Confirm by .

NOTICE: The series of measurements automatically starts

with cylinder 1 at the beginning of a new measurement. Oth-

erwise the system is counting up starting from the last mea-

surement.

A U X E n gi n e 1 10) If data for this cylinder is already stored in the handheld device, de-

M e a s u r e e n ti r e e n g . cide here whether you want to repeat the complete measurement

o r r e d o si n gl e c yl .?

} C yli n d e r E n gi n e } series of the engine by or only that of the cylinder by .

O v e r w rit e 10.1) If the existing cylinder data should be overwritten please confirm

A U X E n gi n e 1 with Button and go to step 11. If canceled with button the

C yli n d e r n o : 0 1?

} No Ye s } display changes back to the main menu.

A U X E n gi n e 1 10.2) Use the arrow key to confirm overwriting the existing engine

O v e r w rit e p r e v . data and go to step 11. If canceled with button the display

M e a s u r e m e n t s?

} No Ye s } changes back to the main menu.

Friedrich Leutert GmbH & Co. KG 19

Digital Pressure Indicator DPI - Bedienungsanleitung

M e a s u r e e n gi n e 11) The number of measuring cycles can be adjusted with the arrow

A U X E n gi n e 1 keys or . Confirm the value by .

C yli n d e r n o : 0 1

C y cl e s : 0 1 0

M e a s u r e e n gi n e 12) In the following display the boost pressure can be adjusted with the

A U X E n gi n e 1 or button. Confirm with the key .

C yli n d e r n o : 0 1

B o o st : 0, 5 0

M e a s u r e e n gi n e 13) Start the measurement with the key . During the measurement

S t a r t m e a s u r e m e n t? the ACT display flashes blue.

} No Ye s }

M e a s u ri n g e n gi n e . . .

A U X E n gi n e 1

} C a n c el

M e a s u ri n g e n gi n e . . .

A U X E n gi n e 1

RPM: 240

} C a n c el

M e a s u ri n g e n gi n e . . . After the measurement is finished the results are calculated.

A U X E n gi n e 1

C al c ul a ti n g . . .

M e a s u r e m e n t fi ni s h e d 14) Close the indicator valve completely.

1 . Cl o s e v alv e!

2 . Di s c o n n e c t s e n s o r!

3 . Hit k e y t o c o nfi r m

15) Unscrew the pressure sensor. Due to expansion of the sealing cone in

the pressure sensor the hollow key may be required for unscrewing.

CAUTION

After completion of the measuring series, remove the pres-

sure sensor from the indication bore in order to avoid overhe-

ating.

NOTICE

If the pressure sensor does not come loose, open the indi-

cator valve for a short time to achieve a loosening through

the combustion pressure. Close this valve immediately after

removing the pressure sensor from the indicator valve.

16) For security reasons confirm the correct performance of steps 14

and 15 by the key .

20 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

» C yli n d e r : 01 « 17) The display shows the measured data which you can watch and

Avg. press. : 45 scroll by use of the arrow keys or . With key switch to data

Max. press. : 46 }

Mi n . p r e s s . : 47

storage immediately, see step 20.

» C yli n d e r : 0 1 « 18) Press the key , until you are asked what should be done with this

S t o r e r e s ult s series of measurements: store results, repeat measurement (redo) or

Redo }

C a n c el

cancel process.

» C yli n d e r : 0 1 « 19) To save scroll with the vertical arrow keys or , until the option

------------------ ‘Store results’ is marked on the display by the arrow }. Confirm

S t o r e r e s ult s }

Redo with .

20) The data of the measured cylinder is saved.

S a vi n g r e s ult s . . .

M e a s u r e e n gi n e The DPI handheld device automatically leads to the measurement of

A U X E n gi n e 1 the next cylinder.

C yli n d e r n o : 0 2

Repeat steps 1 through 3 and 5 through 19 until the last cylinder

has been measured according to the configuration (dataset).

NOTICE

Carry out the series of measurements quickly in order to en-

sure the same conditions for each cylinder.

P MI Switch off the DPI handheld device by pressing the button for approx.

2 seconds.

S wit c h off . . .

. . . x s e c . l ef t

NOTICE

P MI After 5 minutes of inactivity - i.e. without pressing a button - the

handheld device switches off automatically as long as it is not con-

S wit c h off . . .

B y e - b y e! nected to a power supply via USB. The saved entries are retained.

The handheld device must be switched on again for further opera-

tions and the last edited menu must be called up again.

Unplug the sensor cable from the DPI handheld device. The connection will

be detached by pulling the knurled collar away from the handheld device,

it should not be unscrewed. Store the system components in the measu-

ring case.

NOTICE

Never put the pressure sensor back in the transport case when it is

still hot. Wait until the sensor has cooled down.

Friedrich Leutert GmbH & Co. KG 21

Digital Pressure Indicator DPI - Bedienungsanleitung

5 Display measurement results

5.1 Transferring data from the handheld device to the PC

For analysis and interpretation of the recorded cylinder pressure curve

use the DPI software belonging to the system. For this purpose it is

necessary to transfer the saved measurement data from the DPI handheld

device to the PC.

1) Connect the handheld device to the PC using the USB cable.

2) Start the DPI software.

3) In the menu [Handheld] open the command [Import measurement

data]. A window with the measurements saved in the handheld de-

vice appears.

22 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

4) Select the measurement to be imported by clicking on the Check-

box. The following options are activated:

[Import measurements] imports the data set into the DPI software. If

the checkbox (Delete measurements from handheld after import] is

marked with a cross the data set will be automatically deleted from

the handheld device.

NOTICE

If you select this option the data will be irrevocably deleted

from the handheld device.

Alternatively you can delete the measurement data manually at a

later time. To do this press [Delete measurements from handheld].

[Save as ...] assigns the measurements to be imported to an existing

engine.

Under ‘Parameters:’ you can see the engine parameters of the

marked data set applying during the measurement.

Friedrich Leutert GmbH & Co. KG 23

Digital Pressure Indicator DPI - Bedienungsanleitung

5) Click on [Import measurement]. The ’Select ship’ window appears.

6) Select the target directory into which the data record is to be im-

ported and confirm with [OK].

7) The following message shows how many cylinder measurements

are included in the imported data set.

Close the window with [OK].

8) With the next query decide whether the imported data should be

shown now or not. Click accordingly to [Yes] or [No].

If [Yes] the data is preset in the menu [Pressure Plot].

24 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2 Analyze measurement data with the DPI software

Various display modes are available for analyzing the measured values

which are described in the following sections.

1) Start the DPI software on the PC. Open in the menu (File] the Com-

mand [Open Database].

2) Mark the data set to be opened in the list and click on OK].

The measurement data is displayed in the mode [Pressure Plot].

Friedrich Leutert GmbH & Co. KG 25

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2.1 Pressure Plot

The curve progression shown in the [Pressure Plot] display mode shows the

cylinder pressure [bar] for each cylinder measured at the indicator valve

depending on the crankshaft angle [° CA].

Select from the right window area the cylinders to be displayed:

– Checkboxes for individual cylinders (multiple selection possible)

– [All On] shows all cylinders

– [All Off] hides all cylinders

The button [Show Cyl. Overlay] also serves to select cylinders in a separate

window. This function also offers the possibility to select a new dataset

and to display an additional measurement (overlay).

26 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

In the left window the following display options are available:

– Multiple cylinder: selection of all cylinders

– All cycles: display of all measured cycles of a cylinder

– Min / max cycles: shows the minimum and the maximum cycle of a

cylinder

– Single cycle: display of a specific cycle of a cylinder, selection by using

the arrow keys in the box below.

You can use checkboxes to influence the display as follows:

– Avg. cycle:

– Filter:

– [dp/da]: the first derivative of the pressure curve can be switched on / off

Available buttons:

Toggle Grid - switch grid on / off

Export to pdf - open the current view for printing or saving as pdf file

XY-Cross - crosshair for reading the pressure values over the crankshaft angle

Zoom 100% - reset graphics after zooming, scaling or moving

Move - Move the graphic section with the mouse

Zoom - enlarge an area marked with the mouse

Scale - scale the graphic horizontally and / or vertically

Friedrich Leutert GmbH & Co. KG 27

Digital Pressure Indicator DPI - Bedienungsanleitung

A

D

B

C

Some important pressure values to be read

from the cylinder pressure

curve are plotted in the graphic above.

A: Peak pressure

Shows the maximum pressure value of the measurement curve, also

known as ignition pressure.

B: Compression pressure

Pressure measured at the top dead center of the respective cylinder.

C: Start of combustion

D: Differential pressure

Peak pressure minus the pressure at the start of combustion.

If the value is 0 the beginning of the combustion of the engine can-

not be clearly assigned. This can also be the case with engines with

a very early injection or engines having a combustion with linear

beginning.

E: Expansion pressure

Pressure at a particular point in the expansion phase, e.g. 36 ° CA

(crankshaft angle) after top dead center.

28 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

A E C

[Pressure plot] shows the cylinder pressure at the respective indicator valve

depending on the crankshaft angle, at the top with activated first deriva-

tive.

A: Axis for the cylinder pressure, scaling in bar

This axis is automatically adjusted to the max. cylinder pressure of

the current measurement.

B: Crankshaft angle, scaling in °

This axis shows the position of the crank angle for the measured

Cylinder.

C: axis for the curve of the first derivative (dp / da)

D: 0 bar - line for the curve of the 1st derivative

E: TDC (top dead center) line

F: This cylinder pressure curve shows the pressure (rising / falling) de-

pending on the crank angle of the measured cylinders.

Friedrich Leutert GmbH & Co. KG 29

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2.2 TDC Correction

In the display mode [TDC Correction] the position of the top dead center

can be determined which is necessary for the performance calculation.

The cylinder to be displayed is selected in the right window are.

A: Derived pressure curve, scaling in bar / ° crank angle shift; The dp /

da pressure line represents the rise / fall for 1 ° Change of crank

angle. This should not exceed 6 bar / ° to avoid mechanical strain on

the machine parts. This line also allows the position of the TDC to

be calculated. TDC is the position where the pressure does not rise

or fall (except engines with premature combustion).

30 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

Optionally the TDC can also be determined using software or it can be

determined manually.

To correct the top dead center TDC there are various opportunities under

„Correction:“:

– [Auto All Cyl.]

– [AutoCorr.Cyl.01]

– [Corr. all @ 12°]

– [Corr. to Cyl 1]

Choose under „Show Cylinder:“ between single (single) and all (all).

You can use checkboxes to influence the display as follows::

– Filter:

– [dp/da]: Switch on / off the first derivative of the pressure curve

Available buttons:

Toggle Grid - switch grid on / off

Export to pdf - open the current view for printing or saving as pdf file

+ Mark TDC - manual TDC determination by placing the Mark TDC cross

Zoom 100% - reset graphics after zooming, scaling or moving

Move - Move the graphic section with the mouse

Zoom - enlarge an area marked with the mouse

Scale - scale the graphic horizontally and / or vertically

\ RubberBand - The rubber band function can be used to extend the derivation of

the pressure curve (dp / da) in the downward movement to get to the point where

the derivative would cross the zero line..

Friedrich Leutert GmbH & Co. KG 31

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2.3 PV Plot

The display mode [PV Plot] illustrates the cylinder pressure in relation

to the volume curve.

The cylinders to be displayed are selected in the right window area.

Available buttons:

Toggle Crosshair - switch on / off horizontal line for reading the pressure values

Toggle Grid - switch on / off grid

Export to pdf - aopen the current view for printing or saving as pdf file

Zoom 100% - reset graphics after zooming, scaling or moving

Move - Move the graphic section with the mouse

Zoom - enlarge an area marked with the mouse

Scale - scale the graphic horizontally and / or vertically

32 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

The PV diagram [PV Plot] shows the course of the cylinder pressure bet-

ween top dead center (TDC) and bottom dead center (BDC) during a wor-

king cycle.

A: Axis for the pressure in bar

B: axis for volume change from BDC to TDC

C: The inner area represents the “gain of work”.

In the past the PV diagram, also known as the banana curve, has been

applied to measure the work area and to determine the indicated perfor-

mance by use of a planimeter. Today this procedure is no longer necessary

because the electronic indicator carries out this calculation automatically.

Friedrich Leutert GmbH & Co. KG 33

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2.4 Bar Graph

In the [Bar Graph] mode the selected measurement data is displayed in

form of a bar graph. This view allows you to easily compare the individual

cylinders with each other.

The bar chart below shows a sample data set that shows the maximum

of the combustion pressures for all cylinders with automatic scaling. The

optimum is achieved once the deviation between the cylinders is as small

as possible.

The cylinders to be displayed are selected in the right window area.

In the left window area the following display options are available:

„Cylinder:“

– avg. max press .: Average value of the maximum ignition pressure

– P TDC: pressure at top dead center

– min / max press .: minimum and maximum pressure

– MIP: mean indicated pressure

– engine rpm: engine speed

„Cycle:”

– max press .: maximum pressure per cycle and cylinder

– tdc press .: pressure at top dead center per cycle and cylinder

„Value display mode”

– absolute: display of the absolute values

– abs. zoom: graphic enlarged to the maximum values

– relative: display of the relative deviations

34 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

Available buttons:

Toggle Grid - switch grid on / off

Export to pdf - open the current view for printing or saving as a pdf file

Toggle Crosshair - switch on / off horizontal line for reading the pressure values

Friedrich Leutert GmbH & Co. KG 35

Digital Pressure Indicator DPI - Bedienungsanleitung

5.2.5 Data Info

The table [Data Info] shows the measuring data determined for each cylin-

der in numerical order. All presentations and mathematical calculations of

the DPI software are based on these measurements.

– Date, Time: Date and time of the measurement

– Average cycles: number of measured cycles (number of averages)

– Pmax_av: average peak pressure value of all measuring cycles

– Pmax_max: highest peak pressure value of all measuring cycles

– Pmax_low: lowest peak pressure value of all measuring cycles

– MIP: mean indicated pressure

– Deviation: standard deviation related to the mean value of all peak

pressures of a series of measurements.

– Ptdc: pressure value at top dead center

– RPM: engine speed

– Max dp / da: 1. derivation of the pressure curve

– Ind. Power: indicated cylinder power

– Boost pressure: boost pressure of the engine

– Ambient temp .: ambient temperature

The following values are

not measured but can be optionally entered later

to complete the data record.

– Exhaust gas temp .: exhaust gas temperature

– Fuel rack setting: position of the injection linkage

– VIT setting: variable injection time

– Additional information: space for entering additional information

36 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

Available buttons:

Export to Excel - Save and open the DataInfo table as an Excel file

Export to pdf - open the current view for printing or saving as a pdf file

5.2.6 Raw Data

Available buttons:

Toggle Grid - switch on / off grid

Export to pdf - open the current view for printing or saving as a pdf file

Y-PosCross - help line for reading the exact pressure values on the y-axis

Zoom 100% - reset graphics after zooming, scaling or moving

Move - Move the graphic section with the mouse

Zoom - enlarge an area marked with the mouse

Scale - scale the graphic horizontally and / or vertically

Friedrich Leutert GmbH & Co. KG 37

Digital Pressure Indicator DPI - Bedienungsanleitung

5.3 Send and receive measurement data by email

Sometimes it is necessary to send measurement data electronically.

You start this function in the DPI software with the menu command [File]

and [Export to file / email].

If you want to send the data record which is currently opened in the DPI

software, this is already marked in the list. Otherwise select the record

which you would like to send by email in the window above.

Click the button [Export to mail] button. The email program opens and the

file appears in a prefabricated mail as an attachment.

Fill in the appropriate address lines (From :, To :), complete the names and,

if necessary, the text and send the mail.

38 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

Friedrich Leutert GmbH & Co. KG 39

Digital Pressure Indicator DPI - Bedienungsanleitung

6 Organize measurement data in the handheld device

6.1 View data records on the handheld device

While the measured value is being recorded you can see on the DPI display

some of the determined data such as speed, peak and differential pressure.

After completing the series of measurements you can view the complete

data sets on the DPI handheld.

» M ai n m e n u « 1) Press the button for approx. 1 second to switch on the handheld

device. The main menu appears after the start screen. Use the but-

M e a s u r e e n gi n e }

Show data tons or to switch between the lines.

» M ai n m e n u « 2) Confirm with if the line ‘Show data’ is marked with the } arrow.

M e a s u r e e n gi n e

Show data }

D el e t e d a t a

» Show data « 3) The saved motors are displayed. Scroll down this list with the vertical

arrow keys or .

M ai n E n gi n e }

A U X E n gi n e 1

» M e a s u r e e n gi n e « 4) If the chosen engine is marked with the arrow in the display, confirm

M ai n E n gi n e the selection with button .

A U X E n gi n e 1 }

A U X E n gi n e 2

» S el e c t C yli n d e r « 5) The measured cylinders are displayed. Scroll with the keys or ,

until the chosen cylinder is marked with the } arrow. Confirm with

C yli n d e r n o : 0 1 }

C yli n d e r n o : 0 2

the key .

» C yli n d e r : 0 1 « The saved measuring values of the selected cylinder are displayed.

A v g . p r e s s . : 4 5

M a x . p r e s s . : 4 6 }

Mi n . p r e s s . : 47

» C yli n d e r : 0 1 « 6) Scroll with or to view the single measured values.

B o o st : 4. 0 0

C y cl e s : 0 2 0 }

@RPM: 360

» C yli n d e r : 0 2 « 7) Use the key to switch to the next cylinder or leave the ‘Show

A v g . p r e s s . : 4 5 data’ menu by pressing the button to return to the superordi-

M a x . p r e s s . : 4 6 }

Mi n . p r e s s . : 47 nate menu.

» M ai n m e n u «

M e a s u r e e n gi n e

Show data } Switch off the DPI handset by pressing the button for approx. 2 sec-

D el e t e d a t a

onds.

40 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

6.2 Delete data records in the handheld device

During the measurement, the DPI saves the measured values as data re-

cords which can be assigned to each individual cylinder. If you start a new

measurement, this data is overwritten. So it is not mandatory to delete old

measurement results before a new measurement is started. If you wish to

delete old results though, proceed as follows:

NOTE

Make sure that you have already downloaded and saved the mea-

surement data to the PC or that you no longer need the data.

» M ai n m e n u « 1) Press the button for approx. 1 second to switch on the handheld

device. Use the buttons or to switch between the lines.

M e a s u r e e n gi n e }

Show data

» M ai n m e n u « 2) If the ‘Delete data’ line is marked with the } arrow, press the but-

Show data ton .

D el e t e d a t a }

C o nfi g u ra ti o n

» D el e t e d a t a « 3) The saved engines are displayed. Scroll down this list with the verti-

cal arrow keys or .

M ai n E n gi n e }

A U X E n gi n e 1

» D el e t e d a t a « 4) If the chosen engine is marked on the display with the } arrow, con-

M ai n E n gi n e firm the selection with button .

A U X E n gi n e 1 }

A U X E n gi n e 2

» D el e t e d a t a « 5) The measured cylinders are displayed. Scroll with the keys or

until the cylinder to be deleted appears on the display or the selec-

C yli n d e r n o : 0 1 }

C yli n d e r n o : 0 2 tion ‘All cylinders’ is marked with the } arrow.

» D el e t e d a t a « 6) Delete the process with key [Yes] or cancel with [No] ab.

C yli n d e r n o : 0 1?

} N o Ye s }

» M ai n m e n u « 6.1) [Yes] The display changes back to the main menu. ‘Delete data’ ist

Show data is marked with the } arrow.

D el e t e d a t a }

C o nfi g u ra ti o n

» M ai n m e n u « 6.2) [No] ends the deletion process

M e a s u r e e n gi n e }

Show data

Switch off the DPI handset by pressing the button for approx. 2 sec-

onds.

Friedrich Leutert GmbH & Co. KG 41

Digital Pressure Indicator DPI - Bedienungsanleitung

7 Maintenance

7.1 Maintenance of the pressure sensor

The DPI handheld device requires little maintenance. Make sure that the

device and the associated pressure sensor is returned to the manufacturer

after approx. 100 operating hours or after 3 years to check the calibration

data.

NOTE

While the calibration settings are controlled by the manufacturer,

the pressure sensor will be cleaned simultaneously.

7.2 Cleaning of the pressure sensor

Remove regularly any soot or carbon deposits from the pressure sensor sin-

ce they might interfere with the measuring operation. The contamination

rate depends on the indicated engine and its operating conditions. The cle-

aning intervals given below should, thus, be considered as a rough guide::

– after approx. 5 operating hours for a diesel engine running on heavy

oil

– after approx. 30 hours of operation for a diesel engine running on

diesel oil

– No cleaning is required for gas engines.

No warranty claims will be accepted for damage or destruction of the pres-

sure sensor due to non-respect of the following safety instruction.

CAUTION

Before cleaning, allow the sensor to cool down to less than 50 °C.

Use commercial cleaning agent.

Do not introduce any tools into the sensor bore.

Do not disassemble the sensor unit.

Wear safety glasses when blowing out the sensor bore.

For cleaning the pressure sensor proceed as follows:

1) Fix the sensor unit in upright position, with the sensor access bore-

pointing upwards.

2) Pour the cleaning liquid in a mixture ratio of 1:10 into the sensor

bore and allow to react for about 30 min. to 1 hour.

3) Remove the introduced cleaning agent by turning the device upside

down.

4) Afterwards, blow out the sensor bore by means of compressed air

(max. 4 bar).

42 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

5) Any remaining cleaning agent may be removed with clear water by

repeating steps 3 and 4.

If the sensor is heavily stained repeat the cleaning procedure.

7.3 Charge the batteries of the handheld device

NOTICE

Charge the batteries when the BAT indicator on the handheld device

flashes red or lights up or the message ‘charge battery’ appears.

The battery must be charged after 9 months of storage at the latest.

1) Connect the handheld device to the PC by using the USB cable Or

D PI the included charger. It is now automatically in the battery charge

Connected to USB level and cannot be operated using the buttons. The BAT signal

R e c h a r gi n g . . .

- - -} - - - - - - - - - - - - - - - - flashes green.

D PI If the batteries are fully charged, the message ‘batteries recharged’

Connected to USB appears on the display. Depending on the remaining battery charge

B a tt e ri e s r e c h a r g e d

this procedure may take up to 12 hours.

The BAT signal lights up green. The charger turns off automatically

and electricity no longer flows.

2) Finally remove the USB cable from the handheld device, it switches

off automatically..

NOTICE

The charging process can be easily interrupted by disconnecting the

USB cable.

Friedrich Leutert GmbH & Co. KG 43

Digital Pressure Indicator DPI - Bedienungsanleitung

7.4 Changing the batteries

CAUTION

Switch off the DPI hand-held device and disconnect the charger be-

fore beginning the procedure.

NOTICE

Use identical types when replacing the battery.

Make sure that you have already downloaded and saved the mea-

surement data to the PC or that you no longer need the data.

If the battery is to be replaced or removed from the DPI, please proceed as

follows:

1) Use a flat-blade screwdriver to screw off the cover of the battery

compartment. The fastening screw is captive and the shoulder strap

is on the cap.

2) Remove the old ones and insert the new ones. Take notice of the

polarity.

3) Put the cover cap back on and screw it on.

Environmental information

Please note the RoHS directive 2011/65 / EU (RoHS-II) and BattG and

do not dispose the batteries in the household waste for the sake of

the environment.

44 Friedrich Leutert GmbH & Co. KG

Digital Pressure Indicator DPI - Bedienungsanleitung

7.5 Adjusting the contrast and the backlight of the

handheld device.

» M ai n m e n u « 1) Press the button for approx. 1 second to switch on the handheld

device. The main menu appears after the start screen. Use the but-

M e a s u r e e n gi n e }

Show data

tons or to switch between the lines.

» M ai n m e n u « 2) When the ‘Configuration’ line is marked with the } arrow, press

D el e t e d a t a the button .

C o nfi g u ra ti o n }

» C o nfi g m e n u « The display changes to the configuration menu.

S h o w d a t e / ti m e }

S e t d a t e / ti m e

» C o nfi g m e n u « 3) Scroll with the vertical arrow keys or , until ‘Contrast’ is

S e t d a t e / ti m e marked on the display with the }. Confirm with .

C o n t ra st }

B a c kli g h t

S e t c o n t ra st : 4) The display changes to the setting window ‘Set contrast’. Change

the set value with or and confirm with button .

} }

» C o nfi g m e n u « The configuration menu appears in the display, see step 3.

S e t d a t e / ti m e

C o n t ra st }

B a c kli g h t

» C o nfi g m e n u « 5) Switch with the or buttons or until ‘Backlight’ is marked

C o n t ra st

with an } arrow. Confirm with .

B a c kli g h t

}

S e t b a c kli g h t : 6) The display changes to the ‘Set backlight’ setting window. Change

the set value by or and confirm with button .

} }

» C o nfi g m e n u « The configuration menu appears in the display, see step 3.

S e t d a t e / ti m e

C o n t ra st }

B a c kli g h t

» M ai n m e n u « 7) You can now switch back to the main menu with or turn off the

handheld device.

M e a s u r e e n gi n e }

Show data

Friedrich Leutert GmbH & Co. KG 45

Digital Pressure Indicator DPI - Bedienungsanleitung

© Friedrich Leutert GmbH & Co. KG, Schillerstrasse 14,

21365 Adendorf / Germany, 2019

This document including all of its parts is protected by copyright. Any du-

plication or utilization outside of the copyright law is not permitted wi-

thout explicit permission from Friedrich Leutert GmbH & Co. KG and may

be subject to prosecution. This applies in particular to duplications of any

kind, translations and incorporation into electronic systems.

– Translation of the original edition, manuals in other languages on request –

Subject to change without notice

Issue date January 23, 2019

46 Friedrich Leutert GmbH & Co. KG

You might also like

- C LEUTERT DPI Help Software Manual eDocument68 pagesC LEUTERT DPI Help Software Manual epapaki2No ratings yet

- P-52RUE: PrinterDocument28 pagesP-52RUE: PrintermaujaNo ratings yet

- 02 - 2012 - Enus Drager Polytron 8100Document40 pages02 - 2012 - Enus Drager Polytron 8100Roberto de la CruzNo ratings yet

- Manual EDAN h100bDocument99 pagesManual EDAN h100blexor2010No ratings yet

- Brief Operating Instructions for Liquiline CM42 Two-Wire TransmitterDocument44 pagesBrief Operating Instructions for Liquiline CM42 Two-Wire TransmitterkurmakkNo ratings yet

- ATV212 BACnet Manual EN S1A53845 04Document47 pagesATV212 BACnet Manual EN S1A53845 04rahmannafi kurniawanNo ratings yet

- Sentron Automatic Transfer Controller ATC5300Document50 pagesSentron Automatic Transfer Controller ATC5300Leangel HernandezNo ratings yet

- 82-01.54.456077-2.1 C3A, C6A, C6A HD Video Colposcope User Manual-ESDocument118 pages82-01.54.456077-2.1 C3A, C6A, C6A HD Video Colposcope User Manual-ESEdwin Salazar OrtizNo ratings yet

- Fanuc RobotDocument32 pagesFanuc RobotJOHN RIEDELNo ratings yet

- Operating Manual - Bedienungsanleitung - Manuel D'emploi - : English Deutsch FrançaisDocument262 pagesOperating Manual - Bedienungsanleitung - Manuel D'emploi - : English Deutsch FrançaisNerakNo ratings yet

- Operating Instructions Smartec CLD18: Conductivity Measuring SystemDocument48 pagesOperating Instructions Smartec CLD18: Conductivity Measuring SystemGabriel PiticasNo ratings yet

- Technical Docu UM MSI-SR4B en 50124419Document27 pagesTechnical Docu UM MSI-SR4B en 50124419Amaresh DashNo ratings yet

- MAN L1V30415167B-06 en en-USDocument142 pagesMAN L1V30415167B-06 en en-USfernandoNo ratings yet

- Software Manual-Soxtherm Manager SX PCDocument44 pagesSoftware Manual-Soxtherm Manager SX PCAnonymous SiO8gwwRto100% (1)

- ReadMe STEP7 WinCC V15 enUS PDFDocument112 pagesReadMe STEP7 WinCC V15 enUS PDFsrajuNo ratings yet

- Rcma420 D00059 M XxenDocument48 pagesRcma420 D00059 M Xxen王磊(KissYourToes)No ratings yet

- Ba01421den 0115Document130 pagesBa01421den 0115OMiD QahqaieNo ratings yet

- Advanced PM2000B Patient Monitor USER MANUALDocument243 pagesAdvanced PM2000B Patient Monitor USER MANUALNur Adam Abd RahmanNo ratings yet

- Brief Operating Instructions Micropilot NMR81: Tank GaugingDocument40 pagesBrief Operating Instructions Micropilot NMR81: Tank Gaugingjohnf2328No ratings yet

- PAC 3120 Ja 3220Document160 pagesPAC 3120 Ja 3220YAR SOLUTIONSNo ratings yet

- Sonotrax BasicDocument44 pagesSonotrax BasicDaniel F. Guerrero P.No ratings yet

- Detection Operating-Manual BioPhotometer-D30Document94 pagesDetection Operating-Manual BioPhotometer-D30KoxoNo ratings yet

- P3G32 Quick Start 10 23 AnsiDocument42 pagesP3G32 Quick Start 10 23 AnsiVladimir TićakNo ratings yet

- PMP51B Analog ManualDocument60 pagesPMP51B Analog Manualchatheo2025No ratings yet

- Lec-Wm: Monitor Software For Motor Controller (LECP/A)Document50 pagesLec-Wm: Monitor Software For Motor Controller (LECP/A)Cesar ChaconNo ratings yet

- P3G32 Qiuck Start 09 23 IecDocument42 pagesP3G32 Qiuck Start 09 23 IecVladimir TićakNo ratings yet

- Equotip 540 - Operating - Instruction PDFDocument49 pagesEquotip 540 - Operating - Instruction PDFgigi gigiNo ratings yet

- Ba01992den 0221Document198 pagesBa01992den 0221Nurshamira HussainNo ratings yet

- G120C List Manual 0917 en-USDocument756 pagesG120C List Manual 0917 en-USTainan ReichertNo ratings yet

- Shinova DM8D Defibrillator - User ManualDocument63 pagesShinova DM8D Defibrillator - User Manualhüseyin vururNo ratings yet

- Sentron Pac3100 Manual en 03 en-USDocument172 pagesSentron Pac3100 Manual en 03 en-USthangna87No ratings yet

- Promass F100. Profibus DP PDFDocument152 pagesPromass F100. Profibus DP PDFChristian Castillero100% (1)

- Troubleshooting Guide System: Mobile GeneratorDocument200 pagesTroubleshooting Guide System: Mobile Generatordavid75% (4)

- XPR8-260 840 01 04 02Document198 pagesXPR8-260 840 01 04 02Tsegay MeresaNo ratings yet

- Scada Pack 4000Document111 pagesScada Pack 4000Juan LuisNo ratings yet

- Menami Inspector Cond 00Document62 pagesMenami Inspector Cond 00李奇No ratings yet

- Hydrajaws BT ManualDocument15 pagesHydrajaws BT ManualEliana GuzmanNo ratings yet

- Promag D 400 DP (OI)Document168 pagesPromag D 400 DP (OI)Giorgio KappasNo ratings yet

- Electrocardiógrado EDAN SE-301Document66 pagesElectrocardiógrado EDAN SE-301Brevas Cucho0% (1)

- Z10000 Natural Gas Odorization System User's Manual: Sentry Equipment CorpDocument50 pagesZ10000 Natural Gas Odorization System User's Manual: Sentry Equipment CorpPham LanphuongNo ratings yet

- Deltabar S: Brief Operating InstructionsDocument32 pagesDeltabar S: Brief Operating InstructionsMorteza alizadehNo ratings yet

- Ka01024pen 1514Document44 pagesKa01024pen 1514Marcelo GusmanNo ratings yet

- br102 PlusDocument76 pagesbr102 PlusAhmet Hayri KınacılarNo ratings yet

- 2-Sick-Dusthunter Sp100exDocument92 pages2-Sick-Dusthunter Sp100exgudapati9No ratings yet

- Setup Guide: CXDI Control Software NEDocument132 pagesSetup Guide: CXDI Control Software NEAl AlNo ratings yet

- Manual de Servicio At1 2G PDFDocument52 pagesManual de Servicio At1 2G PDFValentina Giraldo BetancourtNo ratings yet

- Micropilot FMR10 ManDocument60 pagesMicropilot FMR10 ManGustavo MazaNo ratings yet

- Simatic Energy Manager Basic Operating Manual en-US en-USDocument311 pagesSimatic Energy Manager Basic Operating Manual en-US en-USShailesh LuteNo ratings yet

- ASIMON V3 en 2008-09 Software Manual 333155802DS02Document180 pagesASIMON V3 en 2008-09 Software Manual 333155802DS02Passenger MedeamNo ratings yet

- Digital Electronic Thermometer: IndexDocument8 pagesDigital Electronic Thermometer: IndexMohamedNo ratings yet

- Dcu002 Pt0250ben - GDocument22 pagesDcu002 Pt0250ben - GHao SuenNo ratings yet

- Operating Instructions CM14: Transmitter, PH and ORPDocument44 pagesOperating Instructions CM14: Transmitter, PH and ORPHery FernandoNo ratings yet

- Alup Allegroi AIR CONTROL 3 PDFDocument48 pagesAlup Allegroi AIR CONTROL 3 PDFsebastian100% (6)

- Downloaded From Manuals Search EngineDocument59 pagesDownloaded From Manuals Search EngineKittiwat WongsuwanNo ratings yet

- 828D PLC FCT Man 0721 en-USDocument356 pages828D PLC FCT Man 0721 en-USHernan MaynaNo ratings yet

- Picomag ManualDocument60 pagesPicomag ManualAllan BarbosaNo ratings yet

- Deep Oscillation PersonalDocument30 pagesDeep Oscillation Personalameth alexNo ratings yet

- Embedded Systems and Software ValidationFrom EverandEmbedded Systems and Software ValidationRating: 4 out of 5 stars4/5 (1)

- Boiler Pot On Service After MaintenanceDocument12 pagesBoiler Pot On Service After MaintenanceNatane AlvesNo ratings yet

- Ethics, Tools and The EngineerDocument321 pagesEthics, Tools and The EngineerNatane AlvesNo ratings yet

- A5 CentriClean App Manual V1.4Document14 pagesA5 CentriClean App Manual V1.4Natane AlvesNo ratings yet

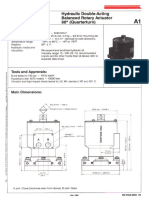

- BRC 012 A1 051 4252 Data SheetDocument2 pagesBRC 012 A1 051 4252 Data SheetNatane AlvesNo ratings yet

- BRC Assembly Disassembly OLD 1Document10 pagesBRC Assembly Disassembly OLD 1Natane AlvesNo ratings yet

- IOW Group A5 MP400 Installation and Service Manual 04.2019 V1.6Document40 pagesIOW Group A5 MP400 Installation and Service Manual 04.2019 V1.6Natane Alves100% (1)

- WSS Water Treatment Technical ManualDocument87 pagesWSS Water Treatment Technical ManualNatane AlvesNo ratings yet

- Manual Compressor PDFDocument233 pagesManual Compressor PDFjbastos12049079100% (2)

- CES is one of the most used tools in the industry to evaluate crew knowledgeDocument2 pagesCES is one of the most used tools in the industry to evaluate crew knowledgeAJ CrucilloNo ratings yet

- Merchant Shipping (Maritime Labour Convention) Regulations 2013Document117 pagesMerchant Shipping (Maritime Labour Convention) Regulations 2013Andreas ChocoboNo ratings yet

- Lubrication in Marine Diesel Engines-MoaraDocument2 pagesLubrication in Marine Diesel Engines-MoaraNatane AlvesNo ratings yet

- Questões EntrevistaDocument5 pagesQuestões EntrevistaNatane AlvesNo ratings yet

- MSI Smart Tool ReleaseNoteDocument2 pagesMSI Smart Tool ReleaseNotecarlos leins riveraNo ratings yet

- Windows Dna ReportDocument36 pagesWindows Dna Reportkunal24051992No ratings yet

- Flash 530 Installation GuideDocument8 pagesFlash 530 Installation Guidekamaleon doradoNo ratings yet

- MP Report v2Document10 pagesMP Report v2Kaushik VenkatNo ratings yet

- IIS Configuration Guide For Web Thin Clients and Secure ViewerDocument10 pagesIIS Configuration Guide For Web Thin Clients and Secure ViewerjoseNo ratings yet

- Auslogics Boostspeed 11.4.0 Crack + Key 2020 (Premium)Document8 pagesAuslogics Boostspeed 11.4.0 Crack + Key 2020 (Premium)aubryNo ratings yet

- Relativity - Upgrade Guide - 9.6 PDFDocument199 pagesRelativity - Upgrade Guide - 9.6 PDFJames Stallins Jr.No ratings yet

- EST EST3 v3.0 Programming Manual PDFDocument176 pagesEST EST3 v3.0 Programming Manual PDFHernan Rea50% (2)

- Windows7 Installation Guide EditDocument50 pagesWindows7 Installation Guide EditCherinet dubaleNo ratings yet

- How To Download With Faster Speed On EmuleDocument2 pagesHow To Download With Faster Speed On EmuleMax PlanckNo ratings yet

- InfoPLC Net Curso NTs NT Win v4 6Document112 pagesInfoPLC Net Curso NTs NT Win v4 6grover2010100% (1)

- Veeam Backup 11 0 Agent Management GuideDocument390 pagesVeeam Backup 11 0 Agent Management GuideBashar ChahedehNo ratings yet

- System Administrator ResumeDocument3 pagesSystem Administrator ResumeGoutam Shreedhar0% (1)

- Dxdiag/mineDocument40 pagesDxdiag/mineFederico CartaNo ratings yet

- Atmdesk X: User'S ManualDocument95 pagesAtmdesk X: User'S ManualMohammed Murtala Mohammed0% (1)

- 142-20144-100 Wireless - Bridge - Setup - AppnoteDocument26 pages142-20144-100 Wireless - Bridge - Setup - AppnotejohnNo ratings yet

- Loop-O9500-TSPA Test Station: DescriptionDocument6 pagesLoop-O9500-TSPA Test Station: DescriptionjorgeNo ratings yet

- ICT 2 Module 2 Lesson 8Document4 pagesICT 2 Module 2 Lesson 8Inesha MontiverosNo ratings yet

- Microsoft Office 2016 AIO 32 & 64Document9 pagesMicrosoft Office 2016 AIO 32 & 64abwinson100% (1)

- ReadmeDocument4 pagesReadmeSerghei PlamadealaNo ratings yet

- En Composer 8.1.4 Deployment PreinstallationDocument17 pagesEn Composer 8.1.4 Deployment PreinstallationRajneesh PatelNo ratings yet

- APIDocument1,559 pagesAPIjuand_121No ratings yet

- Updating Microsoft Dynamics SL To Microsoft Dynamics SL 2018 Cumulative Update 2Document27 pagesUpdating Microsoft Dynamics SL To Microsoft Dynamics SL 2018 Cumulative Update 2Alex ChimalNo ratings yet

- PRONETA Documentation V3 6 enDocument91 pagesPRONETA Documentation V3 6 engerrardmadrigalNo ratings yet

- BODAS Service ConnectionsDocument10 pagesBODAS Service ConnectionsPankaj RamoleNo ratings yet

- Iphone Configuration UtilityDocument20 pagesIphone Configuration UtilityDon MathesNo ratings yet

- Online Examination DocumentationDocument36 pagesOnline Examination DocumentationTimmaraju Radha Krishna Murthy75% (4)

- eS5008LP SMC EN 0000 PDFDocument364 pageseS5008LP SMC EN 0000 PDFAleks MazurNo ratings yet

- ISPI Admin HandbookDocument158 pagesISPI Admin Handbookanda_sn-1No ratings yet