Professional Documents

Culture Documents

Adiabatic Heating Effects On Bourdon Tube Pressure Gauges Test Report

Adiabatic Heating Effects On Bourdon Tube Pressure Gauges Test Report

Uploaded by

SSSOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adiabatic Heating Effects On Bourdon Tube Pressure Gauges Test Report

Adiabatic Heating Effects On Bourdon Tube Pressure Gauges Test Report

Uploaded by

SSSCopyright:

Available Formats

Protecting our customers’ people, processes and profits.

Adiabatic Heating Effect on Bourdon Tube Gauges Encountered During Calibration

There are several methods and tools, which can be used to verify calibration of Bourdon Tube type pressure

gauges. There are pros and cons to each which must be considered when selecting a calibration verification

process. One of the most important considerations is the pressure media used to apply pressure to the gauge

under test. When using a gas such as nitrogen or shop air, the adiabatic heating effect can cause mechanical

gauges to appear to be out of tolerance.

How does adiabatic heating impact calibration processes?

In a closed system with gas as the pressure media, the temperature of the gas affects the volume of the gas,

which has an impact on the pressure. When pressure increases quickly, the temperature of the gas will rise, and

this higher temperature makes the gas expand, thus having a bigger volume and higher pressure. When the

temperature starts to cool down, the volume of the gas becomes smaller, and this will cause the pressure to

drop. This pressure drop may seem like a leak in the system, but it is caused by the adiabatic effect due to

change in the gas temperature. The faster the pressure changes, the bigger is the effect is. The pressure change

caused by this effect will gradually get smaller as the temperature stabilizes. So, if you change the pressure

quickly, make sure you let it stabilize for a while before judging that there is a leak in the system.

What is the impact of adiabatic heating on a bourdon tube?

In simple terms, when gas is rapidly compressed, it gets warmer. When it decompresses, it becomes cooler. In a

bourdon tube gauge, the heated compressed gas contained within the tube assembly transfers some of that

heat energy to the tube. This transference can cause the tube to expand and change the tube’s modulus of

elasticity. The heated bourdon tube drives the gauge movement and can make it appear that the gauge is

displaying pressure greater than what is being applied and appear to be out of tolerance.

A series of tests were run to quantify the adiabatic effect on two 0-3000 psi analog test gauges with ±0.1% of

span accuracy. The test report demonstrates the effect that adiabatic heating has on these particular gauges,

and the findings apply to any range gauge when using gas as the pressure media.

How to diminish the impact of adiabatic heating on calibration procedures?

There are a few different mitigation actions:

1. Using a pressure standard that uses liquid pressure media such as water or oil will eliminate this effect.

2. If gas pressure media is required, then controlling the rate by which the pressure increases and allowing

time between readings to normalize the temperature will also yield favorable results.

3. Heat can be dissipated more quickly by increasing airflow around the tube assembly with a small fan.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-1

Protecting our customers’ people, processes and profits.

Adiabatic Heating Effects on Heise Dial Gauge

Test Report by: Lucian Guadagnoli, Jeremy Payne

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-1

Protecting our customers’ people, processes and profits.

Table of Contents

1. Test Information .................................................................................................................................. 3

2. Product Tested..................................................................................................................................... 3

3. Scope/Purpose..................................................................................................................................... 3

4. Test Equipment .................................................................................................................................... 3

5. Test Procedure(s)................................................................................................................................. 4

Adiabatic Heating Test ............................................................................................................................ 4

Initial Setup.........................................................................................................................................................4

Procedure ...........................................................................................................................................................5

6. Results.................................................................................................................................................. 6

Adiabatic Heating Test ............................................................................................................................ 6

Run 1: No Cycle, Cover On ..................................................................................................................................7

Run 2: Three Cycles, Cover On ...........................................................................................................................9

Run 3: Three Cycles, Cover Off ........................................................................................................................ 11

Run 4: Three Cycles, Cover Off, Fan Cooled .................................................................................................... 13

Additional Testing ................................................................................................................................. 15

Fan Cooled Gauge vs. Cover Installed Gauge .................................................................................................. 15

Water Trials ..................................................................................................................................................... 16

7. Analysis .............................................................................................................................................. 18

Observed Phenomenon ........................................................................................................................ 18

Back Cover Configurations .................................................................................................................... 18

Settling Time.......................................................................................................................................... 18

Indicator Movement ............................................................................................................................. 19

Water-Filled Gauges .............................................................................................................................. 20

Gauge 2 Tip Thermocouple ................................................................................................................... 20

8. Conclusions ........................................................................................................................................ 20

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-2

Protecting our customers’ people, processes and profits.

1. Test Information

Date Requested: 4/10/2019

Requested by: Steve Andersen

Test Performed by: Lucian Guadagnoli

2. Product Tested

Table 1: Sample List

Sample # Product Series Product Code Serial No.

Gauge 1 Heise Test CCAUGV3000BCH-#XA6 CC-145321

Gauge 2 Gauge CCAUGV3000BDP CC-145510

3. Scope/Purpose

The purpose of this test is to determine the effects of heat generated by pressurizing Heise gauges on nitrogen

gas.

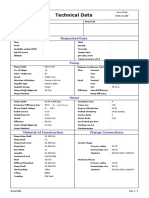

4. Test Equipment

Table 2: Equipment Used in this Report

Lab I.D. Model # Description Manufacturer

1294 34970A Multiplexer Keysight

1297 BTRC Temperature Chamber TPS

1445 CM2-17G Pace 6000 Module (-15/+2000 PSIG) GE Druck

N/A SA1-K K-Type Thermocouple Omega

1056 ST-2H Digital Indicator Ashcroft

0016 HQS-2 Pressure Sensor (0-3000 PSIG, 0.025%) Ashcroft

9517 938 Hydraulic Pump (Water) Additel

0992 681 Digital Pressure Gauge Additel

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-3

Protecting our customers’ people, processes and profits.

5. Test Procedure(s)

Adiabatic Heating Test

Reference: Custom Test

Figure 1: The adiabatic heating test setup with (from left to right) the pressure controller, the pressure manifold holding two gauges,

and the multiplexer resting on a DC power supply.

Initial Setup

The pressure manifold shall contain enough ports to allow connection to a pressure controller, a

pressure transducer, and at least one port for test samples (two were used in this test).

Attach at least four K-Type thermocouples to each bourdon tube in the configuration shown in Figure 2.

Figure 2: The thermocouple configuration on a test gauge. The four location labels shown in this image are used throughout this

report.

The data acquisition system (DAQ) consists of a model 34970A multiplexer (abbreviated to ‘MUX’)

which measures the following instruments:

o An RTD thermocouple to track the internal temperature of the multiplexer.

o The K-type thermocouples, which are attached to the test gauge(s).

o The reference pressure transducer (from the pressure manifold) and the means to energize it.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-4

Protecting our customers’ people, processes and profits.

Procedure

1. Prepare the test system in accordance with the points outlined in the Initial Setup section.

2. Fixture the test gauge to the pressure manifold.

3. Zero the test gauge.

4. Review Table 3 to determine the condition of the gauge’s back-cover.

5. Configure multiplexer profile to scan and record each thermocouple and transducer output every

second for 20 minutes.

6. Run the multiplexer profile.

7. Pressurize the gauge in accordance with the ‘Pressure Profile’ in Table 3.

a. No Cycle Profile: Pressurize the gauge to span at the maximum slew rate.

b. Triple Cycle Profile: Pressurize the gauge to span at the maximum slew rate, then immediately

depressurize to zero at the same rate. Repeat this cycle two more times, and then pressurize to

span and hold.

8. Note the initial indication on each gauge, along with the indication drift as time elapses. Remain at the

maximum pressure reached in step 7 until the multiplexer profile ends.

9. When the multiplexer profile ends, record the final location of the indicators, and depressurize the

manifold to zero at the maximum slew rate.

10. The test run is complete.

Table 3: Adiabatic heating test run configurations

Test Run Pressure Profile Condition of Gauge

1 No Cycle Back-Cover Installed

2 Triple Cycle Back-Cover Installed

3 Triple Cycle Back-Cover Removed

4 Triple Cycle Back-Cover Removed, Fan-Cooled

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-5

Protecting our customers’ people, processes and profits.

6. Results

Adiabatic Heating Test

The charts presented in this section track the temperature of the bourdon tube(s) over a 20-minute scan

duration. The reference pressure is presented to show how the temperature drifts after constant pressure is

achieved. For all adiabatic heating charts in this section, the maximum pressure applied was 1950 PSI.

All charts presented in this section show outputs that are initially normalized against ambient

temperature. This means that each thermocouple’s output (before pressurizing) is compared to ambient

temperature and offset so the readings now begin at ambient temperature. For example: if a thermocouple

initially reports a temperature of 20°C, and ambient temperature is 19°C, then all readings for that

thermocouple are shifted by -1°C. By normalizing temperature to ambient, the temperature drift can be

compared between each thermocouple without considering different initial temperatures (see Figure 3).

Figure 3: A comparison of the initial thermocouple temperature readings before normalizing (left) and after normalizing (right) against

ambient temperature (the purple horizontal line).

Figure 4: The thermocouple locations and labels, shown again for convenience.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-6

Protecting our customers’ people, processes and profits.

Run 1: No Cycle, Cover On

Figure 5: Gauge 1, Run 1

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-7

Protecting our customers’ people, processes and profits.

Figure 6: Gauge 2, Run 1

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-8

Protecting our customers’ people, processes and profits.

Run 2: Three Cycles, Cover On

Figure 7: Gauge 1, Run 2

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-9

Protecting our customers’ people, processes and profits.

Figure 8: Gauge 2, Run 2

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-10

Protecting our customers’ people, processes and profits.

Run 3: Three Cycles, Cover Off

Figure 9: Gauge 1, Run 3

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-11

Protecting our customers’ people, processes and profits.

Figure 10: Gauge 2, Run 3

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-12

Protecting our customers’ people, processes and profits.

Run 4: Three Cycles, Cover Off, Fan Cooled

Figure 11: Gauge 1, Run 4

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-13

Protecting our customers’ people, processes and profits.

Figure 12: Gauge 2, Run 4

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-14

Protecting our customers’ people, processes and profits.

Additional Testing

Fan Cooled Gauge vs. Cover Installed Gauge

In this trial, one gauge had its back-cover installed, while the other gauge was left open and fan cooled. Both gauges were exercised

three times and their thermal responses were recorded over 30 minutes. The maximum temperature observed was 36.603°C at the tip

thermocouple of the Cover-On gauge (based off raw, non-normalized, data. Figure 13 ). This was an increase of about 16.174°C from the

average local temperature for the duration of the test.

Figure 13: A chart comparing the thermal response of a fan cooled gauge to a cover-installed gauge. This chart shows the response at the tip of the gauge

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-15

Protecting our customers’ people, processes and profits.

Water Trials

The purpose of the water trials are to demonstrate how a fluid-filled gauge does not experience the adiabatic heating effect seen on a gas-

filled gauge. The test fluid was distilled water and a hand pump was used to bring the pressure up to span (3000 PSI).

In the No-Cycle trial (Figure 14), the maximum observed temperature across all thermocouples was 19.806 °C, which was 0.669 °C above the

average local temperature at the time of testing. As for the Three-Cycle trial (Figure 15), the maximum temperature was 18.899 °C, about

0.729 °C over the average local temperature at the time of testing.

Figure 14: This chart shows the temperature change when pressurizing two water-filled gauges to span (3000 PSI). This chart shows the response at the top of the two gauge

tubes.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-16

Protecting our customers’ people, processes and profits.

Figure 15: This chart shows the temperature change when first exercising two water-filled gauges three times, and then pressurizing to span (3000 PSI). This chart shows the

response at the top of the two gauge tubes.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the intended recipient(s). Any review, use, distribution, or

disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-17

Protecting our customers’ people, processes and profits.

7. Analysis

Observed Phenomenon

The purpose of this test was to understand the thermal effects associated with using a gas on Heise test

gauges. The underlying principle that governs this test is adiabatic heating. For reference: an adiabatic process

is one in which heat does not enter or leave the system1. This adiabatic heating can distort the indicated reading

on the test gauge.

When a gas-filled gauge is rapidly pressurized, the pressure controller compresses the gas resting in the tube

like a piston compressing a cylinder. The work done on the resting gas not only pressurizes the tube, but also

increases the internal energy of the gas (based on the first law of thermodynamics)2. This internal energy

manifests itself as heat, and because the pressurization of the tube happens so fast, the heat loss through the

walls of the bourdon tube is dwarfed by the increase in internal energy. This allows us to assume an adiabatic

process while the tube is being pressurized.

An increase in the temperature of the tube leads to two relevant effects, thermal expansion and a change in

the modulus of elasticity. When an isotropic metal heats up, it tends to enlarge linearly at a rate defined by its

thermal coefficient of expansion. Its modulus of elasticity, or stiffness, lowers as well. A metal with a lower

modulus of elasticity tends to stretch further under mechanical forces like pressure. Most of the heating

occurred towards the tip of the tube, which is where the indicator linkages connect. Thus, any deformation by

the tube near the tip would translate to an offset in the indication. Specially, the indicator should report higher

readings than actual if the tube expands outwards.

Back Cover Configurations

As seen in the Results section of this report, the temperature response varies depending on the

configuration of the back cover. This is because of the way the heat dissipates from the tube to the

environment. If the back cover is on, then the gas inside the gauge (surrounding the tube) is trapped. This still

gas will initially take heat from the tube via conduction, but cannot easily transfer this heat out of the gauge. As

this trapped gas heats up, it becomes less efficient at removing heat from the tube. Even with the cover off (as

seen in Figure 9 and Figure 10), the heat dissipation rate does not improve much. When a fan is added,

however, both the maximum temperature and settling time (to room temperature) are significantly reduced

(Figure 11 and Figure 12). This is because the fan carries the hot gas away from the tube and room temperature

gas towards the tube.

Settling Time

The Fan Cooled Gauge vs. Cover Installed Gauge trial (in the ‘Additional Testing’ section) was used in

determining the time it takes the gauge to return to local temperature. Table 4 shows these results. The

settling time starts when steady maximum pressure was reached (about 01:17 into the test) and ends when the

thermocouple temperature fell within 5% and 1% of the local temperature. Obviously, these times are not

universal, since factors like maximum pressure, pressurization rate, local temperature and even fluid medium

will affect the exact settling time. Rather, Table 4 seeks to illustrate that using a fan to cool the gauges is

recommended to reduce the wait time between indicator readings.

1

("Adiabatic Heating." World of Earth Science. . Encyclopedia.com. 4 Jun. 2019 <www.encyclopedia.com>)

2

Adiabatic process. (2019, April 4). Retrieved from Wikipedia: www.en.wikipedia.org/wiki/Adiabatic_process

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-18

Protecting our customers’ people, processes and profits.

Table 4: Settling time of a gauge in different configurations. Both gauges were pressurized to 1950 PSI.

Settling Time (mm:ss)

Difference from Local Temp

Cover On Fan Cooled

1% 0.2°C 27:14 03:51

5% 1.0°C 16:09 02:41

Indicator Movement

One additional analysis performed on the Fan vs. Cover trial was a measurement of the total indicator

movement as the test gauge returned to room temperature. Table 5 lists the indicator readings from the

moment the system reached a steady pressure of 1950 PSI to after 30 minutes, when the gauges settle. The

covered gauge reported a larger pressure reading than the fan-cooled gauge. This was expected, as the covered

gauge experienced a larger maximum temperature. After 30 minutes of cooling, both gauges were within three

psi of target, but the covered gauge’s indicator travelled twice as far as the fan-cooled counterpart. Note that

although both gauges settled on readings that were in spec, the initial indications on both gauges were more

than 0.1% off from true pressure. This underpins the significance of adiabatic heating on accuracy.

Table 5: A table mapping indicator movement due to adiabatic heating.

Observed Pressure (PSI)

Error Error

Readings Cover On Fan Cool

(%F.S.) (%F.S.)

Initial 1959 0.30% 1956 0.20%

After 5 min 1952 0.07% 1952 0.07%

After 10 min 1950 0.00% 1951 0.03%

After 30 min 1947 -0.10% 1950 0.00%

Total Movement 12 - 6 -

Figure 16: The indication is offset from 1950 PSI after pressurizing to span.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-19

Protecting our customers’ people, processes and profits.

Water-Filled Gauges

At Ashcroft, the test gauges are calibrated on water. Liquids feature larger heat capacities (i.e. it takes

more energy to raise its temperature) than gas. Additionally, liquids are better conductors of heat, and can

dissipate the heat to the tube much faster than gas. These properties become apparent in Figure 14 and Figure

15. In the three-cycle water trial, the highest temperature drift recorded was only 0.729°C, a stark contrast to

the 16.174°C drift observed in the three-cycle gas trial (Figure 13) with the same back-cover conditions.

Additionally, the water-filled gauges were pressurized to full span (3000 PSI), whereas the gas trial could only

reach 66% of that. Therefore, one of the best methods to reduce the adiabatic heating effect is to switch to a

liquid medium.

Gauge 2 Tip Thermocouple

In the Results section of this report, the tip thermocouple for gauge 2 reported surprisingly muted

temperatures in all four trials. Observing the response of the gauge 1 tip thermocouple, and feeling the tip of

the tube during a test suggested that the gauge 2 thermocouple was not behaving properly. To remedy this, the

thermocouple was reattached to the tube, the electrical connections were checked, and a second thermocouple

was placed adjacent to the tip (as seen in Figure 13). As expected, the thermocouple began to function correctly

in the Fan Cooled Gauge vs. Cover Installed Gauge test. Therefore, the tip response should be disregarded in

Figure 6, Figure 8, Figure 10, and Figure 12.

8. Conclusions

Based on the results obtained in this test:

Rapidly pressurizing the test gauges using gas results in an increase in the temperature of the Bourdon

tube.

The increased tube temperature causes the gauge to indicate a higher pressure than actual.

The adiabatic heating effect is significant enough such that the indication error, immediately after

pressurizing, can exceed the accuracy rating of the gauge.

Exercising (pressurizing, then depressurizing in rapid succession) the gauges before holding at a pressure

generates more heat than pressurizing directly.

Removing the back cover does not appear to cool the gauges much faster than if left on. Fan cooling the

gauges with the back cover removed, however, cools the gauges significantly faster.

o Fan cooling also reduces the maximum temperature reached during pressurization.

Using distilled water almost eliminates the adiabatic heating effect.

250 East Main Street, Stratford, CT 06614 T 800-328-8285 E info@ashcroft.com W www.ashcroft.com

This report contains confidential information and is the property of Ashcroft Inc. The information is for the sole use of the

intended recipient(s). Any review, use, distribution, or disclosure by others is strictly prohibited.

ID: Adiabatic Heating Effects on Bourdon Tube Pressure gauge during the calibration process

8/1/2019

P-20

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Web Yielding, Web Crippling, Web BucklingDocument35 pagesWeb Yielding, Web Crippling, Web BucklingKristin Brienne Leander-Renomeron100% (3)

- Batch DistillationDocument20 pagesBatch Distillationcgjp120391No ratings yet

- LabyrinthDocument9 pagesLabyrinthmohsin931No ratings yet

- Dosatron - Comparativo Sistema de DosagemDocument37 pagesDosatron - Comparativo Sistema de Dosagemmarmaduke32No ratings yet

- 0.25 Marks X 40 MCQ 10 MarksDocument5 pages0.25 Marks X 40 MCQ 10 MarksNilNo ratings yet

- Slide Freeze DryingDocument19 pagesSlide Freeze DryingFarah Mustapha100% (1)

- Data Sheet 4.0HP MVN-4 16TR TCV 1 PUMPSETDocument3 pagesData Sheet 4.0HP MVN-4 16TR TCV 1 PUMPSETrifanderiNo ratings yet

- Experimental and Numerical Study of A Mechanically Ventilated Enclosure With Thermal EffectsDocument8 pagesExperimental and Numerical Study of A Mechanically Ventilated Enclosure With Thermal EffectsIbnu SufajarNo ratings yet

- Physics Project Form 5: Name:Meena Rubini Thoppasamy Class:5 SN 1Document13 pagesPhysics Project Form 5: Name:Meena Rubini Thoppasamy Class:5 SN 1Meena RubiniNo ratings yet

- Chapter 2 Combustion Related Gaseous Fuel PropertiesDocument41 pagesChapter 2 Combustion Related Gaseous Fuel PropertiesHarshini BaskaranNo ratings yet

- Fluent-Intro 14.5 WS04 AirfoilDocument37 pagesFluent-Intro 14.5 WS04 AirfoilalfredozegarraNo ratings yet

- 8-Design of Compression Members PDFDocument36 pages8-Design of Compression Members PDFNina Ysabelle RamosNo ratings yet

- 09 SKKK1113 201516 - 2 Chap 6Document9 pages09 SKKK1113 201516 - 2 Chap 6Jordan MadaraNo ratings yet

- CTB Irc 37 2018Document14 pagesCTB Irc 37 2018Navarun VashisthNo ratings yet

- Self-Learning Home Task (SLHT) : Aasgpnwcw&Q Picture+Of+Condensation&Oq Picture+Of+Condensation&Gs - LCPDocument10 pagesSelf-Learning Home Task (SLHT) : Aasgpnwcw&Q Picture+Of+Condensation&Oq Picture+Of+Condensation&Gs - LCPJim Alesther Lapina100% (1)

- PVA Grades and SpecificationsDocument2 pagesPVA Grades and Specificationspasalacqua85No ratings yet

- Ch-11 (HMT)Document44 pagesCh-11 (HMT)Fahad AbdullahNo ratings yet

- Presentation On StructureDocument32 pagesPresentation On StructureLamiNo ratings yet

- Brazed Plate Heat ExchangerDocument2 pagesBrazed Plate Heat ExchangerAndone GigiNo ratings yet

- Distillation-Assignemnt 2Document14 pagesDistillation-Assignemnt 2Sohail ZafarNo ratings yet

- Odometer Reading (Mi)Document4 pagesOdometer Reading (Mi)Terra DrakeNo ratings yet

- Question Bank: 07 Ce 6324: Design of Prestressed Concrete StructuresDocument8 pagesQuestion Bank: 07 Ce 6324: Design of Prestressed Concrete StructuresIyrin John100% (1)

- Asme PTC-10Document191 pagesAsme PTC-10MarcioNo ratings yet

- Costa BulbDocument10 pagesCosta BulbVictor MartinsNo ratings yet

- Design Check CofferdamDocument3 pagesDesign Check Cofferdamzms msswiNo ratings yet

- Isolated FootingDocument5 pagesIsolated FootingannNo ratings yet

- Total Dynamic HeadDocument2 pagesTotal Dynamic Headrajbhar_sNo ratings yet

- Yarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Document8 pagesYarmouk University Civil Engineering Department Fluid Mechanics and Hydraulic Laboratory CE 354Mohammed MigdadyNo ratings yet

- Fatigue & Creep in Engineering Fatigue & Creep in Engineering Materials Materials (Chapter 8) (Chapter 8)Document27 pagesFatigue & Creep in Engineering Fatigue & Creep in Engineering Materials Materials (Chapter 8) (Chapter 8)simma suryanarayanaNo ratings yet

- Taller 1 - Veronica OñateDocument11 pagesTaller 1 - Veronica OñateVeronica OñateNo ratings yet