Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsReception Materials

Reception Materials

Uploaded by

Vijayakumar Karunanidhipkjjjj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Confined Space PTWDocument2 pagesConfined Space PTWVijayakumar KarunanidhiNo ratings yet

- LETTER IDocument10 pagesLETTER IVijayakumar KarunanidhiNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitVijayakumar KarunanidhiNo ratings yet

- Hot Work PTWDocument2 pagesHot Work PTWVijayakumar KarunanidhiNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Laminated MDF Shelves For PoliceDocument4 pagesLaminated MDF Shelves For PoliceVijayakumar KarunanidhiNo ratings yet

- 135749-Smoking LoungeDocument4 pages135749-Smoking LoungeVijayakumar KarunanidhiNo ratings yet

- Hero - Mep ContatinmentDocument10 pagesHero - Mep ContatinmentVijayakumar KarunanidhiNo ratings yet

- Change of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownDocument1 pageChange of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownVijayakumar KarunanidhiNo ratings yet

- Telephone Booth Terminal2Document5 pagesTelephone Booth Terminal2Vijayakumar KarunanidhiNo ratings yet

- Technical Submital Form - Du PontDocument1 pageTechnical Submital Form - Du PontVijayakumar KarunanidhiNo ratings yet

Reception Materials

Reception Materials

Uploaded by

Vijayakumar Karunanidhi0 ratings0% found this document useful (0 votes)

11 views14 pagespkjjjj

Original Title

68984 - Reception materials

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpkjjjj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views14 pagesReception Materials

Reception Materials

Uploaded by

Vijayakumar Karunanidhipkjjjj

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

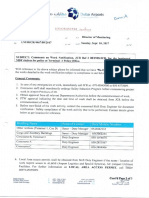

Dubai Airports inva

i Airpo oxen

SSE?

Engineering Services Division ‘ALUMINIUM & GLASS CO. L.L.C.

Project No: 68984

Project name: Detention center Modification

TECHNICAL SUBMITTAL

Date: 03/04/2016

Contactor | Locator] Disciptine | Submital | Revision | Spec. | Spec. | sub,

Cove Number section | clase | contactor

[yeamece METHOD STATEMENT [7] TECHNICAL DATA

TESTING WARRANTY OTHER

MANUFACTURER: DveontT a

DESCRIPTION: Dugent Koeln “Top

COMMENTS:

o_o je tna

I, Ene ay proces

DATE «03/04/2016 \ o la (=) Revise and resubmit, work may proceed subject to

wea * incorporation of changes indicated.

siGneo:_¢: oe | 5 I eve ations win toe

(4 Rev ntraind wa mayprsres

SONTRACTOR CERTIFICATION | IMPORTANT : Permission to proceed does not constute

ptance or approval of design detals, calculations,

st method of mateials developed or selected by

jer and does nat relieve supplier fom. ful

‘with contractual obigation.

WE CERTIFY THAT THE SUBMITTED ITEM:

Complies with the Specifications referred to above

[Is an alternative for the specified item and complies DCA ENGINEERING SERVICES

with the intent of the Specification

| soe QP owe 3.4. ale

Form: OCA(ES)-TOU-02 (Rev. 0)

corian

my

DUPONT™ CORIAN® PRODUCT OVERVIEW

DuPone™ Corian* Solid Surface

DuPont Building Innovations

Chestnut Run Plaza 735/2175-1

974 Centre Road

PO Box 2915

‘Wilmington, DE 19805

“Toll free 1-800-4-CORIAN (1-800-426-7426)

crim na lupout.com

Basic use

DuPont™ Corian* solid surface is an advanced composite

product used as an architectural and design material in a

variety of residential and commercial applications, Corian*

solid surface offers design versatility, Functionality and,

durability. Supplied in sheets and shapes, i¢ can be fabricated

with conventional woodworking tools into virally any

design. Ici the original solid surface macerial made only by

DuPont. Ic is widely accepted as a material for countertops,

vanity tops, tub/shower walls, kitchen sinks, vanity basins

and laboratory bench cops in numerous markets induding

lodging, healthcare, banks, boutiques, restaurants

Composition

DuPone™ Corian* solid surface is a solid, nonporous,

homogeneous surfacing material, composed of ='/s acrylic

resin (also known as polymethyl methacrylate or PMMA),

and = natural minerals. These minerals ate composed of

aluminum trihydrate (ATH) derived from bauxite, an ore

from which aluminum is extracted. For more information

on the composition of the material, please consult the

Corian* solid surface Material Safety Daca Sheets (MSDS)

available via the msds.dupont.com website or via your

local supplice.

HARD PRACT

DuPont™ Corian® Sheets

“Available in various standard thicknesses, easily cut to size

by professional fabricators.

All colors in the standard color palette are available in

U2" x 30" x 144” (12 x 760 x 3658 mm) sheets. Selected

colors may include additional dimensional options: 36.6"

(930 mm) width; 72", 98", or 120" (1829 mm, 2490 mm,

‘or 3050 mm) length; '/:" and °/:" (6 and 19 mm) thickness.

Please consult the DuPont™ Corian* website,

‘corlen.cdupenn.cons for more deals.

DuPont™ Corian® Sinks and Lavatories

‘Awide range of DuPont” Corian” sinks and lavatories is

available in 5 solid colors for custom integration with,

Corian* sheets to create a continuous surface. This includes

vanity basins in solid colors for bathrooms, and single and

double sinks for kitchens, bars and small wash-up areas,

hospitals and laboratories. Seamed undermounting.

climinates rims that trap dirt and water, minimizing,

cleaning and maintenance and providing improved

hygiene. Care, maintenance and installation inscructions

are included in the packaging. Appropriate accessory

products, including installation hardware, are available and

recommended for residencial kicchens only.

The Colors of Corian® Solid Surface

A broad palette of colors allows for an almost unlimited

‘working palette. You can choose a single color; a neutral

basis for design; or experiment with eye-catching.

harmonies. DuPont Corian” solid surface can also be used

as inlays, accents, or as a versatile complement to other

‘materials ike metal, wood, stone, etc.

For complete information on colors, refer to the latest

Corian” colors leaflet or to corisn.uut.upont.coms Hues,

patterns and textures are related by style and character

Dark, heavily pigmented Corian* colors will show

scratches, dust and ordinary wear and tear mote readily

than lighter, textured colors. As a result, these colors are

recommended for applications where surface contact is

light or for use as inlays and accent colors. However, the

DeepColor™ series incorporates an innovative, proprietary

technology that delivers greater depth of color and

increased durability compared to other dark Corian* colors.

Page oF

i DUPONT™ CORIAN® PRODUCT OVERVIEW

Custom Sheets

DuPont can manufacture Corian® sheets in custom colors,

patterns and dimensions, within manufacturing capability

limics and based on a minimum order quantity

Limitations

Alchough DuPont” Corian® solid surface can withstand

high temperatures, it should be protected against direce

heat with hot pads or heat shields

Use of!" (6 mm) sheets should be restricted to vertical

applications or certain furnicure applications only. The

choice beeween Yo" and */" (12 mm and 19 mm) is

generally based on performance and cost considerations.

Due co the complex blending of natural minerals and

man-made acrylics, sight color variations may be found

within a sheet or from sheet co sheet of same color.

Therefore, checking for color matching is an essential

clement of sheet inspection before starting fabrication,

DuPont Corian” solid surface is nonporous so spills and

stains remain on the surface. However, some chemicals can

stain, discolor or damage the surface of Corian’ solid

surface. These chemicals include strong acids (like

concencraced sulfuric acid), ketones (like acetone),

chlorinated solvents (like chloroform) or strong solvent

combinations (like paint remover). The extent of the

damage will depend om the lengch of contact. Except for

strong solvents such as paint remover, short periods of

contact will not usually cause severe damage to Corian”

solid surface, Acid drain cleaners should not be used as they

can damage both Corian’ solid surface and any plastic

plumbing beneath. Corian* solid susface is not

recommended for use in photographic processing,

laboratories. More information can be found in DuePont

Coriaut” Chemical Resistance (K-27406). In some hospitals

and laboratories where strong disinfectants come in contact

with DuPont™ Corian” applications, the recommendation

is to use solid colors and avoid extended contact.

Since its introduction in 1967, DuPont” Corian’ solid

surface has proven itself to be remarkably durable, versatile

and easy to live with in both the home and commercial

Page 20k

Typical performance properties of DuPont" Corian*

products are shown in Dut’ rain” Performance

Properties (K-26829). The performance of Corian” sheets

may vary according to the thickness of the material, is

aesthetics and surface finish

Colors and patterns run through the entire thickness of

the material and cannot wear away or delaminate, Joints

can be glued inconspicuously, making virtually unlimited

surfaces possible

Corian® surfaces ate restorable, meaning they can be fully

restored with ordinary mild abrasive cleansers and a scouring

pad. Cigarette bums, for example, can be easily removed in.

this way. Damage caused by abuse can usually be repaired on

site without having to completely replace the material

Corian” solid surface is nonporous with a smooth, seamless

appearance. With proper cleaning, the material docs not

promote the growth of mold, mildew and bacteria

Corian® solid surface is nontoxic and nonallergenic co

humans. Corian” solid surface meets or exceeds emissions

guidelines for volatile organic compounds (VOCS),

hazardous air pollutants (HAPs) and has achieved

GREENGUARD GOLD Certification.

When burned, it releases mainly carbon oxides and the

smoke generated is optically light and does not contain

toxic halogenated gases. Because of these properties,

Corian" solid surface is used in public spaces and delicace

applications such as airport check-in counters, wall and

work surfaces in hospitals and hotels.

DuPone™ Corian” sheets can be thermoformed in wooden

cor metal molds at consrolled temperatures in order to create

various 2D and 3D design objects. Embossing effects ean

also be created.

“The translucency of DuPont™ Corian’ sheet is expecially

ing in the lighter colors as well as in thinner sheets. As

ers are using it to create lamps or

a result, many des

lighting effects in various applications.

Inlaying DuPont” Corian® with different materials or with

different colors of Corian’ is possible and ean enbance the

inherent beauty of che material. Inlays and logos can also

be created on Corian” using dye sublimation or direce

princing eechniques

Dione” Cain Sold Sonic Prodvut Overview

DUPONT™ CORIAN® PRODUCT OVERVIEW

DuPont trains and certifies fabricators and installers who

are provided detailed information regarding proper

procedures; the following is a general overview, not a

comprehensive guide co proper use.

ams

‘To minimize material usage and facilitate insallacion, a

corner block of Corian” should be made square (butt) rather

than mitered. The edges to be joined should be straight,

smooth and clean. Some seams need to be reinforced (see

fabrication manual for details) Joints should only be made

with DuPont” Joine Adhesive. Cutouts should be made with

2 router equipped with a sharp carbide bie, with a minimum

diameter of +" (10 mm). All comers of a cutoue must be

rounded to 5 mm radius and the edges smoothed, both on

top and bottom, all around a cutout. “L” and “U" shaped

corners need smooth, */«” (5 mm) radius inside corners. For

hob cutouts, corners should be reinforced with a Covian*

‘corner block. See fabrication manual for more details

Some Corian* colors that feature random veins and

irregular patcerns require special considerations regarding

the seams. Please refer to the related technical bulletin for

best practices in fabrication of these colors

Sealants and Adhesives

Corian* solid surface is compatible with many commercially

available caulks and sealants. 100% silicone products are

recommended. Vertical panels of Corian" may be installed

over suitable substrates, including water-resistant gypsum,

board, marine-grade plywood and ceramic tiles. In case «

supporcis needed, apply perimeter frame or full suppore

direct to Corian* using large beads of flexible adhesive

leaving a space with a minimum thickness of is" (1.5 mm).

For making scams in countertops, repairs and custom edges,

color-coordinated DuPont” Joine Adhesive should be used.

‘When used in accordance with manufacturer's inseructions,

it provides a smooth and inconspicuous joint. DuPont™

Joint Adhesive is available from DuPont or its distributors

Clearances

“The minimum expansion clearance in inches for Corian”

solid surface is 2.2 x 10° in.fin."F x (length of the piece of

Corian’ solid surface in inches) x (biggest temperature

range expected in °F) In mm the minimum expansion

clearance is 3.9 x 10° mm/mm "C x (length of the piece of

‘DuPont Corian” Soi Sufi - Pact Overview

Corian’ solid surface in mm) x (biggest temperacure range

expected in °C). Joints to be caulked should be a minimum

of '/s" (1.5 mm) wide to allow satisfactory sealant

penetration and expansion.

Precautions

Product dimensions are nominal, If tolerances are critical,

review your needs with a Corian* specialist.

Availability

DuPont™ Corian” sheet, shape, and accessory products are

readily available through a worldwide network of

Distributors and certified Fabricators/Installers

«¢ varies with color, thickness, and wideh as well as

custom fabrication and installation details.

DuPont offers limited coneria! and, vesidencial warranties.

nauscieaat

Preventing Damage to Corian® Solid Surface

Avoid profonged exposure to strong chemicals such as

acids, bases, and organic solvents. Spills should be cleaned

up promptly. Refer to Dison!” Corian’ Chemival

Ress iaice (K-27406) for additional details regarding

chemical exposures, clean up, and general maintenance. In

case of exposure outside the specifications listed in che

Class I Reagents section, the 10-year limited product

warranty will be void and handled as a case of abuse.

While unaffected by minor impacts, Corian® solid surface

can be damaged by heavy impacts, especially from pointed

dbjects. Ie can also be damaged by excessive heat. A local

Corian’ specialise can help you include appropriate heat

‘management into your designs.

Repairing Corian® Solid Surface

DuPont” Corian’ solid surface provides superior value by

being inconspicuously repairable in most cases. Minar cuts,

scratches, and stains can be removed by owners using fine

sandpaper and Scotch-Brite™ pads. Deeper cuts or impact

damage such as eracks may require an authorized Corian”

fabricator/installer co make inconspicuous repaits

Page 3 oF 4

DUPONT™ CORIAN® PRODUCT OVERVIEW

ADDITIONAL INFORMATION

For additional information or support

loca distributor, visit corian.na.dupont.com or cll

1-800-4-CORIAN (800-426-7426).

REFERENCED DOCUMENTS.

DuPont” Corian* Pexformance Properties (K-26829)

DuPont™ Corién” Chemical Resistamnce (K-27406)

ee Onl P

Limited Warnanty For North Anievica

Dulont™ Corian* 10-Year Limited Residential Warnasey For.

North America

Page of 4

Dubai Airports

en Se

ion ALUMINIUM & GLASS CO. L.L.C.

Project No: 68984 Project name: Detention center Modification

TECHNICAL SUBMITTAL

Engineering Services Di

Date: 03/04/2016

Contractor | Locator | Discipline | Submittal | Revision | Spec. Spec. Sub.

Code ‘Number Section | Clause | Contractor

SAMPLE METHOD STATEMENT TECHNICAL DATA

TESTING WARRANTY OTHER

MANUFACTURER: jedire

DESCRIPTION: g Hasek foe Dares Mor foo

COMMENTS:

A _sbyection —___

|, Dawns -

| 1, Zao maypocns

’ 2. (J Revise and resubmit, wrk may proceed subject to

w Incorporation of changes Inde

SIGNED:_¢ Ned

CONTRACTOR CERTIFICATION

DATE : 030472016

7 Revise and re-submi, work may not proceed,

IMPORTANT : Permission to proceed does not constitute

acceptance or approval of dotals, calculations,

analysis, test method or materials developed or selected by

the “supper ‘and. does not relieve supplier from fill

compliance with contractual obigation,

WE CERTIFY THAT THE SUBMITTED ITEM:

TJ Complies with the Specifications referred to above,

Is an alternative for the specified item and complies DCA ENGINEERING SERVICES

Is

| © a even ntcoed wor ny ron

|

|

|

with the intent of the Specification. |

sien Io one, 27. Db

Form: DCA(ES)-TDU-02 (Rev. 0)

ALUMINIUM & GLASS CO. L.L.C.

Project name :

ROSsovVo @ Tz Cone

TECHNICAL SUBMITTAL

Date:26 /11/2015

Convector | tocour | oacipine ] = Revsi | Spec | apne. | |

| ode Number section | clause | Contactor

SAMPLE [7] METHOD STATEMENT [| Technica cara

[_] TesTING [-] WARRANTY [__] OTHER

ga

MANUFACTURER: (ye dle FR _

DESCRIPTION

Afmmm twice Fe Rares mp e

COMMENTS.

Work may proceed

DATE 26/11/2015

[5 Revise and resubmit work may proceed subject to

\ Ineorperatin af changes indiated,

voneo. “Za

= Revise and resubmit, work may not proceed

(I Review not requted work may proceed

CONTRACTOR CERTIFICATION

WE CERTIFY THAT THE SUBMITTED ITEM

IMPORTANT : Permission to proseed does aot constitute

acceptance or approval of design detail, calculations,

snalyss, test metnod or materials developed of elected by

- ‘he "supplier “and doee not relave suppler fem hil

[1 Complies with the Specifications referred to above compliance with conactal obligation

| Is an alternative forthe specified item and complies GA ENGINEERING SERVICES

win the intent of the Specification

Form: DGNES)TOU.02 (Rev. 0)

Applications: Madite FR Eco Euroslass Bis a

panel product suitable for use as wall inings,

partitions, caling tes, display pane's and cases,

{furniture and tncings within an environmentally

sensitive area such as museums, laboratories,

hospitals and all public buildings,

Megite FR Eco Euroclass Bis not suitable for

external or structural applications, or where

exposure to water or high relative humidity may be:

encountered, Medite FR Eco Euroclass 8 is suitable

for use in internal cry conditions as defined in EN

622 ~ 5. Boards of this type are suitable for use in

Hazard Class 1 of EN 335-3,

Performance-fire resistance: Medite FR Eco

Euroctass 8 has no formaldehyde added to the

softwood fiores in the manuacture, The resultant

Product far exceeds the rgid Class E1 low

formaldehyde standards and also the lower levels:

required by CARB Phase 2.

Formaldehyde is found naturally in wood and no

‘wood product can be entiraly formaldehyde tree,

independent tests have shown that the free

formaldehyde content of Medite FR Eco Euoclass B

is less than 1.0mg/100g (equivalent or less than

natural wood}. The formaldehyde emissions from

Medite FR Eco Euoclass B are well below general

ambient outdoor levats

Appearance: Medite FR Eco Euroclass 8 is

distinguishable from other Mecite products by its

dark tan colour.

Machining/finishing: Cut or profiled edges of

Medite FR Eco Euroctass B should first ee sandod

with 150-240 grit, prior to painting. When choosing

2 coating system it should be confirmed with the

paint manufacturer that the coating wil not

adversely atfect the classification of the Medite FR

+ Feo Euroctass 8 panel. There is a varity of flame

retardant paints to choose from, which provi

resistanon aind wear qualities equal to goneral

decorative paints. The method of application will

depend directly on the tyne of paint selected,

Consition.ng: The moisture content of Mecite FR.

Eco Furaclass 8 is in the range of 4-895 at the

time of manufacture, Changes in dimensions of

‘wood and wooc-based sheet materials occur due

to changes in relative humidity. For this reason,

Modite FR Eco Euroclass B panels should be

Cconcitioned to the fival environment for two to three

days before cutting and fixing,

Authority: Medte FR Feo Euroctass B (EN 19823

++ EN 11925-2) is manufactured under an

NSAI registered LS. ENN ISO 8001 qualily

management system,

Supply: Medite FR Eco Euroctass fs produced

(on request {0 minimum volume requirements,

(odie FH Eou EuroclaseB HDF Technical Speciieaton

Tre Bonet tin WG

Modus 6 Porto a Tug

eas a Uasteny i ina

EN320

Scsee ling Edge 30

WidinyOaont Fur

os Tl Fuze

“Thickness Se ia inar?

engin ENT

cies Este

Fire saling: FR eentiteation available on request.

Sevuice: For further information and/or technical

advice regarding processing and painting finishing

Medite FR Eco Eurociass B please contact Medite

Technical Support Pers

European offices:

+44 (0) 1322 424900

+31 (0) 476 999740

+883 (0) 61 832700

sel through any of our

wawmedite-europe.cam

AV te MOF movies mpi ee const

vb ave marked acer oh autem os has

Fup sant Wet ase ae 1588 Ts pes e nets

sot a dss ewe:

lw eset eget a Grstacton

scence

por rarer

‘unui BFE? Sand

Pras ce ha 8 eee Me abe

id Pay erate ae in Fe Rina Or

Tne Conta IC the Caen Bec ant

(CAR 8 ae BE ote CARB Pre ° Coma

Pty Csi PC Prt wesngsan Prats terete idl SPH IC

At 69-910 crac rs peta eq corset 8

fat ark cote we a spe nate os ca

2 aed EPH we

raisin

A

opts Thiet

Nin a0 a0

We: 280 780

Wii Fow 2000

N

a a

% s0-80

mn OIG HOTS O15

5 i “00 70

% 40 a4 ao

5 i 6x co

v70

Pa

2300

i300

Ton

40-68

a5

ALUMINIUM & GLASS CO. L.L.C.

Project No: 68984 Project namo: Detention center Modification

TECHNICAL SUBMITTAL

Date: 03/04/2016

Contractor | Locator | Discipline | Submittal | Revision | Spec. Spec. Sub.

‘Code ‘Number Section | Clause | Contractor

SAMPLE METHOD STATEMENT TECHNICAL DATA

TESTING WARRANTY OTHER

MANUFACTURER:

DESCRIPTION: Fe 2 Pa F y 5 Ee 84.

foe moe Siadding on walle

COMMENTS: =

1, [2 Work may proceed

2, [5] Revise and resubmit, work may proceed subject to

oe Feaporaton of eange none

sioneo:_o- Se"

3, (1 Revise and re-submit, work may nat proceed,

DATE: 09/04/2016 , |

4. 5 Review net required work may proceed

ONTRACTOR CERTIFICATION IMPORTANT © Permission to procead dors not constitute

39 detals, calculations,

floped oF selected by

‘does not relieve supplier trom ful

1 Comptes with the Specifications referred to above. compliance with contractual obligation,

WE CERTIFY THAT THE SUBMITTED ITEM:

1 Is an atterative for the specified item and complies DCA ENGINEERING SERVICES

with the intent of the Specification,

| sien; pate:_3.4. 24

Ll

Form: DCA(ES)-TOU-02 (Rev. 0)

Tae)

Generic Type

Description

Features

Color

Finish

Topeoats

Wet Firm

Thickness

ry Alm

Thickness

Solids Content

coverage rate

voc content

Limitations

Shield Industries, Inc.

‘water-based inturescent coating designed forthe fre

protection of gypsum and wood,

Thin fli Inumescent coating that creates a fire retardant

and fire resistant barrier ona wide range a bulling surfaces

Including gypsum, wood, andstee! eee tech datasheet for

steel,

sted and certified by Guardian Fire Test Laboratories Ie

[ASTM £119 ASTM E-84Tested

Decorative Finsh- Gives smooth decorate nish

‘Cane top-coated to color cove

{Can be brushed on, rolled on, or prayed on

Durable rish- Provides hard pact and abrasion

resstant surface

“Topeost finishes smooth

“Thin fim coaing- space saving footprints

Low VOC content

LEED compliant

write

smooth

Can be used a6 nied coat or primer.

For interior space a topcoat i optional. For exterior

application the material mast be top coated with an

Impermeabl exterior coating The choice of topcoat wll

depend on project requirements and mil hiceness of

Intumescent coating. FreGuard &-€8°Intumescent Coating

Imustbe alowed to cure for 45 days prior tothe application

of topcoat. Application must be protected fom the

elements unl topcoat isin place. When apelying 2 tp cot,

Aryl applications thickness to achieve 3 desired rating may

change,

Upto 25-20milsper coat

Upto 135-162 mis per coat

By value 54%

66 /6al a Li

Bsf/6al a 10m

28.ft/6al at 30m

‘Mow fr loss in ming and application.

36a

Not or use on exterior environment o for interior stelwark

that willbe exposed to reexe/haw cing o long-term

surface temperatures over 140° (60°C) anormal use

without the use ofa sutabe topcoat

ForceField® FireGuard E-84°

For Gypsum/ Wood/ OSB

Intumescent Paint

ree eee eee

General

Prot to aplleaton surfaces need to be cleaned by removin,

allel grease or ny laoze particles that may interfere with

the hon of Forceleld® FireGuard®. tis highly

recommended to prime drywall substrates before the

application of FreGuard E88

‘On wood substrates where the Wood i extremely old and

red ou, it willbe necessary to serape off any old aking of

pain (if painted) and prime the surface before the

application of FreGuard E82

Cen Caue ae)

‘Stondords Tested To Results

‘ASTRA TOR /ASTAI E84 30 min tended | Flame Spread-O smoke Index

ASTM Eas

ASTM 2 Hour on gypsum and wood

Tas wall and floor een assemblies

NPA 2ST

Wes

Nira Mur

ner

xing

“Thinning

Tinting

Use" electric alr riven dil with 2 slotted paddle mit

{200epm under load.

Ficeguard® must be mote uting "electric or ar driven

With slotted paddle or ify mixer lade. Mix materia fore

‘minimum ofS minutes to achieve the necessary texture

‘required before spraying.

bo not thin.

0 not tnt.

Pe eMagrec ts

rushed or Rolled

‘Airless Spray

Generally creates an 11 to 12 mil wet apleation

‘Mutt coats willbe requires to meet

specications tothe Job requirements Allow eae

coat to completely dry to touch before appiving

[single coat, bul up with a number af quick

poses, llows greater control over quantities,

‘thickness and nth In most conltons, tis

advantageous to apply two thin coats ther that

one thick ct

‘hse dt sheet was desired incrpratinginfermation othe best of owe tht ws re ad accurate nthe dat that hs invexmaton wos published No guraree of aeuaey

ive or mpeg We gate out progucteto conform Shiels insist earl He athe ata of ar Knd a mae by Shins, ne. To deterne neds spect

Spoteton a cores of eterno reference mansteture pecan shes and cnt held Indie rey, Forel FeGuaed&HeGuard 8% serge

‘ademarhs of held nse ne

‘Shield industries, ne

131 Smokehil lane, Woodstock, Gf 30188 (770) 517-6859,

Application Procedures

Application Rates ‘Atan ambient temperature of 70° (21°C), the

following application rates ave applicable

25~ 30 ils po coat (vet)

24 hour recant ime between coats

Lcoatperday

*Frequard can be recoated when previous coat

has ashore D ardness of SO massed at 70°F (24°C)

‘Wee Fl Thickness Frequent thickness messurements with a wet fm

gauge are recommended during the aplication

process to ensure uniform thickness

ry Fl Thickness Final thickness can be measured using an

electronic dy fl thickness gauge, Positector 200

far equivalent may be used, Wet mail thickness dies

054%, (Ge. 20m wet = 20.6 ey)

Application Equipment Guideline:

Usted below are general equpment gules for the applition ofthis product when

Spray apie

Ite en

lesnup Pump, Gun, Tips, Moses, and Meer should be cleaned once p

ay with clean water

Ieisrecommended protective equipment shouldbe worn whe

_spplyngFitepvaré®, including spray sus, eve protection,

foves, and respirators. Refer to Fireguotd Material Safety D:

Sheet.

Ventilation should nat be less than 4 complete ar exchanges

er hour unt the materials ry

Safety

entiation

(WEcueuc)

General coating becomes damaged, rebuild required thickness by

spray, brush a tol When dry, saath and tnsh with topcoat

tormateh, Damaged areas must be abraded back oa frm ea

bbysanding or scraping, The topcoat should be abraded back 1

(25.4 min) from the damaged area. The surace must be clean

and dry before aplying Fireguard E34,

Meee acces ead

Uncertalety Measurement Guarcan’s fre testing sles than 1% as per

ante Seer iso 54 erent rer a

‘Spray Gun Standard airless spray gun Guardian is accredited and meets the requirements of ISO/IEC 17025 as

‘Spray Tips ae certificate and scope of accreditation report AT1247. Guardian also Is

‘atedtad an apeton pene pero 70 trauge ANAS

Hose Length 150" (45en) N.B.: ANSI/ASQ/ACLASS is @ signatory member of the International

Motel tose 8088250). armor st ue)

hip Hoe 4 (635mm LD minim po) Any sSancAss creda cf Gurdon ne lol canon

Gundorssewess

Oeste

eee

naiion | “Water | —Sace | — ent ram) sha te 1 year rom poco ate

storage soe ideo ry evicamert een E1077

Curing Schedule Packaging

Scat rate

‘Surface Temp. & 50% Relative Dry to Recoat

ty

TTF (25°C) 2a Hours wi

when previous coat has a Shore hardness of 8 measured at 70° (24°) canbe top a

ated when a hardness of 6s achieved after 45 dy cute ine

Ths echo data weet was deste corporat iefaraton othe bet of owed ht was trv accurate onthe dite ath rmatin wa gublbed apart of cerry

tmp, We guarantee our product to conform Shiels uses ualtyeonrl Nes ther warrant of ny Hn mae by Shel Insts,

Corrects of ek slnportnt to reference maafacturer pein shes and cnt std aes diet area, ecard & feud

eegiteea vademans of Se

Shield industries,

4131 Smokehil lane. Woodstock, GA 30188 (770) 517-6868

age Dubai Airports ra)

Renee

Engineering Services Division ALUMINIUM & GLASS CO. L.L.C.

Project No: 68984 Project name: Detention center Modification

TECHNICAL SUBMITTAL

Date: 03/04/2016

Contractor | Locator | Discipline | Submittal | Revision | Spec. Spec. Sub.

Code ‘Number Section | clause | Contractor

7 SAMPLE METHOD STATEMENT CJ TECHNICAL DATA

TESTING WARRANTY OTHER

MANUFACTURER: Cw fom sind e

DESCRIPTION:

Qooptiern Coumee fimiss — Giossy . white

COMMENTS:

Afi

1 Sicten proceed

2. 5) Revise and resubmit, work may proceed subject

Incorporation of changes indicated

)

wee

sieneo:__¢:e# * 2, 1 Reviee and re-subm, work may no proceed,

4. (Review not required work may proceed

DATE : 03/04/2016

CONTRACTOR CERTIFICATION IMPORTANT : Permission to prosced docs not conte

sceoplanee of oppor of design deta eaeatens,

WE CERTIFY THAT THE SUBMITTED ITEM analy, test eed or mane develope or selected by

iho upper ‘and done” not releve topper fom. Ml

1 Complies with the Specifications referred to above. compliance with contractual obligation.

Isan aterative for the specied tem and complies | DEA ENGINEERING SERMICES

with the intent of the Specification,

| sen Qe pare: PY. ol

Form: DCA(ES)-TDU-02 (Rev. 0)

ag Dubai Airports

Engineering Services Division ALUMINIUM & GLASS CO. L.L.C,

Project No: 68984 Project name: Detention center Modification

TECHNICAL SUBMITTAL

Date: 03/04/2016

Contractor ] Locator | Discipline | Submittal ] Revision | Spec. Spec. Sub.

Code Number section | Clause | Contractor

SAMPLE METHOD STATEMENT TECHNICAL DATA

TESTING WARRANTY OTHER

MANUFACTURER: Crem Mada.

DESCRIPTION: 7

Wal Cladding finish — Math white

COMMENTS:

(1, 2 workmay posted

DATE: Gxosi2n16 2. [J Revise and resubmit, work may proceed subject to

Incorporation ot changes ndosted

3, (7) Revie and re-submit, work may not proceed,

SIGNED

4. (5) Review not required work may proceed.

IMPORTANT : Permission to proceed does not constitute

‘acceptance of approval of design deta, calculations,

analysis, test method or materials developed or selected by

the supplier and does not reliove supplier ffom full

‘compliance with contractual obligation.

|

CONTRACTOR CERTIFICATION |

— Complies with the Specifications referres to above

[5 Is an atemative for the specified item and complies DGAERame=nelc senvicns

‘with the intent of the Specification,

sin pon pare: 3.%f, 20/6

Form: DGA(ES)-TDU-02 (Rev. 0)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Confined Space PTWDocument2 pagesConfined Space PTWVijayakumar KarunanidhiNo ratings yet

- LETTER IDocument10 pagesLETTER IVijayakumar KarunanidhiNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitVijayakumar KarunanidhiNo ratings yet

- Hot Work PTWDocument2 pagesHot Work PTWVijayakumar KarunanidhiNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Laminated MDF Shelves For PoliceDocument4 pagesLaminated MDF Shelves For PoliceVijayakumar KarunanidhiNo ratings yet

- 135749-Smoking LoungeDocument4 pages135749-Smoking LoungeVijayakumar KarunanidhiNo ratings yet

- Hero - Mep ContatinmentDocument10 pagesHero - Mep ContatinmentVijayakumar KarunanidhiNo ratings yet

- Change of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownDocument1 pageChange of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownVijayakumar KarunanidhiNo ratings yet

- Telephone Booth Terminal2Document5 pagesTelephone Booth Terminal2Vijayakumar KarunanidhiNo ratings yet

- Technical Submital Form - Du PontDocument1 pageTechnical Submital Form - Du PontVijayakumar KarunanidhiNo ratings yet