Professional Documents

Culture Documents

Hot Work Permit

Uploaded by

Vijayakumar KarunanidhiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work Permit

Uploaded by

Vijayakumar KarunanidhiCopyright:

Available Formats

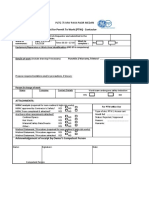

AL DHAFRA PAPER MANUFACTURING COMPANY LLC

Long Duration □

Duration □

Short

HOT WORK PERMIT Work Permit No:

Department Section Equipment to be worked on:

A. Validity of Permit Date: Start Time: End Time: Equip. ID Work Location

Requestor

B. Job Description: Contact No.:

Name:

Tick in the Appropriate Box No. of Persons working under the scope of this permit

Isolation Tag No.

C. Type of Isolation / Arrangements Yes No N/A Details & Precautions Electrical / Valve

1. Job Safety Analysis Available

2. Process Isolation - System Fully Depressurized State (Tank / Line)

3. Electrical Isolation Required

4. Instrument Isolation (Power / Pneumatic) Required

5. Radiation Isolation, Required (If any)

6. Safe Access / Egress Available

7. Working at Height

8. Flammable Materials Removed

9. Competent Supervsior / Chargehand at site

10. Temporary Lighting Arrangement Required / Available

11. Adequate Mechanical Ventilation (i.e Fans, Exhaust)

if

12.required

Housekeeping Required

13. Hot Work Equipments are in good Working Condition

14. Traffic Management, If any

15. Fire Watch / Observer Available

16. Others, If any

D. PPE Requirement:

□ Safety Helmets □ Safety Shoe □ Safety Goggles □ Face Shield □ Ear Plug □ Cotton Gloves □ Leather Gloves □ Chemical / PVC Gloves □ Safety Harness

□ Cover all □ Fall Arrest □ Dust Mask □ Half Mask □ Gas Monitor □ Air Line □ Fire Extinguisher □ Fire Blancket □ Edge Protection (Hand Rail) □ Step Ladder □ Mobile Scaffolding

□ Fixed Scaffolding □ Manlift □ Boom Loader □ Mobile Crane □ Barrications & Signages □ Chemical Suit

□ Others, Please Mention if any, ________________________________________________________________________________________________________________

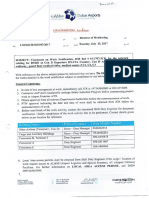

E. Electrical Isolation: (LOTO System)

Name of Requestor: __________________________ Sign of the Requestor: _______________________ PADLOCK / KEY NO: ____________________

Cable Connection Removed □ Yes □ No

Name of Isolator: _____________________________ Sign of the Isolator: ________________________ ○ Long Duration ○ Permit Duration

F. Instrumentation Isolation:

Name of Requestor: ____________________ Sign of the Requestor: _______________________

Airline Removed □ Yes □ No

Name of Isolator: _____________________ Sign of the Isolator: ________________________ ○ Long Duration ○ Permit Duration

G. Gas Test Reading, if any : ○ Required ○ Not Required Gas Test Result: ____________________________________________________________________________________________

Name of Gas Tester: ______________________________________________ Signature of Gas Tester: _______________________________________________________________________________

H. Available Fire Watch Name: _____________________________________________________________________________ Contact Number: _______________________________________________________

I. If the Job is carried out by Contractor, Name of Contracting Company ………………………………………………………………………………………………Contact Person: ………………………………………….. Contact Number: …………………………………………………………………..

J. Permission granted for work to commence

Job preparations & precautions were well explained in TBT / SOP / JSA, etc., to the Receiver System is FULLY SAFE to start the Job: I understand the Job explanation, preparation, precautions to be taken while executing & will inform the issuing

& their Team Permit Issuer (Process Owner): authority about any discrepancies.

Permit Requestor : Name: …………………………………………………………... Permit Receiver Name: …………………………………...

Name: ……………………………………………………………………………………... Signature: .………………………………………………………… Signature: …………………………………………………………

Signature: ………………………………………………………………………………… Date & Time: ...…………………………………………………… Date & Time:………………………………………………………

Date & Time: …………………………………………………………………………...

Date & Time: Remarks:

K. Confirmation from HSE Safety Officer Name:

at the time of Permit

Issue:

Signature:

L. Permission / Communication for the TRIAL RUN

Job preparations & precautions were well explained in TBT, SOP & JSA, etc., to the Receiver System is FULLY SAFE for the Trial Run: I understand the Job explanation, preparation, precautions to be taken while executing & will inform the issuing

& their Team Permit Issuer (Process Owner): authority about any discrepancies.

Permit Requestor Name: ………………………………………………………………………... Name: ……………………………………………………………... Permit Receiver Name: ..……………………………………...

Signature: ………………………………………………………………………………………………... Signature: ………………………………………………………… Signature: .....…………………………………………………………

Date & Time: ……………………………………………………………………………................ Date & Time: …………………………………………………… Date & Time: ...………………………………………………………

M. Extension of Permit, if required Reliever Mobile No.

Date Permit Extend From: Permit Extended upto:

Requestor Name: Permit Issuer (Process Owner)Name: Permit Receiver Name:

Requestor Sign: Permit Issuer (Process Owner)Sign: Permit Receiver Sign:

N. Surrender of the Work Permit

• Man, Materials, Tools & Tackles cleared from the work area, Requestor Name Signature Date & Time

• All guards placed back in position.

• Manhole dummies fixed, ensuring that no person/material inside.

• House Keeping to be done from mechanical side.

• The work permit can be closed/ cancelled.

O. Restoration (Process / Issuer)

• All required dummies removed Issuer Name Signature Date & Time

• Necessary valves opened and Isolation tags removed

• System of equipment is ready to start

• Please restore power supply

P. Electrical Authorized Person Name Signature Date & Time

• Motor Cables are connected back

•Power, Control Fuses put back.

• Interlocks connected back & tested The Above Equipment is taken into the Circuit Safely

• Padlock Key returned by Requestor & LOTO Tag removed. Issuer Name Signature Date & Time

• Power restored & Equipment is ready for starting

Q. MONITORING OF JOB SITE (For 1 hour after the Completion of Job)

Responsible Person Name Signature Date & Time

White Copy: Receiver Pink Copy: Electrical, Yellow: Permit Issuer / Process Blue Copy: Permit Book

Note: Short Duration valid for 12 hours only Emergency Contact No. 1) Safety Dept. : 056 417 6699 / 02305 2521 2) First Aider : 056 544 8043 / 02305 2536

You might also like

- Hot Work Permit ChecklistDocument3 pagesHot Work Permit ChecklistUmair KhanNo ratings yet

- HSE Hot Work PermitDocument3 pagesHSE Hot Work PermitCSD shakthiNo ratings yet

- VR-ForM-F06.10 (Hot Work Permit Request Form)Document1 pageVR-ForM-F06.10 (Hot Work Permit Request Form)imtz2013No ratings yet

- Contractor - Permit To Work in Occupied Areas: (Select All That Apply)Document2 pagesContractor - Permit To Work in Occupied Areas: (Select All That Apply)AAT SupplyNo ratings yet

- Confined Space Entry Permit DetailsDocument2 pagesConfined Space Entry Permit DetailsradeepNo ratings yet

- Maraba Al Iraq Al Khadraa: Emergency Drill ReportDocument3 pagesMaraba Al Iraq Al Khadraa: Emergency Drill Reportfdfddf dfsdfNo ratings yet

- R-16 Safety Management Review MeetingDocument2 pagesR-16 Safety Management Review MeetingSandeep Kumar100% (1)

- Confined Space Work PermitDocument2 pagesConfined Space Work PermitDimas Dwi SwarnaNo ratings yet

- 18A - FO - Permit To Work LogDocument2 pages18A - FO - Permit To Work Lograjesh_rathNo ratings yet

- Annexure 9 - Declaration by The Subcontractor For HSE ComplianceDocument1 pageAnnexure 9 - Declaration by The Subcontractor For HSE ComplianceShamim Mahmudur RahmanNo ratings yet

- Permit To DigDocument3 pagesPermit To DigMarco DonatiNo ratings yet

- Environmental Incident Reporting FormDocument1 pageEnvironmental Incident Reporting FormKathleen PaladanNo ratings yet

- HSE-P-07 Work Permit Procedure Issue 2.1Document30 pagesHSE-P-07 Work Permit Procedure Issue 2.1eng20072007100% (1)

- Near Miss Report FormDocument1 pageNear Miss Report FormVikas YamagarNo ratings yet

- Permit To Work Compliance AuditDocument3 pagesPermit To Work Compliance AuditefeNo ratings yet

- Natural Gas Pipeline Safety Walk ReportDocument2 pagesNatural Gas Pipeline Safety Walk ReportNibhaNo ratings yet

- HS&EP General Work Permit ProceduresDocument2 pagesHS&EP General Work Permit ProceduresvladNo ratings yet

- General Work PermitDocument2 pagesGeneral Work Permitloganathan0% (1)

- HSE PlanDocument52 pagesHSE PlanSyahriadin SyamNo ratings yet

- FORM-03-OHSE-08 General Work Permit (GWP)Document2 pagesFORM-03-OHSE-08 General Work Permit (GWP)Fadil MuhammadNo ratings yet

- Review Safe Work Permit Hazard ChecklistDocument3 pagesReview Safe Work Permit Hazard ChecklistJohn Harold CastroNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitKlyneRamirezNo ratings yet

- GGC-HSEF 037 Site Daily ObservationDocument1 pageGGC-HSEF 037 Site Daily ObservationAmjadNo ratings yet

- General work permitDocument1 pageGeneral work permitgurvinder singhNo ratings yet

- Cps 0460 Incident Notification ReportDocument2 pagesCps 0460 Incident Notification ReporttabaquiNo ratings yet

- Safety Officer Inspection ChecklistDocument3 pagesSafety Officer Inspection ChecklistSomesh Ingale100% (1)

- Excavation Permit FormDocument2 pagesExcavation Permit FormKarim KachourNo ratings yet

- Entry Permit Confined Space 1Document4 pagesEntry Permit Confined Space 1ramodNo ratings yet

- PPE Issue ReordDocument1 pagePPE Issue ReordHuman ResourcesNo ratings yet

- BP Safety AlertDocument2 pagesBP Safety AlertRikza AhmadNo ratings yet

- Permit To Work ProceduceDocument4 pagesPermit To Work ProceduceQuý Hoàng ChuNo ratings yet

- FORM 3 For Maintaining Records of Hazardous Waste at FacilityDocument1 pageFORM 3 For Maintaining Records of Hazardous Waste at Facilitysandeep MNo ratings yet

- Procedure For Accident Incident and Near MissDocument2 pagesProcedure For Accident Incident and Near MissrgmNo ratings yet

- OCP - 21 - Safe Use of HelmetDocument2 pagesOCP - 21 - Safe Use of HelmetNagendra Kumar SinghNo ratings yet

- Emergency PreparednessDocument16 pagesEmergency PreparednessMuntaj AnsariNo ratings yet

- Work PermitDocument17 pagesWork PermitRiccar303No ratings yet

- HSE Policy SampleDocument1 pageHSE Policy SampleRajkumar NandaNo ratings yet

- Confined Space Entry PermitsDocument7 pagesConfined Space Entry PermitsCris SuyamNo ratings yet

- FirmDocument3 pagesFirmTatiana Garcia MendozaNo ratings yet

- HSE Exception Request Form Rev.1Document1 pageHSE Exception Request Form Rev.1Dhimaz YudiNo ratings yet

- Monthly HSE Performance Report Form DTLP FEB-21Document2 pagesMonthly HSE Performance Report Form DTLP FEB-21Muhammad Khan100% (1)

- 4.3 - B - 10 - Procedure For Hazard Identification and ControlDocument5 pages4.3 - B - 10 - Procedure For Hazard Identification and ControlSASIKUMAR SNo ratings yet

- 13 Emergency Response: Project Employer Engineer ContractorDocument9 pages13 Emergency Response: Project Employer Engineer ContractorcenkunalNo ratings yet

- HSE Monthly ReportDocument1 pageHSE Monthly ReportAdham Abo bakrNo ratings yet

- PPE AnalysisDocument1 pagePPE AnalysisHaleem Ur Rashid BangashNo ratings yet

- Monthly Safety Report SampleDocument2 pagesMonthly Safety Report SamplenagaaNo ratings yet

- P99-HS-200223-Activity Briefing Form-Rev 2Document2 pagesP99-HS-200223-Activity Briefing Form-Rev 2Darius AdeNo ratings yet

- 5 - Equipment's Master ChecklistDocument5 pages5 - Equipment's Master ChecklistSaboor KabierNo ratings yet

- Permit To Work ProcedureDocument42 pagesPermit To Work ProcedureKhuda Buksh100% (1)

- FR - HSE - 061 - en Permit To Work Audit ChecklistDocument2 pagesFR - HSE - 061 - en Permit To Work Audit ChecklistNibu P ShajiNo ratings yet

- Company Safety Manual Training & Behaviour Induction SummaryDocument8 pagesCompany Safety Manual Training & Behaviour Induction SummaryEsamKhalilAlQadi100% (1)

- 7.electrical LOTO Check List InspectionDocument1 page7.electrical LOTO Check List Inspectionfitri widyaNo ratings yet

- PLTG 75 MW PAYA PASIR MEDAN PTW RequestDocument2 pagesPLTG 75 MW PAYA PASIR MEDAN PTW RequestDimas Dwi SwarnaNo ratings yet

- Emergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTDocument3 pagesEmergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTSyifa Ula HamidyaNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormHSE S4No ratings yet

- Accident and Incident Report AUGUST 30 2021Document21 pagesAccident and Incident Report AUGUST 30 2021Charles Doria100% (1)

- Plant Checklist PDFDocument2 pagesPlant Checklist PDFmj santosNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Confined Space PTWDocument2 pagesConfined Space PTWVijayakumar KarunanidhiNo ratings yet

- Hot Work PTWDocument2 pagesHot Work PTWVijayakumar KarunanidhiNo ratings yet

- Final General or Cold PTWDocument1 pageFinal General or Cold PTWVijayakumar KarunanidhiNo ratings yet

- LETTER IDocument10 pagesLETTER IVijayakumar KarunanidhiNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- 140919-Hero Project-Phase 3Document11 pages140919-Hero Project-Phase 3Vijayakumar KarunanidhiNo ratings yet

- 127263-New APS Pass OfficeDocument4 pages127263-New APS Pass OfficeVijayakumar KarunanidhiNo ratings yet

- 135749-Smoking LoungeDocument4 pages135749-Smoking LoungeVijayakumar KarunanidhiNo ratings yet

- Laminated MDF Shelves For PoliceDocument4 pagesLaminated MDF Shelves For PoliceVijayakumar KarunanidhiNo ratings yet

- Change of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownDocument1 pageChange of Location: Assembly Point No.2 New Location: Between Masjid, Pm3 and Chemical GodownVijayakumar KarunanidhiNo ratings yet

- Intrusive SurveyDocument4 pagesIntrusive SurveyVijayakumar KarunanidhiNo ratings yet

- Kidney RemovalDocument11 pagesKidney RemovalVijayakumar KarunanidhiNo ratings yet

- Inspection Report 4.0 (PRM)Document2 pagesInspection Report 4.0 (PRM)Vijayakumar KarunanidhiNo ratings yet

- 128466-Phone Booth RemovalDocument5 pages128466-Phone Booth RemovalVijayakumar KarunanidhiNo ratings yet

- All Assembly PointsDocument3 pagesAll Assembly PointsVijayakumar KarunanidhiNo ratings yet

- 4 Assembly Points Location: B Ackside of Admin Car Parking 2. O Pen Area Between Pm3 & MosqueDocument1 page4 Assembly Points Location: B Ackside of Admin Car Parking 2. O Pen Area Between Pm3 & MosqueVijayakumar KarunanidhiNo ratings yet

- Telephone Booth Terminal2Document5 pagesTelephone Booth Terminal2Vijayakumar KarunanidhiNo ratings yet

- Inspection Report (Jones The Grocer Outlet - Fusion)Document1 pageInspection Report (Jones The Grocer Outlet - Fusion)Vijayakumar KarunanidhiNo ratings yet

- Inspection Report 1.0 (PRM)Document2 pagesInspection Report 1.0 (PRM)Vijayakumar KarunanidhiNo ratings yet

- Inspection Report (NEC TV Installation - Darwish)Document2 pagesInspection Report (NEC TV Installation - Darwish)Vijayakumar KarunanidhiNo ratings yet

- 4 Assembly Points Locations Location LandmarkDocument1 page4 Assembly Points Locations Location LandmarkVijayakumar KarunanidhiNo ratings yet

- LF Refirdgerator001Document3 pagesLF Refirdgerator001Vijayakumar KarunanidhiNo ratings yet

- Inspection Report 1.0Document2 pagesInspection Report 1.0Vijayakumar KarunanidhiNo ratings yet

- 126654-Network Cabling DNRDDocument4 pages126654-Network Cabling DNRDVijayakumar KarunanidhiNo ratings yet

- Inspection Report (API Operations Centre - GBM)Document2 pagesInspection Report (API Operations Centre - GBM)Vijayakumar KarunanidhiNo ratings yet

- Inspection Report (DNRD - Blue Camel)Document2 pagesInspection Report (DNRD - Blue Camel)Vijayakumar KarunanidhiNo ratings yet

- Parking Bay Con DDocument3 pagesParking Bay Con DVijayakumar KarunanidhiNo ratings yet

- Police Parade Building Engineering SubmittalDocument1 pagePolice Parade Building Engineering SubmittalVijayakumar KarunanidhiNo ratings yet

- 126657-APM Glass Removal Con ADocument5 pages126657-APM Glass Removal Con AVijayakumar KarunanidhiNo ratings yet

- Basic Principles of Cleaning Unit 1Document2 pagesBasic Principles of Cleaning Unit 1ISHAN BAGCHINo ratings yet

- Corona Cavach Policy WordingsDocument14 pagesCorona Cavach Policy WordingsRajesh SirsathNo ratings yet

- MARIELLE CHUA - (Template) SOAPIE CaseletDocument9 pagesMARIELLE CHUA - (Template) SOAPIE CaseletMarielle Chua100% (1)

- Hill, C - Written Assingment 3Document10 pagesHill, C - Written Assingment 3Collin HillNo ratings yet

- Implementation of QMP in An OrganisationDocument4 pagesImplementation of QMP in An Organisationshipra damirNo ratings yet

- Hospitals' EmailsDocument8 pagesHospitals' EmailsAkil eswarNo ratings yet

- Textbook Atopic DermatitisDocument285 pagesTextbook Atopic DermatitisYogi Anjasmara100% (3)

- Assessment PrintDocument204 pagesAssessment Printbruceaq100% (7)

- WLP-BLP GRADE 10 Week 8 L2-4 HDocument7 pagesWLP-BLP GRADE 10 Week 8 L2-4 HKalabit PengeNo ratings yet

- QED Achieves 1 Million Safe ManhoursDocument2 pagesQED Achieves 1 Million Safe ManhoursBernabe AlmirolNo ratings yet

- RTM 3Document8 pagesRTM 3Christine Danica BiteraNo ratings yet

- 26 - LEAN Weekly Guide - On - October 12Document15 pages26 - LEAN Weekly Guide - On - October 12Andrea CsillaNo ratings yet

- Psychosocial Support PlanDocument2 pagesPsychosocial Support PlanGwendolyn Lalamonan AnganaNo ratings yet

- Reinforcement TheoryDocument10 pagesReinforcement TheorySana taNo ratings yet

- CREST Final ReportDocument21 pagesCREST Final ReportDarren KrauseNo ratings yet

- EssayDocument5 pagesEssayPranjal SrivastavaNo ratings yet

- Childhood BlindnessDocument6 pagesChildhood BlindnessMonika Diaz KristyanindaNo ratings yet

- PhysicsinOrthodontics04 17 21SLJMRDocument43 pagesPhysicsinOrthodontics04 17 21SLJMRYaser JasNo ratings yet

- Corporate Responsibility: Principles and Perspectives (Mn20445)Document3 pagesCorporate Responsibility: Principles and Perspectives (Mn20445)WilliamArugaNo ratings yet

- Cynthia Orange - Sing Your Own Song - A Guide For Single Moms-Hazelden (2001) PDFDocument203 pagesCynthia Orange - Sing Your Own Song - A Guide For Single Moms-Hazelden (2001) PDFegalNo ratings yet

- Pulmonary Tuberculosis - Curitana BSN 2bDocument10 pagesPulmonary Tuberculosis - Curitana BSN 2bDrex CuritanaNo ratings yet

- IBNII Write UpDocument4 pagesIBNII Write Updani danielsNo ratings yet

- Endo-perio Lesion DilemmaDocument10 pagesEndo-perio Lesion DilemmaElly ZaiNo ratings yet

- HRM Practices in RMG Industry in Bangladesh: NexusDocument28 pagesHRM Practices in RMG Industry in Bangladesh: NexusFahimNo ratings yet

- Assessing The Life Satisfaction of Elderly Living in Old Age Homes in The City of Ahmedabad-28-43Document16 pagesAssessing The Life Satisfaction of Elderly Living in Old Age Homes in The City of Ahmedabad-28-43Nageswara Rao AmbatiNo ratings yet

- 11 Thyroid HacksDocument13 pages11 Thyroid HackstthorgalNo ratings yet

- Performance Rating FormDocument2 pagesPerformance Rating FormArielle Ramirez67% (3)

- The Mental Health Status of Grade 11 ABM Students During The Online Learning Set Up in Davao CityDocument19 pagesThe Mental Health Status of Grade 11 ABM Students During The Online Learning Set Up in Davao CityALYANNA SARMIENTONo ratings yet

- Dr. Warren Morgan's 100-Day Plan For CMSDDocument15 pagesDr. Warren Morgan's 100-Day Plan For CMSDWKYC.comNo ratings yet

- 15-SOP Munsell Hue TestDocument2 pages15-SOP Munsell Hue TestImran NazirNo ratings yet