Professional Documents

Culture Documents

Architectural Drawings 1

Uploaded by

Manish PandeyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Architectural Drawings 1

Uploaded by

Manish PandeyCopyright:

Available Formats

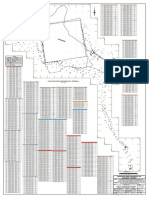

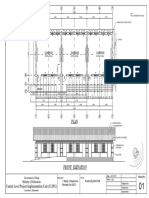

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. .

Note: roof

sheets and all necessary accessories, such as flashings, ridge cappings CLIENT APPROVAL

and polyclosures to be installed strictly in accordance with manufacturer's

USER DEPARTMENT (MARLBORO DEPOT)

5°

specifications and details.

NAME: ............................................................

N bounda

ry wall

DESIGNATION: REGIONAL MANAGER

14 Existing

Existin

g boun

dary w SIGNATURE: .................................................

all

DATE: ............................................................

259

PROJECT MANAGER CAPEX

14 812

0

NAME: ............................................................

ll

760

2 ry wa

bounda

Ex isting DESIGNATION: .............................................

SIGNATURE: .................................................

259

475 DATE: ............................................................

All steel member sizes and specifications

4925 as per structural engineers detail

wall FACILITY DEPARTMENT

2805

ary

Kliplock roof shee ound

ting with Chromad ing b

Exist

Fixed to mild steel ek finish, 5000 20800 NAME: ............................................................

lip channel purlin

s as per

manufacturers sp DESIGNATION: .............................................

2232

ec.

5000

NEW CARPORT SIGNATURE: .................................................

4925 DATE: ............................................................

475

OHS

NAME: ............................................................

14 DESIGNATION: .............................................

327

A

w

d Ne SIGNATURE: .................................................

0

o s e y

Prop Canop N.G.L. DATE: ............................................................

r

Ca 01)

(

654

0

14

14

327

0

3270

Propo

sed

Car Ca New

nopy

6540

Kliploc (02)

13

k roof

14 CAR PORT PLAN Fixed sh

to mild eeting with C Concrete foundations

steel li h

p chan romadek fin to Engineers details

Scale 1:50 nel pu ish,

manufa rlins as per

H

cturers

3270

spec.

TYPICAL - SECTION A-A

I

Scale 1:25

12

J

8120

20722

520 7080 520 530 4792 5000 5000 4925 475

K

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. Note: roof sheets and all 0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. .Note: roof sheets and all

L

necessary accessories, such as flashings, ridge cappings and polyclosures to be necessary accessories, such as flashings, ridge cappings and polyclosures to be installed strictly

installed strictly in accordance with manufacturer's specifications and details. in accordance with manufacturer's specifications and details.

All steel member sizes and specifications All steel member sizes and specifications All steel member sizes and specifications

as per structural engineers detail as per structural engineers detail as per structural engineers detail

N.G.L. N.G.L.

Concrete foundations Concrete foundations Concrete foundations Concrete foundations Concrete foundations

to Engineers details to Engineers details to Engineers details to Engineers details to Engineers details

ELEVATION - BACK ELEVATION - BACK

Scale 1:50 Scale 1:50

8120 20800

259 7602 259 475 4925 5000 5000 4925 475

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting.

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. Note: roof sheets and .Note: roof sheets and all necessary accessories, such as

all necessary accessories, such as flashings, ridge cappings and polyclosures to be flashings, ridge cappings and polyclosures to be installed

installed strictly in accordance with manufacturer's specifications and details. strictly in accordance with manufacturer's specifications and

details.

All steel member sizes and specifications

as per structural engineers detail

All steel member sizes and specifications All steel member sizes and specifications

as per structural engineers detail as per structural engineers detail

N.G.L.

N.G.L.

Concrete foundations Concrete foundations

to Engineers details to Engineers details Concrete foundations Concrete foundations Concrete foundations

to Engineers details to Engineers details to Engineers details

ELEVATION - FRONT ELEVATION - FRONT

Scale 1:50 Scale 1:50

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW CARPORTS AT

DRAWING CHECK: M WAYITI R17017-CS-ARC-001

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

LAYOUT, SECTIONS & DETAILS

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA CAR CANOPY 01 & 02

A 2017/10/06 ISSUED FOR INFORMATION ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. .Note: roof

sheets and all necessary accessories, such as flashings, ridge cappings

and polyclosures to be installed strictly in accordance with manufacturer's

CLIENT APPROVAL

5°

specifications and details.

12 13 14

USER DEPARTMENT (MARLBORO DEPOT)

NAME: ............................................................

DESIGNATION: REGIONAL MANAGER N

SIGNATURE: .................................................

DATE: ............................................................

PROJECT MANAGER CAPEX

NAME: ............................................................

DESIGNATION: .............................................

Kliplock roof sheeting with Chromadek finish, fixed to mild

SIGNATURE: ................................................. steel lip channel purlins as per manufacturers spec. 6540

All steel member sizes and specifications 3270 3270

DATE: ............................................................ as per structural engineers detail

2805

475

FACILITY DEPARTMENT M

NAME: ............................................................

2232

DESIGNATION: .............................................

NEW CARPORT

SIGNATURE: .................................................

DATE: ............................................................

5590

OHS

NAME: ............................................................

DESIGNATION: .............................................

SIGNATURE: ................................................. N.G.L.

DATE: ............................................................ N

5590

Concrete foundations

to Engineers details

SECTION A-A O

Scale 1:25

Existing Building

28900

475 5590 5590 5590 5590 5590 475

28900

5590

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting. .Note: roof sheets and all

necessary accessories, such as flashings, ridge cappings and polyclosures to be installed strictly Proposed New

in accordance with manufacturer's specifications and details.

Car Canopy

(03)

A A

All steel member sizes and specifications All steel member sizes and specifications

as per structural engineers detail as per structural engineers detail

5590

N.G.L.

Concrete foundations Concrete foundations Concrete foundations

to Engineers details to Engineers details to Engineers details

5590

ELEVATION - BACK

Scale 1:50

R

475

28900

475 5590 5590 5590 5590 5590 475

0.58mm KLIPLOK 700 - Z200/C1S chromodek roof sheeting.

.Note: roof sheets and all necessary accessories, such as

flashings, ridge cappings and polyclosures to be installed

strictly in accordance with manufacturer's specifications and

details.

CAR PORT PLAN

Scale 1:50

All steel member sizes and specifications All steel member sizes and specifications

as per structural engineers detail as per structural engineers detail

N.G.L.

Concrete foundations Concrete foundations Concrete foundations

to Engineers details to Engineers details to Engineers details

ELEVATION - FRONT

Scale 1:50

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW CARPORTS AT

DRAWING CHECK: M WAYITI R17017-CS-ARC-002

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

LAYOUT, SECTIONS & DETAILS

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA CAR CANOPY 03

A 2017/10/06 ISSUED FOR INFORMATION ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

GENERAL NOTES:

CLIENT APPROVAL · The design on this drawing is copyright & remains

USER DEPARTMENT (MARLBORO DEPOT) property of the Robust Consulting Engineers.

· All work to be carried out strictly in accordance

NAME: ............................................................ with municipal regulations, National Building

DESIGNATION: REGIONAL MANAGER Regulations and SANS 10400.

· Figured dimensions to be taken in preference to

SIGNATURE: ................................................. scaling drawings.

DATE: ............................................................ · All platforms and ground levels to Civil Engineer's

details.

PROJECT MANAGER CAPEX · All bulk sewer and stormwater reticulation to Civil

engineer's details and specifications. Internal

NAME: ............................................................ waste water reticulation and drainage to mechanical

DESIGNATION: ............................................. Engineer's details.

· All structural work to structural engineer's details

SIGNATURE: .................................................

and specifications.

DATE: ............................................................ · All Fire requirements to Mechanical engineers

detail and specifications.

FACILITY DEPARTMENT · All relevant details, levels & dimensions to be

checked on site before commencement of work.

NAME: ............................................................

· All drawings are to be checked by the main

DESIGNATION: ............................................. contractor & any discrepancies on the drawings or

SIGNATURE: ................................................. between the drawings are to be referred to the

Robust Consulting Engineers or relevant consultant

DATE: ............................................................ for clarity prior to any construction work.

· This drawing is to be read in conjunction to

OHS relevant consultant drawings and other detailed

NAME: ............................................................ drawing documentation.

· Main Contractor/consultants to ensure that the

DESIGNATION: ............................................. latest drawings are referred to at all times.

SIGNATURE: ................................................. The 'Drawing Revisions' column on this drawing to

be cross referenced with the latest issued drawing

DATE: ............................................................ register in this regard.

NOTES FOR ELECTRONIC DRAWINGS:

· This drawing may be issued electronically.

1 2 20 560

3 4 5 1 2 3 4 5 · This drawing may contain external references

(xrefs) which would have been "bound" into the

N 6 890 4 415 2 895 6 360

N 20 560 drawing prior to issue.

175 290

195 253 6 890 4 415 2 895 6 360

500 2 540 1 200 1 224 730 3 528 1 200 730 1 200 1 360 6 075 615 1 252 600 1 400 600 998 730 1 326 600 1 400 600 998 730 973 600 1 996 600 1 436 864 1 100 600 354 730

galv. steel handrail galv. steel handrail

1m high galv. steel handrail

NOTES:

Emergency fire escape

· All drawings are to be read in conjunction with

1m high galv. steel handrail

1m high galv. steel handrail

1m high galv. steel handrail

B Steel staircase as per

engineers detail

B Down

facebrick finish to external wall.

floor plans, sections, elevations, schedules, roof

2 250

galv. steel handrail galv. steel handrail

outer face of inner skin to be bagged

galv. steel handrail and bitumen tarred.

Emergency fire escape

galv. steel handrail

powder coated alum. & ceiling plans, and site plan.

UP powder coated alum.

windows

150Ø pvc pipe. windows

Steel staircase as per

EMERGENCY · Finish to concrete: Un-plastered and un-painted

380 730

engineers detail EXIT

(rwdp to discharge into existing SW line) galv. steel handrail

Slab line above W1 W1 W1 W1 W1 galv. steel handrail W1 W1

Concrete structure must be smooth, even

A A A A colouring, plumb with recessed joints rubbed

290

290

Existing window to Existing window to Existing window to Beam above to Eng. detail D02

be reinstated be reinstated be reinstated smooth and even with exposed ferrels which will

Beam above to Eng. detail

1 585

Verandah be architectural feature. The lines of the form

600

3 465

W1

(grano)

Slab line above

3 425

2 950

Upper Seating Area work to be exposed and finished smooth plumb

FFL - 1587.700

(Tier 4) Store room and consistent in colour. New and clean shutter

4 205

Upper Seating Area

FFL - 1593.645 (polished finish)

4 445

4 445

board to be used.

1 500

9,203 m2

6 360

EXISTING ADJACENT (Tier 3)

2 735

EXISTING ADJACENT FFL - 1593.145

FFL - 1593.645

· Facebrick : To match existing

TD3

PROPOSED NEW 80 115 OFFICE BLOCK

230

Existing Boardroom

6 085

OFFICES

1 010 80 1 010 1 930 950 1 025 240 · Allow for ruled joints between brickwork &

OFFICE BLOCK

65 115 495

865

concrete junctions.

D02

MH1

Upper Seating Area

1 500

Service Duct

· All fire doors to be connected to the fire detection

275

(Tier 2)

FFL - 1592.645

system.

B B B B

730

730

Ur.

115

concrete column to eng.

· The fire doors must be released open when the

2m High wall

2m High wall

WC WC WC WC

detail (smooth off shutter Paraplegic Ur. 115 2 250 fire detection system is activated.

1 500

finish)

1 121

936

(ceramic tiles) G

3,265 m2 5 079 500 5 153 500 6 648 2 365

Wb · Allow for aluminium cover strips at junction

Upper Seating Area

115 600

D03 D03 D03 1m High glass & steel balustrade

between internal brickwork and columns.

115

600

Slab line above D05

(Tier 1)

W1

Female Toilet Male Toilet

Elec. Data f.d

(ceramic tiles) (ceramic tiles)

-173mm Risers FFL - 1592.145

· All gound levels / lines are to be read in

1 200

1 200

1 270

UP Concrete Staircase as per grano grano F.H.R Sound

Concrete Staircase as per Down 1m High glass & steel balustrade

grano Room 6,930 m2 6,765 m2Wb. conjunction with the civil eng's drawings.

D04

D04

-173mm Risers grano

engineers details

385

D02 D02 D02 Wb. G engineers details

5 641

5 641

-280mm Threads

1 900

· Brickwork to be tied to concrete columns with

209 230

-280mm Threads D02

485

110

1m High glass & steel handrail

hoop iron ties to engineers specification (shot into

1 490 435

230 115 115 110 2 520 1 000 3 640 1 600 2 062

2 520 1 000 3 640 1 370 1 060 770 1 000 1 000 230 2 100 110 1 710 110 2 100 concrete & tied every 4th course)

EMERGENCY

476 1 490

8 760

D01

8 760

190 · Bitumen impregnated soft board joint between all

730 875 600

EXIT

D01

W1

ENTRANCE

1 968 115 1 156 864 135

concrete & brick work. Ends of soft board to be

MAIN

Concrete Beam to Eng. detail

2 720 raked out & sealed over

1 490

with polysulphide sealant. refer to detail.

20 630

19 900

19 900

D01

20 515

C C C C

600 695 730

concrete column to eng. · All sizing of rainwater downpipes & gutters to be

Canopy Roof line above

D02

1 635 230

detail (smooth off shutter confirmed by engineer.

490

1m High glass & steel balustrade

finish) R 5,000

Dia. 110mm Drainage pipe laid to 1:100 fall

9 343

· All cavity walls to comply with NBR KK 8.1

600

2 700

2 700

8 800

W1

Roof Below and SANS 10400-K:2011, 4.2.1.3

2 335

facebrick finish to external wall.

17 090

1 585

W1

outer face of inner skin to be Concrete Steps to eng. detail

bagged

and bitumen tarred. -160 Risers

609

-250 Threads

1 000

1 898

1 693

Slab line above

PROPOSED NEW HALL

D 200 seats D D D

Roller shutter door

Marmoleum Kitchen

2 000

concrete column to eng. detail 1 300

6 814

FFL - 1588.000

(ceramic tiles) (smooth off shutter finish) PROPOSED SEATING AREA

600

600

Concrete column to eng. detail (smooth

W1

W1

15,119 m2

off shutter finish)

2 945

A A A A

1 000

1 000

fr.

BELOW

706

1 900

1 900

Concrete Beam to Eng. detail

concrete floor

8 987

fr.

1m High glass & steel balustrade

Raised Platform slab to eng. detail

5 475

(Polished finish)

Down

Canopy Roof line above

1 635

(polished finish)

1m High glass & steel handrail

7 115

7 115

230

FFL - 1588.800

600

600

6 950

W1

W1

4 920

3 640

3 640

Si.

5 940

Planter

6 200

Concrete Staircase as per

Concrete Staircase as

1 418

per engineers details

230

1 898

Planter

3 192

facebrick finish to

external wall.

engineers details

4 065

4 835 outer face of inner

skin to be bagged

1 435 3 400 and bitumen tarred. 1 500 1 500 1 500 1 815

875

EMERGENCY

-280mm Threads

1 490

600

D01

115

EXIT

W1

238

concrete column to eng. detail

1 300

1 300

1 300

Access ramp to engineers detail (smooth off shutter finish) -160mm Risers

UP

Slope to fall 1:12

-160mm Risers

730 500

E E E E

820

-280mm Threads

Dia. 110mm Drainage pipe

Concrete Beam Above to Eng. detail Concrete Beam Above to Eng. detail

510

1 360

to existing sewer line

W1 W1 W1 W1 W1

365

1 300 3 080 3 225 powder coated

alum. windows

730 6 085 730 6 580 730 5 630 730 730 6 085 730 6 580 730 676 600 1 400 600 1 400 600 354 730 facebrick finish to external wall.

21 215 4 920 21 215 outer face of inner skin to be bagged

and bitumen tarred.

26 135

B B

1 2 3 4 5 1 2 3 4 5

FIRST FLOOR PLAN

GROUND FLOOR PLAN scale 1:100

LEGEND

scale 1:100

si - sink

fr - fridge

st - stove

shw - shower

wm - washing machine

dr - drying machine

wt - wash trough

FHR - Fire hose reel

Ur. - Urinal

Wc. - Water Closet

Wb. - Wash Basin

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-001

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

GROUND & FIRST FLOOR PLAN

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

GENERAL NOTES:

CLIENT APPROVAL · The design on this drawing is copyright & remains

USER DEPARTMENT (MARLBORO DEPOT) property of the Robust Consulting Engineers.

· All work to be carried out strictly in accordance

NAME: ............................................................ with municipal regulations, National Building

DESIGNATION: REGIONAL MANAGER Regulations and SANS 10400.

· Figured dimensions to be taken in preference to

SIGNATURE: ................................................. scaling drawings.

DATE: ............................................................ · All platforms and ground levels to Civil Engineer's

details.

PROJECT MANAGER CAPEX · All bulk sewer and stormwater reticulation to Civil

engineer's details and specifications. Internal

NAME: ............................................................ waste water reticulation and drainage to mechanical

DESIGNATION: ............................................. Engineer's details.

· All structural work to structural engineer's details

SIGNATURE: .................................................

and specifications.

DATE: ............................................................ · All Fire requirements to Mechanical engineers

detail and specifications.

FACILITY DEPARTMENT · All relevant details, levels & dimensions to be

checked on site before commencement of work.

NAME: ............................................................

· All drawings are to be checked by the main

DESIGNATION: ............................................. contractor & any discrepancies on the drawings or

SIGNATURE: ................................................. between the drawings are to be referred to the

Robust Consulting Engineers or relevant consultant

DATE: ............................................................ for clarity prior to any construction work.

· This drawing is to be read in conjunction to

OHS relevant consultant drawings and other detailed

1 2 3 4 5 NAME: ............................................................

·

drawing documentation.

Main Contractor/consultants to ensure that the

DESIGNATION: ............................................. latest drawings are referred to at all times.

275mmx80mm Nutec barge & fascia 275mmx80mm Nutec barge & fascia SIGNATURE: ................................................. The 'Drawing Revisions' column on this drawing to

boards or equally approved boards or equally approved be cross referenced with the latest issued drawing

DATE: ............................................................ register in this regard.

NOTES FOR ELECTRONIC DRAWINGS:

· This drawing may be issued electronically.

· This drawing may contain external references

100mm x100mm down pipes (xrefs) which would have been "bound" into the

A A drawing prior to issue.

NOTES:

· All drawings are to be read in conjunction with

fall fall floor plans, sections, elevations, schedules, roof

Mill finish 0.58mm

150mm wide x 100mm Chromadek Kliplok 700 & ceiling plans, and site plan.

deep aluminium gutter roof sheeting @ 5° roof · Finish to concrete: Un-plastered and un-painted

pitch. Concrete structure must be smooth, even

colouring, plumb with recessed joints rubbed

smooth and even with exposed ferrels which will

B B be architectural feature. The lines of the form

work to be exposed and finished smooth plumb

and consistent in colour. New and clean shutter

board to be used.

100mm x100mm down pipes · Facebrick : To match existing

· Allow for ruled joints between brickwork &

concrete junctions.

· All fire doors to be connected to the fire detection

system.

150mm wide x 100mm · The fire doors must be released open when the

deep aluminium gutter fire detection system is activated.

fall fall · Allow for aluminium cover strips at junction

between internal brickwork and columns.

· All gound levels / lines are to be read in

C C conjunction with the civil eng's drawings.

· Brickwork to be tied to concrete columns with

hoop iron ties to engineers specification (shot into

concrete & tied every 4th course)

· Bitumen impregnated soft board joint between all

100mm x100mm down pipes

concrete & brick work. Ends of soft board to be

D D raked out & sealed over

with polysulphide sealant. refer to detail.

· All sizing of rainwater downpipes & gutters to be

confirmed by engineer.

· All cavity walls to comply with NBR KK 8.1

and SANS 10400-K:2011, 4.2.1.3

Mill finish 0.58mm

150mm wide x 100mm Chromadek Kliplok 700

deep aluminium gutter roof sheeting @ 5° roof

fall fall

pitch.

100mm x100mm down pipes

E E

275mmx80mm Nutec barge & fascia 275mmx80mm Nutec barge & fascia

boards or equally approved boards or equally approved

1 2 3 4 5

ROOF PLAN

scale 1:100

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-002

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

ROOF PLAN

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

CLIENT APPROVAL

USER DEPARTMENT (MARLBORO DEPOT)

NAME: ............................................................

1 2 3 4 5

DESIGNATION: REGIONAL MANAGER

E D C B A 20 560 SIGNATURE: .................................................

6 890 4 415 2 895 6 360 DATE: ............................................................

19 900

7 115 2 700 5 641 4 445

PROJECT MANAGER CAPEX

NAME: ............................................................

Top of Roof Top of Roof Top of Roof Top of Roof

5°

1600.000 1600.000 1600.000 1600.000 DESIGNATION: .............................................

SIGNATURE: .................................................

Facebrick Facebrick Facebrick DATE: ............................................................

FACILITY DEPARTMENT

NAME: ............................................................

Upper Ceiling Lvl. Upper Ceiling Lvl. Upper Ceiling Lvl. Upper Ceiling Lvl.

1596.000 1596.000 1596.000 1596.000 DESIGNATION: .............................................

SIGNATURE: .................................................

DATE: ............................................................

Mez. Lvl. W01 W01 W01 W01 W01 W01 W01 Mez. Lvl. Mez. Lvl. W01 W01 W01 Mez. Lvl. OHS

1593.645 1593.645 1593.645 1593.645

NAME: ............................................................

Facebrick Facebrick Facebrick Facebrick Facebrick Facebrick

DESIGNATION: .............................................

First Floor Lvl. First Floor Lvl. First Floor Lvl. First Floor Lvl.

1592.145 1592.145 1592.145 1592.145 SIGNATURE: .................................................

DATE: ............................................................

D01 D01

D06 existing

Ground Floor Lvl. W01 W01 W01 window Ground Floor Lvl. Ground Floor Lvl. W01 W01 Ground Floor Lvl.

1588.000 1588.000 1588.000 1588.000

MH1

Dia. 110mm Drainage pipe laid to 1:100 fall

GENERAL NOTES:

· The design on this drawing is copyright & remains

1 2 3 4 5 property of the Robust Consulting Engineers.

· All work to be carried out strictly in accordance

E D C B A with municipal regulations, National Building

Regulations and SANS 10400.

· Figured dimensions to be taken in preference to

EAST ELEVATION SOUTH ELEVATION ·

scaling drawings.

All platforms and ground levels to Civil Engineer's

scale 1:100 scale 1:100 details.

· All bulk sewer and stormwater reticulation to Civil

engineer's details and specifications. Internal

waste water reticulation and drainage to mechanical

Engineer's details.

· All structural work to structural engineer's details

and specifications.

· All Fire requirements to Mechanical engineers

detail and specifications.

· All relevant details, levels & dimensions to be

checked on site before commencement of work.

· All drawings are to be checked by the main

contractor & any discrepancies on the drawings or

5 4 3 2 1 A B C D E between the drawings are to be referred to the

Robust Consulting Engineers or relevant consultant

20 560

19 900 for clarity prior to any construction work.

4 445 5 641 2 700 7 115 · This drawing is to be read in conjunction to

6 360 2 895 4 415 6 890

relevant consultant drawings and other detailed

drawing documentation.

Top of Roof Top of Roof Top of Roof Top of Roof · Main Contractor/consultants to ensure that the

1600.000 1600.000 1600.000 1600.000 latest drawings are referred to at all times.

The 'Drawing Revisions' column on this drawing to

5°

Mill finish 0.58mm Chromadek Kliplok 700 roof sheeting @ 5° roof pitch. be cross referenced with the latest issued drawing

register in this regard.

NOTES FOR ELECTRONIC DRAWINGS:

· This drawing may be issued electronically.

Upper Ceiling Lvl. Upper Ceiling Lvl. Upper Ceiling Lvl. Upper Ceiling Lvl. · This drawing may contain external references

1596.000 1596.000 1596.000 1596.000 (xrefs) which would have been "bound" into the

drawing prior to issue.

Facebrick Facebrick

NOTES:

Mez. Lvl. W01 W01 W01 W01 W01 W01 W01 Mez. Lvl. Mez. Lvl. Mez. Lvl.

· All drawings are to be read in conjunction with

1593.645 1593.645 1593.645 1593.645 floor plans, sections, elevations, schedules, roof

Facebrick Facebrick Facebrick & ceiling plans, and site plan.

· Finish to concrete: Un-plastered and un-painted

First Floor Lvl. First Floor Lvl. First Floor Lvl. First Floor Lvl. Concrete structure must be smooth, even

1592.145 1592.145 1592.145 1592.145

colouring, plumb with recessed joints rubbed

EXISTING ADJACENT smooth and even with exposed ferrels which will

OFFICE BLOCK be architectural feature. The lines of the form

work to be exposed and finished smooth plumb

and consistent in colour. New and clean shutter

board to be used.

Facebrick · Facebrick : To match existing

D01 D01 · Allow for ruled joints between brickwork &

existing existing existing

window window window

concrete junctions.

Ground Floor Lvl. Ground Floor Lvl. Ground Floor Lvl. Ground Floor Lvl. · All fire doors to be connected to the fire detection

1588.000 1588.000 1588.000 1588.000 system.

· The fire doors must be released open when the

fire detection system is activated.

· Allow for aluminium cover strips at junction

between internal brickwork and columns.

· All gound levels / lines are to be read in

conjunction with the civil eng's drawings.

· Brickwork to be tied to concrete columns with

hoop iron ties to engineers specification (shot into

5 4 3 2 1 A B C D E concrete & tied every 4th course)

· Bitumen impregnated soft board joint between all

concrete & brick work. Ends of soft board to be

raked out & sealed over

NORTH ELEVATION WEST ELEVATION ·

with polysulphide sealant. refer to detail.

All sizing of rainwater downpipes & gutters to be

scale 1:100 scale 1:100 confirmed by engineer.

· All cavity walls to comply with NBR KK 8.1

and SANS 10400-K:2011, 4.2.1.3

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-003

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

ELEVATIONS

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

GENERAL NOTES:

CLIENT APPROVAL · The design on this drawing is copyright & remains

USER DEPARTMENT (MARLBORO DEPOT) property of the Robust Consulting Engineers.

· All work to be carried out strictly in accordance

NAME: ............................................................ with municipal regulations, National Building

DESIGNATION: REGIONAL MANAGER Regulations and SANS 10400.

· Figured dimensions to be taken in preference to

SIGNATURE: ................................................. scaling drawings.

DATE: ............................................................ · All platforms and ground levels to Civil Engineer's

details.

PROJECT MANAGER CAPEX · All bulk sewer and stormwater reticulation to Civil

engineer's details and specifications. Internal

NAME: ............................................................ waste water reticulation and drainage to mechanical

1 2 3 4 5

DESIGNATION: ............................................. Engineer's details.

20 560 · All structural work to structural engineer's details

SIGNATURE: .................................................

and specifications.

6 890 4 415 2 895 6 360 DATE: ............................................................ · All Fire requirements to Mechanical engineers

detail and specifications.

Top of Roof Top of Roof

c-channel to Eng's spec 1600.000 FACILITY DEPARTMENT · All relevant details, levels & dimensions to be

1600.000 Mill finish 0.58mm Chromadek Kliplok

700 roof sheeting @ 5° roof pitch. 5°

checked on site before commencement of work.

100mm thick Factory Lite Foil insulation between purlins and NAME: ............................................................

· All drawings are to be checked by the main

sheeting, white pvc coated straining wires, below roofs that

have ceilings. Refelctive foil sisilation to be included to DESIGNATION: ............................................. contractor & any discrepancies on the drawings or

175mm x 350mm Aluminium gutter

satisfy minimum thermal insulation as per SANS 10400.

SIGNATURE: ................................................. between the drawings are to be referred to the

Steel truss @ 50fall, to Eng's design & specifications Note: Allow minimum 15mm air space between sisilation & Robust Consulting Engineers or relevant consultant

roof sheeting. DATE: ............................................................

R.C ring beam to eng. detail (smooth off

for clarity prior to any construction work.

· This drawing is to be read in conjunction to

600

shutter finish). Top of toe to be at grade.

Upper Ceiling Lvl. Upper Ceiling Lvl.

1596.000

OHS relevant consultant drawings and other detailed

1596.000

600 600

Suspended ceiling as per spec Suspended ceiling as per spec

NAME: ............................................................ drawing documentation.

Raked Ceiling · Main Contractor/consultants to ensure that the

2 355

Pelican Systems Econocoust Silica Sand 600 x 600 x 15mm thick white DESIGNATION: .............................................

R.C ring beam to eng. detail (smooth off square edged ceiling tiles, laid on 24mm wide x 38mm high pre-painted latest drawings are referred to at all times.

shutter finish). Top of toe to be at grade. Exposed Econogrid tee suspension system, including all necessary hangers, Reinforced concrete slab as per engineers details

1 155

SIGNATURE: ................................................. The 'Drawing Revisions' column on this drawing to

grids and hold down clips. Ceiling perimeter to be finished with prepainted

500

be cross referenced with the latest issued drawing

11 378

Mez. Lvl. shadow trims. Mez. Lvl.

1593.645

FIRST FLOOR GALLERY 1593.645

DATE: ............................................................ register in this regard.

1 500

500

Entrance canopy to match NOTES FOR ELECTRONIC DRAWINGS:

First Floor Lvl. existing to engineers detail First Floor Lvl. · This drawing may be issued electronically.

8 000

500

1592.145

Suspended ceiling 1592.145 · This drawing may contain external references

Pelican Systems Econocoust Silica Sand 600 x 600 x 15mm thick (xrefs) which would have been "bound" into the

white square edged ceiling tiles, laid on 24mm wide x 38mm high

pre-painted Exposed Econogrid tee suspension system, including all

drawing prior to issue.

necessary hangers, grids and hold down clips. Ceiling perimeter to be

GROUND FLOOR AUDITORIUM Kitchen finished with prepainted shadow trims.

marmoleum ceramic tiles Reinforced concrete slab as per engineers details

NOTES:

4 145

Internal walls to receive Min. 15mm Internal walls to receive Min. 15mm · All drawings are to be read in conjunction with

Facebrick wall, outer face of inner cement plaster applied in one operation cement plaster applied in one

skin to be bagged and bitumen

tarred. operation and finished with a steel floor plans, sections, elevations, schedules, roof

and finished with a steel trowel trowel

& ceiling plans, and site plan.

rubble fill · Finish to concrete: Un-plastered and un-painted

Ground Floor Lvl. Ground Floor Lvl.

1588.000 1588.000 Concrete structure must be smooth, even

Floor finish as chosen by client on,33mm grano cement screed on, colouring, plumb with recessed joints rubbed

100mm Oversite concrete, on 50mm Sand blinding, on at least smooth and even with exposed ferrels which will

150mm Hard core, Earthwork as per Geotechnical report details

be architectural feature. The lines of the form

Concrete Foundation to Engineer's design Concrete Foundation to Engineer's design work to be exposed and finished smooth plumb

and consistent in colour. New and clean shutter

board to be used.

· Facebrick : To match existing

· Allow for ruled joints between brickwork &

SECTION A - A ·

concrete junctions.

All fire doors to be connected to the fire detection

scale 1:100 system.

· The fire doors must be released open when the

fire detection system is activated.

· Allow for aluminium cover strips at junction

between internal brickwork and columns.

· All gound levels / lines are to be read in

conjunction with the civil eng's drawings.

· Brickwork to be tied to concrete columns with

hoop iron ties to engineers specification (shot into

concrete & tied every 4th course)

· Bitumen impregnated soft board joint between all

concrete & brick work. Ends of soft board to be

raked out & sealed over

A B C D E with polysulphide sealant. refer to detail.

19 900

· All sizing of rainwater downpipes & gutters to be

4 445 5 641 2 700 7 115

confirmed by engineer.

Mill finish 0.58mm Chromadek 100mm thick Factory Lite Foil insulation between purlins and sheeting, white pvc coated straining wires, below roofs that have ceilings. · All cavity walls to comply with NBR KK 8.1

Kliplok 700 roof sheeting @ 5° Refelctive foil sisilation to be included to satisfy minimum thermal insulation as per SANS 10400.

Note: Allow minimum 15mm air space between sisilation & roof sheeting.

and SANS 10400-K:2011, 4.2.1.3

Top of Roof roof pitch. Top of Roof

1600.000 1600.000

2 778

R.C ring beam to eng. detail

(smooth off shutter finish).

Top of toe to be at grade.

600

Upper Ceiling Lvl. Upper Ceiling Lvl.

1596.000 1596.000

600

Facebrick wall, outer face of

inner skin to be bagged and Raked Ceiling

2 355

Pelican Systems Econocoust Silica Sand 600 x 600 x 15mm thick white

bitumen tarred.

500 1 755

Reinforced concrete slab square edged ceiling tiles, laid on 24mm wide x 38mm high pre-painted

as per engineers details Exposed Econogrid tee suspension system, including all necessary hangers,

grids and hold down clips. Ceiling perimeter to be finished with prepainted

11 378

11 378

Mez. Lvl. shadow trims. Mez. Lvl.

1593.645

1593.645

1 500

500

2 580

First Floor Lvl. First Floor Lvl.

8 000

2 240 500

1592.145

1592.145

5 645

Reinforced

concrete slab

GROUND FLOOR AUDITORIUM as per engineers

4 145

Fire escape staircase steel Reinforced

marmoleum details

as per engineers details concrete

Internal walls to receive Min. 15mm cement plaster

staircase

3 065

EXISTING applied in one operation and finished with a steel trowel

1 905

as per engineers

BOARDROOM

details

Ground Floor Lvl. Ground Floor Lvl.

1588.000 1588.000

Floor finish as chosen by client on,33mm grano cement screed on,

100mm Oversite concrete, on 50mm Sand blinding, on at least

150mm Hard core, Earthwork as per Geotechnical report details

0 = (+1588.000)

SECTION B - B

scale 1:100

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-004

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

SECTIONS A & B

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

GENERAL NOTES:

CLIENT APPROVAL · The design on this drawing is copyright & remains

USER DEPARTMENT (MARLBORO DEPOT) property of the Robust Consulting Engineers.

· All work to be carried out strictly in accordance

NAME: ............................................................ with municipal regulations, National Building

DESIGNATION: REGIONAL MANAGER Regulations and SANS 10400.

· Figured dimensions to be taken in preference to

SIGNATURE: ................................................. scaling drawings.

DOOR TYPE

DOOR TYPE

DOOR TYPE

DOOR TYPE

D-01 D-02 D-03 D-04

DATE: ............................................................ · All platforms and ground levels to Civil Engineer's

details.

PROJECT MANAGER CAPEX · All bulk sewer and stormwater reticulation to Civil

R.B.L +2.400 R.B.L +2.400 R.B.L +2.400

L.L +2.100 L.L +2.100 DOOR HEIGHT +2.100 L.L +2.100 engineer's details and specifications. Internal

FIX

NAME: ............................................................ waste water reticulation and drainage to mechanical

5MM CLEARANCE

5MM CLEARANCE

RIGHT ROUND

RIGHT ROUND 5MM CLEARANCE

RIGHT ROUND DESIGNATION: ............................................. Engineer's details.

OUTSIDE INSIDE INSIDE OUTSIDE INSIDE OUTSIDE INSIDE OUTSIDE · All structural work to structural engineer's details

SIGNATURE: .................................................

and specifications.

weather bar

F.F.L 0.000 F.F.L +/-0.000

OPENING

F.F.L +/-0.000 F.F.L +/-0.000 DATE: ............................................................ · All Fire requirements to Mechanical engineers

detail and specifications.

FACILITY DEPARTMENT · All relevant details, levels & dimensions to be

INSIDE

INSIDE INSIDE checked on site before commencement of work.

NAME: ............................................................

INSIDE

· All drawings are to be checked by the main

OUTSIDE

OUTSIDE

OUTSIDE OUTSIDE

DESIGNATION: ............................................. contractor & any discrepancies on the drawings or

SCALE 1:50 SCALE 1:50 SCALE 1:50 SCALE 1:50

SIGNATURE: ................................................. between the drawings are to be referred to the

Robust Consulting Engineers or relevant consultant

DATE: ............................................................ for clarity prior to any construction work.

· This drawing is to be read in conjunction to

OHS relevant consultant drawings and other detailed

drawing documentation.

WALL LOCATION

WALL LOCATION

WALL LOCATION

WALL LOCATION

LOCATION EXTERNAL: MAIN ENTRANCES LOCATION INTERNAL: ELECTRICAL, DATA, SOUND ROOM, KITCHEN, STOREROOM, FIRE ESCAPE LOCATION INTERNAL: TOILET CUBICLES LOCATION INTERNAL: TOILET ENTRANCE

NAME: ............................................................

DOOR NUMBER D-01 QUANTITY: LH RLH RH RRH DOOR NUMBER D-02 QUANTITY: LH RLH RH RRH DOOR NUMBER D-03 QUANTITY: LH RLH RH RRH DOOR NUMBER D-04 QUANTITY: LH RLH RH RRH

· Main Contractor/consultants to ensure that the

4 1 06 01 06 3 1 2 02 01 01 DESIGNATION: ............................................. latest drawings are referred to at all times.

CONSTRUCTION 230MM MASONRY CONSTRUCTION, CONCRETE RING BEAM @ 2.400M HEIGHT CONSTRUCTION 13 ON 115MM MASONRY CONSTRUCTION, 2 ON 230MM MASONRY CONSTRUCTION

, 2 ON 90MM ALUMINIUM PARTITION BOARDS

CONSTRUCTION

50MM TIMBER PARTITIONS IN ALUMINIUM C-CHANNELS ON EDGE

CONSTRUCTION 13 ON 115MM MASONRY CONSTRUCTION, 2 ON 230MM MASONRY CONSTRUCTION

, 2 ON 90MM ALUMINIUM PARTITION BOARDS SIGNATURE: ................................................. The 'Drawing Revisions' column on this drawing to

OPENING SIZE 1800MM X 2400MM DOOR OPENING OPENING SIZE 800MM X 2135MM DOOR OPENING

be cross referenced with the latest issued drawing

OPENING SIZE 900MM X 2135MM DOOR OPENING OPENING SIZE 900MM X 2135MM DOOR OPENING, 900MM X 200MM TOPLIGHT WINDOW

DATE: ............................................................ register in this regard.

75MM X 45MM X 2MM ALUMINIUM FRAME SECTION ANCHORED IN BRICK WALL, WITH 5MM 75MM X 45MM X 2MM ALUMINIUM FRAME SECTION ANCHORED IN BRICK WALL, WITH 5MM

FRAME

FRAME

FRAME

FRAME

DESCRIPTION 75MM X 45MM X 2MM ALUMINIUM FRAME ANCHORED IN BRICK WALL DESCRIPTION DESCRIPTION FRAME TO SPECIALIST'S DETAILS AND SPECIFICATIONS DESCRIPTION

CLEARANCE RIGHT ROUND AGAINST THE WALLS CLEARANCE RIGHT ROUND AGAINST THE WALLS

FINISH POWDER COATED ALUMINIUM FRAMES, COLOUR BLACK

FINISH POWDER COATED ALUMINIUM FRAMES, NATURAL FINISH POWDER COATED ALUMINIUM FRAMES, NATURAL FINISH POWDER COATED ALUMINIUM FRAMES, NATURAL NOTES FOR ELECTRONIC DRAWINGS:

DESCRIPTION 45MM THICK SWING ALUMINIUM DOUBLE DOOR, OPENING INWARDS, OUTSIDE WEATHER DESCRIPTION 40MM SOLID CORE FLUSH PANEL STANDARD DOOR WITH 3.2 MM HARDBOARD DESCRIPTION 35MM SOLID CORE FLUSH PANEL DOOR WITH, CONCEALED EDGES HUNG ON DESCRIPTION 40MM SOLID CORE FLUSH PANEL STANDARD DOOR WITH 3.2 MM HARDBOARD · This drawing may be issued electronically.

BAR ON BOTH DOOR LEAVES COVERING ON BOTH SIDES AND CONCEALED EDGES HUNG ON ALUMINIUM FRAME ALUMINIUM C-CHANNEL FRAME COVERING ON BOTH SIDES AND CONCEALED EDGES HUNG ON ALUMINIUM FRAME

· This drawing may contain external references

DOOR

DOOR

DOOR

DOOR

FINISH SAND PAPERED, SEALED PRIMED, 3 COATS OF GLASS ENAMEL PAINT, COLOUR TO FINISH SAND PAPERED, SEALED PRIMED, 3 COATS OF GLASS ENAMEL PAINT, COLOUR TO FINISH SAND PAPERED, SEALED PRIMED, 3 COATS OF GLASS ENAMEL PAINT, COLOUR TO

FINISH POWDER COATED ALUMINIUM FRAMES, COLOUR BLACK

CLIENT'S DISCRETION CLIENT'S DISCRETION CLIENT'S DISCRETION

(xrefs) which would have been "bound" into the

GLAZING 3MM + 3MM LAMINATED SAFETY GLASS PANES, LOW E GLASS GLAZING GLAZING GLAZING drawing prior to issue.

NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER

HINGES 3 ALUMINIUM REFLEX HINGES WITH NYLON BUSHES , REFER TO IRONMONGER SCHEDULE HINGES 2 ALUMINIUM REFLEX HINGES WITH NYLON BUSHES , REFER TO IRONMONGER SCHEDULE HINGES 2 ALUMINIUM REFLEX HINGES WITH NYLON BUSHES , REFER TO IRONMONGER SCHEDULE HINGES 2 ALUMINIUM REFLEX HINGES WITH NYLON BUSHES , REFER TO IRONMONGER SCHEDULE

NOTES:

IRONMONGERY

IRONMONGERY

IRONMONGERY

IRONMONGERY

PULL HANDLES 2 HANDLE BARS (1 OUTSIDE & 1 INSIDE) , REFER TO IRONMONGER SCHEDULE PULL HANDLES PULL HANDLES PULL HANDLES

· All drawings are to be read in conjunction with

LOCK SET REFER TO IRONMONGER SCHEDULE LOCK SET REFER TO IRONMONGER SCHEDULE LOCK SET REFER TO IRONMONGER SCHEDULE LOCK SET REFER TO IRONMONGER SCHEDULE

floor plans, sections, elevations, schedules, roof

DOOR STOP 2 DOOR STOPS FOR EACH DOOR LEAF DOOR STOP DOOR STOP DOOR STOP

& ceiling plans, and site plan.

FLUSH BOLTS FLUSH BOLTS FLUSH BOLTS FLUSH BOLTS

· Finish to concrete: Un-plastered and un-painted

DOOR CLOSER DOOR CLOSER DOOR CLOSER DOOR CLOSER

Concrete structure must be smooth, even

DOOR SPRINGS DOOR SPRINGS DOOR SPRINGS DOOR SPRINGS

colouring, plumb with recessed joints rubbed

smooth and even with exposed ferrels which will

be architectural feature. The lines of the form

DOOR TYPE

D-05

DOOR TYPE

D-06 W-07

work to be exposed and finished smooth plumb

u/s of lintel 2400.00

ELEVATION and consistent in colour. New and clean shutter

R.B.L +2.400 R.B.L +2.400

board to be used.

L.L +2.100 800 L.L +2.100

[ WINDOWS

· Facebrick : To match existing

5MM CLEARANCE

VIEWED · Allow for ruled joints between brickwork &

EXTERNALLY ]

RIGHT ROUND concrete junctions.

1 930

INSIDE OUTSIDE

2 100

INSIDE OUTSIDE

ffl toc

· All fire doors to be connected to the fire detection

system.

KICK PLATE F.F.L +/-0.000 F.F.L +/-0.000 · The fire doors must be released open when the

170

2 BRICK COURSE 2 BRICK COURSE fire detection system is activated.

PLAN

EXTERNAL · Allow for aluminium cover strips at junction

INSIDE INSIDE

SCALE 1:50 between internal brickwork and columns.

OUTSIDE TOTAL 22

· All gound levels / lines are to be read in

OUTSIDE 800

SCALE 1:50 SCALE 1:50

conjunction with the civil eng's drawings.

AREAS MAIN AUDITORIUM, KITCHEN, STORE ROOM · Brickwork to be tied to concrete columns with

hoop iron ties to engineers specification (shot into

NUMBER W-01 concrete & tied every 4th course)

DESCRIPTION PURPOSE MADE RIBBON ALUMINIUM CASEMENT TO SPECIALIST DETAIL · Bitumen impregnated soft board joint between all

4mm CLEAR LOW E GLASS ON DEFAULT ALUMINIUM FRAME WITH A

U-value, 5.73 and SHGc of 0.6 concrete & brick work. Ends of soft board to be

WALL LOCATION

LOCATION INTERNAL: PARAPLEGIC ABLUTIONS CILL EXTERNAL: BRICK ON EDGE

WALL LOCATION

LOCATION ABLUTIONS DUCTS

CILL INTERNAL: FIBRE CEMENT raked out & sealed over

DOOR NUMBER D-05 QUANTITY: LH RLH RH RRH DOOR NUMBER D-06 QUANTITY: LH RLH RH RRH GLASS 4MM CLEAR FLOAT GLASS WITH RUBBER SEAL with polysulphide sealant. refer to detail.

1 1 1

FITTINGS FIXED TO FRAME BY MANUFACTURER / SPECIALIST · All sizing of rainwater downpipes & gutters to be

CONSTRUCTION 2 ON 115MM MASONRY CONSTRUCTION, SOLDIER BRICK LINTEL @ 2.100M HEIGHT CONSTRUCTION 3 ON 230MM MASONRY CONSTRUCTION, BRICK ON EDGR LINTEL @ 2.100M

HEIGHT AND CONCRETE RING BEAM @ 2.400M HEIGHT FINISH POWDER COATED ALUMINIUM FRAMES

confirmed by engineer.

OPENING SIZE 1000MM X 2135MM DOOR OPENING OPENING SIZE 800MM X 2135MM DOOR OPENING

· All cavity walls to comply with NBR KK 8.1

75MM X 45MM X 2MM ALUMINIUM FRAME SECTION ANCHORED IN BRICK WALL, WITH 5MM and SANS 10400-K:2011, 4.2.1.3

FRAME

DESCRIPTION 45MM X 45MM X 2MM ALUMINIUM FRAME SECTION ANCHORED IN BRICK WALL, WITH 5MM

FRAME

DESCRIPTION NOTES ALUMINIUN FRAMES

CLEARANCE RIGHT ROUND AGAINST THE WALLS CLEARANCE RIGHT ROUND AGAINST THE WALLS

FINISH POWDER COATED ALUMINIUM FRAMES, NATURAL FINISH POWDER COATED ALUMINIUM FRAMES, NATURAL

DESCRIPTION 40MM SOLID CORE FLUSH PANEL STANDARD DOOR WITH 3.2 MM HARDBOARD

DESCRIPTION 30MM ALUMINIUM BOX SECTIONS, WITH ALUMINIUM PANEL IN-FILL, SCREWED IN FRAME

COVERING ON BOTH SIDES AND CONCEALED EDGES HUNG ON ALUMINIUM FRAME

DOOR

DOOR

FINISH SAND PAPERED, SEALED PRIMED, 3 COATS OF GLASS ENAMEL PAINT, COLOUR TO FINISH

POWDER COATED ALUMINIUM PANEL WITH NATURAL FINISH

CLIENT'S DISCRETION

GLAZING GLAZING

NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER NOTE ALL SPECIFICATIONS TO BE CHECKED BY MANUFACTURER

HINGES 2 ALUMINIUM REFLEX HINGES WITH NYLON BUSHES , REFER TO IRONMONGER SCHEDULE HINGES SCREWS TO MANUFACTURER'S DETAILS

IRONMONGERY

IRONMONGERY

PULL HANDLES PULL HANDLES

LOCK SET REFER TO IRONMONGER SCHEDULE LOCK SET

DOOR STOP DOOR STOP

FLUSH BOLTS FLUSH BOLTS

DOOR CLOSER DOOR CLOSER

DOOR SPRINGS DOOR SPRINGS

DOOR SCHEDULE

NOTE: THIS DRAWING IS TO READ IN CONJUNCTION WITH THE FLOOR PLANS

SPECIALIST TO MEASURE DOOR AND WINDOW OPENINGS ON SITE BEFORE INSTALLING WINDOWS AND DOORS

SHOP DRAWINGS TO BE APPROVED BY THE ARCHITECT BEFORE MANUFACTURE ALL PURPOSE MADE DOORS

AND FRAMES.

THE ARCHITECT DRAWING REMAINS THE PRIMARY INDICATOR OF THE DESIGN INTENT AND CANNOT BE

SUPERSEEDED BY THE SPECIALIST SHOP DRAWINGS

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-005

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

WINDOW & DOOR SCHEDULES

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

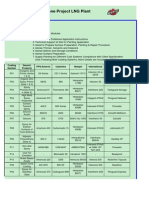

Floors Walls Ceilings Skirting Type Specifications

Disa. Type Specifications

General

Floors Grab

W.C W.h.b Taps S1 W.C

Spec F1 Marmoleum Rails

- "Jika - DINO" White - Wall-Hung Toilet (Code : 8.2137.0.000.3)

Supply and fix 2,5mm thick x 2m wide Marmoleum Piano/Striata Sheeting manufactured by Forbo - "Jika - DINO" - Toilet Seat & Cover - White. (Code : 8.9337.0.000.1)

Type S10 - Paraplegic Cistern Back Rail

Flooring Systems or similar approved, laid in Contact adhesive and in accordance with - Geberit: Kombifix wall mounting element for wall hung pans. (Code : G110.350.00.5)

Finishing Schedule manufacturers recommendations. Sheets to be laid strictly to manufacturers' specifications &

Type S7 - WH Basin Tap (Paraplegic)

- Geberit: WC flush control, pneumatic single flush. (Code: 115.943.21.1)

New Hall instructions. NOTE: Sheeting to be laid on category B (as measured by 'BRE' tester), class 1 - All WC and Cisterns to be supplied with matching seals, rubbers, connectors and all other

Type S5 - WH Basin (Paraplegic)

cement screed, with smooth steel trowelled finish. All imperfections to screed to be suitably

Type S9 - Paraplegic Angle Bar

Spec W3: Smooth Offshutter Concrete

relevant accessories.

repaired to achieve a smooth level finish. Floor to be free of all loose material/debris/contaminants Sanitary Schedule: - Installation and fixings to be as per the manufacturers specifications.

Spec W5: Face Brick External walls

Spec C4: Hanging Ceiling element

and moisture prior to laying of vinyl sheets. New Hall

Type S2 - Paraplegic W.C

Spec C2: Plasterboard bulkhead

Type S6 - WH Basin Tap

S2 Paraplegic W.C

Spec W1: Plastered & Painted

Spec C1: Off-Shutter Concrete

NOTE: Only approved installers to be used.

Spec W2: Bag washed walls

All floors to be tested for moisture content prior to installation.

Type S8 - Sink Mixer

- "Jika Olymp" wall hung paraplegic pan and seat cover ,suitable for handicapped special length of

Type S4 - WH Basin

Spec W4: Porcelain Tiles

Type S11 - Mirrors

70cm ,sitting height of 50cm. Color - White (Code 8.2064.2.000.1)

Spec S3: Porcelain Tiles

Spec F3: Porcelain Tiles

Spec F2: Grano Screed

Spec F2 Grano

Type S3 - Urinal

Type S12 - Sink

- Geberit: Kombifix wall mounting element for wall hung pans. (Code : G110.350.00.5)

Spec S1: Marmoleum

Spec F1: Marmoleum

Spec C3: Ceiling tiles

Type S1 - W.C

Spec S4: Aluminium

Min. 40 thick Grano screed of 30mpa strength. Screed to receive smooth steel trowelled finish. - Geberit: Delta 15 Actuator Plate - Stainless Steel - Flush Actuator. (Code : 115.101.00.1)

- All WC and Cisterns to be supplied with matching seals, rubbers, connectors and all other

Spec S2: Grano

Spec F3 Porcelain Tiles relevant accessories.

300x300x7.8mm Full bodied porcelain tiles. Code : 'MML R26' & 'MML R29' Pizarra Range, as per - Installation and fixings to be as per the manufacturers specifications.

Union tiles or equal and approved. Colours (R26: Black & R29: Grey) to be mixed in a 50/50 ratio. Room Name

Room Name S3 Urinal

Ground Floor Appropriate adhesive & installation to be strictly to manufacturer's specification. Tiles to be laid Ground Floor "Jika GOLEM" urinal with installation kit, rubber bung & urinal trap

with 5mm joints with tile expansion joints at 5m centres (both ways) on surface bed, and 3m Male Ablutions 1 2 1 1 1 (Code : 8.4306.0.000.1)

Stair 01 centres (both ways) on suspended slabs. Expansion centres must be confirmed with tile - "Geberit" urinal flush actuator housing. (Code : GEB116.004.00.1)

Male/Female Disabled W.c 1 1 1 1 1 1

Stair 02 manufacturer. Expansion joints to black tiles to receive 'AMJ 100.08 B' movement strips & AMJ - "Geberit Contract" - Actuator Plate (Code : 116.015.SN.1)

100.09 G movement strips for Grey tiles as per 'Kirk Marketing'. Female Ablutions 2 1 1 1 - All WC and Cisterns to be supplied with matching seals, rubbers, connectors and all

Main Hall Area

Allow for ASE 100.1N aluminium edgetrim by Kirk marketing to all waists & nosing. Kitchen 1 1 other relevant accessories.

Ducts (fhr/ data/ elec./Sound) - Installation and fixings to be as per the manufacturers specifications.

Kitchen Grouting to have high flexibilty, high anti-abrasive and anti-bacterial properties. (Colour : Dove TOTAL 3 1 2 2 1 2 1 1 1 1 3 1

Grey) S4 WH Basin

Ablution (Paraplegic)

NOTE: No tile fix or grouting between the wall and floor tile junction. Joint to be min 5mm wide - "Laufen Jika" ibon drop in basin 560x475 - Color White (Code 8.1301.1)

Ablutions (male & female) and kept free of all debris. Sample of all items to be provided for approval, prior to placing final orders. - "Giobella - Gio" - Waste And Overflows Bottle Trap (Code : A186)

Approved samples to remain in the sample room for the duration of the - All WHB's to be supplied with matching seals, rubbers, connectors and all other relevant accessories.

First Floor Only approved installers to be used. - Chrome plated bottle traps to suit pipe size and waste outlet size.

Seating Area

contract. - Installation and fixings to be as per the manufacturers specifications

Walls

Store Room

All sanitary ware and fittings to comply with SABS standards. S5 WH Basin (Paraplegic)

Spec W1 Plastered Walls (internal)

15mm thick plaster to comply with SANS 2001-EMI:2007.

All quantities to be verified in conjunction with Floor plans prior to placing -"Jika - MIO" Hospital Basin 64cm with one tap hole for paraplegic application (Code 8.1371.4.104.1)

Minor imperfections/fine plaster cracks to be remedied with "Polycell Polyfiller" or equal and final orders. -"Giobella - Gio" - Waste And Overflows Bottle Trap. (Code : A186)

approved suitable compound. Remedial work to be sanded smooth prior to painting. Substrate to - All WHB's to be supplied with matching seals, rubbers, connectors and all other relevant accessories.

be suitably prepared strictly to paint manufacturer's specifications/instructions. - Chrome plated bottle traps to suit pipe size and waste outlet size.

Finish : - Installation and fixings to be as per the manufacturers specifications.

Apply 1 Coat alkali resistant Professional Plaster Primer (Code: PP700), as per Plascon & 2 coats S6 WH Basin Tap

'Wall & All" as per 'Plascon Paints' (or similar approved) on brick works & 3 coats for patitions.

Additional coats maybe required in order to achieve desired finish. Colours to be confirmed. - "Hansgrohe - LOGIS SQUARE" - Tap - Single Lever Basin Mixer

- Code : HG71070

Spec W2 Bag Washed Walls - 2 x Hansgrohe - Valves - Chrome - Angle valve & Compression nut 10mm X 15mm

A three coat system of Professional Copolymer Acrylic over Plaster Primer. - Code : HG90610800

· Professional Plaster Prime (PP 700)

S7 WH Basin Tap (Paraplegic)

· Plascon Mineral Turpentin (AZH 1)

· Professional Copolymer Acrylic (PEM 600) - "Hansgrohe" - E2 - Single lever basin mixer 70 with pop-up waste set and extra long handle

· Approved Plascon system - Code : HG31910

· One coat Professional Plaster Primer. - 2 x Hansgrohe - Valves - Chrome - Angle valve & Compression nut 10mm X 15mm

· Two coats Professional Copolymer Acrylic. - Code : HG90610800

· Surface preparation, coating and application to be as per the manufacturers - Installation and fixings to be as per the manufacturers specifications.

specification. S8 Sink Mixer

Spec W3 Off-Shutter Concrete Cobra: Sink Mixer

Smooth off-shutter concrete with reasonably consistent colour. Ferrules to be exposed (holes to - Cobra 'Ledimo' LO-296 -One hole sink mixer with aerated swivel outlet. 12" BSP female inlet.

be grouted). SANS 226 - Type 2

Concrete surface may be required to be rubbed down smooth with Carborundum stone to S9 Paraplegic Angle Bar

achieve desired finish to architect's approval. Any imperfections on wall to be suitably repaired(as

- Franke grab rail (Angle Bar 135 CNTX700A-code. 359877) with Franke fine grip to prevent slipping with

per methodology approved by engineer).

an ergonomically, comfortable diameter of 32mm. Mounting plates for easy mounting. Covers in

Porcelain Tiles stainless steel. Screws & dowels included. H=256 W=618 D=95.

Spec W4

300x300x7.8mm Full bodied porcelain tiles to be installed to a height of 1.5m above F.F.L. S10 Paraplegic Cistern Back Rail

Code : 'MML R26' & 'MML R29' Pizarra Range, as per Union tiles or equal and approved. Colours - Franke grab rail (Grab Bar CNTX750-code. 359874) with Franke fine grip to prevent slipping with an

(R26: Black & R29: Grey) to be mixed in a 50/50 ratio. ergonomically, comfortable diameter of 32mm. Mounting plates for easy mounting. Covers in

stainless steel. Screws & dowels included. W=750 D=95.

Appropriate adhesive & installation to be strictly to manufacturer's specification. Tiles to be laid with

5mm joints. Expansion centres as required to be confirmed with tile manufacturer. S11 Mirrors

Allow for ASE 100.1N aluminium edgetrim by Kirk marketing.

- Mirrors to be fitted into aluminium frames that are to be fixed to the wall above the whb's.

Frames to be fixed to walls with nickel plated chrome domed screws. (900mm x 600mm)

Grouting to match floor tiles.

Only approved installers to be used.

S12 Sink

Spec W5 Face Brick External walls

- Franke Model Cascade CDX 621-120 Stainless Steel

Face brick with well raked and ruled joints. - 1200 x 500 x 157mm deep, manufactured from grade 304 (18 / 10) Stainless Steel

All to match existing.

Ceilings

Spec C1 Off-Shutter Concrete

Smooth off-shutter concrete with reasonably consistent colour. Ferrules to be covered. Concrete

surface may be required to be rubbed down smooth with Carborundum Stone to achieve desired

finish to architects approval. Any imperfections on ceiling to be suitably repaired(as per

methodology approved by engineer).

Spec C2 Plasterboard Bulkheads

Supply & install Jumbo Plasterboard flush jointed ceiling system constructed of Gridlock Steel

brandering fixed at a maximum of 500mm centres in one direction/

[ 9.0mm] Tapered edge Plasterboard is fixed at right angles to the appropriate suspension

system using 25mm drywall screws placed at 150mm centres. All joints are to be taped over &

finished with a suitable skimming compound, sanded down & prepared for final finish.

Spec C3 Ceiling tiles

Pelican Systems Econocoust Silica Sand 1200 x 600 x 15mm thick white square edged ceiling

tiles, laid on 24mm wide x 38mm high pre-painted Exposed Econogrid tee suspension system,

including all necessary hangers, grids and hold down clips. Ceiling perimeter to be finished with

prepainted shadow trims.

Spec C4 Hanging Ceiling Element

AMF Thermatex Sonic Arc concave & convex elements fixed to roof rafters as per AMF

specifications.

Skirtings

Spec S1 Marmoleum skirting

Pre-formed Marmoleum skirtings. "Marmoform S Skirting 25 240"

Spec S2 Grano skirting

75mm high coved grano skirting to match grano floor spec. Face of skirting to be flush with face

of plastered wall surface and to be coved with 25mm radius.

Spec S3 Porcelain tile skirting

300x75x7.8mm tile skirting to match floor tiles (colour : black). Front face of skirting to be flush with

tiled wall surface.

Installation as per wall tiles (refer to spec W4).

Spec S4 Aluminium skirting

75 mm high x 1.3mm thick natural anodised aluminium skirting.

REFERENCE DRAWINGS APPROVER: PIKITUP HEAD OFFICE Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: JORISSEN PLACE, 66 JORISSEN STREET 1 BRUNEL ROAD

BRAAMFONTEIN DRAWN BY: P HANSRAJ EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2017 2280 PROPOSED NEW HALL AT

DRAWING CHECK: M WAYITI R17017-NH-ARC-006

PRIVATE BAG X74 P.O. Box 3211

For: ROBUST CONSULTING BRAAMFONTEIN, SECUNDA PIKITUP, MARLBORO DEPOT JOHANNESBURG

JOHANNESBURG DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

2017

FINISHING & SANITARY SCHEDULES

A1 2017/10/20 ISSUED FOR TENDER PURPOSES ONLY PH Tell: 086 117 7726

Sign: Tell: +27(0) 11 712 5200 DESIGN ENG.: V CHIYA

A 2017/07/20 ISSUED FOR APPROVAL ONLY PH Fax: 086 535 3817

Fax: +27(0) 11 712 5322

Date:

No. Date Description Initial Website: www.pikitup.co.za

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

CLIENT APPROVAL

USER DEPARTMENT (MARLBORO DEPOT)

N NAME: ............................................................

DESIGNATION: REGIONAL MANAGER

SIGNATURE: .................................................

Y 91240

Y 91200

Y 91160

Y 91120

Y 91080

DATE: ............................................................

.SP

PROJECT MANAGER CAPEX

NAME: ............................................................

.SP DESIGNATION: .............................................

.LP SIGNATURE: .................................................

DEPTH 1.9 ATER LINE

SEWER LINE

0m

160Ø ST

MW

400Ø STOR

ORMWAT

DATE: ............................................................

ER

LINE

KERB

GATE FACILITY DEPARTMENT

KERB

KERB

160Ø STORM NAME: ............................................................

KERB

FH WATER LINE

.FH

WATER LINE

DEPTH 1.20m .LP

DESIGNATION: .............................................

DEPTH 0.3AT0mER LINE

R LINE

DEPTH 1.9ATER LINE

110Ø STORMW

UNKNOWN SER

110Ø STORMWATE

EXISTING RADIO MAST SIGNATURE: .................................................

0m

.SB

110Ø STOR

ORMW

.SB WATER

LINE

SEWER LINE

ELECTRICAL LINE

400Ø ST

110Ø

ELECTRICAL LINE

VICE

DEPTH 0.40m

MWATER LIN

UNKNOWN SERVICE

S

.LP

TORM

DEPTH 0.30m

GATE

DATE: ............................................................

TO BE RELOCATED

WATE

SIGN

R

STORMWATER LINE

LINE

UNKNOWN SERVICE

EMERGE

NCY EXIT

EXISTING

AL LINE

OFFICE ADJACENT

PROPOSED NEW 160Ø STORMWA

OHS

BLOCK

H 1.5 LINE

TER LINE UP

ELECTRIC

DEPT WATER

FENCE SEWER LINE EXISTING

0m

BOARDR

TORM

OOM

S

WATER LINE

NAME: ............................................................

ELECTRICAL LINE

INE

450Ø

KERB

CARPORT 01 ER L

DEPTH 0.30m

PROPOS

ELECTRICAL 200Ø STORMWATE ED

ELECTR H 0.35m

OFFICESNEW

SEW DEPTH 0.50mLINE R LINE

DEPT

160Ø STORM

ICAL LINE

ELECTRICAL

LINE

BM1

1591.142

PROPOSED NEW 200Ø STORMWA

TER LINE

UP

STAIRCA

SE 1

SERVICE

DUCT DESIGNATION: .............................................

0.20m

WATER LINE FEMALE

PARAPL

EGIC

PTH

TOILET

CE

TOILET

KERB SEWER LINE

MAIN

ENTRAN

DE

SIGNATURE: .................................................

CARPORT 02

INE

MALE

AL L

TOILET

TRIC

ELECTRICAL LIN

GRID INLET

E

ELEC

DEPTH 1.20m

PROPOSED .LP DATE: ............................................................

ATER LINE

300Ø STORMW

LINE DEPTH 1.00m

NCY

ER

SEW

NEW HALL

EMERGE

EXIT

UNKNOWN

E

.40m LIN

ELECTRICAL LINE

TH 1 TER

KERB

DEP ORMWA

SERVICE

BM4

PROPOS

1588.63 NEW ED

HALL

ST

300Ø

FENC

E

KERB

RM

PLATFOED

KERB

door

INV 1588.37 SW TOC 1590.07

RAIS

shutter

KITCHENNEW

ED

Roller

PROPOS

UNKN PTH 0.80m

OWN S

DE

INE

ELECTRFIBER OPTI

ER L

ERVIC

AND

WATER

SEW DEPTH 0.5LIN0mE

WATER LINE

ICAL LI CS

SEWER LINE

DEPTH 1.30m

NE

400Ø STORM

UNKNOW

E LIN

N SE

ELECTRICAL

STAIRCA

SE 2

WATER

DEPTH 0.60LINmE

RVICE

NCY

UP

EMERGE

EXIT

WATER LINE

ELECTRIC

PROPOSED

E

DEPTH 1.20mR LINE

WATER LIN

UNKNOWPTH 1.80m

450Ø STORMWATE

AL LINE

DE

KERB

WATER LINE

N SERVIC

MH

DEPTH 0.3

WATER LINE

UNK EPTH 0

NEW SEWER LIN

NOW .90m

E

E

D

N SE

WATER LINE

FH

5m

RVIC

E

E

FENC

1 CARPORT 03

SEWER

CE

ELECTRFIBER OPTIC

RAN

AND

ENT

LINE

ICS

E

ELECTR L LIN

ICAL LI S

S

AND FIBERICAOPT

CES

NE

C

O TE A

REM

NE

ELE

AL LI

CTR

E

TRIC

ELECTRICAL LIN

DEP IC

TH 0 AL LINE

ELEC

.40m

EXISTING BUILDING

TO BE DEMOLISHED

E

GAT

WATER

KERB

LINE

2

.LP ENT

RAN

CE ELECTRICAL LINE

DEPTH 0.95m

S 300Ø ST

AC CES ORM

DEPTH WATER LINE

ELECTRICAL LINE

DEPTH 1.40m

OTE 0.50m

AND FIBERICAOPL LINE

DEPTH 0.80mTICS

REM

KERB

UNKN

STORMWATER LINE

ELECTR

OWN S

ERVIC

E

H 0.9 LINE

DEPT WATER

0m

UNKN

PVC

OWN

DEPTH 2.00m R LINE

110Ø

SERV

450Ø STORMWATE

ICE

ELEC

ICS

AND FIBER OPTLINE

KERB

DEP TRICAL

FENCE

ELECTRICAL

TH 0 LIN

.20m E

300Ø ST .SB

ORM

DEPTH WATER LINE .LP

DEPTH 0.20mLINE

1.30m

.SB

ELECTRICAL

WATER

LINE

UNKNOWN SER

VICE

DEPTH 0.50m KERB ELECTRICAL LIN

UNKNOWN SERVICE

E

DEPTH 0.30m

INV

UNKN H 0.30m