Professional Documents

Culture Documents

Manual Pesacargas OM-560

Uploaded by

Jenssy SayagoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Pesacargas OM-560

Uploaded by

Jenssy SayagoCopyright:

Available Formats

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

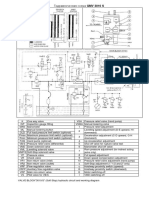

2. Interfaces of the main controller

OMS-560 Elevator overload measurement system

User's Manual

1. Appearance and installation dimensions of the main controller

⑽ ⑴ :Display window COM0 Y01 Y02 COM1 Y03 Y04 COM2 Y05 Y06 COM3 Y07 COM4 Y08

⑵ :Display in percentage

⑶ ① ① ① ① ② ③ ④ ④

⑴ ⑶ :Display in weight

⑾

⑵ ⑷:Up key;

⑻

Prolonged press to speed up OMS-560 Control unit

⑹ ⑤ ⑥ ⑦

⑼ ⑷ ⑸:Down key;

⑺ ⑸ Prolonged press to speed up COM5 X06 AV+ AV- AS+ AS- BV+ BV- BS+ BS- NC P1 P2

⑽

⑹ :Confirm;

⑺ :Exit;

⑻:No load learning; AC/DC10-45V

77.5mm 59.0mm ⑼:Rated load learning;

⑿ ⑽ :Input and output contacts To door

lock switch Power supply

⑾:In-curcuit programming port or elevator A sensor B sensor AC/DC16-45V

controller

switch

⒀ 90.0mm ⑿ :Ф4 screw fitting

⒀ :35mm rail fitting NOTES:

⒁ ① :Acts when measured weight≥rated load×(1+P01%) ;

⒁ :Rail clip

⑿ ② :Acts when rated load×P08%≤measured weight≤rated load×(1+P01%);

③ :Acts when 0%≤measured weight ≤rated load×P07%;

④ :Acts when measured weight ≥rated load×90%;

⑤ :If X06 lock signal is effective, the relay output keeps the same even if the load changes;

X06 signal is enabled or not based on the setting of parameter P03;

Input voltage :AC/DC10V~45V ;( No connection if no special requirements.)

⑥ :Contacts for sensors have two groups, namely A and B. If only one sensor is used, it can be connected to either one of

them. Contact v+, v-, s+, s- shall be connected to red wire, black wire, green wire and white wire on sensor respectively.

avoid placing the connection wires in the same wiring groove with 110V or 220V power supply wires ;

⑦ :Please make sure the working voltage is AC/DC16V-45V before normal operation;

ANT ELECTRONIC CO.,LTD(NINGBO,CHINA)

Version :V1.8

SUMMIT ELECTRONIC CO.,LTD(NINGBO,CHINA)

Tel: +86-0574-87164091/87164092

Fax: +86-0574-87150953

Web: www.summit3e.com www.ant-china.com

Email: sales03@summit3e.com

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

4. The display codes and their meanings

Parameter Parameter range Default

Meanings

Codes Explanation States value

00 – Learning with full weight load;

Code entrance Mode setting for rated

Twinkle for code entrance; 03 – Learning with no weight load; 00

load learning; 04 – Learning with any known weight load;

Twinkle for initialization; Initialization state

Parameter setting; Initialization state Spare 00

Value of Pn (n = 01-16) ; Initialization state 05~75 – Indicate 5~75%, light load

Light load range relay acts when measuring load is 05

Weight: 1080 Kilogram; Measuring state setting; in range of 0% to P07% rated load;

Percentage display of 101%; Measuring state 90~99 – Indicate 90~99%, heavy load

Heavy load range

relay acts when measuring load is in 90

Overload; setting;

Measuring state range of P08% to (1+P01%) rated load;

00 – Contact closes when in

Ready for no load learning; Initialization state Light load contact light load range;

01– Contact releases when in 00

setting; light load range;

No load learning complete; Initialization state

00 – Contact closes when in

Ready for rated load learning ; Initialization state heavy load contact heavy load range;

01– Contact releases when in 00

setting;

heavy load range;

Rated load learning complete; Initialization state

Rope and sheave ratio 01~10 – Indicates the ratio of

setting; (only good for

Error code; Initialization state rated load learning with 1/1~1/10, proportion the force 01

no load) sensor carried to actual load;

5. The menu structure and parameter setting Sensor`s correction 0000~9500 – Input correction code

code or any known during rate load learning with no load

or input weight during rated load 0000

Parameter Parameter range Default weight;

Meanings learning with known weight in KG ;

value

0000~9500 – Input rated load in

00~20 – Indicat es 0~20% , Rated load value KG; In rated load learning with

Overload range over load relay acts when full weight, 0000 can be used to 0000

m easuring load exceeds 10 setting; treat the full weight as rated load;

Setting;

(1+P01% ) rated load ;

Buzzer switch 00 – Buzzer close ;

Bouncing sensitivity 00~10 – The sensitivity decreases 01

setting; 05 01– Buzzer open;

with the value of P02 increasing;

00 – Signal lock is effective

Output lock signal when power on; Spare 00

setting ; 01– Signal lock is effective 00

when power off;

Delay time setting

Version

for overload relay 00~05 – Indicates 0~5 seconds; 02

release;

ELEVATOR OVERLOAD MEASUREMENT SYSTEM ELEVATOR OVERLOAD MEASUREMENT SYSTEM

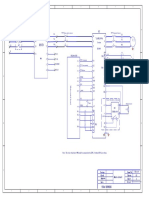

6. Common trouble code and countermeasure to the trouble 8. Flow chart for device initialization

Codes Phenomena/explanation Countermeasure Measuring state.

No load learning .

Sensor not installed properly, Check for installation or wiring Move car to

wiring wrong, or used weight error; use heavier weight on rated If car is on lowest level.

lowest level? Take load off.

too light during initialization; load learning; (No)

If the load taken off?

(Yes) (No)

Press [ESC]+[OK]

No no load learning performed Perform no load learning before rated waiting for

Press [OK] or

(Yes) toggle X06 signal for 5s.

during initialization process; load learning process; pass code.

No load learning

Press [+] or [-] done.

Absence of correction Restart initialization , and set P12 Display pass code. (Yes) Press [B]

code during rated load Waiting for rated

learning with no weight; properly; load learning.

Press [+] or [-]

Restart initialization , and set P13 If pass code is 11? (No) Add more weight.

Absence of rated load; properly; If the weight enough? (No)

(Yes) Press [OK] Press [OK] or

Ready for (Yes)

Reduce the load or use larger toggle X06 signal for 5s.

Over sensor range; initialization. Rated load

range sensor; learning done.

Press [ESC]

If P1-16 needs to Press [A]

7. Procedures for device initialization be modified? (No) Measuring state.

This system provides 3 initialization methods: (Yes) Press [+] or [-]

I nitialization with full weight load : if there is enough weight on site and high Display P1-P16.

measurement precision required. Press [OK]

Initialization with no load: if there is no weight on site and no special Display value of P1-P16.

precision requirement .

I nitialization with a ny known weight load: if there is not enough weight Press [+] or [-]

on site and high measurement precision required. If the value wanted?

(No)

According to on site situation, one of the following procedures can be used

for I nitialization , and following examples may be referred to accordingly. (Yes) Press [OK]

★Initialization with full weight load Display P1-P16.

★Initialization with no weight load

★Initialization with any known weight load If other Press[A]

parameters need to

Other fast modification: be modified? (No)

■Fast parameter modification (Yes) Press [+] or [-]

■Reset to factory setting

★Initialization with full weight rated load

(In this case, rated load is 2000KG and weight is 2000KG)

Waiting for code Code display Initialization ready Parameter Value of P05 Value of P05 Parameter No-load learning Learning finish Rated load learning Initialization complete

No action in

5 seconds

Press [OK] and [ESC]

simultaneously to enter Press [OK]. Press [A] to start no Press [OK] to finish no Press [OK] to finished rated Press [ESC]

Press [+]or[-] to choose press [OK] load earning process . load learning process, Press [B] to start load learning. (please make to exit

initialization, would go The code is Press [OK] to Press [+]or[-] to

back to measuring state the code 11. It will return to finish (Press [A] only when make sure there is no rated load learning sure the lifting load is the full initialization .

right and the Press [+] to display the change the P05 process with full

if there is no action in to display weight if there modification the elevator is at the load before pressing weight. In this example the

system is ready choose P05. weight load.

5 seconds. is no action in 5 seconds. value of P05. value to 00. of P05. lowest floor) [OK]) full weight load is 2000KG.

for initialization.

NOTE: initialization with full weight , P05 should be 00. The equipment should lift rated load. Input rated load value to P13, press [OK] to switch display in percentage or in weight .

★Initialization with known weight load

(In this case, weight is 800KG and rated load is 2000KG)

Waiting for code Code display Initialization ready Parameter Value of P05 Value of P05 Parameter Parameter Value of P12 Value of P12 Parameter Parameter

No action in

5 seconds

Press [OK] and [ESC]

simultaneously to enter press [OK] Press [+]or[-] to change the press [OK]

initialization, would go Press [+]or[-] to choose Press [OK]. The Press [OK] to Press [OK] to

Press [+]or[-] to to finish value of P12 . (Enter the known to finish

back to measuring state the code 11. It will return code is right and

the system is ready Press [+] to display P05 change the P05 modification Press [+] to display the weight . In this example enter modification Press [+] to

if there is no action in to display weight if there 800kg.)

is no action in 5 seconds. for initialization. choose P05. value. value to 04. of P05. choose P12. value of P12. of P12. choose P13.

5 seconds.

Initialization complete Rated load learning Learning finish No-load learning Parameter Value of P13 Value of P13

Press [OK] to finish Press [+]or [-] to enter

Press [ESC] Press [OK] to finished rated Press [B] to start Press [A] to start no

load learning. (please make no load learning press [OK] rated load.(Displayed

to exit rated load learning load learning process . to finish Press [OK] to

process, make sure rated load is 2000

initialization. sure the lifting load is the process with

there is no load before

(Press [A] only when

modification Kilogram, can be set display the

known weight. In this example known weight load. the elevator is at the

the weight load is 800KG. pressing [OK]) of P13. based on requirements) value of P13.

lowest floor)

NOTE: initialization with any known weight, parameter P05 shoud be 04 and P12 and P13 should also be modified. the equipment should lift known weight during rated load learning period. input

rated load value to P13. Press [OK] to switch display in percentage or in weight .

★Initialization with no weight load

(Different sensor has different correction code. Please contact us if you need it. In this case, correction code is 6300 and the equipment rated load is 2000 Kilogram)

Waiting for code Code display Initialization ready Parameter Value of P05 Value of P05 Parameter Parameter Value of P11 Value of P11 Parameter Parameter

No action in

5 seconds

Press [OK] and [ESC]

simultaneously to enter Press [+] or[-] to change the

Press [+]or[-] to choose Press [OK]. The press [OK] value of P11.(Thisvalue press [OK]

initialization, would go Press [OK] to Press [+]or[-] to Press [OK] to

back to measuring state the code 11. It will return code is right and to finish indicates the ratio of the to finish

the system is ready Press [+] to display the change the P05 modification Press [+] to display the modification Press [+] to

if there is no action in to display weight if there rope and the sheave. In this

5 seconds. is no action in 5 seconds. for initialization. choose P05. value of P05. value to 03. of P05. choose P11. value of P11. example 02 indicates 2:1) of P11. choose P12.

Initialization complete Rated load learning Learning finish No load learning Parameter Value of P13 Value of P13 Parameter Parameter Value of P12 Value of P12

Press [+]or [-] to enter Press [+]or[-] to enter correction

Press [ESC] Press [OK] to finished Press [OK] to finish no Press [A] to start no load

rated load learning. Press [B] to start press [OK] rated load.(Displayed Press [OK] code.(The value is marked on

to exit load learning process, learning process .(Press to finish Press [OK] to to finish Press [OK] to

(please make sure rated load learning rated load is 2000 the sensor. Each sensor has

initialization . process without make sure there is no [A] only when the elevator modification display the Press [+] to modification display the

there is no load before Kilogram, can be set its own code, in this example

load. load before pressing [OK]) is at the lowest floor) of P13. value of P13. choose P13. of P12. value of P11.

pressing [OK]. based on requirements) the code is 6300)

NOTE: initialization without weight, parameter P05 should be 03 and P12 and P13 should also be modified. The equipment should lift no load during rated load learning period. Input rated load

value to P13. Press [OK] to switch display in percentage or in weight .

■Fast parameter modification ■Reset to factory setting

(Following is parameter P13 modification procedures)

Waiting for code Code display Initialization ready Parameter Value of P13 Value of P13 Parameter Waiting for code Code display Initialization ready

No action in No action in

5 seconds 5 seconds

Press [OK] and [ESC] Press [+] and [-]

simultaneously to enter Press [ESC] simultaneously to enter

Press [+]or[-] to choose Press [OK]. The Press [OK] to Press [+]or [-] to enter Press [OK] to Press [+]or[-] to choose

calibration, would go to exit initialization, would go the code 11. It will return

back to measuring state the code 11. It will return code is right and display P13 . rated load.(Displayed finish the P13 initialization . back to measuring state Press [OK] to reset

if there is no action in to display weight if there the system is ready . Press [+] to rated load is 1000 KG) if there is no action in to display weight if there

to factory setting.

choose P13. modification. is no action in 5 seconds.

5 seconds. is no action in 5 seconds. 5 seconds.

NOTE: procedure is the same for all parameters . data will be saved after press [RESET]. WARNING: after reset, all previous calibration is gone. please make sure before resetting.

-5-

You might also like

- PESA CARGA DTZZIII-DK100系列说明书英文Document6 pagesPESA CARGA DTZZIII-DK100系列说明书英文NelsonEnrriqueInfante100% (2)

- ME320LNnew Elevator Specialized AC Drive User Manual 20151030Document158 pagesME320LNnew Elevator Specialized AC Drive User Manual 20151030andre carrion100% (1)

- Plano LEEAV PDFDocument5 pagesPlano LEEAV PDFCristian Orosco ValverdeNo ratings yet

- Manual Mont20Document66 pagesManual Mont20Yok MulyonoNo ratings yet

- Manual Inglês Encoder SinCos PG E3 PDFDocument33 pagesManual Inglês Encoder SinCos PG E3 PDFvicenteunicoNo ratings yet

- ME320L N Elevator Specialized Inverter User Manual PDFDocument132 pagesME320L N Elevator Specialized Inverter User Manual PDFMAG.NET TechnicNo ratings yet

- Canny Instalacion Mecanica Manual InglesDocument57 pagesCanny Instalacion Mecanica Manual InglesBeltran Héctor100% (1)

- BLT MPK708CDocument185 pagesBLT MPK708CFabian Garrido100% (2)

- AMC 528 V8: User'S Manual And Technical Specification GSM 89864.4000МЕDocument23 pagesAMC 528 V8: User'S Manual And Technical Specification GSM 89864.4000МЕAbenether Bekele100% (1)

- Microzed V Microzed V3.5 3.5: User'S ManualDocument58 pagesMicrozed V Microzed V3.5 3.5: User'S ManualKhaled ZakariaNo ratings yet

- Dcu-2d Operador de PuertaDocument3 pagesDcu-2d Operador de PuertaJms Quintero50% (2)

- Elevator Door Controller - NSFC01-01Document14 pagesElevator Door Controller - NSFC01-01احمد المقرمي100% (1)

- NICE1000new Integrated Elevator Controller User ManualDocument205 pagesNICE1000new Integrated Elevator Controller User ManualVinay SharmaNo ratings yet

- Product Information 4. Wiring: MCTC-ARD-C Series Elevator Auto Rescue Device User ManualDocument2 pagesProduct Information 4. Wiring: MCTC-ARD-C Series Elevator Auto Rescue Device User ManualJesús David Diaz MontesNo ratings yet

- Al Toot - Emerson Door Drive - Enydrive-EV3200user-EnDocument63 pagesAl Toot - Emerson Door Drive - Enydrive-EV3200user-Enrajamdeee5833No ratings yet

- Manual-DESSEN (SM-01-F5021)Document114 pagesManual-DESSEN (SM-01-F5021)jose0% (2)

- O1 Prisma Fox Door Drive PDFDocument11 pagesO1 Prisma Fox Door Drive PDFfirasalthiyabyNo ratings yet

- EI53C9.25-2048-SA5N2TH SC53 SIN-COS Photoelectric Encoder User GuideDocument2 pagesEI53C9.25-2048-SA5N2TH SC53 SIN-COS Photoelectric Encoder User Guideben omar Hmidou100% (1)

- IRIS_NV Control Panel OverviewDocument20 pagesIRIS_NV Control Panel OverviewHeiner HidalgoNo ratings yet

- FUSION Integrated Control SG-01-0003 B2 PDFDocument179 pagesFUSION Integrated Control SG-01-0003 B2 PDFraga tamaNo ratings yet

- HT-52 Kullanim Klavuzu-EngDocument15 pagesHT-52 Kullanim Klavuzu-EngFrancisco Javier BurgosNo ratings yet

- D10D622 Drive CircutDocument31 pagesD10D622 Drive CircutVertec Engineering0% (1)

- Ht-53 Mini User ManualDocument15 pagesHt-53 Mini User Manualjhoncristian27m71% (7)

- BG101-S20P4A: 1、Functional keys introductionDocument10 pagesBG101-S20P4A: 1、Functional keys introductionLuis Henriqüe Jr.No ratings yet

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Document7 pages标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- Astra v10Document9 pagesAstra v10toni100% (4)

- Manual Fermator C2TDocument2 pagesManual Fermator C2TMaiko de SousaNo ratings yet

- YS K01 Operador Manual InglesDocument56 pagesYS K01 Operador Manual Inglesmohammad ghassan100% (3)

- Manual Sigma BG221Document29 pagesManual Sigma BG221Quang Pham DuyNo ratings yet

- Manual BLT Mpdk136Document275 pagesManual BLT Mpdk136Edwing SilvaNo ratings yet

- HT34 Control PanelDocument19 pagesHT34 Control PaneljhfbtyNo ratings yet

- Revo-Drive Lift Motor Drive User GuideDocument16 pagesRevo-Drive Lift Motor Drive User GuideRedouane Talhamrite100% (2)

- Hydraulic circuit diagram for GMV 3010 SDocument1 pageHydraulic circuit diagram for GMV 3010 SAnton LyakhovNo ratings yet

- Varispeed L7: Instruction Manual and Parameter DescriptionDocument258 pagesVarispeed L7: Instruction Manual and Parameter DescriptionRath AsypadenNo ratings yet

- Elevator Encoder Product GuideDocument6 pagesElevator Encoder Product GuideReynold Suarez100% (1)

- Hosting Manual InglesDocument57 pagesHosting Manual InglesEdgar Zamora67% (3)

- AAD03010 Door OperatorDocument21 pagesAAD03010 Door Operatorreynold0% (1)

- BG202-OE31E Functional Key and Parameter GuideDocument10 pagesBG202-OE31E Functional Key and Parameter GuideQuang Pham DuyNo ratings yet

- The UML-51 / ELV-5R: Advance Elevator ControllerDocument25 pagesThe UML-51 / ELV-5R: Advance Elevator ControllerCristian Millan100% (1)

- Fuji Yida Plano Electrico Yaskawa H1000Document14 pagesFuji Yida Plano Electrico Yaskawa H1000oro plata100% (2)

- Hh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdDocument3 pagesHh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdRebecca DangNo ratings yet

- EWD-H-KXJ3 Elevator Load Weighing GuideDocument10 pagesEWD-H-KXJ3 Elevator Load Weighing GuideKang RohendyNo ratings yet

- ZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)Document24 pagesZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)BrianEstebanNo ratings yet

- Manual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDocument70 pagesManual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDio ChanNo ratings yet

- S50-E6 Elevator Control System Commissioning Manual (2017.12) - Ae4Document56 pagesS50-E6 Elevator Control System Commissioning Manual (2017.12) - Ae4Yesid Castellanos Triana100% (2)

- Braking Resistor For FRENIC-Lift - ECOMSADocument5 pagesBraking Resistor For FRENIC-Lift - ECOMSAsd23100% (1)

- Mldoorplus Automatic Door Control CardDocument4 pagesMldoorplus Automatic Door Control CardDmitriy ShevchenkoNo ratings yet

- 19010269-SC - A01 NICE900 Door Drive User Manual - 20161224Document98 pages19010269-SC - A01 NICE900 Door Drive User Manual - 20161224Ks BharathiyarNo ratings yet

- 2010 New Electric Drawing-FUJI YIDA - 1Document16 pages2010 New Electric Drawing-FUJI YIDA - 1oro plata100% (1)

- GM.2.001045.EN - Ed-F - Eco + New Norms - 2018 PDFDocument40 pagesGM.2.001045.EN - Ed-F - Eco + New Norms - 2018 PDFCoil98100% (2)

- Elevator Control Module: User'SDocument9 pagesElevator Control Module: User'SjhfbtyNo ratings yet

- Canny DiagramasDocument24 pagesCanny DiagramasHeiner HidalgoNo ratings yet

- Dielro 101 EsDocument50 pagesDielro 101 Eschiki_0No ratings yet

- X-Mini 5V: Instruction of Operating Manual of Service/Restaurant Elevator Control SystemDocument12 pagesX-Mini 5V: Instruction of Operating Manual of Service/Restaurant Elevator Control Systemmohammad ghassan100% (3)

- YS-K01 Door Drive ManualDocument46 pagesYS-K01 Door Drive ManualMuhammad Rashid100% (6)

- FNIRSI-138 PRO Handheld Digital Oscilloscope ManualDocument5 pagesFNIRSI-138 PRO Handheld Digital Oscilloscope ManualArduinoBeto RojasNo ratings yet

- Mitsubhishi Cop ProgrameDocument61 pagesMitsubhishi Cop ProgrameSunil KumarNo ratings yet

- Avc118 ADocument27 pagesAvc118 ARafik Mohamed AlhajiNo ratings yet

- TTi TS Series Power Supplies ManualDocument27 pagesTTi TS Series Power Supplies Manualj.bycroft126No ratings yet

- Ontime THC AVC118 ManualDocument27 pagesOntime THC AVC118 ManualNawres ArifNo ratings yet

- Computer - An Introduction: Computer, Machine That Performs Tasks, Such As Mathematical Calculations or ElectronicDocument14 pagesComputer - An Introduction: Computer, Machine That Performs Tasks, Such As Mathematical Calculations or ElectronicprakashkumarvermaNo ratings yet

- HUFFY Bicycle Multispeed - ManualDocument44 pagesHUFFY Bicycle Multispeed - ManualottuserNo ratings yet

- RET 670 3windingDocument4 pagesRET 670 3windingm khNo ratings yet

- RTD Sensor Guide for Temperature MeasurementDocument2 pagesRTD Sensor Guide for Temperature MeasurementvjNo ratings yet

- Home Made Metal Spinning LatheDocument7 pagesHome Made Metal Spinning Latheuragunbaga75% (4)

- Protection Coordination Back UpDocument35 pagesProtection Coordination Back UpJohn Paul Inovero JavierNo ratings yet

- BSL Maintenance Manual Version 1Document27 pagesBSL Maintenance Manual Version 1Nirus GoodNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument20 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Best PSU Deals - Seasonic, Corsair, FSP and MoreDocument13 pagesBest PSU Deals - Seasonic, Corsair, FSP and MoreFahmi AlhubilahNo ratings yet

- B sc115Document1 pageB sc115Marcos TapiaNo ratings yet

- Functionality Document Ied-Ep Dtva E1-Line F d3301311000-d220000000000200000-ddDocument6 pagesFunctionality Document Ied-Ep Dtva E1-Line F d3301311000-d220000000000200000-ddPouyan HoseiniNo ratings yet

- Lab Report 1Document3 pagesLab Report 1Hassan MehmoodNo ratings yet

- Elcometer 101: 101 - TMA - 0465 - 00 - 03 (Part Number 2185) .FM Page - 1 Tuesday, August 20, 2013 11:03 AMDocument7 pagesElcometer 101: 101 - TMA - 0465 - 00 - 03 (Part Number 2185) .FM Page - 1 Tuesday, August 20, 2013 11:03 AMDania GomezNo ratings yet

- Aeg L82470bi PDFDocument72 pagesAeg L82470bi PDFCecília PerdigãoNo ratings yet

- Goes 800rsDocument43 pagesGoes 800rsrhadamanteNo ratings yet

- AMD B450 GAMING PLUS MICRO-ATX MOTHERBOARDDocument63 pagesAMD B450 GAMING PLUS MICRO-ATX MOTHERBOARDjose luis de granadaNo ratings yet

- Pre-Lab: 1Dph BBBBBBBBBBBBBBBBBBBBBBBBBB ,' BBBBBBBBBBBBBB /de 6Hfwlrq BBBBBBBDocument2 pagesPre-Lab: 1Dph BBBBBBBBBBBBBBBBBBBBBBBBBB ,' BBBBBBBBBBBBBB /de 6Hfwlrq BBBBBBBAhnafHabibKhanNo ratings yet

- Washing Machine: Owner'S ManualDocument92 pagesWashing Machine: Owner'S ManualmarkoloniusNo ratings yet

- STM32 Microcontroller General Oct2012Document69 pagesSTM32 Microcontroller General Oct2012dcesentherNo ratings yet

- Systems Physical Planning GuideDocument42 pagesSystems Physical Planning GuideEugene EzekielNo ratings yet

- Voith Safeset NEW - Tourque Limiting Coupl - LRDocument32 pagesVoith Safeset NEW - Tourque Limiting Coupl - LRHector Rivera Beltrán0% (1)

- Service Manual Heavy-Duty E-Series Index Drives Models 950E, 1150E, 1550E, 2050EDocument27 pagesService Manual Heavy-Duty E-Series Index Drives Models 950E, 1150E, 1550E, 2050ESuhas KODRENo ratings yet

- HP070 - EN 单页Document4 pagesHP070 - EN 单页symantec37No ratings yet

- Esquema Electrico Scania 1Document211 pagesEsquema Electrico Scania 1Leonardo Gonzalez95% (22)

- ECE429 Laboratory 3 Inverter Layout: Prasanna N A20489739 21/09/2021Document14 pagesECE429 Laboratory 3 Inverter Layout: Prasanna N A20489739 21/09/2021Prasanna NalawarNo ratings yet

- Gardner Denver Part List Gardner Denver Elc99aDocument34 pagesGardner Denver Part List Gardner Denver Elc99aUbanAirlangga100% (2)

- 3 - Suspension, Steering and Brakes PDFDocument111 pages3 - Suspension, Steering and Brakes PDFintejam75% (4)

- 5MP76341Document64 pages5MP76341eliminar2024No ratings yet

- SR85-TR85 SMDocument226 pagesSR85-TR85 SMshef981100% (1)

- QDD 30 S 45 SDocument4 pagesQDD 30 S 45 SfaniNo ratings yet