Professional Documents

Culture Documents

ASME B16.36 2009 Orifices Flanges

ASME B16.36 2009 Orifices Flanges

Uploaded by

Boris Chicoma0 ratings0% found this document useful (0 votes)

16 views27 pagesASME B16.36 2009 Orifices Flanges

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASME B16.36 2009 Orifices Flanges

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views27 pagesASME B16.36 2009 Orifices Flanges

ASME B16.36 2009 Orifices Flanges

Uploaded by

Boris ChicomaASME B16.36 2009 Orifices Flanges

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 27

Pv) aera

(Revision of ASME B16,36-2006)

Orifice Flanges

AN AMERICAN NATIONAL STANDARD

Y

e UO

Bio aricy

eo ance: Novenbe 4 2008

‘The nest eon ofthis Standard scheduled for publeation in 2016. Tere wil be no addenda

[esued to his edo.

ASME issues witen replies to inquiies concermng interpretation of technical aspects ofthis

Standard Interpretations and erata are pushed onthe ASME WeD ste urder he Commies Pages

at tp festolsasme.org as they ae issued.

‘A he epee ae of he ern Sty chan Eanes.

‘i coe or sada as dele unde rads seceded a meting the ct fo Amer Katina

‘Sheet ond onan! ont heh epporantopricose, Te roons Code snd wk mace

‘UES tpatc sve oncom een opparany raion poe pattem dy. sade,

‘usar omc ane bps

SE doesnt prec anda” an em, cosinor devo 2

dent nh apa bay of yt ra ae coin wh

‘Stent ny stacy puts oreo ay nce ai, ses of ace rsd pea

‘hice tat decane vay om 00 pate SE, a8 he keg sch AS

‘Sty er oom pone

septa ysl apc moms) a pean efiaed wh nc srt ob meted a8

serum ry edzcament ds ae snd

"Sirs puny rel oe nrptacne h docmen edn acorn wht eles

st pesca ts poe nach cues e sie epson div

oprah ance maybe eens fy

Trantor merle oor,

caret ©3886

‘can SBT OF HELHANCA EGE

‘ramen

‘CONTENTS

Foreword e

Commitee Roster

CCormspondence With the 816 Committe

Scope

Generat

1

2

3 Pressure-Temperature Ratings “

4 Material

5 Ste

6 Marking

1

8

°

meats a!

Flange Facing Psish zl :

Gasets for Raised Face Ranges.

Pressure Taps.

10 Jack Screw Provision

11. Range Dimensions.

42 Mange Treads

13 Tolerances

Figures

1 Comer Taps

2 Angular Mete Tp fr RT} anges

5 Jack Bolts

Thbtes

‘Cass 200 Onifce Fanges, Welding Neck, Threaded, and Slip-On

‘Gass Oniice Fanges, Welding Neck

‘Css 900 Once Fangs, Welding Neck

‘Cass 1500 Onifiee Flanges, Welding Neck

(Gass 2500 Oflce Fanges, Welding Neck

Mandatory Appendices

1 Dimansonal Data for Clases 300, 60, 90,150, and 2500 Flanges in

‘US Customary Units u

irmensional Dat for Class 400 Flanges in US. Castomary Unis uv

References. »

Nonmandatory Appendix

A Qualty Sytem Program »

FOREWORD:

August of 1956 mated the frst recorded correspondence noting the lack of standardization

for once flanges. There were, and stil are, several codes forthe performance and calibration

of orice Manges, but the had been no standardization ofthe anges themeelves. Over the

‘ensuing 3 year cormespondence continued among De Instrument Society of America, American

‘Gas Assodation, andthe Ble Standards Commitee

‘On December 3, 1989, Subconunitiee 3 (Qow Subcommittee C) of BIS authorized the appoint

sent ofa Task Fore to undertake drafting of a standard. Although the inal work proresed

Soobly,a controversy develope over te standard sizeof aps to be specified forthe anges.

‘Ths required any yeast resolve It was Gnallyachleved in 1973 with the ssuance of draft

fom the Tsk Force Comments and cbjections to this draft fom mambers of Subcommittee C

were resolved and aredrat was approved bythe Subcommittee lle in 1974 The B16 Standards

Conte was blloted inthe sping of 1975 and approval was gained, Comments from B16

‘members from the gas industry requested tat the Class 400 orifice Nange be included, and the

‘BisSubcomitiee Cagrec to consider this for a possible addendum. TheStandard was approved

by ANSI on August 15,1575.

[On April 30, 1979, an addenda was issued, which added Class 400 flanges and

[Mandatory Appendix I covering reference documents and organization,

In 192, American Natioal Sandarde Comte B16 was reorganized ae an ASME Commitee

operating under procedure ateredied by ANSL In the 1988 ein, figures were added to

Uhastate Jock bolts and comer taps, metric units have been omitted, and references to other

‘tandards have been updaved. Following approval bythe B16 Main Commitee and the ASME

Supervisory Board, the Sundard was approved as an American National Standard by ANSI on

abruary 18 1968

Tn 1986, several revisions were made, including the addition of angular meter taps for ring

Joint anges in sizes not previously covered. Following approval by the 6 Main Commitee

land the ASME Supervsory Board, the Standard was approved as an American Natonal Standard

by ANSI on November 6 96,

in 206 several revisions were made including the use of metic unis a the pimary reference

unis, while maistaiing US. Customary units i ether parethatal or separate forms. Changes

to dimensions and nomenclature followed that were contained within the 2003 edition of

[ASME BI6S, Ths includes the change of minimum flange thickness from Ct and comections

for ¥ and Y, Clas 00 remains in US. Customary tables in Mandatory Appendis I but snot

vent themetrle dimensional tables, Ther are numerous equrement aiieatons and editorial

‘visions. Following the aprovals af the Standards Commitee and ASME, approval forthe new

‘dition was granted by the American National Standards Isitute on November 6, 2006

In the 2009 edition Masdatry Appendie Il was revised and updated. Also section & the

atria section has been revised to over requirement of tate specication editions other

than those ltd in Appendix Il of ASME Bie.

Requests for interpretaons oF suggestions fr revisions shouldbe sen othe Secretary,

B16 Commits, Tree Park Avene, New York, NY 10016950, Asan alternative, quis may

be submited via ema to Secretary Beene ory

“Ths revision was approved bythe American National Standard instute on August 13,2008.

ASME B16 COMMITTEE

Standardization of Valves, Flanges,

Fittings, and Gaskets

(loving tester he onmie athe ieofpo hi Sd)

‘STANDARDS COMMITTEE OFFICERS

W. beesen, co

Mec eye Char

Shar soy

‘STANDARDS COMMITTEE PERSONNEL

was A eps 6 A oy Yor ara enene

1 ede, Eon Seca & Engng Co 1 eer yer mato

De daeee, oat Psu Co Ae Mean, 8 8 geeing

1. Aen Shs arlene TEX Wesahn, be ost tema

Facrge us noc tout Commision

Wei avi he bow Cems

TE Sai Nay ohne

128 Sharh amtan Si of Mecha Engineers

1 ram Bet Ege 1 Sondengpy st nbn ne

fr cms US cont Cae We Span fs

AU Mn, TE ne A ve oct company Sevens

‘SUBCOMMITTEE C ~ STEEL FLANGES AND FLANGED FITINGS

© £ bat, ai, Se Wes CL Mena ta ent

teal Seay own Sy eciah —E aCo

plan, Moy Sais roduc oe Winsome Spoccng

11 ese, Coron ea pag SL Aaya Becta Por Co

IM Chet, Sh WesthtonTecloy Case, (i atc, he bo heme

1 demas na Rasch TE eomaleaay, oped vessel Cnncons

[eee Consent A Samide said

1 es Egg eer, Romer

MUL Medosen TE ne i Ice

‘CORRESPONDENCE WITH THE B16 COMMITTEE

Gener ASME Standanls are developed and maintained with the intent to represent the

consensus of concerned interests, Aa ich, ser ofthis Standard may interact withthe Commitee

by requesting interpretations, propoang revisions, and attending Commitee meetings. Come

spondence should be addresed te

Secretary, BIS Standards Commitee

‘The American Society of Mechanical Enginoers

“Thre Pak fvenve

New York, NY 10016-5900

‘Asam alternative, inquiries may be submted via e-mail to: SocearyB16@asme on

‘Proposing Revision. Revisions re made periodically tothe Standard to incorporate changes.

that appear necesary or desirable, a emonstatd by the experience gained from the application

ofthe Standard Approved revisions wil be published perdi.

"The Commitee welcomes propos oe revisions tothe Standaré. Such proposals shoul! be

as spect as possible lng the paragraph suber), the proposed wording, and a detailed

‘eaziption ofthe reasons forthe proposal induding any pertinent documentation.

Interpretations. Upon request the B16 Commute wl render an interpretation of any require

iment ofthe Stands Inerpetations can ony be rendered in response fo a writen request sent

{othe Secretary of the Ble Standards Comme

"The request for interpretation shouldbe car and unambiguous I i further recommended

thatthe nies sult his/her request i the following format

Subject: Cite the applcale paragraph numbers and the topic of the inguiry.

ition ‘Gite the applicable editon of the Standard fr which the interpretation is

Dain requested.

Question: Phone the questo as request for an interpretation ofa specifi requirement

Suilable for general understanding and uae, not asa request fr an approval

fof proprietary design or etuation. The inuirer may also include any plans

tr drvrings which ae necessary to explain the question, howevet, they

Should not comin proprietary names or information.

Requests that are not in this format wil be rwriten in this format bythe Commitee prior

to beng answered which may inadvertently change the intent of the onginal request.

"ASME procedures provide for ssonsderation Of any interpretation when or if adiional

inormation that might afc an interpretation ie available. Further, persons aggrieved by an

{nterpretaton may appea! othe copzant ASME Commitee or Subcammite, ASME doesnot

Nipprove’ "cert “ate- or “endorse” any ie, constriction, proptar device of activi

"Kending Committe Meetings. The Bi6Standarés Committe regularly hols meetings, which

art open tothe puble Pemone wishing to atlend any meeting should contact the Secretary of

the Bie Standards Commitee.

Ase 81636208

ORIFICE FLANGES

1 SCOPE

‘This Standard coveraflnges similar to those covered

‘in ASME BIS) that have onde pressure diferentia

“connections. Coverage i ited t the following:

a) welding neck anges Classes 300, 600, 900,150,

and 2500, US. Custemary units are presented in

Mandatory Appendix

(b)slip-on and thread Clas 300.

(e) welding neck ages Clas 00 in US. Customary

sits in Mandatory Appendix IL

2 GENERAL

2.4 References

Codes standards and specifications containing prov

sonst the extent referenced heria conse Feire

‘ents ofthis Standard These reference documents ae

Tite in Mandatory Appendix I

2.2 Quality Systems

‘Nonmandatory requtements rating tothe product

manufacturer's Quality Sjtem Program are described

in Nenmandatory Appendix A,

2.3 Relevant Uns

“This Standard state values im both metric and US.

Customary units Asar exception diameter of belts and

flange bolt hoes ae expressed in inch urs only. These

sytams of units ae tobe regarded separately as stan-

dard, Within the text the US. Customary nite are

"Showa in parentheses on separate tables The vals

Stated in doch syst are not exact equivalents; there

fore, is required thot each syst of unis be used

ly ofthe oer Except fr dlameter of ols

sd fange bolt hoes, combining values fom the two

‘ystems contitutes nonconformance withthe standard

Except for Class 400, he values ia US. Customary uns

fe fh Mandatory Appendix 1. The rain text Of ths

‘Standard does not cortain requirements for Class 400

‘welding nck lange: however Mandatory Append I

‘does contin requires for this las, expressed (3

US Customary unt oly.

24 Convention

For the purposes of determining conformance with

‘his Standard, the convention for ngsigrcant digs

there Uta and msicnn and mite vals ae

spec, shall be rounded as defined in ASTM Practice

12s, Ths requires that an bserved or calculated value

shall be rounded of to the nearest unit inthe last

Tighthand digit used fr expressing the it, Dedal

‘aloe and tolerance donot ply ¢ particular method

‘of measurement

25 Denotation

25.1 Pressure Rating Designation

(a) Clas followed bya dimensionless number, the

designation for prenrure- temperature ratings a flows:

‘Hass 300 6 500 1500 2500

(@) Class A etaned inthe US. Customary tables

25.2 Sizes. NPS, followed by a dimensioaless

umber, the designation forthe nominal Mange siz.

[NDS related to the reference nominal diameter, DN,

‘edn international standards, The elaorship i YP

cally 35 follows:

oa oe

ee

(OAR, NOTE Fer NPS, he ltd DN = 255,

26 Service Conditions

Ctra for sletion of materials suitable for the per

ticular fs service are not within the scope o! this

Standard

|3- PRESSURE-TEMPERATURE RATINGS

“The pressure-temperature ratings, including al use

recommendations and liltatons andthe method of

{afing given in ASME B16S apply to thes flanges

4 MATERIAL

‘Aa General

Flange materials shall be in accordance with the

requirements of ASME B65. For materials marvfac-

tured to ecitions ofthe material specfeation other than

those sted in Append Ill of ASME BIG5, rer to

porn 43,

Aste 316362008

‘42 Boling

Belting material recommendations are given in

ASME B165. For materiale manufactured to editions

‘ofthe material specication other than thowe lite in

‘Appendix Il of ASME BI65, refer © pera. 43.

‘43, Matelals Manufactured to Other Eons

“Material ay ene the requirements of tater spec

tation editors other than those sted in Append I

Of ASME B165, provided

(a) the materials ae the same specification,

grade, type, class, oF alloy and heat ueated conditions,

2 applicable

) the flange manefacturer certifies thatthe eu

iments of the edition ofthe specification listed in

‘Appendix Il of ASME B16. have been mat

4.4 Plugs

Presture-setaining plogs shall conform to

ASME Ble, unlest‘lherwice agreed between pur

‘chaser and manulactrer. Plug material shal be atleast

‘corrosion resistant as the corsesponding flange

toatl

Orifice flange sis ae indicated by the nominal pipe

size to which they aze attached. Only thon Ute in

‘ables 1 through 5, Tables Li through [-5, and

Mandatory Appondic sr considered standard

6 MARKING.

shall be marked as required in ASME B16.

For welding neck flanges only the bore diameter shall

‘be marked

7 FLANGE FACING FINISH

‘The nish of contact faces shall conform tothe requ

rents of ASME BIG.

18. GASKETS FOR RAISED FACE FLANGES,

8.1 Gasket Thickness

Flange dimensions are based on the ute of 15 mm

(006 8) thick gaskets

‘82 Flange Gaskets Requling Dimensional Changes

When the location of the pressure ap with spect to

the once plate i rit othe service and metering

‘conditions ts location may be altered to accommodate

ther than 15 mn (006 in) thick gaskets or

oun gaskats whose thickness may vary from that ited

In Tables 23,4 and Sor those sted In Tables 12,

and 15 ot Mandatory Append I

‘The alteration of location may also be accomplished

by the removal of 2mm (006 In) from the raised face

ofthe ange If an original 2 mum (208 in) high vse

face isremeved th useriscautiond nlite outside

dlinmeter ofthe gasket or once plate tothe tabulated

Reimenson.

9 PRESSURE TAPS.

9.4 Genera

ach orice flange shall be provided with two pres

sure lap holes extending radially fom the ouside dart

ter ofthe flange to the inside diameter ofthe flange.

{Comer tap may be used on NPS 1% and smaller

space penta Se Pg 1

For ving jin flanges listed in Tables 2 trough 5,

‘Tables U1 through 15, and Mandatory Append I,

‘where radial taps will nefee withthe Ting greO¥,

ngular meter taps as illustrated in Fig, 2 wil be

required. Each pressure tap hoe shall be equipped with

2 pipe plo

9.2 Location

92.1 Measurement, The2¢mm(0%4in) dimension

for rsd face and 19 mon (075 in) for rng joint shal

‘be mensued at the bore.

92.2 entiation. For rng ont anges requiring

alteration of pressure tap lcaion due 1 inererence

With the ving groove otter than methods provided in

this Sundar, such alteration shall be idenied per

‘agreement between purchaser and manufacturer

9.3 Pipe Connection

Unies othervise specified, pressure tp oles may be

either tapped NPT in accordance with ASME 81201

for %4 NPS socket connection in accordance with

‘Sse B16

10. JACK SCREW PROVISION

102 Location

‘ach flange shall have a machine bolt mounted ina

hole dled on the flange bol cee centerline at 90 deg.

from the pressure tps, for use asa ack srew. The

‘machine bot shall be raglar with one heavy hex nu

seg 3

102 Slot for Nut

‘A slot shal be provided in the flange 2mm (006 in)

wider than the width arose lat ofthe nat The depth of

‘he slot shall admit the nto that heres no interference

with the Joining of the flanges when belted together

‘without orifice plate

owe 636300

403 Tapped Hole

[Asan alemative to para, 102, a tapped hole may

‘be provided aed the hex nut omited when agreed on

betwen the purchaser and the manufacturer

111 FLANGE DIMENSIONS.

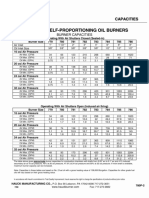

Dimensions are listed in Table 1, 2,3, 4 and 5 for

metric, and Tables 11, 1-2, F314, and 15, and

Mandatory Appendix Il for US. Customary

12. FLANGE THREADS.

‘Threaded flanges shall have an American National

Standard taper pipe thread. conforming. t0

‘ASME 81.201

(a) The tread shal be concentric with he axis ofthe

‘ange. Variations inalignment shall not exceed Samm

(@0s in

(@) The fanges are made with courterbores atthe

back of the flange and the threads shall be chamfered

tothe dante ofthe counterboreatanangie of prox

smatly 45 cag with the ais ofthe thread to atford easy

enuance nenaling joint. The counterbore and chamfer

Shall be conencic withthe thread.

(In oréer to permit the pipe tobe inserted tothe

face ofthe flange, the tveads should have ful root

lamers through tothe ace ofthe Nange, or shall have

' counterbore afte face of the flange.

(a) The gaging notch ofthe working gage shall come

ftush with the Bower ofthe chamfet inal headed

flanges and shall be considered as being the intersection

ofthe chamfer cone and the pte cone of the thread

‘This depth of chamfer spprosimately equal tone half

the pt of he teed

(e) The maximum allowable thread variation i one

‘urn large o smal fom the gaging noth

13, TOURANCES,

“olernees on all dimensions shal be at shown in

ASME BI65 except for those shown blow

13.1 Pressure Tap Location

‘Tolerance on location of center of pressure tap hole!

from flange face shall be

(a) 05mm (0.02in) for fanges smaller than NPS4

(6) =08 mum (2003 in) for Sages NPS 4 and lager

13.2 Bore Diameter

Bore diameter tolerance (welding neck anges only)

i= 405% of nominal val,

"Sepa 92

12 S40 Sa (80) pe 2

un 2 5 pa

end wos 2

Ped

o-dns pue ‘papeanuL ON BuIpIIM ‘saBUEL oyUO OE SSD AIgEL

Table 2 Class 600 Orifice Flanges, Welding Neck

fd 2m 58) rs 38,

f+] seeee sees

ASHE 96362008

21 Sa 5)

‘eave San 1 1 Sa (4 20m ox PoE

‘agumery sine 0

“ow wea

:

292 Buprom “saBumy soyUo 006 8m) € age

sue 16362008

2P2N SupIom ‘sa8uR 2yHO OOST S8EID v OIgEL

Ase 636009

ove pu sty ol 6 00) e085 CS 9 EUR NE p44

de ood Sa uo

1 ogee

peu Buiprem ‘seBuel e240 00Sz SED 5 aIgeL

Ase 816362008

Fig. 1 Comer Taps

Fig. 2 Angular Meter Tap fr RT) Flanges

Brin in

ito |

" i

—

swe 6362009

MANDATORY APPENDIX |

DIMENSIONAL DATA FOR CLASSES 300, 600, 900, 1500, AND

2500 FLANGES IN U.S. CUSTOMARY UNITS

This Appendix is an integral part of

ASME 81636209, ani placed afer the main text

forconveruence lables 1 trough 19, ncaa inthis

‘Appendix provide dimensional data in US. Cstomary.

{us forthe following: Classes 300, 00, S00, 30, and.

200 anges

is, Welding Neck, Threaded, and Slip-On

Table L4 Class 300 Office Fan

‘ner

ij

fF

‘ipon

a

ahi

hi

netgear asen ani fe Fos.

‘able +2 Class 600 Orifice Flanges, Welding Neck

25 fr PS $0 NPS 12 and 038m OMFS 1 NS 24 Beng Fag pe

sad in WPS 2,

le 13 Class 900 orice Flanges, Welding Neck

eal

¥

i

st

rq u

i=}

i

ort

si

osniN

omen

5 kat ci 0

959 NPS 1 md .38 Oe NPS 14 NPS 24, BR Mn oH pe

gs] esc cess

2pon Buipom ‘seuss e2yu0 Oost s5eD v1 o1gEL

e e es e e

ovenoy apo try wo! 20s Ye x al SiN STOP HUHNE Pen HO Heo

rib depen ep 4

ys

aun

pen Buyprem ‘sours soyvO oosz $8 $1 aE

MANDATORY APPENDIX II

DIMENSIONAL DATA FOR CLASS 400 FLANGES IN

U.S, CUSTOMARY UNITS

This Appendix is an integral part of

ASME 816362009, andi is placed ater the an text

for converiens. Table IF, icladed in this Appendix,

provides dimensional data in US. Customary tits for

las 400 fangs.

eo yay 09“ Sa SHB

eee ae z =

ES. sty pie sole pnt en ama Sao eu hn en "ok he nung Sow ving sie ys

rhe ae “neo

‘ume i 290

wea “perdu sseyom 520

ccm oseuo mcs 7

ci be U EL =

pan Buplom ‘saBuey syvO OW SHRI) TH aL

swe 16362009

MANDATORY APPENDIX Ill

REFERENCES

‘The following Is 2 ist of publiations referenced in

‘his Standard. The ates edions of ASME pubiatons

ae tbewed,

[ASME BI.201, Pipe Threaded, General Purpose (inch)

[ASME BI6S; Pipe Manges and Flanged Fitings

ASME BIG.11, Forged Fittings, Sockat Welding and

"Toesded

[ASME BI621, Nonmetalic Gaskets for Pipe Flanges

[ASME Boiler and Pressure Vessel Code Sein Power

Boilers; Section Il, Materials Section Il, Nuclear

Power Fant Components Section VI, Divisions T

and 2 Pressure Vessels

Publisher: The American Society of Mechanical

Enginsers (ASME, Thre Park Avene New Yor,

»

NY 10016-5990; Order Department:22 Law Deve, PO.

‘Box 2300, Farid, N] 0707-200 (www asme orp)

SO 9000-2008, Quality management systems —

‘Fundamentals and vocabulary

150 9001-2008, Quality management systems —

Requzements

180 3004:2000, Quality management systems —

(Guidelines for performance improvernens

Publisher: International Organization for

‘Standardization ($0) 1 ch, de la Vole-Creuse, Case

Postale 6, CH-1211 Genive 20, Switzedand/Suine

(risocg)

NONMANDATORY APPENDIX A

QUALITY SYSTEM PROGRAM

"The products manufactured in acconance with this

Standard shall be predced under «quality system pro-

‘gram following the principles of en appropiate see

‘Sard from the 150 900 series” determination ofthe

eed for registration, certifeatonorbot, ofthe product

‘manufacturer's quality system program by an indepen

dent organization sallbe the respon ofthe mans

facture, The delalled documentation demonstating,

‘rogram compliance shall be avallble othe purchase

tthe manufacturer's facility. A written summa

‘eacription ofthe program tian bythe product man

‘Macturer shal be available to the purchaser upon

request, The product manufacture defined atthe

B16 AMERICAN NATIONAL STANDARDS FOR PIPING,

PIPE FLANGES, FITTINGS, AND VALVES

Sey on ares nad ig hs 12, 290

Tse ngs Cases 75 an 30. a

Pipe Page Ranges Pes NPS ough NS iin Sod

Facade Wmugh ume hg

Fare Png ote wigs rade

(aatton neaed Dingess.

Ferour pe us Srna ts wih Pass

(ls Copp Alay eae gs

le Copp Aly Suge tt ess Fas.

Nei Goi Po ane i i

"Et pe Ao Slat Daye Fang

{Sey Fares an Fa in Gis 5,5 36 |

Gat ope ying Ft pps ibs

‘ugh Sel Guowldng Stor as owe and ns

‘ah Cone ond Wes Cope’ Aly Sols oat ge i

‘Manan perder Sen as Pine Sisto p02 ol

‘ies wT WS

wee = Rane Tae 6 Wiig

ta ee ae fir i ian away Gp Ww 33; 69)

TENS 12 Sah 35 peg bat mam,

‘analy Operates Temopeste Gs Shots aa Yates Gs Dion Sas.

Fine ascatn Reuter fr owe: Opens Ac tae Asm ce Pot Ps.

‘ates Pipe Range Reged Pings Cases 30 on 300

‘ony pets er a aver ran amend Pine Stns To

‘Gt on ngs Soe” Damage Sens.

‘Ban es sh ich Sad

ian i cin i rt i ns

‘Wout Cope on ape lay seat ete nar

idiooee ea

idisaee ga010)

116332002 2007)

Bisse 2002 2007)

ties i9s food)

ies 200 ama)

‘he ASME Pens Calo shows camp st al eStats bythe Scie or compet aa, ate

‘omen abut ur ants, al a00 MEAS 0450809769.

ASME Services

ASME commited to deine

(esos

ete hil nforston ALAS Ioan Cen we met ft anor your

ed youre Or pees oe steal Yoh e lone ses

ASME Press Member ences & Benefits Publi lformation

Codes 8 Stondards Other ASME Pogams SetStudy Courses

rei Crd Orders Payment Inquites ‘Shipping formation

‘Meche Publications Professional Development ‘Subscritonsourals/ Magazines

Meetings & Conerences ‘Shor Courses ‘Symposia Volumes

Member Dues Status ubeatons ‘eenial Papers

ow can you reach us? W's easier than ever!

“There are four options fr making ingultes or placing rds. Simply mal phone, fx or mall us and an information

Cental representative wil handle your request

‘mai al Free Fo=24 hows ——EMoil~24 hours

ASME US Canada: soo-THEASME 973.882.1717 _Infocentalgasmeorg

22 Law ve, Box 2900 (000-043 2763), proaees

Fail, New frsey Mexico 95-8006 ASME

97007-2900) (95.800-863.2763)

Univers 97882-1167

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASME STD B30.12 Handling Loads Suspended From Rotorcraft (2011)Document36 pagesASME STD B30.12 Handling Loads Suspended From Rotorcraft (2011)JoelCristobalNo ratings yet

- So PortesDocument1 pageSo PortesJoelCristobalNo ratings yet

- PR 101Document74 pagesPR 101JoelCristobalNo ratings yet

- PR 359Document114 pagesPR 359JoelCristobalNo ratings yet

- Vastago EmboloDocument1 pageVastago EmboloJoelCristobalNo ratings yet

- PR 006Document166 pagesPR 006JoelCristobalNo ratings yet

- Archivos Parker - Bombas de Pistones Circuito CerradosDocument1 pageArchivos Parker - Bombas de Pistones Circuito CerradosJoelCristobalNo ratings yet

- Hydraulics of Closed Conduit Spillways: Esetstiea!. C$PyDocument62 pagesHydraulics of Closed Conduit Spillways: Esetstiea!. C$PyJoelCristobalNo ratings yet

- Threadolet Roscado 3000 LBS Acero ForjadoDocument1 pageThreadolet Roscado 3000 LBS Acero ForjadoJoelCristobalNo ratings yet

- Archivos Bombas de Pistones Circuito Cerrado Danfoss1Document1 pageArchivos Bombas de Pistones Circuito Cerrado Danfoss1JoelCristobalNo ratings yet

- Simulador de Gestión Estratégica - Manual Del ParticipanteDocument18 pagesSimulador de Gestión Estratégica - Manual Del ParticipanteJoelCristobalNo ratings yet

- Inspection and Heat Treatment SummaryDocument1 pageInspection and Heat Treatment SummaryJoelCristobalNo ratings yet

- Archivos Bombas de Pistones Circuito Abierto Danfoss - HDIDocument1 pageArchivos Bombas de Pistones Circuito Abierto Danfoss - HDIJoelCristobalNo ratings yet

- 780 PDocument12 pages780 PJoelCristobalNo ratings yet

- Nalco Elimin-Ox®: Material Safety Data SheetDocument11 pagesNalco Elimin-Ox®: Material Safety Data SheetJoelCristobalNo ratings yet

- CP041Fen Bypass DampfkesselDocument12 pagesCP041Fen Bypass DampfkesselJoelCristobalNo ratings yet

- 87 SDRDocument124 pages87 SDRJoelCristobalNo ratings yet

- Residual R-500 Ficha de Seguridad - Oct 16Document13 pagesResidual R-500 Ficha de Seguridad - Oct 16JoelCristobalNo ratings yet