Professional Documents

Culture Documents

Job Safety Analysis Template For Construction

Job Safety Analysis Template For Construction

Uploaded by

Bernat GeboyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis Template For Construction

Job Safety Analysis Template For Construction

Uploaded by

Bernat GeboyCopyright:

Available Formats

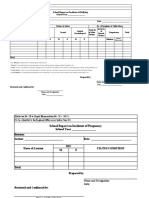

In case of an incident, the following people

will be contacted:

Job/Task: ___________________________________________________ Date: ___________

New Supervisor:________________________

Work Location: _____________________________________ Safety:___________________________

Employee(s): _________________________________________________________________ Revised Other:_____________________________

• What is the most hazardous part of this job and what are you going to do to control the hazard?_____________________________________

• Are you properly trained to complete these tasks? _____________________________ SSE___________________ Mentor __________________

• What do you need to ensure this job is completed incident and injury free? _____________________________________________________

• What conditions, job changes or distractions could call for the need to use Stop Work Authority?_____________________________________

Sequence of Job Steps Potential Hazard(s) Recommended Action/Procedure Examine each step

carefully to find and

identify hazards or

potential dangers that

could lead to injury,

illness or damage.

Consider the following:

Chemical Hazard:

_Inhalation _Skin Contact

_Absorption _Injection

_Ingestion

Biological Hazards:

_Bloodborne Pathogens

_Mold _Valley Fever

_Plant/Insect/Animal

Physical Hazards:

_Electrical

_Fire/Explosion

_Noise _Radiation

_Thermal Stress

_Pinch Point/Line of Fire

_Slips/Falls

_Strike against/Struck by

face shield chemical goggles chemical protective clothing rubber boots chemical resistant gloves Ergonomic Hazards:

Additional Personal

leather gloves cut resistant gloves respiratory protection ______________________ arm protection _Repetition

Protective Equipment Req’d hearing protection fall protection Other ____________________________________________________ _Forceful exertion

Required Permits/Safe Work General SWP Hot Work Permit Confined Space Entry Excavation and Trenching Lift Plan/Crane Ops _Awkward Posture

Plans Work in proximity to Overhead Conductors Simultaneous Operations _Contact Stress

_Vibration

Gas Detection

H2S monitor LEL, O2, H2S, CO Monitor Other _______________________________________________ _Work Area Design

Equipment Needed

List hazardous substances

MSDS reviewed? yes n/a

barricades post signs caution tape designated area for vehicles heavy equipment spotter

Site Control establish meet and greet process Other_________________________ Other _______________________

Environmental Conditions Weather: Terrain: Wildlife:

LO/TO checklist complete LO/TO devices in place energy isolation verified Stored Energy _______

Hazardous Energy Control

electrical hydraulic pneumatic mechanical thermal chemical Line Of Fire _________

pre-use inspection complete trained in use of tool/equipment

Tools and Equipment List tools/equipment being used:____________________________________________________

Copyright © 2008 Chevron Corporation All rights reserved.

Work Site Diagram – Include equipment set-up, evacuation route, assembly area and identified hazards

JSA Reviewed by:

_________________________________ _____________________________________ ____________________________________

_________________________________ _____________________________________ ____________________________________

_________________________________ _____________________________________ ____________________________________

_________________________________ _____________________________________ ____________________________________

_________________________________ _____________________________________ ____________________________________

_________________________________ _____________________________________ ____________________________________

Copyright © 2008 Chevron Corporation All rights reserved.

You might also like

- SAC - Planning - Usecase ExplorationDocument23 pagesSAC - Planning - Usecase ExplorationGasserNo ratings yet

- IMT - Ceres - Tarun Singh ChauhanDocument6 pagesIMT - Ceres - Tarun Singh ChauhanTarun Singh ChauhanNo ratings yet

- Final HiraDocument39 pagesFinal HiraAnsari HarisNo ratings yet

- MBA Notes For Insurance Risk ManagementDocument14 pagesMBA Notes For Insurance Risk ManagementSudhanshu Sharma100% (3)

- Are Cloud (Virtual) Kitchens Profitable - Aadil Kazmi - MediumDocument9 pagesAre Cloud (Virtual) Kitchens Profitable - Aadil Kazmi - Mediumfatank0450% (2)

- Injury Incident Report FormDocument3 pagesInjury Incident Report FormDave Joseph Conde100% (1)

- IC 34 Question Bank - Answer PaperDocument40 pagesIC 34 Question Bank - Answer Papermaakabhawan2667% (9)

- 5S Action PlanDocument4 pages5S Action Planjaimmariant jucomNo ratings yet

- Job-Safety-Analysis-Template PDF - PDF Version 1Document2 pagesJob-Safety-Analysis-Template PDF - PDF Version 1Tarik SenaneNo ratings yet

- Frontline Personnel in Basic Education and Higher Education IDocument2 pagesFrontline Personnel in Basic Education and Higher Education IanneNo ratings yet

- Inhalation - Skin Contact - Absorption - Injection - IngestionDocument3 pagesInhalation - Skin Contact - Absorption - Injection - IngestionMuhammadShoaibNo ratings yet

- CHD3 - NUEVA ECIJA - CBC05604 - Day10 (05-07-21)Document2 pagesCHD3 - NUEVA ECIJA - CBC05604 - Day10 (05-07-21)RHU PeñarandaNo ratings yet

- DPHS Self Inventory FormDocument3 pagesDPHS Self Inventory FormFelipe SantillanNo ratings yet

- Covid 19 Vaccination Masterlist FormDocument2 pagesCovid 19 Vaccination Masterlist FormChrislyn RejasNo ratings yet

- Workplace Hazard Assessment FormDocument2 pagesWorkplace Hazard Assessment FormAndré BensbergNo ratings yet

- THC 2 Module 1 - Risk Management Concept & PrinciplesDocument4 pagesTHC 2 Module 1 - Risk Management Concept & PrinciplesRyan ZarcoNo ratings yet

- Non-Neonatal Tetanus: (ICD 10 Code: A35)Document2 pagesNon-Neonatal Tetanus: (ICD 10 Code: A35)CHICKY100% (1)

- Masterlisting DOHDocument2 pagesMasterlisting DOHANTONETTE LAPLANANo ratings yet

- Ceir Form-Bikal BHS 2021Document2 pagesCeir Form-Bikal BHS 2021Mark Jake RodriguezNo ratings yet

- Risk and Hazard 1234567890Document2 pagesRisk and Hazard 1234567890Philip Frantz GuerreroNo ratings yet

- Covid 19 Baseline Risk Assessment 13 October 21Document9 pagesCovid 19 Baseline Risk Assessment 13 October 21Pieter HerbstNo ratings yet

- Nature of Bullying Victims PerpetratorDocument4 pagesNature of Bullying Victims Perpetratorjc juanero100% (1)

- Hazard Identification and Risk AssessmentDocument4 pagesHazard Identification and Risk AssessmentAmalay Raffli ArnoldyNo ratings yet

- Risk Management PPT - Dr.J.MexonDocument47 pagesRisk Management PPT - Dr.J.MexonDr.J. MexonNo ratings yet

- Principles of InsuranceDocument35 pagesPrinciples of Insuranceckchetankhatri967No ratings yet

- Form Incident Investigation Report Form Tiybi9Document5 pagesForm Incident Investigation Report Form Tiybi9Godfrey TamaneNo ratings yet

- Ceir Form-PanimanDocument9 pagesCeir Form-PanimanMark Jake RodriguezNo ratings yet

- 29 CFR 1910.132 Equipo de Protección Personal Analisis de PuestosDocument5 pages29 CFR 1910.132 Equipo de Protección Personal Analisis de PuestosAlejandro CristalesNo ratings yet

- D3R - Module-1 - 2ND Sem - 2ND Quarter - Grade-11 - Stem-Del-Pilar - Stem-Malvar - Mr.-Arnold-PaombongDocument15 pagesD3R - Module-1 - 2ND Sem - 2ND Quarter - Grade-11 - Stem-Del-Pilar - Stem-Malvar - Mr.-Arnold-PaombongArnold Arada PaombongNo ratings yet

- Template OSHprogramDocument12 pagesTemplate OSHprogramRico SengcoNo ratings yet

- Instructions:: Office NameDocument3 pagesInstructions:: Office NameRengie RoxasNo ratings yet

- Housekeeping: Mr. Jerwin R. LuctoDocument10 pagesHousekeeping: Mr. Jerwin R. LuctoMarion AlbertoNo ratings yet

- Insurance Lecture 1-2Document21 pagesInsurance Lecture 1-2Rabita ShahnazNo ratings yet

- Important Terminologies OSH Concept: Reasons For Preventing Accidents. - Moral/Humane - Cost - LegislationDocument2 pagesImportant Terminologies OSH Concept: Reasons For Preventing Accidents. - Moral/Humane - Cost - LegislationNur Atiqah NabilaNo ratings yet

- Template For DO Report Incidents of Child Abuse Incidents-Of-BullyingDocument5 pagesTemplate For DO Report Incidents of Child Abuse Incidents-Of-BullyingJewelNo ratings yet

- Chapter 1-3 SummaryDocument9 pagesChapter 1-3 SummaryalessiamenNo ratings yet

- BME 2205 (Lec-1.1)Document9 pagesBME 2205 (Lec-1.1)Atika Mustari SamiNo ratings yet

- Ceir-Form Oroc-OsocDocument2 pagesCeir-Form Oroc-OsocMark Jake RodriguezNo ratings yet

- Insurance - Types of RiskDocument3 pagesInsurance - Types of RiskMohit SharmaNo ratings yet

- ESH Incident Investigation FormDocument2 pagesESH Incident Investigation FormElvyn Fabellore HerreraNo ratings yet

- Risk ManagementDocument9 pagesRisk ManagementSoleil Sierra ReigoNo ratings yet

- Camp Highland - Adult Medical-Liability FormDocument1 pageCamp Highland - Adult Medical-Liability FormMark AdamsNo ratings yet

- RISK Meanng, Classification - Class-4Document6 pagesRISK Meanng, Classification - Class-4surya kumarNo ratings yet

- Staff Health PDFDocument1 pageStaff Health PDFJorgeNo ratings yet

- Pure Vs Speculative RiskDocument5 pagesPure Vs Speculative Riskpriti mishraNo ratings yet

- School-Based Report On Incidents of Bullying SY 2020-2021Document5 pagesSchool-Based Report On Incidents of Bullying SY 2020-2021Jeraldine MayolNo ratings yet

- Grade - Section - SHS Health ProfileDocument122 pagesGrade - Section - SHS Health ProfileOfelia DavidNo ratings yet

- Risk ManagementDocument9 pagesRisk ManagementKumkum SultanaNo ratings yet

- Ch1. Risk and Its TreatmentDocument7 pagesCh1. Risk and Its TreatmentRaghda HussienNo ratings yet

- Types of RisksDocument3 pagesTypes of RisksayushdixitNo ratings yet

- Hazard Near Miss ReportDocument1 pageHazard Near Miss ReportvNo ratings yet

- FM 11-9 Gbs For Week 02 03 PDFDocument11 pagesFM 11-9 Gbs For Week 02 03 PDFShugi YenNo ratings yet

- Waiver For Physical Classes: (Name of The Student)Document1 pageWaiver For Physical Classes: (Name of The Student)James PotenteNo ratings yet

- Quarter 4 Week 5 and 6 FinalDocument9 pagesQuarter 4 Week 5 and 6 FinalJD SevillaNo ratings yet

- Policy Premium (Taxes Extra) : EligibilityDocument2 pagesPolicy Premium (Taxes Extra) : EligibilitysyamprasadNo ratings yet

- Chapter 1 Nature of RiskDocument17 pagesChapter 1 Nature of RiskNur Syhuhada Che HussinNo ratings yet

- Hazard and Risk1111Document5 pagesHazard and Risk1111Janel Buhat GrimaldoNo ratings yet

- FORM 07 Latihan HIRADocument20 pagesFORM 07 Latihan HIRAahmad vocheNo ratings yet

- Quarter 3: Caregiving: Teacher: Jolina Mae C. Anit, LPTDocument15 pagesQuarter 3: Caregiving: Teacher: Jolina Mae C. Anit, LPTJolina AnitNo ratings yet

- Drug Study FormatDocument2 pagesDrug Study FormatSheena Marie M. TarleNo ratings yet

- 2021 Undergraduate Scholarships Online Application Form Form C - Certificate of Good Moral CharacterDocument2 pages2021 Undergraduate Scholarships Online Application Form Form C - Certificate of Good Moral CharacterHaneyzil Medico LarangjoNo ratings yet

- Directed Writing - Article (Haze)Document2 pagesDirected Writing - Article (Haze)M Arshad M Amir100% (1)

- Hse For Engineers-PresentDocument30 pagesHse For Engineers-PresentMalayalam musical CollectionNo ratings yet

- Prepping for Survival in a Disaster: Be Tougher than the DisastersFrom EverandPrepping for Survival in a Disaster: Be Tougher than the DisastersNo ratings yet

- Amazon Sued Over Smart Speakers and Targeted AdsDocument33 pagesAmazon Sued Over Smart Speakers and Targeted AdsGeekWireNo ratings yet

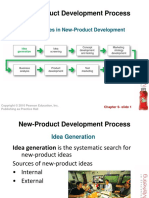

- Major Stages in New-Product DevelopmentDocument14 pagesMajor Stages in New-Product Developmentasif tajNo ratings yet

- "Banking and Finance": Project Report OnDocument49 pages"Banking and Finance": Project Report OnRiya ThakkarNo ratings yet

- DMAIC Unit2Document12 pagesDMAIC Unit2karamNo ratings yet

- Pres 20150608 Roadshow Presentatie Electrabel Final PDFDocument8 pagesPres 20150608 Roadshow Presentatie Electrabel Final PDFfakesasoNo ratings yet

- Monthly Test Acc - XiiDocument4 pagesMonthly Test Acc - Xiiramandeep kaurNo ratings yet

- Feature Paper Dr. Felice Yeban Adrian Cabarle Ii-8 BsseDocument8 pagesFeature Paper Dr. Felice Yeban Adrian Cabarle Ii-8 BsseAdrian CabarleNo ratings yet

- Dissertation Implications of Fair Value Accounting After Transition To IFRS-1-KJA-NTDocument26 pagesDissertation Implications of Fair Value Accounting After Transition To IFRS-1-KJA-NTGerda AbdeevaNo ratings yet

- Supply Chain & Visual MerchandisingDocument32 pagesSupply Chain & Visual MerchandisingprashantmiracleNo ratings yet

- Management Practices of Multipurpose Coo PDFDocument11 pagesManagement Practices of Multipurpose Coo PDFred calabiaoNo ratings yet

- AUDIT InterviewDocument72 pagesAUDIT InterviewTituNo ratings yet

- Culture-Strategy-Execution Trio A How-To Guide by Ming-Jer Chen, Yi Ping Chan, Charles TuckerDocument13 pagesCulture-Strategy-Execution Trio A How-To Guide by Ming-Jer Chen, Yi Ping Chan, Charles TuckerAmit Sahoo SSSVV100% (1)

- Inventories - SolutionDocument2 pagesInventories - SolutionKyla De LunaNo ratings yet

- Strategy and Simulation PPT Ca 2Document9 pagesStrategy and Simulation PPT Ca 2Jyoti Arvind PathakNo ratings yet

- Chapter 6: Overview of Transaction Processing and Financial Reporting SystemsDocument6 pagesChapter 6: Overview of Transaction Processing and Financial Reporting Systemsmostafakhaled333No ratings yet

- Mini Project of ProjectDocument10 pagesMini Project of ProjectBorisNo ratings yet

- Cinta Nastasya - Case Study Report - Leadership & Organization Behavior Assignment - FinDocument9 pagesCinta Nastasya - Case Study Report - Leadership & Organization Behavior Assignment - FinCinta NastasyaNo ratings yet

- Project Report ON Electrical&Electronics Repairing (Service Sector Unit) Under P.M.E.G.PDocument6 pagesProject Report ON Electrical&Electronics Repairing (Service Sector Unit) Under P.M.E.G.PGlobal Law FirmNo ratings yet

- Pitch DeckDocument21 pagesPitch DeckIANo ratings yet

- Ratan TataDocument11 pagesRatan TataHemant KumarNo ratings yet

- MURALI Hero Honda Ltd.Document1 pageMURALI Hero Honda Ltd.balki123No ratings yet

- 08 - Nurturing Green (C)Document14 pages08 - Nurturing Green (C)miku hrshNo ratings yet

- PGPLI BrochureDocument12 pagesPGPLI BrochureAbhijeet RajputNo ratings yet

- Iso 13485Document1 pageIso 13485TBYT Đông DươngNo ratings yet

- Standard Plastics Industry Bulk Box/Pallet Unit Size Classified by Bulk DensityDocument5 pagesStandard Plastics Industry Bulk Box/Pallet Unit Size Classified by Bulk Densityasma hamzaNo ratings yet