Professional Documents

Culture Documents

18F42-ol-6-Air Compressors-Ehab Abowarda

Uploaded by

ehabwardaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18F42-ol-6-Air Compressors-Ehab Abowarda

Uploaded by

ehabwardaCopyright:

Available Formats

Program #04:

Air Compressors Maintenance Inspection & Overhaul

Training Descriptions:

This program will provide the participants with the fundamental concepts of the compressed air systems.

Participants will have in depth knowledge of improving performance, proper operation, inspection,

predictive and preventive maintenance and troubleshooting through presentation of actual case studies.

Training Objectives:

By the end of the training, participants will be able to:

Identification of different components of compressed air systems.

Specifications of instrument air characteristics and quality parameters.

Compressor classification and working principles of each type.

Screw air compressor working theory and practice.

Air dryers types and working principles

Air compressor components and its specifications.

Setting maintenance program to achieve optimum operating conditions.

Predictive maintenance techniques applicable to instrument air systems.

Training Designed for:

This course is intended for Mechanical Engineers, supervisors and foremen working with instrument air

systems operation and maintenance.

Topics:

DAY ONE:

PRE-TEST

Compressed air theory

o Physical units: pressure, temperature, thermal capacity, work, power, volume air flow rate.

o Thermodynamics: gas laws, heat transfer, flow through pipes, throttling

o Air: chemical composition of air, vapour pressure, relative humidity

Air compressor classification

o Positive Displacement compressors: reciprocating, rotary; screw, roots blowers, sliding vane

types.

o Dynamic air compressors: centrifugal, mixed flow, axial flow

o Multistage compression.

DAY TWO:

Regulation and Unloading systems

o Regulation in general.

o Pressure relief.

o Suction Loading/ unloading valve

DAY THREE:

Bearings and lubrication systems.

o Oil free vs. oil flooded air compressors

Rev.001 COURSE OUTLINE Page 1 of 2

o Friction and bearing types

o Lube oil system components and working principles

DAY FOUR:

Air cooling and drying

o Intercooling and after-cooling

o Water cooling vs. air cooling systems.

o Moisture traps

o Adsorption dryers.

o Absorption dryers.

o Refrigerant dryers.

o Membrane dryers.

o Air filters.

DAY FIVE:

Air distribution network improvement and optimization

o Air receiver

o Distribution network dimensioning and design

Troubleshooting and maintenance program

o Preventive maintenance program

o Predictive maintenance techniques

Course Conclusion

POST-TEST and EVALUATION

Training Requirement:

“Hand’s on practical sessions, equipment and software will be applied during the course if required

and as per the client’s request”.

Training Methodology:

This interactive training course includes the following training methodologies as a percentage of the total

tuition hours:-

30% Lectures, Concepts, Role Play

30% Workshops & Work Presentations, Techniques

20% Based on Case Studies & Practical Exercises

20% Videos, Software & General Discussions

Pre and Post Test

Rev.001 COURSE OUTLINE Page 2 of 2

You might also like

- 2 Shaftp-SealingDocument23 pages2 Shaftp-SealingehabwardaNo ratings yet

- 18F39-3-Rotating Equipment-EHAB ABOWARDA-olDocument3 pages18F39-3-Rotating Equipment-EHAB ABOWARDA-olehabwardaNo ratings yet

- 1 - Theory and PrinciplesDocument29 pages1 - Theory and PrinciplesehabwardaNo ratings yet

- 18f39 18 Valves Ehab Abowarda OlDocument4 pages18f39 18 Valves Ehab Abowarda OlehabwardaNo ratings yet

- On-Call Equipment Maintenance Agreement: Pitney Bowes Inc., Through Its Document Messaging Technologies DivisionDocument9 pagesOn-Call Equipment Maintenance Agreement: Pitney Bowes Inc., Through Its Document Messaging Technologies DivisionehabwardaNo ratings yet

- 18F42-ol-4-Advanced Maintenance-Ehab AbowardaDocument2 pages18F42-ol-4-Advanced Maintenance-Ehab AbowardaehabwardaNo ratings yet

- 1 - Theory and PrinciplesDocument29 pages1 - Theory and PrinciplesehabwardaNo ratings yet

- 18f39 18 Valves Ehab Abowarda OlDocument4 pages18f39 18 Valves Ehab Abowarda OlehabwardaNo ratings yet

- 01 Interpretation of Engineering Drawing-AgendaDocument2 pages01 Interpretation of Engineering Drawing-AgendaehabwardaNo ratings yet

- 18F46-Introduction To Piping SystemDocument2 pages18F46-Introduction To Piping SystemehabwardaNo ratings yet

- 18F46-DOMI of Piping System and Valves Level 2Document5 pages18F46-DOMI of Piping System and Valves Level 2ehabwardaNo ratings yet

- Ol Maintenance Planning Ehab AbowardaDocument2 pagesOl Maintenance Planning Ehab AbowardaehabwardaNo ratings yet

- 18F46-Valves and Safety Valves Operation MaintenanceDocument2 pages18F46-Valves and Safety Valves Operation MaintenanceehabwardaNo ratings yet

- 18F46-DOMI of Compressors Blowers Level 2Document2 pages18F46-DOMI of Compressors Blowers Level 2ehabwardaNo ratings yet

- In-depth Pump Technology TrainingDocument2 pagesIn-depth Pump Technology TrainingehabwardaNo ratings yet

- 18F46-DOMI of Rotating Equipment Level 1Document3 pages18F46-DOMI of Rotating Equipment Level 1ehabwardaNo ratings yet

- Mechanical Technician Basic Training-EHAB ABOWARDA-olDocument2 pagesMechanical Technician Basic Training-EHAB ABOWARDA-olehabwardaNo ratings yet

- 05.04.16 Special Tribal Consultation Agreement Share Exchange DataDocument7 pages05.04.16 Special Tribal Consultation Agreement Share Exchange DataehabwardaNo ratings yet

- A05-02 Agency Client Agreement CleanDocument10 pagesA05-02 Agency Client Agreement CleanehabwardaNo ratings yet

- Ol-Air Compressors Operation and Maintenance-Ehab Abowarda-OlDocument2 pagesOl-Air Compressors Operation and Maintenance-Ehab Abowarda-OlehabwardaNo ratings yet

- 18F42 Ol 43 Mechanical Maintenance Ehab AbowardaDocument2 pages18F42 Ol 43 Mechanical Maintenance Ehab AbowardaehabwardaNo ratings yet

- 0A1185 - Supplement 5 - Data Sharing and Confidentiality AgreementDocument7 pages0A1185 - Supplement 5 - Data Sharing and Confidentiality AgreementehabwardaNo ratings yet

- Mechanical Maintenance ToT OlDocument2 pagesMechanical Maintenance ToT OlehabwardaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Principles of Ship HandlingDocument10 pagesPrinciples of Ship HandlingFrednixen GapoyNo ratings yet

- KS D 3504: Steel bars for concrete reinforcementDocument36 pagesKS D 3504: Steel bars for concrete reinforcementTrọng Đẹp TraiNo ratings yet

- Experienced Welder ResumeDocument2 pagesExperienced Welder ResumeHarry DemeterioNo ratings yet

- Science 8 - Module 3 - Version 3Document11 pagesScience 8 - Module 3 - Version 3buena fe chavezNo ratings yet

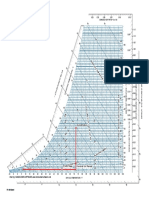

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDocument1 pageState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyNo ratings yet

- Form and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMDocument1 pageForm and Position Tolerances: Tolerance Classes General Tolerances For Straightness and Flatness in MMTrọng NgôNo ratings yet

- ECT018 - Analisis de Sist 3F Con Componentes SimetricosDocument33 pagesECT018 - Analisis de Sist 3F Con Componentes SimetricosfsalviniNo ratings yet

- Bhamal Dugwell - EstimateDocument30 pagesBhamal Dugwell - EstimateOm ChauhanNo ratings yet

- Excess Electronic Recoil Events in XENON1TDocument26 pagesExcess Electronic Recoil Events in XENON1Tkelvingno2No ratings yet

- Pepak FrasDocument1 pagePepak Frasapi-59387842No ratings yet

- An Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite WallsDocument11 pagesAn Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite Wallsci_balaNo ratings yet

- Prepp - In-Preparation Strategy For IAS UPSC CSE Electrical Engineering OptionalDocument6 pagesPrepp - In-Preparation Strategy For IAS UPSC CSE Electrical Engineering Optionalmojo xoxoNo ratings yet

- Industrial Electronic ReportDocument5 pagesIndustrial Electronic ReportAkmal HazimNo ratings yet

- IAPB 08 PosterDocument1 pageIAPB 08 Postertovih27684No ratings yet

- Research Paper - Beyond The Knee Point (CT Saturation)Document23 pagesResearch Paper - Beyond The Knee Point (CT Saturation)James BurtonNo ratings yet

- Tightening Torque of A Bolted Joint - MetricDocument2 pagesTightening Torque of A Bolted Joint - MetricgdwvcdNo ratings yet

- Artists' Pastels: Standard Specification ForDocument5 pagesArtists' Pastels: Standard Specification ForPyone Ei ZinNo ratings yet

- Sriram Physics PDFDocument108 pagesSriram Physics PDFRamesh GavvaNo ratings yet

- 03-07-2022 SolDocument11 pages03-07-2022 SolPrajjwal DwivediNo ratings yet

- Ac Generator TheoryDocument3 pagesAc Generator TheoryKrizelle ManaloNo ratings yet

- Science Pre BoardDocument6 pagesScience Pre BoardvspkpracticalNo ratings yet

- Answer Key Its All About WavesDocument4 pagesAnswer Key Its All About WavesyeiNo ratings yet

- Kennametal - Tungsten Carbide Composite Brazing Rods DatasheetDocument1 pageKennametal - Tungsten Carbide Composite Brazing Rods DatasheetsakthiNo ratings yet

- Simbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsDocument3 pagesSimbawa Oliver Task 2 Reading Report Calculus and Its Application To PhysicsOliver SimbawaNo ratings yet

- Lectur2 SCDocument35 pagesLectur2 SCbouk omraNo ratings yet

- NEW BENNI - Manual de ServicioDocument678 pagesNEW BENNI - Manual de ServicioSantiago CosNo ratings yet

- 4ch1 1c Rms 20220303Document18 pages4ch1 1c Rms 20220303unknow nowwNo ratings yet

- Model 570 Pressure TransmitterDocument4 pagesModel 570 Pressure TransmitterToan KeNo ratings yet

- Lecture 2 The Manufacturing Process 2020Document48 pagesLecture 2 The Manufacturing Process 2020Noam ShemlaNo ratings yet

- Assembly Features: Front ViewDocument2 pagesAssembly Features: Front ViewUTC Fire & Security SpainNo ratings yet