Professional Documents

Culture Documents

Closed Crawl Spaces Do Double Duty

Uploaded by

Ken GrossOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Closed Crawl Spaces Do Double Duty

Uploaded by

Ken GrossCopyright:

Available Formats

CLOSED CRAWL SPACES

DO DOUBLE DUTY

A field demonstration project in North Carolina shows that

this robust moisture control method also offers significant

energy savings.

BY CYRUS DASTUR

AND BRUCE DAVIS

W all-vented crawl spaces are

widely used in building con-

struction throughout North

America. Approximately 200,000 new

homes are built on crawl spaces every

year, and an estimated 26 million such

homes are already in existence.They are

cheap to build; functional in terms of pro-

viding a level foundation for flooring on

sloping sites; and popular as spaces in

which to locate plumbing, ductwork, and

heating and air conditioning systems.

ADVANCED ENERGY

Unfortunately, wall-vented crawl spaces

can also host a variety of serious moisture

problems. Closed (also called sealed or

unvented) crawl spaces represent both a Closed crawl spaces represent both a new business opportunity and a risk management tool for many

new business opportunity and a risk man- different stakeholders in the construction industry.

agement tool for many different stake-

holders in the construction industry, from

pest management companies to building ious crawl space ventilation and insula- fingers crossed against the possibility that

performance contractors and foundation tion strategies affect moisture levels and the moisture solutions might actually

specialists.As complaints and legal action energy use in houses in the southeastern cause an increase in energy consump-

related to mold growth in homes have United States.Another primary goal of tion.We were pleasantly surprised when

increased, homeowners, tenants, and the this research has been to demonstrate measurements showed the techniques to

construction industry have become much practical, easily transferable, and clearly be very beneficial for both moisture

more aware of the need to control mois- understandable crawl space construction control and energy efficiency.

ture in homes.This awareness is prompt- techniques that would solve a multitude

ing a growing number of owners and of moisture problems and would be at Experimental Setup

builders to invest the additional time and least energy neutral; at best, we were

money required to install closed crawl hoping to reduce energy consumption The 12 homes studied in this project

spaces in both new and existing homes. for space conditioning.When the project are located in the same development in

In response to these growing con- began in the fall of 2001, we did not Princeville, North Carolina. Six houses

cerns,Advanced Energy has undertaken know whether the interventions would are built, side-by-side, on each side of one

a multiyear effort to document how var- show energy savings. Some of us had our street.All are the same size—1,040 ft2—

HOME ENERGY • 2005 SPECIAL ISSUE www.homeenergy.org 1

foundation wall, stopping 3 inches from

the top of the masonry to provide a ter-

mite inspection gap. The seams of the

liner are sealed with fiberglass mesh tape

and mastic, and the edges are sealed with

mastic and mesh tape to the foundation

wall or intermediate piers. The liner is

mechanically secured to the soil with

turf staples and to the foundation wall

with a furring strip.

Mechanical drying in the closed crawl

spaces is provided by a 4-inch duct that

delivers 35 CFM of conditioned air to the

crawl space from the supply plenum

whenever the air handler is running. As

designed, the extra air simply exfiltrates

ADVANCED ENERGY

through the crawl space perimeter wall.

No fan-timing or fan-cycling controls are

used in the mechanical system, and no

We outfitted all 12 houses with electricity submeters to record exact energy consumption by each stand-alone dehumidifiers are used for

home’s package unit heat pump system. moisture control.A balancing damper per-

mits adjustment of the flow, and a back-

flow butterfly gravity damper with a

with the same floor plan and window of filtered fresh air is mixed into the nonmetallic hinge prevents movement of

schedule.The development was built on return airstream, conditioned, and then air from the crawl space into the supply

controlled-fill soil to elevate it above the distributed to the house. No fan-timing plenum when the system is off.

100-year floodplain, which added to the or fan-cycling controls are used in the Four of the closed crawl spaces are

uniformity of the site soil conditions, and mechanical system. insulated with R-19 kraft-faced fiberglass

each home site was graded to provide The four control houses have conven- batts in the floor, and the other four are

proper drainage. tionally vented crawl spaces, with 11 8 insulated with 2 inches of R-13 foil-faced

The study homes are broken into inch x 16 inch foundation vents. Each polyisocyanurate foam on the perimeter

three groups of four homes each: one house has a 6-mil polyethylene ground wall and on the band joist.This closed-

control group and two experimental cover that is mechanically secured to the cell foam was installed with a 3-inch gap

groups. We reduced duct leakage and soil with turf staples. The seams are between the top of the foam and the bot-

house leakage to comparable levels across lapped approximately 6 inches but are tom of the sill plate, to allow for monitor-

all the groups.Average duct leakage varies not sealed. The ground cover extends ing of termite activity, and there is a

from 51 CFM25 to 68 CFM25 for these completely to the foundation wall and second gap at the bottom of the foam

groups, which represents rates of 5%–7% intermediate piers, covering 100% of the insulation to prevent ground contact and

CFM25 per square foot of floor area. soil.Although the building code allows a wicking of moisture into the foam insu-

Dividing the leakage by the conditioned reduction in the amount of wall venting lation.This foam meets the ASTM E84

floor area lets us use a consistent target when a ground vapor retarder is present, and Factory Mutual FM 4880 require-

across many different sizes of home.Aver- all 11 foundation vents were retained. ments of the International Residential

age house leakage varies from 0.22 to (Note that 2000 North Carolina code Code for use without a thermal barrier.

0.27 CFM50 per square foot of envelope does not require the ground vapor The ground vapor retarder is attached to

area. Insulation deficiencies were cor- retarder, since these vents provide the net the inside surface of the foam insulation

rected in all houses, and heat pump free area to meet the 1:150 ventilation with fiberglass mesh tape and mastic.We

refrigerant charge and system air flow area to crawl space area requirement.) specifically did not install the wall insula-

were measured and corrected as needed The floors of the control houses are insu- tion in the typically recommended form,

in all houses. lated with well-installed R-19 Kraft- which specifies wall insulation to 24

All the houses have a fresh-air venti- faced fiberglass batts. inches below outside grade or horizon-

lation intake integrated with the HVAC The crawl space vents of the experi- tally on top of the soil in from the foun-

ductwork. A 6-inch insulated flex duct ment homes were sealed with rigid dation wall for 24 inches. Instead, the

from outside routs air through a 1-inch polystyrene foam and mastic or spray bottom edge of the crawl space wall insu-

pleated media filter and then connects foam. Each of these closed crawl spaces lation extends only 3 to 6 inches below

directly to the return plenum.Whenever has a sealed, 6-mil polyethylene liner outside soil grade level.

the HVAC system is operating, 40 CFM covering the floor and extending up the

2 www.homeenergy.org 2005 SPECIAL ISSUE • HOME ENERGY

Instrumentation Crawl Space and Outdoor Relative Humidity

and Data Collection 100

Outside

90 Wall vented

Relative humidity (%)

80 Closed

We have been recording outside air

temperature and moisture content using 70

three battery-operated data loggers dis- 60

tributed across the development in loca- 50

tions shielded from rain and direct sun.

We used the same type of logger to 40

record conditions inside each house and 30

ADVANCED ENERGY

inside each crawl space. Measurements 20

were recorded at 15-minute intervals. 06/03 07/03 08/03 09/03 10/03 11/03 12/03 01/04 02/04 03/04 04/04

The house data logger was placed at the

center of the house in the HVAC return Figure 1. The closed crawl spaces performed better than the vented ones with regard to RH.

closet, and two loggers (one extra for

redundancy) were located together in the

center of the crawl space on the support

beam for the floor joists. We measured Average Wood Moisture Content

18

wood moisture content on a 60-day

16 Vented + Closed + Closed +

interval at ten locations in each crawl R-19 floor R-19 floor R-13 wall

Wood MC (%)

space, including sill plate, band joist, floor 14

joist, center beam, and subfloor readings.

12

After seeing the potential for energy

savings during a billing analysis in early 10

2003, we outfitted all 12 houses with 8

ADVANCED ENERGY

electricity submeters to record exact

energy consumption by each home’s 6

09/03 10/03 12/04 02/04 04/04 06/04 09/04

package unit heat pump system. The

whole-house meter and the submeters Figure 2. Closed crawl spaces were also better off than vented ones with regard to wood moisture.

are read monthly.

The crawl space experiment has

been monitored for more than three

years as of this writing. Ongoing mea- Table 1. Summer (June–August) Relative is notable, not only

surements clearly indicate that the Humidity Summary because it reduces the

closed crawl spaces consistently outper- 2002 2003 likelihood of surface

form the wall-vented crawl spaces in RH Threshold Vented Closed Vented Closed mold growth but also

terms of both moisture control and Above 90% 1 00% 100% 123% 100% because dry lumber is

Above 80% 1 39% 100% 186% 100%

energy use.What follows is a cross sec- less attractive to ter-

Above 70% 1 79% 100% 198% 105%

tion of our findings from a one-year mites and very inhos-

Above 60% 1 94% 100% 100% 164%

period ranging from June of 2003 Above 50% 100% 100% 100% 100%

pitable to

through May of 2004. Monitoring of Southeastern species

these crawl spaces will continue until of wood-boring beetle

March 2005. the germination of mold spores, along pests.

with high relative humidity (RH) for As fate would have it, 2003 was the

Moisture Performance extended periods of time, makes a wettest year in recorded history in most

vented crawl space in the Southeast an of North Carolina, while 2002 was a

Typical problems we see regularly in ideal location for mold growth and record-setting drought year. In the sum-

wall-vented crawl spaces include con- wood decay to take hold. mer of 2003, the RH in the vented

densation on air conditioning ducts, The closed crawl spaces in our pro- crawl spaces stayed above 70% almost all

water lines, and insulation; standing ject perform notably better than the the time, while the closed crawl spaces

water on top of the ground vapor vented crawl spaces with regard to RH reached similar humidity levels only 5%

retarder; stained walls from water pene- and wood moisture content (see Figures of the time (see Table 1).

tration and efflorescence; and water-sat- 1 and 2).The fact that the framing lum- Clearly, the closed crawl spaces pro-

urated soil inside the crawl space. The ber in the closed crawl spaces stays vided far better performance under the

presence of liquid water, which supports below the 12% wood moisture threshold harshest conditions than the vented

HOME ENERGY • 2005 SPECIAL ISSUE www.homeenergy.org 3

retarder installation and maintenance in

general construction.

During any warm season here in

Princeville, the outside air contains

more moisture than the air in the

vented crawl spaces and instead of pro-

viding drying potential, contributes

moisture. Consider this: The average

dew point of the outside air at

Princeville during the summer of 2003

was 73°F.This corresponds to relatively

moderate conditions of 88°F and 60%

RH.When that air goes into the crawl

space and encounters any object that is

cooler than 73°F, the RH peaks at

100% and the water vapor in the air

will condense on that object just as it

ADVANCED ENERGY

would on a cool drink set out on the

porch railing. Supply ducts (55°F-

65°F), water pipes and tanks (55°F-

The wall-vented control houses in this study have much better crawl spaces than the typical crawl 65°F), and even the floor of the crawl

space we encounter in the field. The control houses have well-installed insulation and 100% ground space (65°F-70°F) and the wood fram-

vapor retarder coverage of the soil, and no problems with intrusion of liquid water from outside. ing above (70°F-78°F) can experience

this condensation, especially if the

homeowner likes to condition the

house to temperatures below 72°F.

Even if conditions aren’t bad enough

for condensation, the RH of the air

entering the crawl space will still easily

reach levels of 90% or higher for pro-

longed periods of time.

From our dew point measurements,

we observed that the closed crawl

spaces stay moister than the vented

crawl spaces in winter. Limiting the

moisture swing seen by the house over

the course of the year reduces the like-

lihood of common cosmetic problems

like shrinking and swelling of hard-

wood floors and trim carpentry and

cracking or nail pops in drywall.

ADVANCED ENERGY

Energy Performance

Going beyond our expectations, the

A more typical vented crawl space in North Carolina exhibits water leakage, poor drainage, a low- closed-crawl space houses exhibit clear

quality vapor retarder, if any, and various complications such as attached under-porch areas.

energy savings over the control houses

(see Figure 3).This is true even for the

four closed-crawl space houses with

crawl spaces did under even the mildest extensively wall-vented crawl spaces wall insulation where we provided a ter-

conditions. These results highlight the without water intrusion and with a mite inspection gap and did not install

fact that even a carefully installed and 100% vapor retarder ground cover may the insulation either down 24 inches

maintained ground vapor retarder cov- prevent wood rot in crawl spaces, but below grade or 24 inches horizontally

ering 100% of the soil is not sufficient moisture control would be even worse onto the crawl space floor, as is typically

to control crawl space moisture levels in in typical vented crawl spaces, given the recommended in energy codes and

a vented crawl space.Well-constructed, usual poor quality of ground vapor design guidelines.

4 www.homeenergy.org 2005 SPECIAL ISSUE • HOME ENERGY

For the 12 months analyzed, the floor-

Seasonal and Annual Space Conditioning Energy Use

insulated closed-crawl space houses have 25

used an average of 15% less energy for Savings Closed with Closed with

space conditioning than the control R-19 floor R-13 wall

houses. This represents a savings of 20 Summer -22% -36%

approximately 870 kWh, or roughly $87, Fall -05% -10%

per year for each household. The wall-

insulated closed-crawl space houses have Winter -10% + 4%

15

used, on average, 18% less energy than the Spring -19% -28%

kWh

control houses over the same 12-month Annual -15% -18%

period. This represents a savings of 10

approximately 1,030 kWh, or roughly

$100, per year for each household.

By the luck of the draw, the control 5

houses ended up with higher occupancy

numbers and more children than the

experiment houses.While we could and 0

did control for the variables of climate, site Summer Fall Winter Spring Annual

drainage, architecture, insulation, shell (06–08/03) (09–11/03) (12/03–02/04) (03–05/04)

ADVANCED ENERGY

leakage, duct leakage, and mechanical Wall-vented Closed + R-19 floor Closed + R-13 wall

equipment performance, there remain

variations in base- load consumption and

occupant thermostat settings among the Figure 3. The submetered heating and cooling energy use for the period June 2003 through May 2004

groups that may be significant due to the indicates significant energy savings. (The bars represent the average per house usage for each group.)

small sample size.

We did not submeter the appliance,

lighting, water heating, or exhaust fan

loads, but noted that the total baseload regard to these differences in thermostat

use in the control houses was signifi- setpoint, we graphed average temperature Implications

cantly higher—10%-20% in any given difference between outside and inside for This project is scheduled to

month—than that in the experiment each house in each month and plotted conclude after the winter of 2004-05,

houses over the entire year. The extra that against the kWh consumption for when we will test one final configura-

occupants and baseload in the controls space conditioning for that house in the tion to assess the energy impact of 24

would theoretically increase the need same month. The trendlines for each inches of foam insulation installed hor-

for cooling in the summer and decrease group of houses indicate the same sea- izontally on the ground of the wall-

the need for heating in the winter.The sonal patterns of performance that we insulated, closed-crawl space houses.

difference in baseload use between the observed in the raw submeter data. Final results and additional analysis will

controls and the floor-insulated experi- We have not administered a formal be posted on the project Web site,

ment houses is about the same in both survey of occupant comfort, but we www.crawl spaces.org.

summer and winter, which suggests that recently had an experience that indicated We’re very excited about the degree of

the surpluses offset each other in terms that the crawl space’s moisture perfor- performance improvement shown by the

of heat pump energy used and saved in mance may also affect the occupant’s closed crawl spaces, especially considering

the control houses to compensate for thermostat settings. In June of this year, that our control houses represent the best

the difference. However, there is more we modified the vented control crawl possible performance of wall-vented

of a difference in baseload consumption spaces to test a new version of a closed crawl spaces.The vast majority of newly

between the controls and the wall-insu- crawl space. We installed a crawl space built vented crawl spaces are not installed

lated experiment houses in the summer supply duct to provide supplemental dry- or maintained to the standards used for

than there is in the winter, which makes ing, as was done in the other closed crawl this project.We believe that the findings

the summertime wall-experiment house spaces.When we returned to the site four of this study will transfer well to houses

performance look better. days later, one resident (who rarely adjusts whose geometry and geography are sim-

A review of the interior house data her thermostat) excitedly told us that the ilar to those of the study homes. How-

indicates that the control houses were day after we improved her crawl space, ever, additional consideration and study

operated 1°F –2°F cooler than the she had to turn up her thermostat are required for houses in other locations

experiment houses in the summer and because she felt too cold in the house! or with different geometry. The energy

1°F–2°F warmer than the experiment results seem to indicate that wall-insulated

houses in the winter. To normalize the closed crawl spaces will perform best in

heat pump energy consumption with cooling-based climates; it seems likely that

HOME ENERGY • 2005 SPECIAL ISSUE www.homeenergy.org 5

floor-insulated closed crawl spaces the potential indoor air quality (IAQ)

will perform best in heating-based and health impacts of closed-crawl

climates. Of course, these homes have space construction, which could indi-

shallow foundations, and we have not cate a whole new class of benefits

tested crawl space foundations with from this technology. The future

deeper footings, such as may be could include insurance premium

found farther north.A wall insulation savings for houses built on certified

strategy may prove to perform best in closed crawl spaces.

such houses. We won’t know with One specific measure of IAQ that

any certainty how well the improve- we have addressed in this project is

ments in moisture and energy perfor- radon risk. Long term radon moni-

mance will transfer to houses in other toring was performed in all the crawl

climates until a number of such spaces and conditioned areas. Slightly

houses are actually constructed and higher average concentrations were

monitored.We are now starting up a found in the closed crawl spaces, with

project to gather those data in multi- measurements averaging 0.5 pic-

ple climate zones. This project will ocuries per liter (pCi/l) in the vented

also demonstrate the ability of the crawl spaces and 1.1 pCi/l in the

ADVANCED ENERGY

production housing market to incor- closed crawl spaces.The radon mea-

porate closed crawl space technology surements in the conditioned space

into their construction processes. do not show any difference correlated

Currently we find that the energy This floor-insulated crawl space has a termite inspection gap

with the type of foundation they are

benefits of closed crawl spaces are at the top of the vapor retarder. Note that penetrations are on; all houses average approximately

not completely predicted by popular thoroughly sealed with mastic. 0.5 pCi/l with a maximum reading

energy analysis software packages, so of 0.7 pCi/l in any house.The com-

it may be some time before closed monly accepted action level for

crawl spaces get their due respect radon remediation is 4 pCi/l. We

when builders choose house specifi- believe that a closed crawl space

cations aimed at achieving a certified should be thought of as a short base-

minimum energy rating. We hope ment when it comes to radon miti-

that our research findings will spur gation, since similar measures are

refinements in the analysis tools, and applicable for assessment and control

that in the meantime the data will of risk where needed.

reinforce the argument that con- Professionals seeking to install

sumers can improve their homes by closed crawl spaces face a formidable

building or retrofitting a properly learning curve to be successful. As

closed crawl space. Data from a sub- with all aspects of the construction

set of two highly instrumented industry,choosing the correct materi-

houses in the project are being used als, tools, and techniques is only half

to validate a hygrothermal modeling the battle; training and quality assur-

tool under development at Oak ance are also critical to ensure that the

Ridge National Laboratory. right work is performed the right way

Initial construction costs associated at the right time.A good closed crawl

with building closed crawl spaces will space must be designed properly with

ADVANCED ENERGY

likely be more than for traditional regard to control of internal and

wall-vented construction.As the new external water sources from the very

construction methods are evaluated start of construction.You must choose

by both builders and researchers, it This wall-insulated crawl space uses 2-inch-thick foil-faced

a drying mechanism—conditioned

will be important to factor in the polyisocyanurate insulation. The foam plugs in the band air supply or a dehumidifier, for

value of reduced callbacks for mois- could be replaced by sections of batt insulation. A termite example—for long term, active

ture and mold complaints, the percep- inspection gap is visible at the top of the wall insulation. moisture control. Other important

tion of enhanced value by the design issues include pest manage-

consumer, and the resulting improve- ment, combustion safety, fire safety,

ment in sales price and volume, and proper insulation, and radon control,

reduced legal action. Reduced mainte- enhance the value of closed-crawl space if applicable.

nance; a reduction in costly, long-term construction to the consumer. Other Implementation requires close coor-

repairs; and significant energy savings will Advanced Energy research is focused on dination with building officials, since the

6 www.homeenergy.org 2005 SPECIAL ISSUE • HOME ENERGY

FOR MORE INFORMATION:

We are by no means the first to investi-

gate the moisture performance of wall-

vented crawl spaces. Previous work

includes a review of crawl space inves-

tigation and regulation through history

(Rose 1994) and a review of many of

the issues associated with wall vented

crawl space construction (Rose & Ten-

Wolde 1994). These reviews, along with

several others, are included in Recom-

mended Practices for Controlling Mois-

ture in Crawl Spaces, ASHRAE Technical

Data Bulletin, volume 10, number 3.

ADVANCED ENERGY

Davis, Bruce and William E. Warren.

“Field Study Pilot Report: A Field

Study Comparison of the Energy and

The butterfly damper of this crawl space supply opens while the system is running. The Moisture Performance Characteristics

assembly is sealed with mastic and supported by strapping to ensure that the butterfly of Ventilated Versus Sealed Crawl

damper continues to operate properly. spaces in the South,” Raleigh, N.C.:

Advanced Energy, 2002.

building codes are lagging behind this from $4,200 for a simple, new-construc- Davis, Bruce, William E. Warren, and

William B. Rose. “Technology

technology, and many current codes pro- tion project to $6,700 for a complex

Assessment Report: A Field Study Com-

vide only a tortuous compliance path for retrofit project. Including wall insulation

parison of the Energy and Moisture Per-

closed crawl spaces. During our work to adds $1,500–$3,000 to the sale for these formance Characteristics of Ventilated

set up the houses in this study, the scat- examples, minus the cost of floor insula- Versus Sealed Crawl spaces in the

tered and conflicting nature of different tion if it is a new construction project. South,” Raleigh, N.C.: Advanced Energy,

building code elements governing closed Complexities that increase the price over 2002.

crawl spaces became evident. For closed the simple baseline include the extra

crawl spaces to be practical for both length of perimeter for houses with lots Davis, Bruce, and Cyrus K. Dastur.

builders and code enforcement officials, of angles, the number of support “Moisture Solution Becomes Efficiency

we are recommending a separate section columns that break up the floor of the Bonanza in the Southeastern United

States,” in Proceedings of the 2004

in the code that is specifically dedicated crawl space, and a sloping grade that

Summer Study on Energy Efficiency in

to these construction methods.We have requires additional material and fitting

Buildings, Vol. 1. Washington, D.C.

helped the North Carolina Building on the crawl space walls. Retrofit com- American Council for an Energy

Code Council and code services staff to plications can also include existing water Efficient Economy, 2004.

draft new code language for closed crawl problems, contaminated or damaged

spaces with the assistance of the North materials, and debris that must be Hill, William W. “Measured Energy

Carolina Structural Pest Control Board, removed before the work starts. Penalties from Crawl Space

the National Pest Management Associa- Closed crawl spaces clearly represent Ventilation,” in Proceedings of the

tion, and several installers of closed crawl both a new business opportunity and a 1998 Summer Study on Energy

spaces across the state.The draft language risk management service for the shelter Efficiency in Buildings, Vol. 1.

Washington, D.C. American Council for

has been approved by the Building Code industry. Firms that rise to the challenge

an Energy Efficient Economy, 1998.

Council and is now under final review of implementing specifications and pro-

by state agencies before it becomes avail- cedures for installing closed crawl spaces Rose, W. B. “A Review of the Regulatory

able for use. as a moisture control technique will be and Technical Literature Related to

Pricing contracts, and managing the able to profit from the knowledge that Crawl space Moisture Control,” in

safety and training of employees, are both they are also giving their customers the ASHRAE Transactions, Vol. 100 Pt. 1.

especially important when one is devel- benefit of energy savings. Atlanta, Ga. American Society of Heat-

oping and offering any new service. In ing, Refrigerating and Air-Conditioning

closed-crawl space work, coordination Cyrus Dastur is a building science associate Engineers, 1994.

with other trades becomes an even and Bruce Davis is research director at Rose, W. B. and A. TenWolde. “Issues in

greater factor, since they will be literally Advanced Energy, in Raleigh, North Carolina. Crawl Space Design and Construction —

walking all over that work to do their a Symposium Summary.” ASHRAE Tech-

own.As one example of pricing, closed The project described in this article is cofunded nical Data Bulletin: Recommended

crawl spaces in one North Carolina mar- by DOE and Advanced Energy. Practices for Controlling Moisture in

ket, assuming a 2,000 ft2 house, range Crawl spaces 10 (3), 1994.

HOME ENERGY • 2005 SPECIAL ISSUE www.homeenergy.org 7

www.advancedenergy.org

You might also like

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeFrom EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNo ratings yet

- Low-Permeance Materials in The Building EnvelopeDocument6 pagesLow-Permeance Materials in The Building EnvelopebatteekhNo ratings yet

- Architectural Representation and Detailing Report: SEM X - 17AR40Document4 pagesArchitectural Representation and Detailing Report: SEM X - 17AR40Divya VishwakarmaNo ratings yet

- BuildingDocument12 pagesBuildingjuan leyyonNo ratings yet

- By Douglas C. Fishburn: Roof DeckDocument4 pagesBy Douglas C. Fishburn: Roof DeckalperkarabulutNo ratings yet

- Flachdachkatalog Englisch Gravity DrainageDocument55 pagesFlachdachkatalog Englisch Gravity DrainageKrish StormNo ratings yet

- Waterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsDocument20 pagesWaterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsVaishamNo ratings yet

- Wind 01 00003Document19 pagesWind 01 00003Piel ArquitectónicaNo ratings yet

- Dryroom Basement Waterproofing PDFDocument4 pagesDryroom Basement Waterproofing PDFKevin BallNo ratings yet

- Exterior Ductwork Retrofit Boosts Efficiency 89Document42 pagesExterior Ductwork Retrofit Boosts Efficiency 89Shiyamraj ThamodharanNo ratings yet

- What's New in Biological Control of Weeds? Issue 52 Vol 10Document8 pagesWhat's New in Biological Control of Weeds? Issue 52 Vol 10lellobotNo ratings yet

- Understanding Rainscreen Design White PaperDocument3 pagesUnderstanding Rainscreen Design White PaperСтанислав ПодольскийNo ratings yet

- Basement and Structural Waterproofing PDFDocument4 pagesBasement and Structural Waterproofing PDFPaul LawlessNo ratings yet

- 2002 10 Venting of Attics & Cathedral Ceilings - _RoseDocument8 pages2002 10 Venting of Attics & Cathedral Ceilings - _RosemeomeportabNo ratings yet

- Innovative Design Concept For The New Bangkok International Airport, NBIADocument9 pagesInnovative Design Concept For The New Bangkok International Airport, NBIAtower yaleNo ratings yet

- Ventilated Wall Claddings: Review, Field Performance, and Hygrothermal ModelingDocument25 pagesVentilated Wall Claddings: Review, Field Performance, and Hygrothermal ModelingСтанислав ПодольскийNo ratings yet

- ChilledBeamBasics HPAC Engineering 2011-7Document4 pagesChilledBeamBasics HPAC Engineering 2011-7Balaji DhandapaniNo ratings yet

- On Brick Construction: Technical NotesDocument10 pagesOn Brick Construction: Technical NotesMekonnen SileshiNo ratings yet

- Earth TubesDocument2 pagesEarth TubesRAMESHNo ratings yet

- Breather Membranes and Vapour Control Layers in Walls: Technical Note No 33Document10 pagesBreather Membranes and Vapour Control Layers in Walls: Technical Note No 33Kevin Crawford100% (2)

- Deck Over Living SpaceDocument6 pagesDeck Over Living SpaceSegun AwoyinkaNo ratings yet

- Performance Evaluation of A Stratified Chilled-Water Thermal Storage SystemDocument9 pagesPerformance Evaluation of A Stratified Chilled-Water Thermal Storage SystemMilos IvosevicNo ratings yet

- NRCC - Why Houses need Mechanical Ventilation SystemsDocument4 pagesNRCC - Why Houses need Mechanical Ventilation Systemstrshnbx01No ratings yet

- Rubble Trench Foundation3Document6 pagesRubble Trench Foundation3Vicces P. EstradaNo ratings yet

- Cool corridors with smoke ventilationDocument6 pagesCool corridors with smoke ventilationArun CherianNo ratings yet

- Onstructing Moke Arriers Ypsum Roducts: C S B G PDocument3 pagesOnstructing Moke Arriers Ypsum Roducts: C S B G PcodefinderNo ratings yet

- Concrete Construction Article PDF Reinforcing New and Old Masonry ChimneysDocument4 pagesConcrete Construction Article PDF Reinforcing New and Old Masonry ChimneysasperfudNo ratings yet

- A Guide To Installing Unvented Attics in CanadaDocument8 pagesA Guide To Installing Unvented Attics in CanadaWaldzNo ratings yet

- Duct PDFDocument12 pagesDuct PDFroshan jaiswalNo ratings yet

- ISOVER guide to new energy regulations for single-family homesDocument36 pagesISOVER guide to new energy regulations for single-family homesLoredana PalimaruNo ratings yet

- Engineering StructuresDocument13 pagesEngineering StructuresAnonymous sQGjGjo7oNo ratings yet

- The Performance Characteristics of Multi-Outlet Siphonic Roof Drainage SystemsDocument15 pagesThe Performance Characteristics of Multi-Outlet Siphonic Roof Drainage SystemsJOAN SEBASTIAN NIÑO GARCÍANo ratings yet

- Fbuil 07 647594Document12 pagesFbuil 07 647594Ayu Febriana AntonNo ratings yet

- Prezentare Uponor - Tabs - Bochure ENDocument11 pagesPrezentare Uponor - Tabs - Bochure ENNistor PaulNo ratings yet

- srds3 Siphonic Roof Drainage Jan19Document12 pagessrds3 Siphonic Roof Drainage Jan19Asoka Kumarasiri JayawardanaNo ratings yet

- Submitted By, Abidha Karthu.E.K Syanece002 Under The Guidance Of, Mrs. RAMYA.K.M Asst. Prof. of Civil Engg SIMAT, VavanoorDocument35 pagesSubmitted By, Abidha Karthu.E.K Syanece002 Under The Guidance Of, Mrs. RAMYA.K.M Asst. Prof. of Civil Engg SIMAT, VavanoorSadia SamiNo ratings yet

- Electronic Leak Detection: Performance AssuranceDocument3 pagesElectronic Leak Detection: Performance AssuranceGabriel RiscanuNo ratings yet

- Strawbalehomebasics 2008Document7 pagesStrawbalehomebasics 2008earthboy2uNo ratings yet

- CFD Investigation of A Ducting SystemDocument12 pagesCFD Investigation of A Ducting Systemomi flashNo ratings yet

- Energy GroupeDocument14 pagesEnergy GroupeSalan XierzatiNo ratings yet

- Net Zero BuildingDocument3 pagesNet Zero BuildingAgneyi BalluNo ratings yet

- Proteus CX BrochureDocument9 pagesProteus CX BrochureSte GrahamNo ratings yet

- British Gypsum WB DriLyner DabDocument6 pagesBritish Gypsum WB DriLyner DabManu FraguelaNo ratings yet

- 1 s2.0 S0306261914000257 MainDocument7 pages1 s2.0 S0306261914000257 MainAndres RuizNo ratings yet

- Historical Roof Decks - Clay TileDocument7 pagesHistorical Roof Decks - Clay TileMichael SchultzNo ratings yet

- GFRC vs. Green Wall Systems: Which Works More Efficiently?Document26 pagesGFRC vs. Green Wall Systems: Which Works More Efficiently?Elanur MayaNo ratings yet

- NRCC - Designing Exterior Walls According to the Rainscreen PrincipleDocument8 pagesNRCC - Designing Exterior Walls According to the Rainscreen Principletrshnbx01No ratings yet

- Effect of Roof Surface Type On Storm-Water Runoff From Full-Scale Roofs in A Temperate ClimateDocument9 pagesEffect of Roof Surface Type On Storm-Water Runoff From Full-Scale Roofs in A Temperate ClimateHiteshNo ratings yet

- NETLINER Geonet Drainage CompositeDocument9 pagesNETLINER Geonet Drainage CompositeAnonymous CQ4rbzLVENo ratings yet

- Geocomposite DrainsDocument6 pagesGeocomposite DrainssanjeevgupNo ratings yet

- DefinitionDocument6 pagesDefinitionShubham PatidarNo ratings yet

- Case Study2Document11 pagesCase Study2Sanjana BhandiwadNo ratings yet

- Elastoseal EPDM Roofing SystemsDocument8 pagesElastoseal EPDM Roofing SystemsStephenNo ratings yet

- Casa de Madeira Technical-GuideDocument16 pagesCasa de Madeira Technical-GuideJoaquim ArezNo ratings yet

- Project Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al UlaDocument2 pagesProject Title: Al Ula Primary & Childhood School Client Name: Royal Commission For Al Ulathahar ali syedNo ratings yet

- Rooftop DetentionDocument2 pagesRooftop DetentioncoutohahaNo ratings yet

- Sustainability PDFDocument24 pagesSustainability PDFEdmund YoongNo ratings yet

- Modern Sewer Design: Two 6m Joints of Fully Perforated Pipe Banded Together For Ease of InstallationDocument32 pagesModern Sewer Design: Two 6m Joints of Fully Perforated Pipe Banded Together For Ease of InstallationJuan GrajalesNo ratings yet

- A Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationFrom EverandA Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationNo ratings yet

- Genie Model 2028 - Info SheetDocument2 pagesGenie Model 2028 - Info SheetKen GrossNo ratings yet

- Empire TrailsDocument1 pageEmpire TrailsKen GrossNo ratings yet

- Crafts Radial Saw Instruction Manual Model 113.199250Document44 pagesCrafts Radial Saw Instruction Manual Model 113.199250jandre61100% (2)

- To Vent or Not to Vent Crawl SpacesDocument2 pagesTo Vent or Not to Vent Crawl Spaceskulov1592No ratings yet

- Closing The Crawl: HouseDocument2 pagesClosing The Crawl: HouseKen GrossNo ratings yet

- Assignment 2Document17 pagesAssignment 2maryam kamalNo ratings yet

- Deep FoundationsDocument9 pagesDeep FoundationsKeen MedinaNo ratings yet

- Joints Movement Detail PDFDocument48 pagesJoints Movement Detail PDFRamesh P KoiralaNo ratings yet

- Wallmount - JCIDocument12 pagesWallmount - JCIALEXNo ratings yet

- Design 5Document2 pagesDesign 5Kyla SordillaNo ratings yet

- Ashrae EstandaresDocument7 pagesAshrae EstandaresVictor Hugo Alarcon CubaNo ratings yet

- BOQ For 2 Storied BuildingDocument12 pagesBOQ For 2 Storied BuildingVinoj Mno100% (1)

- CVBC-SC-Weekly Report No. 44Document10 pagesCVBC-SC-Weekly Report No. 44Eleazar SacloloNo ratings yet

- Madras Terrace RoofingDocument25 pagesMadras Terrace RoofingVarshith Reddy67% (6)

- EzyBrace 2011 Technical BookDocument32 pagesEzyBrace 2011 Technical BookHaisheng YinNo ratings yet

- Gas Boiler System Commissioning Checklist: ControlsDocument2 pagesGas Boiler System Commissioning Checklist: ControlsTut Riskyada DharyantaNo ratings yet

- Gypsum BoardDocument11 pagesGypsum BoardFavorSea Industrial Channel Limited, Building Materials DivisionNo ratings yet

- 11 - Meher Prasad - Tech For Mass HousingDocument35 pages11 - Meher Prasad - Tech For Mass HousingKiran KoraddiNo ratings yet

- Steel Pipe Pile Foundations PDFDocument25 pagesSteel Pipe Pile Foundations PDFmutton moonswami100% (2)

- Guide To Cold Formed Steel FramingDocument14 pagesGuide To Cold Formed Steel Framingjackcan501No ratings yet

- Sl. No. Description of Work Unit Qty. Rate Amount Rate Amount Total Amount Rs. Rs. Rs. Rs. Rs. I Option-1Document12 pagesSl. No. Description of Work Unit Qty. Rate Amount Rate Amount Total Amount Rs. Rs. Rs. Rs. Rs. I Option-1mdalt9180100% (2)

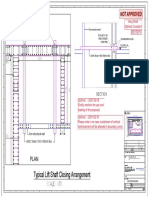

- Typical Lift Shaft Closing Arrangement SK-092Document1 pageTypical Lift Shaft Closing Arrangement SK-092ANUJ SHAHNo ratings yet

- Canvass materials for RT3 Building plumbing projectDocument1 pageCanvass materials for RT3 Building plumbing projectTeddy AcedoNo ratings yet

- Ashrae Limiting Indoor Mold and Dampness in BuildingsDocument22 pagesAshrae Limiting Indoor Mold and Dampness in BuildingsDeva RajNo ratings yet

- Chiller and cooling equipment scheduleDocument53 pagesChiller and cooling equipment scheduleRaju KsnNo ratings yet

- Alphaton 09-08 enDocument16 pagesAlphaton 09-08 ensebkahnNo ratings yet

- Simpson SDWC ScrewDocument5 pagesSimpson SDWC Screwdnl_vicarsNo ratings yet

- Liter Tank DetailDocument281 pagesLiter Tank DetailrkpragadeeshNo ratings yet

- Kohinoor Square, MumbaiDocument15 pagesKohinoor Square, MumbaiRiddhiraj Raisar50% (2)

- Lecture 71 (Site Requirements Residential Buildings)Document13 pagesLecture 71 (Site Requirements Residential Buildings)Sami UllahNo ratings yet

- DraftDocument3 pagesDraftziraziziNo ratings yet

- Common Construction PT Issues ArticleDocument4 pagesCommon Construction PT Issues ArticleUdom RithNo ratings yet

- Brickwork ChecklistDocument1 pageBrickwork ChecklistAdam MulengaNo ratings yet

- Inspection Checklist Masonry WallDocument3 pagesInspection Checklist Masonry WallJonatan LopezNo ratings yet

- EC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFDocument36 pagesEC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFAnNo ratings yet