Professional Documents

Culture Documents

24AA04/24LC04B: 4KI C Serial EEPROM

24AA04/24LC04B: 4KI C Serial EEPROM

Uploaded by

Gabriel TorresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

24AA04/24LC04B: 4KI C Serial EEPROM

24AA04/24LC04B: 4KI C Serial EEPROM

Uploaded by

Gabriel TorresCopyright:

Available Formats

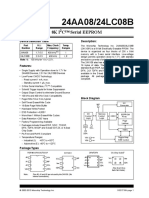

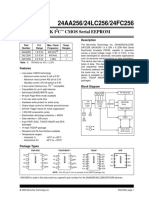

24AA04/24LC04B

4K I2C™ Serial EEPROM

Device Selection Table Description:

Part Vcc Max. Clock Temp. The Microchip Technology Inc. 24AA04/24LC04B

Number Range Frequency Ranges (24XX04*) is a 4 Kbit Electrically Erasable PROM. The

device is organized as two blocks of 256 x 8-bit

24AA04 1.7-5.5 400 kHz(1) I

memory with a 2-wire serial interface. Low-voltage

24LC04B 2.5-5.5 400 kHz I, E design permits operation down to 1.7V, with standby

Note 1: 100 kHz for VCC <2.5V and active currents of only 1 μA and 1 mA,

respectively. The 24XX04 also has a page write

Features: capability for up to 16 bytes of data. The 24XX04 is

available in the standard 8-pin PDIP, surface mount

• Single supply with operation down to 1.7V for SOIC, TSSOP, 2x3 DFN and MSOP packages and is

24AA04 devices, 2.5V for 24LC04B devices also available in the 5-lead SOT-23 package.

• Low-power CMOS technology:

- Read current 1 mA, typical Package Types

- Standby current 1 μA, typical PDIP, MSOP SOIC, TSSOP

• 2-wire serial interface, I2C™ compatible

A0 1 8 VCC A0 1 8 VCC

• Schmitt Trigger inputs for noise suppression

A1 2 7 WP A1 2 7 WP

• Output slope control to eliminate ground bounce

• 100 kHz and 400 kHz clock compatibility A2 3 6 SCL A2 3 6 SCL

• Page write time 3 ms, typical VSS 4 5 SDA VSS 4 5 SDA

• Self-timed erase/write cycle

SOT-23-5 DFN

• 16-byte page write buffer

• Hardware write-protect 1 5 WP A0 1 8 VCC

SCL

• ESD protection >4,000V A1 2 7 WP

• More than 1 million erase/write cycles Vss 2 A2 3 6 SCL

VSS 4 5 SDA

• Data retention >200 years SDA 3 4 Vcc

• Factory programming available

• Packages include 8-lead PDIP, SOIC, TSSOP, Note: Pins A0, A1 and A2 are not used by the 24XX04. (No

internal connections).

DFN, MSOP and 5-lead SOT-23

• Pb-free and RoHS compliant

• Temperature ranges: Block Diagram

- Industrial (I): -40°C to +85°C HV

WP Generator

- Automotive (E): -40°C to +125°C

I/O Memory EEPROM

Control Control XDEC Array

Logic Logic

Page

Latches

I/O

SCL

YDEC

SDA

VCC

VSS Sense Amp.

R/W Control

© 2007 Microchip Technology Inc. DS21708G-page 1

24AA04/24LC04B

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings (†)

VCC .............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. VSS ......................................................................................................... -0.3V to VCC +1.0V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temperature with power applied ................................................................................................-40°C to +125°C

ESD protection on all pins ......................................................................................................................................................≥ 4 kV

† NOTICE: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to

the device. This is a stress rating only and functional operation of the device at those or any other conditions

above those indicated in the operational listings of this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

TABLE 1-1: DC CHARACTERISTICS

Industrial (I): TA = -40°C to +85°C, VCC = +1.7V to +5.5V

DC CHARACTERISTICS

Automotive (E): TA = -40°C to +125°C, VCC = +2.5V to +5.5V

Param.

Sym. Characteristic Min. Typ. Max. Units Conditions

No.

D1 VIH WP, SCL and SDA pins — — — — —

D2 — High-level input voltage 0.7 VCC — — V —

D3 VIL Low-level input voltage — — 0.3 VCC V —

D4 VHYS Hysteresis of Schmitt 0.05 VCC — — V (Note)

Trigger inputs

D5 VOL Low-level output voltage — — 0.40 V IOL = 3.0 mA, VCC = 2.5V

D6 ILI Input leakage current — — ±1 μA VIN = VSS or VCC

D7 ILO Output leakage current — — ±1 μA VOUT = VSS or VCC

D8 CIN, Pin capacitance — — 10 pF VCC = 5.0V (Note)

COUT (all inputs/outputs) TA = 25°C, FCLK = 1 MHz

D9 ICC write Operating current — 0.1 3 mA VCC = 5.5V, SCL = 400 kHz

D10 ICC read — 0.05 1 mA —

D11 ICCS Standby current — 0.01 1 μA Industrial

— — 5 μA Automotive

SDA = SCL = VCC

WP = VSS

Note: This parameter is periodically sampled and not 100% tested.

DS21708G-page 2 © 2007 Microchip Technology Inc.

24AA04/24LC04B

TABLE 1-2: AC CHARACTERISTICS

Industrial (I): TA = -40°C to +85°C, VCC = +1.7V to +5.5V

AC CHARACTERISTICS

Automotive (E): TA = -40°C to +125°C, VCC = +2.5V to +5.5V

Param.

Sym. Characteristic Min. Typ. Max. Units Conditions

No.

1 FCLK Clock frequency — — 400 kHz 2.5V ≤ VCC ≤ 5.5V

— — 100 1.7V ≤ VCC < 2.5V (24AA04)

2 THIGH Clock high time 600 — — ns 2.5V ≤ VCC ≤ 5.5V

4000 — — 1.7V ≤ VCC < 2.5V (24AA04)

3 TLOW Clock low time 1300 — — ns 2.5V ≤ VCC ≤ 5.5V

4700 — — 1.7V ≤ VCC < 2.5V (24AA04)

4 TR SDA and SCL rise time — — 300 ns 2.5V ≤ VCC ≤ 5.5V (Note 1)

(Note 1) — — 1000 1.7V ≤ VCC < 2.5V (24AA04)

(Note 1)

5 TF SDA and SCL fall time — — 300 ns (Note 1)

—

6 THD:STA Start condition hold time 600 — — ns 2.5V ≤ VCC ≤ 5.5V

4000 — — 1.7V ≤ VCC < 2.5V (24AA04)

7 TSU:STA Start condition setup 600 — — ns 2.5V ≤ VCC ≤ 5.5V

time 4700 — — 1.7V ≤ VCC < 2.5V (24AA04)

8 THD:DAT Data input hold time 0 — — ns (Note 2)

—

9 TSU:DAT Data input setup time 100 — — ns 2.5V ≤ VCC ≤ 5.5V

250 — — 1.7V ≤ VCC < 2.5V (24AA04)

10 TSU:STO Stop condition setup 600 — — ns 2.5V ≤ VCC ≤ 5.5V

time 4000 — — 1.7V ≤ VCC < 2.5V (24AA04)

11 TAA Output valid from clock — — 900 ns 2.5V ≤ VCC ≤ 5.5V

(Note 2) — — 3500 1.7V ≤ VCC < 2.5V (24AA04)

12 TBUF Bus free time: Time the 1300 — — ns 2.5V ≤ VCC ≤ 5.5V

bus must be free before 4700 — — 1.7V ≤ VCC < 2.5V (24AA04)

a new transmission can

start

13 TOF Output fall time from VIH 20+0.1CB — 250 ns 2.5V ≤ VCC ≤ 5.5V

minimum to VIL — — 250 1.7V ≤ VCC < 2.5V (24AA04)

maximum

14 TSP Input filter spike — — 50 ns (Notes 1 and 3)

suppression

(SDA and SCL pins)

15 TWC Write cycle time — — 5 ms —

(byte or page)

16 — Endurance 1M — — cycles 25°C, (Note 4)

Note 1: Not 100% tested. CB = total capacitance of one bus line in pF.

2: As a transmitter, the device must provide an internal minimum delay time to bridge the undefined region

(minimum 300 ns) of the falling edge of SCL to avoid unintended generation of Start or Stop conditions.

3: The combined TSP and VHYS specifications are due to new Schmitt Trigger inputs which provide improved

noise spike suppression. This eliminates the need for a TI specification for standard operation.

4: This parameter is not tested but ensured by characterization. For endurance estimates in a specific

application, please consult the Total Endurance™ Model which can be obtained from Microchip’s web site

at www.microchip.com.

© 2007 Microchip Technology Inc. DS21708G-page 3

24AA04/24LC04B

FIGURE 1-1: BUS TIMING DATA

5 4

2

3

SCL

7

8 9 10

6

SDA

IN 14

11 12

SDA

OUT

FIGURE 1-2: BUS TIMING START/STOP

D4

SCL

6

7 10

SDA

Start Stop

DS21708G-page 4 © 2007 Microchip Technology Inc.

24AA04/24LC04B

2.0 FUNCTIONAL DESCRIPTION 3.4 Data Valid (D)

The 24XX04 supports a bidirectional, 2-wire bus and The state of the data line represents valid data when,

data transmission protocol. A device that sends data after a Start condition, the data line is stable for the

onto the bus is defined as transmitter, while a device duration of the high period of the clock signal.

receiving data is defined as a receiver. The bus has to The data on the line must be changed during the low

be controlled by a master device which generates the period of the clock signal. There is one clock pulse per

Serial Clock (SCL), controls the bus access and bit of data.

generates the Start and Stop conditions, while the

24XX04 works as slave. Both master and slave can Each data transfer is initiated with a Start condition and

operate as transmitter or receiver, but the master terminated with a Stop condition. The number of data

device determines which mode is activated. bytes transferred between Start and Stop conditions is

determined by the master device and is, theoretically,

unlimited (although only the last sixteen will be stored

3.0 BUS CHARACTERISTICS when doing a write operation). When an overwrite does

occur, it will replace data in a first-in first-out (FIFO)

The following bus protocol has been defined:

fashion.

• Data transfer may be initiated only when the bus

is not busy. 3.5 Acknowledge

• During data transfer, the data line must remain

stable whenever the clock line is high. Changes in Each receiving device, when addressed, is obliged to

the data line while the clock line is high will be generate an acknowledge after the reception of each

interpreted as a Start or Stop condition. byte. The master device must generate an extra clock

pulse which is associated with this Acknowledge bit.

Accordingly, the following bus conditions have been

defined (Figure 3-1). Note: The 24XX04 does not generate any

Acknowledge bits if an internal

3.1 Bus Not Busy (A) programming cycle is in progress.

The device that acknowledges has to pull down the

Both data and clock lines remain high.

SDA line during the acknowledge clock pulse in such a

way that the SDA line is stable low during the high

3.2 Start Data Transfer (B) period of the acknowledge related clock pulse. Of

A high-to-low transition of the SDA line while the clock course, setup and hold times must be taken into

(SCL) is high determines a Start condition. All account. During reads, a master must signal an end of

commands must be preceded by a Start condition. data to the slave by not generating an Acknowledge bit

on the last byte that has been clocked out of the slave.

In this case, the slave (24XX04) will leave the data line

3.3 Stop Data Transfer (C)

high to enable the master to generate the Stop

A low-to-high transition of the SDA line while the clock condition.

(SCL) is high determines a Stop condition. All

operations must be ended with a Stop condition.

FIGURE 3-1: DATA TRANSFER SEQUENCE ON THE SERIAL BUS

(A) (B) (D) (D) (C) (A)

SCL

SDA

Start Address or Data Stop

Condition Acknowledge Allowed Condition

Valid to Change

© 2007 Microchip Technology Inc. DS21708G-page 5

24AA04/24LC04B

3.6 Device Addressing FIGURE 3-2: CONTROL BYTE

ALLOCATION

A control byte is the first byte received following the

Start condition from the master device. The control byte

Read/Write Bit

consists of a four-bit control code. For the 24XX04, this

is set as ‘1010’ binary for read and write operations. Block

The next two bits of the control byte are “don’t cares” for Select

Control Code Bits

the 24XX04. The last bit, B0, is used by the master

device to select which of the two 256-word blocks of

memory are to be accessed. This bit is, in effect, the S 1 0 1 0 x x B0 R/W ACK

Most Significant bit of the word address.

The last bit of the control byte defines the operation to Slave Address

be performed. When set to ‘1’, a read operation is

selected. When set to ‘0’, a write operation is selected.

Start Bit Acknowledge Bit

Following the Start condition, the 24XX04 monitors the

SDA bus checking the device type identifier being

transmitted and, upon receiving a ‘1010’ code, the x = “don’t care”

slave device outputs an Acknowledge signal on the

SDA line. Depending on the state of the R/W bit, the

24XX04 will select a read or write operation.

Control

Operation Block Select R/W

Code

Read 1010 Block Address 1

Write 1010 Block Address 0

DS21708G-page 6 © 2007 Microchip Technology Inc.

24AA04/24LC04B

4.0 WRITE OPERATION 4.2 Page Write

The write control byte, word address and the first data

4.1 Byte Write byte are transmitted to the 24XX04 in the same way as

Following the Start condition from the master, the in a byte write. But instead of generating a Stop condi-

device code (4 bits), the block address (3 bits) and the tion the master transmits up to 16 data bytes to the

R/W bit, which is a logic low, is placed onto the bus by 24XX04, which are temporarily stored in the on-chip

the master transmitter. This indicates to the addressed page buffer and will be written into memory once the

slave receiver that a byte with a word address will master has transmitted a Stop condition. Upon receipt

follow once it has generated an Acknowledge bit during of each word, the four lower-order Address Pointer bits

the ninth clock cycle. Therefore, the next byte transmit- are internally incremented by ‘1’. The higher-order 7

ted by the master is the word address and will be bits of the word address remain constant. If the master

written into the Address Pointer of the 24XX04. After should transmit more than 16 words prior to generating

receiving another Acknowledge signal from the the Stop condition, the address counter will roll over

24XX04, the master device will transmit the data word and the previously received data will be overwritten. As

to be written into the addressed memory location. The with the byte write operation, once the Stop condition is

24XX04 acknowledges again and the master received an internal write cycle will begin (Figure 4-2).

generates a Stop condition. This initiates the internal

Note: Page write operations are limited to writing

write cycle and, during this time, the 24XX04 will not

bytes within a single physical page

generate Acknowledge signals (Figure 4-1).

regardless of the number of bytes

actually being written. Physical page

boundaries start at addresses that are

integer multiples of the page buffer size (or

‘page size’) and end at addresses that are

integer multiples of [page size – 1]. If a

Page Write command attempts to write

across a physical page boundary, the

result is that the data wraps around to the

beginning of the current page (overwriting

data previously stored there), instead of

being written to the next page as might be

expected. It is therefore necessary for the

application software to prevent page write

operations that would attempt to cross a

page boundary.

FIGURE 4-1: BYTE WRITE

S S

Bus Activity T Control Word T

Master A Byte Address O

R Data

T P

SDA Line S 1 0 1 0 x x B0 0 P

A A A

Bus Activity Block C C C

Select K K K

x = “don’t care”

Bits

FIGURE 4-2: PAGE WRITE

S S

Bus Activity T Control Word T

A O

Master R Byte Address (n) Data (n) Data (n + 1) Data (n + 15)

P

T

SDA Line S 1 0 1 0 x x B0 0 P

A A A A A

Bus Activity Block C C C C C

Select K K K K K

x = “don’t care” Bits

© 2007 Microchip Technology Inc. DS21708G-page 7

24AA04/24LC04B

5.0 ACKNOWLEDGE POLLING 6.0 WRITE PROTECTION

Since the device will not acknowledge during a write The WP pin allows the user to write-protect the entire

cycle, this can be used to determine when the cycle is array (000-1FF) when the pin is tied to VCC. If tied to

complete (this feature can be used to maximize bus VSS the write protection is disabled.

throughput). Once the Stop condition for a Write

command has been issued from the master, the device

initiates the internally-timed write cycle and ACK polling

can then be initiated immediately. This involves the

master sending a Start condition followed by the control

byte for a Write command (R/W = 0). If the device is still

busy with the write cycle, no ACK will be returned. If the

cycle is complete, the device will return the ACK and

the master can then proceed with the next Read or

Write command. See Figure 5-1 for a flow diagram of

this operation.

FIGURE 5-1: ACKNOWLEDGE POLLING

FLOW

Send

Write Command

Send Stop

Condition to

Initiate Write Cycle

Send Start

Send Control Byte

with R/W = 0

Did Device

No

Acknowledge

(ACK = 0)?

Yes

Next

Operation

DS21708G-page 8 © 2007 Microchip Technology Inc.

24AA04/24LC04B

7.0 READ OPERATION 7.3 Sequential Read

Read operations are initiated in the same way as write Sequential reads are initiated in the same way as a

operations, with the exception that the R/W bit of the random read, except that once the 24XX04 transmits

slave address is set to ‘1’. There are three basic types the first data byte, the master issues an acknowledge

of read operations: current address read, random read as opposed to a Stop condition in a random read. This

and sequential read. directs the 24XX04 to transmit the next sequentially-

addressed 8-bit word (Figure 7-3).

7.1 Current Address Read To provide sequential reads, the 24XX04 contains an

internal Address Pointer that is incremented by one

The 24XX04 contains an address counter that main-

upon completion of each operation. This Address

tains the address of the last word accessed, internally

Pointer allows the entire memory contents to be serially

incremented by ‘1’. Therefore, if the previous access

read during one operation.

(either a read or write operation) was to address n, the

next current address read operation would access data

from address n + 1. Upon receipt of the slave address 7.4 Noise Protection

with R/W bit set to ‘1’, the 24XX04 issues an acknowl- The 24XX04 employs a VCC threshold detector circuit

edge and transmits the 8-bit data word. The master will which disables the internal erase/write logic if the VCC

not acknowledge the transfer, but does generate a Stop is below 1.5V at nominal conditions.

condition and the 24XX04 discontinues transmission

(Figure 7-1). The SCL and SDA inputs have Schmitt Trigger and

filter circuits which suppress noise spikes to assure

proper device operation, even on a noisy bus.

7.2 Random Read

Random read operations allow the master to access

any memory location in a random manner. To perform

this type of read operation, the word address must first

be set. This is accomplished by sending the word

address to the 24XX04 as part of a write operation.

Once the word address is sent, the master generates a

Start condition following the acknowledge. This termi-

nates the write operation, but not before the internal

Address Pointer is set. The master then issues the

control byte again, but with the R/W bit set to a ‘1’. The

24XX04 will then issue an acknowledge and transmit

the 8-bit data word. The master will not acknowledge

the transfer, but does generate a Stop condition and the

24XX04, will discontinue transmission (Figure 7-2).

FIGURE 7-1: CURRENT ADDRESS READ

S

Bus Activity T Control S

Master A Byte T

R Data (n)

O

T P

SDA Line S 1 0 1 0 x x B0 1 P

A N

Bus Activity C o

Block

K

Select A

Bits C

x = “don’t care”

K

© 2007 Microchip Technology Inc. DS21708G-page 9

24AA04/24LC04B

FIGURE 7-2: RANDOM READ

S S

Bus Activity T Control Word T Control S

Master A Byte Address (n) A Byte T

R R Data (n) O

T T P

S 1 0 1 0 x x B0 0 S 1 0 1 0 x x B0 1 P

SDA Line

A A A N

Block C C Block C o

Select K K Select K

Bus Activity Bits Bits A

C

x = “don’t care” K

FIGURE 7-3: SEQUENTIAL READ

Control S

Bus Activity T

Master Byte Data (n) Data (n + 1) Data (n + 2) Data (n + x) O

P

SDA Line 1 P

A A A A N

C C C C o

Bus Activity K K K K

A

C

K

DS21708G-page 10 © 2007 Microchip Technology Inc.

24AA04/24LC04B

8.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table 8-1.

TABLE 8-1: PIN FUNCTION TABLE

Name PDIP SOIC TSSOP DFN MSOP SOT23 Description

A0 1 1 1 1 1 — Not Connected

A1 2 2 2 2 2 — Not Connected

A2 3 3 3 3 3 — Not Connected

VSS 4 4 4 4 4 2 Ground

SDA 5 5 5 5 5 3 Serial Address/Data I/O

SCL 6 6 6 6 6 1 Serial Clock

WP 7 7 7 7 7 5 Write-Protect Input

VCC 8 8 8 8 8 4 +1.7V to 5.5V Power Supply

8.1 Serial Address/Data Input/Output 8.3 Write-Protect (WP)

(SDA) The WP pin must be connected to either VSS or VCC.

SDA is a bidirectional pin used to transfer addresses If tied to VSS, normal memory operation is enabled

and data into and out of the device. Since it is an open- (read/write the entire memory 000-1FF).

drain terminal, the SDA bus requires a pull-up resistor

If tied to VCC, write operations are inhibited. The entire

to VCC (typical 10 kΩ for 100 kHz, 2 kΩ for 400 kHz).

memory will be write-protected. Read operations are

For normal data transfer, SDA is allowed to change not affected.

only during SCL low. Changes during SCL high are

This feature allows the user to use the 24XX04 as a

reserved for indicating Start and Stop conditions.

serial ROM when WP is enabled (tied to VCC).

8.2 Serial Clock (SCL)

8.4 A0, A1, A2

The SCL input is used to synchronize the data transfer

The A0, A1 and A2 pins are not used by the 24XX04.

to and from the device.

They may be left floating or tied to either VSS or VCC.

© 2007 Microchip Technology Inc. DS21708G-page 11

24AA04/24LC04B

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

8-Lead PDIP (300 mil) Example:

XXXXXXXX 24LC04B

T/XXXNNN I/P e3 13F

YYWW 0527

8-Lead SOIC (3.90 mm) Example:

XXXXXXXT 24LC04BI

XXXXYYWW SN e3 0527

NNN 13F

8-Lead TSSOP Example:

XXXX 4L04

TYWW I527

NNN 13F

8-Lead MSOP Example:

XXXXXT 4L4BI

YWWNNN 52713

5-Lead SOT-23 Example:

XXNN M33F

8-Lead 2x3 DFN Example:

XXX 234

YWW 527

NN 13

DS21708G-page 12 © 2007 Microchip Technology Inc.

24AA04/24LC04B

1st Line Marking Codes

Part Number SOT-23 DFN

TSSOP MSOP

I Temp. E Temp. I Temp. E Temp.

24AA04 4A04 4A04T B3NN — 231 —

24LC04B 4L04 4L4BT M3NN N3NN 234 235

Note: T = Temperature grade (I, E)

NN = Alphanumeric traceability code

Legend: XX...X Part number or part number code

T Temperature (I, E)

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code (2 characters for small packages)

e3 Pb-free JEDEC designator for Matte Tin (Sn)

Note: For very small packages with no room for the Pb-free JEDEC designator

e3 , the marking will only appear on the outer carton or reel label.

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line, thus limiting the number of available

characters for customer-specific information.

Note: Please visit www.microchip.com/Pbfree for the latest information on Pb-free conversion.

*Standard OTP marking consists of Microchip part number, year code, week code, and traceability code.

© 2007 Microchip Technology Inc. DS21708G-page 13

24AA04/24LC04B

8-Lead Plastic Dual In-Line (P or PA) – 300 mil Body [PDIP]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

NOTE 1

E1

1 2 3

D

E

A A2

A1 L

c

e

b1 eB

b

Units INCHES

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e .100 BSC

Top to Seating Plane A – – .210

Molded Package Thickness A2 .115 .130 .195

Base to Seating Plane A1 .015 – –

Shoulder to Shoulder Width E .290 .310 .325

Molded Package Width E1 .240 .250 .280

Overall Length D .348 .365 .400

Tip to Seating Plane L .115 .130 .150

Lead Thickness c .008 .010 .015

Upper Lead Width b1 .040 .060 .070

Lower Lead Width b .014 .018 .022

Overall Row Spacing § eB – – .430

Notes:

1. Pin 1 visual index feature may vary, but must be located with the hatched area.

2. § Significant Characteristic.

3. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed .010" per side.

4. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Microchip Technology Drawing C04-018B

DS21708G-page 14 © 2007 Microchip Technology Inc.

24AA04/24LC04B

8-Lead Plastic Small Outline (SN or OA) – Narrow, 3.90 mm Body [SOIC]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

e

N

E1

NOTE 1

1 2 3

h α

b

h

c

A A2 φ

A1 L

L1 β

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 1.27 BSC

Overall Height A – – 1.75

Molded Package Thickness A2 1.25 – –

Standoff § A1 0.10 – 0.25

Overall Width E 6.00 BSC

Molded Package Width E1 3.90 BSC

Overall Length D 4.90 BSC

Chamfer (optional) h 0.25 – 0.50

Foot Length L 0.40 – 1.27

Footprint L1 1.04 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.17 – 0.25

Lead Width b 0.31 – 0.51

Mold Draft Angle Top α 5° – 15°

Mold Draft Angle Bottom β 5° – 15°

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. § Significant Characteristic.

3. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

4. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Microchip Technology Drawing C04-057B

© 2007 Microchip Technology Inc. DS21708G-page 15

24AA04/24LC04B

8-Lead Plastic Thin Shrink Small Outline (ST) – 4.4 mm Body [TSSOP]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

E1

NOTE 1

1 2

b

e

c

A A2 φ

A1 L1 L

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 0.65 BSC

Overall Height A – – 1.20

Molded Package Thickness A2 0.80 1.00 1.05

Standoff A1 0.05 – 0.15

Overall Width E 6.40 BSC

Molded Package Width E1 4.30 4.40 4.50

Molded Package Length D 2.90 3.00 3.10

Foot Length L 0.45 0.60 0.75

Footprint L1 1.00 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.09 – 0.20

Lead Width b 0.19 – 0.30

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

3. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Microchip Technology Drawing C04-086B

DS21708G-page 16 © 2007 Microchip Technology Inc.

24AA04/24LC04B

8-Lead Plastic Micro Small Outline Package (MS or UA) [MSOP]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

D

N

E

E1

NOTE 1

1 2

e

c φ

A A2

A1 L1 L

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 0.65 BSC

Overall Height A – – 1.10

Molded Package Thickness A2 0.75 0.85 0.95

Standoff A1 0.00 – 0.15

Overall Width E 4.90 BSC

Molded Package Width E1 3.00 BSC

Overall Length D 3.00 BSC

Foot Length L 0.40 0.60 0.80

Footprint L1 0.95 REF

Foot Angle φ 0° – 8°

Lead Thickness c 0.08 – 0.23

Lead Width b 0.22 – 0.40

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15 mm per side.

3. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Microchip Technology Drawing C04-111B

© 2007 Microchip Technology Inc. DS21708G-page 17

24AA04/24LC04B

5-Lead Plastic Small Outline Transistor (OT or CT) [SOT-23]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

b

N

E

E1

1 2 3

e

e1

D

A A2 c φ

A1 L

L1

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 5

Lead Pitch e 0.95 BSC

Outside Lead Pitch e1 1.90 BSC

Overall Height A 0.90 – 1.45

Molded Package Thickness A2 0.89 – 1.30

Standoff A1 0.00 – 0.15

Overall Width E 2.20 – 3.20

Molded Package Width E1 1.30 – 1.80

Overall Length D 2.70 – 3.10

Foot Length L 0.10 – 0.60

Footprint L1 0.35 – 0.80

Foot Angle φ 0° – 30°

Lead Thickness c 0.08 – 0.26

Lead Width b 0.20 – 0.51

Notes:

1. Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.127 mm per side.

2. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

Microchip Technology Drawing C04-091B

DS21708G-page 18 © 2007 Microchip Technology Inc.

24AA04/24LC04B

8-Lead Plastic Dual Flat, No Lead Package (MC) – 2x3x0.9 mm Body [DFN]

Note: For the most current package drawings, please see the Microchip Packaging Specification located at

http://www.microchip.com/packaging

D e

b

N N

L

E E2

EXPOSED PAD

NOTE 1

NOTE 1

1 2 2 1

D2

TOP VIEW BOTTOM VIEW

A3 A1 NOTE 2

Units MILLIMETERS

Dimension Limits MIN NOM MAX

Number of Pins N 8

Pitch e 0.50 BSC

Overall Height A 0.80 0.90 1.00

Standoff A1 0.00 0.02 0.05

Contact Thickness A3 0.20 REF

Overall Length D 2.00 BSC

Overall Width E 3.00 BSC

Exposed Pad Length D2 1.30 – 1.75

Exposed Pad Width E2 1.50 – 1.90

Contact Width b 0.18 0.25 0.30

Contact Length L 0.30 0.40 0.50

Contact-to-Exposed Pad K 0.20 – –

Notes:

1. Pin 1 visual index feature may vary, but must be located within the hatched area.

2. Package may have one or more exposed tie bars at ends.

3. Package is saw singulated.

4. Dimensioning and tolerancing per ASME Y14.5M.

BSC: Basic Dimension. Theoretically exact value shown without tolerances.

REF: Reference Dimension, usually without tolerance, for information purposes only.

Microchip Technology Drawing C04-123B

© 2007 Microchip Technology Inc. DS21708G-page 19

24AA04/24LC04B

APPENDIX A: REVISION HISTORY

Revision C

Corrections to Section 1.0, Electrical Characteristics.

Revision D

Added DFN package.

Revision E

Revised Figure 3-2 Control Byte Allocation; Figure 4-1

Byte Write; Figure 4-2 Page Write; Section 6.0 Write

Protection; Figure 7-1 Current Address Read; Figure 7-

2 Random Read; Figure 7-3 Sequential Read.

Revision F (01/2007)

Revised Features section; Changed 1.8V to 1.7V in

Tables and text; Revised Ambient Temperature,

Section 1.0; Replaced Package Drawings; Revised

Product ID section.

Revision G (03/2007)

Replaced Package Drawings (Rev. AM).

DS21708G-page 20 © 2007 Microchip Technology Inc.

24AA04/24LC04B

THE MICROCHIP WEB SITE CUSTOMER SUPPORT

Microchip provides online support via our WWW site at Users of Microchip products can receive assistance

www.microchip.com. This web site is used as a means through several channels:

to make files and information easily available to • Distributor or Representative

customers. Accessible by using your favorite Internet

• Local Sales Office

browser, the web site contains the following

information: • Field Application Engineer (FAE)

• Technical Support

• Product Support – Data sheets and errata,

application notes and sample programs, design • Development Systems Information Line

resources, user’s guides and hardware support Customers should contact their distributor,

documents, latest software releases and archived representative or field application engineer (FAE) for

software support. Local sales offices are also available to help

• General Technical Support – Frequently Asked customers. A listing of sales offices and locations is

Questions (FAQ), technical support requests, included in the back of this document.

online discussion groups, Microchip consultant Technical support is available through the web site

program member listing at: http://support.microchip.com

• Business of Microchip – Product selector and

ordering guides, latest Microchip press releases,

listing of seminars and events, listings of

Microchip sales offices, distributors and factory

representatives

CUSTOMER CHANGE NOTIFICATION

SERVICE

Microchip’s customer notification service helps keep

customers current on Microchip products. Subscribers

will receive e-mail notification whenever there are

changes, updates, revisions or errata related to a

specified product family or development tool of interest.

To register, access the Microchip web site at

www.microchip.com, click on Customer Change

Notification and follow the registration instructions.

© 2007 Microchip Technology Inc. DS21708G-page 21

24AA04/24LC04B

READER RESPONSE

It is our intention to provide you with the best documentation possible to ensure successful use of your Microchip prod-

uct. If you wish to provide your comments on organization, clarity, subject matter, and ways in which our documentation

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To: Technical Publications Manager Total Pages Sent ________

RE: Reader Response

From: Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________ FAX: (______) _________ - _________

Application (optional):

Would you like a reply? Y N

Device: 24AA04/24LC04B Literature Number: DS21708G

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21708G-page 22 © 2007 Microchip Technology Inc.

24AA04/24LC04B

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX

Examples:

Device Temperature Package a) 24AA04-I/P: Industrial Temperature,

Range 1.7V, PDIP package

b) 24AA04-I/SN: Industrial Temperature,

Device: 24AA04: = 1.7V, 4 Kbit I2C Serial EEPROM 1.7V, SOIC package

24AA04T: = 1.7V, 4 Kbit I2C Serial EEPROM c) 24AA04T-I/OT: Industrial Temperature,

(Tape and Reel) 1.7V, SOT-23 package, tape and reel

24LC04B: = 2.5V, 4 Kbit I2C Serial EEPROM d) 24LC04B-I/P: Industrial Temperature,

24LC04BT: = 2.5V, 4 Kbit I2C Serial EEPROM 2.5V, PDIP package

(Tape and Reel) e) 24LC04B-E/SN: Extended Temperature,

2.5V, SOIC package

f) 24LC04BT-I/OT: Industrial Temperature,

Temperature I = -40°C to +85°C

2.5V, SOT-23 package, tape and reel

Range: E = -40°C to +125°C

Package: MC = 2x3 DFN, 8-lead

P = Plastic DIP (300 mil body), 8-lead

SN = Plastic SOIC (3.90 mm body), 8-lead

ST = Plastic TSSOP (4.4 mm), 8-lead

MS = Plastic Micro Small Outline (MSOP), 8-lead

OT = SOT-23, 5-lead (Tape and Reel only)

© 2007 Microchip Technology Inc. DS21708G-page23

24AA04/24LC04B

NOTES:

DS21708G-page 24 © 2007 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device Trademarks

applications and the like is provided only for your convenience

The Microchip name and logo, the Microchip logo, Accuron,

and may be superseded by updates. It is your responsibility to

dsPIC, KEELOQ, KEELOQ logo, microID, MPLAB, PIC,

ensure that your application meets with your specifications.

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, and

MICROCHIP MAKES NO REPRESENTATIONS OR

SmartShunt are registered trademarks of Microchip

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

Technology Incorporated in the U.S.A. and other countries.

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION, AmpLab, FilterLab, Linear Active Thermistor, Migratable

INCLUDING BUT NOT LIMITED TO ITS CONDITION, Memory, MXDEV, MXLAB, PS logo, SEEVAL, SmartSensor

QUALITY, PERFORMANCE, MERCHANTABILITY OR and The Embedded Control Solutions Company are

FITNESS FOR PURPOSE. Microchip disclaims all liability registered trademarks of Microchip Technology Incorporated

arising from this information and its use. Use of Microchip in the U.S.A.

devices in life support and/or safety applications is entirely at Analog-for-the-Digital Age, Application Maestro, CodeGuard,

the buyer’s risk, and the buyer agrees to defend, indemnify and dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

hold harmless Microchip from any and all damages, claims, ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

suits, or expenses resulting from such use. No licenses are In-Circuit Serial Programming, ICSP, ICEPIC, Mindi, MiWi,

conveyed, implicitly or otherwise, under any Microchip MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

intellectual property rights. PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC®

MCUs and dsPIC® DSCs, KEELOQ® code hopping devices, Serial

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

© 2007 Microchip Technology Inc. DS21708G-page 25

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC ASIA/PACIFIC EUROPE

Corporate Office Asia Pacific Office India - Bangalore Austria - Wels

2355 West Chandler Blvd. Suites 3707-14, 37th Floor Tel: 91-80-4182-8400 Tel: 43-7242-2244-39

Chandler, AZ 85224-6199 Tower 6, The Gateway Fax: 91-80-4182-8422 Fax: 43-7242-2244-393

Tel: 480-792-7200 Habour City, Kowloon Denmark - Copenhagen

India - New Delhi

Fax: 480-792-7277 Hong Kong Tel: 45-4450-2828

Tel: 91-11-4160-8631

Technical Support: Tel: 852-2401-1200 Fax: 45-4485-2829

Fax: 91-11-4160-8632

http://support.microchip.com Fax: 852-2401-3431

India - Pune France - Paris

Web Address:

Australia - Sydney Tel: 91-20-2566-1512 Tel: 33-1-69-53-63-20

www.microchip.com

Tel: 61-2-9868-6733 Fax: 91-20-2566-1513 Fax: 33-1-69-30-90-79

Atlanta Fax: 61-2-9868-6755

Japan - Yokohama Germany - Munich

Duluth, GA

China - Beijing Tel: 49-89-627-144-0

Tel: 678-957-9614 Tel: 81-45-471- 6166

Tel: 86-10-8528-2100 Fax: 49-89-627-144-44

Fax: 678-957-1455 Fax: 81-45-471-6122

Fax: 86-10-8528-2104 Italy - Milan

Boston Korea - Gumi

China - Chengdu Tel: 39-0331-742611

Westborough, MA Tel: 82-54-473-4301

Tel: 86-28-8665-5511 Fax: 39-0331-466781

Tel: 774-760-0087 Fax: 82-54-473-4302

Fax: 86-28-8665-7889 Netherlands - Drunen

Fax: 774-760-0088 Korea - Seoul

China - Fuzhou Tel: 82-2-554-7200 Tel: 31-416-690399

Chicago

Tel: 86-591-8750-3506 Fax: 82-2-558-5932 or Fax: 31-416-690340

Itasca, IL

Tel: 630-285-0071 Fax: 86-591-8750-3521 82-2-558-5934 Spain - Madrid

Fax: 630-285-0075 China - Hong Kong SAR Tel: 34-91-708-08-90

Malaysia - Penang

Tel: 852-2401-1200 Tel: 60-4-646-8870 Fax: 34-91-708-08-91

Dallas

Addison, TX Fax: 852-2401-3431 Fax: 60-4-646-5086 UK - Wokingham

Tel: 972-818-7423 China - Qingdao Tel: 44-118-921-5869

Philippines - Manila

Fax: 972-818-2924 Tel: 86-532-8502-7355 Fax: 44-118-921-5820

Tel: 63-2-634-9065

Detroit Fax: 86-532-8502-7205 Fax: 63-2-634-9069

Farmington Hills, MI China - Shanghai Singapore

Tel: 248-538-2250 Tel: 86-21-5407-5533 Tel: 65-6334-8870

Fax: 248-538-2260 Fax: 86-21-5407-5066 Fax: 65-6334-8850

Kokomo China - Shenyang Taiwan - Hsin Chu

Kokomo, IN Tel: 86-24-2334-2829 Tel: 886-3-572-9526

Tel: 765-864-8360 Fax: 86-24-2334-2393 Fax: 886-3-572-6459

Fax: 765-864-8387

China - Shenzhen Taiwan - Kaohsiung

Los Angeles Tel: 86-755-8203-2660 Tel: 886-7-536-4818

Mission Viejo, CA Fax: 86-755-8203-1760 Fax: 886-7-536-4803

Tel: 949-462-9523

China - Shunde Taiwan - Taipei

Fax: 949-462-9608

Tel: 86-757-2839-5507 Tel: 886-2-2500-6610

Santa Clara Fax: 86-757-2839-5571 Fax: 886-2-2508-0102

Santa Clara, CA

China - Wuhan Thailand - Bangkok

Tel: 408-961-6444

Tel: 86-27-5980-5300 Tel: 66-2-694-1351

Fax: 408-961-6445

Fax: 86-27-5980-5118 Fax: 66-2-694-1350

Toronto

China - Xian

Mississauga, Ontario,

Tel: 86-29-8833-7250

Canada

Fax: 86-29-8833-7256

Tel: 905-673-0699

Fax: 905-673-6509

12/08/06

DS21708G-page 26 © 2007 Microchip Technology Inc.

You might also like

- Build A Mouse Trap Using Arduino UNODocument6 pagesBuild A Mouse Trap Using Arduino UNOdeath noteNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNo ratings yet

- 24AA16/24LC16B: 16K I C Serial EEPROMDocument25 pages24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezNo ratings yet

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonNo ratings yet

- 24LC04B PDFDocument22 pages24LC04B PDFEddy RosarioNo ratings yet

- 24LC08 PDFDocument30 pages24LC08 PDFJaime BarrancoNo ratings yet

- 1K 5.0V I C™ Serial EEPROM: Features: DescriptionDocument36 pages1K 5.0V I C™ Serial EEPROM: Features: DescriptionDanna PerezNo ratings yet

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pages24AA08/24LC08B: 8KI C Serial EEPROMjoseNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument24 pages24AA02/24LC02B: 2KI C Serial EEPROMMayk OzNo ratings yet

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pages24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaNo ratings yet

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Document32 pages24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluNo ratings yet

- 21711c PDFDocument24 pages21711c PDFAbdessamad EladakNo ratings yet

- 24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BDocument40 pages24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BAlhassan Ahmed OmranNo ratings yet

- 24FC1025 EepromDocument28 pages24FC1025 EepromAnirudh ReddyNo ratings yet

- 24l1026i Memoria EEPROM 1024kDocument28 pages24l1026i Memoria EEPROM 1024kMarta_d_eNo ratings yet

- Atmel 24c02 PDFDocument30 pagesAtmel 24c02 PDFMAX GNo ratings yet

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNo ratings yet

- 24aa515, 24LC515, 24FC515Document20 pages24aa515, 24LC515, 24FC515dorudNo ratings yet

- 24 LC 256Document38 pages24 LC 256johnNo ratings yet

- 1K/2K 5.0V I C Serial EEPROM: Obsolete DeviceDocument10 pages1K/2K 5.0V I C Serial EEPROM: Obsolete DevicesixtodeathNo ratings yet

- Ic PDFDocument36 pagesIc PDFdharamNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- 24aa512 Mic PDFDocument28 pages24aa512 Mic PDFkt2018No ratings yet

- 24C32Document12 pages24C32SilviuCocoloșNo ratings yet

- EEPROM 24LC256 - Microchip PDFDocument28 pagesEEPROM 24LC256 - Microchip PDFValdir DerlannNo ratings yet

- 24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703PDocument49 pages24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703Pmarko.jojicoo777No ratings yet

- 16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangesDocument22 pages16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangeshcarcaroNo ratings yet

- 32K 2.5V I C Serial EEPROM: Features Package TypesDocument12 pages32K 2.5V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- I2c EEPROM 24xx256 DsDocument28 pagesI2c EEPROM 24xx256 DsRizwan AmirNo ratings yet

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDocument24 pages24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanNo ratings yet

- 24AA04/24LC04B/24FC04: 4KI C Serial EEPROMDocument45 pages24AA04/24LC04B/24FC04: 4KI C Serial EEPROMDinu Racautanu MironNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDocument45 pages24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package TypesChrono GtzNo ratings yet

- 24AA256/24LC256: 256K I C Cmos Serial EepromDocument12 pages24AA256/24LC256: 256K I C Cmos Serial EepromWelleyNo ratings yet

- 24lc512 DatasheetDocument27 pages24lc512 DatasheetLeonardo QuevedoNo ratings yet

- 24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMDocument12 pages24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMmacepaNo ratings yet

- 1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesDocument12 pages1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesVictor TruccoNo ratings yet

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezNo ratings yet

- 24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dDocument28 pages24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dAbhishek BhattacharjeeNo ratings yet

- 24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromDocument26 pages24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromcraponzelNo ratings yet

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pages25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийNo ratings yet

- 24AA128/24LC128/24FC128: 128K I C Serial EEPROMDocument44 pages24AA128/24LC128/24FC128: 128K I C Serial EEPROMJosemar M. FerreiraNo ratings yet

- 24AA02 24LC02B 24FC02 2K I2C Serial EEPROM 2000170-2577009Document52 pages24AA02 24LC02B 24FC02 2K I2C Serial EEPROM 2000170-2577009MindSet MarcosNo ratings yet

- 21073K PDFDocument24 pages21073K PDFadfumegaNo ratings yet

- 25 LC 1024Document28 pages25 LC 1024hyd27No ratings yet

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaNo ratings yet

- 24AA256/24LC256/24FC256: 256K I C Serial EEPROMDocument42 pages24AA256/24LC256/24FC256: 256K I C Serial EEPROMAbhishek BhattacharjeeNo ratings yet

- Bus Serial EEPROMDocument12 pagesBus Serial EEPROMMatiasNo ratings yet

- 8K/16K 5.0V I C Serial Eeproms: Features Package TypesDocument13 pages8K/16K 5.0V I C Serial Eeproms: Features Package Typesarunan55No ratings yet

- 22131c PDFDocument24 pages22131c PDFAdilsonAmorimNo ratings yet

- 25AA1024Document30 pages25AA1024Bình MaiNo ratings yet

- 25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMDocument26 pages25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMmuglanNo ratings yet

- 24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesDocument12 pages24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesarminNo ratings yet

- Write Protect Pin For Hardware Data ProtectionDocument16 pagesWrite Protect Pin For Hardware Data Protectionisc44242100% (2)

- 24AA024 MicrochipTechnologyDocument22 pages24AA024 MicrochipTechnologydasdracheNo ratings yet

- 2-Wire Serial EEPROM: FeaturesDocument19 pages2-Wire Serial EEPROM: FeaturesAgustin AndrokaitesNo ratings yet

- 4 PDFDocument31 pages4 PDFAgus OrtizNo ratings yet

- 8K/16K 5.0V SPI Bus Serial EEPROM: Features Package TypesDocument12 pages8K/16K 5.0V SPI Bus Serial EEPROM: Features Package Typesrıdvan71No ratings yet

- Strapdown Inertial Navigation Integration Algorithm Design Part 1: Attitude AlgorithmsDocument10 pagesStrapdown Inertial Navigation Integration Algorithm Design Part 1: Attitude AlgorithmsNicoli LourençoNo ratings yet

- A Tutorial To Inertial Navigation: Yuanxin WuDocument100 pagesA Tutorial To Inertial Navigation: Yuanxin WuNicoli Lourenço100% (2)

- A Tutorial To Inertial Navigation: Yuanxin WuDocument68 pagesA Tutorial To Inertial Navigation: Yuanxin WuNicoli LourençoNo ratings yet

- Bix TesteDocument1,765 pagesBix TesteNicoli LourençoNo ratings yet

- Wireless LocalizationDocument137 pagesWireless LocalizationNicoli LourençoNo ratings yet

- Gnss SignalDocument16 pagesGnss SignalNicoli LourençoNo ratings yet

- Lateration and Signal StrengthDocument6 pagesLateration and Signal StrengthNicoli LourençoNo ratings yet

- PVT and ReceiverDocument45 pagesPVT and ReceiverNicoli LourençoNo ratings yet

- Navigation Technology: Part 1.3 - GPS Coordinates and Orbits Lecturer: Prof. Xin ChenDocument34 pagesNavigation Technology: Part 1.3 - GPS Coordinates and Orbits Lecturer: Prof. Xin ChenNicoli LourençoNo ratings yet

- Signal Processing: Simon Yiu, Marzieh Dashti, Holger Claussen, Fernando Perez-CruzDocument10 pagesSignal Processing: Simon Yiu, Marzieh Dashti, Holger Claussen, Fernando Perez-CruzNicoli LourençoNo ratings yet

- Secure Digital Card: Product ManualDocument117 pagesSecure Digital Card: Product ManualNicoli LourençoNo ratings yet

- 8-Bit, 100 MSPS+ Txdac D/A Converter: LinearityDocument17 pages8-Bit, 100 MSPS+ Txdac D/A Converter: LinearityNicoli LourençoNo ratings yet

- Quartus Prime Introduction Using VHDL DesignsDocument31 pagesQuartus Prime Introduction Using VHDL DesignsNicoli LourençoNo ratings yet

- Rhythm Training: Written by David BarrettDocument3 pagesRhythm Training: Written by David BarrettNicoli LourençoNo ratings yet

- 8-/6-/4-Channel DAS With 16-Bit, Bipolar Input, Simultaneous Sampling ADCDocument36 pages8-/6-/4-Channel DAS With 16-Bit, Bipolar Input, Simultaneous Sampling ADCNicoli LourençoNo ratings yet

- An Illustrated History of ComputersDocument18 pagesAn Illustrated History of Computersmirarad5052No ratings yet

- American International University-Bangladesh (AIUB) Faculty of EngineeringDocument11 pagesAmerican International University-Bangladesh (AIUB) Faculty of EngineeringAbeer HussainNo ratings yet

- Quiz ObservationDocument3 pagesQuiz ObservationSherry-Ann TulauanNo ratings yet

- Arthanari V ResumeDocument2 pagesArthanari V ResumeVijay DaeNo ratings yet

- Division Araling Panlipunan Tools: Parts of A Whole, Emerging Patterns, Causes and Consequences of TrendsDocument12 pagesDivision Araling Panlipunan Tools: Parts of A Whole, Emerging Patterns, Causes and Consequences of TrendsNestor MoresNo ratings yet

- Definition of CRMDocument3 pagesDefinition of CRMjs_pp_2006No ratings yet

- LPR ProposalDocument3 pagesLPR ProposalRecordTrac - City of OaklandNo ratings yet

- Human Factors EngineeringDocument57 pagesHuman Factors EngineeringAnonymous NGXdt2BxNo ratings yet

- Isophase Condition EvaluationDocument9 pagesIsophase Condition Evaluationdinesh_rajan1986No ratings yet

- CV-Agus Nugraha (11.01.2021)Document11 pagesCV-Agus Nugraha (11.01.2021)Agus NugrahaNo ratings yet

- RDC6334G Biref EnglishDocument4 pagesRDC6334G Biref EnglishJuanjo AcvdoNo ratings yet

- D475a-5e0 SN 30001-Up (Tier3)Document614 pagesD475a-5e0 SN 30001-Up (Tier3)João MariaNo ratings yet

- SEVEN Materials (MIR) Work (WIR) Inspection Requests Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00005Document11 pagesSEVEN Materials (MIR) Work (WIR) Inspection Requests Procedure 0DMQL00-DLVR-00-SEV-QM-PRO-00005Meshaal ALBalharithNo ratings yet

- Elster A1884 Alpha DNP MeterDocument2 pagesElster A1884 Alpha DNP MeterUdaya Kumar Majeti100% (1)

- Dell Latitude E6420 XFR: Real-World RuggedDocument2 pagesDell Latitude E6420 XFR: Real-World Ruggedbedoo54No ratings yet

- Digital Servo Adapter-MODEL B: Driving FANUC Servo Motors With Customer' S ControllerDocument2 pagesDigital Servo Adapter-MODEL B: Driving FANUC Servo Motors With Customer' S ControllerHoang Nam NguyenNo ratings yet

- OK REV W.hse-014 F.02 Formulir Inspeksi Safety Crane (Monthly)Document2 pagesOK REV W.hse-014 F.02 Formulir Inspeksi Safety Crane (Monthly)Ahfi Rizqi FajrinNo ratings yet

- Module 2 Manpower LevelingDocument24 pagesModule 2 Manpower LevelingrandomstalkingwomenNo ratings yet

- Applications: FX-SC8XIOR34-0 Module Installation InstructionsDocument16 pagesApplications: FX-SC8XIOR34-0 Module Installation InstructionsUdo IheanachoNo ratings yet

- MulampakaRamana (4y 2m)Document3 pagesMulampakaRamana (4y 2m)Tony JammanNo ratings yet

- RRC Connected User License: Re-Balance Between EnodebsDocument5 pagesRRC Connected User License: Re-Balance Between Enodebsquyphamvan100% (1)

- Dokumen - Tips - Caterpillar Cat 416e Backhoe Loader Prefix Lms Service Repair Manual lms00001 and Up 1586118026Document20 pagesDokumen - Tips - Caterpillar Cat 416e Backhoe Loader Prefix Lms Service Repair Manual lms00001 and Up 1586118026Victor Admin Baus Ingeniería AplicadaNo ratings yet

- 5993 Energy Consumption in The Uk All Data Tables in TDocument132 pages5993 Energy Consumption in The Uk All Data Tables in TtmturnbullNo ratings yet

- IDM Lab5Document5 pagesIDM Lab5gudursrinath11No ratings yet

- Lab #1 Logic Gates: ObjectiveDocument6 pagesLab #1 Logic Gates: ObjectiveZbiggNo ratings yet

- TSE2251 SAD Revision NoteDocument190 pagesTSE2251 SAD Revision NoteazuraNo ratings yet

- ARM Experiment ProgrammsDocument52 pagesARM Experiment ProgrammsShweta KulkarniNo ratings yet

- Siemens S7200 Modbus GuideDocument6 pagesSiemens S7200 Modbus GuideVinothNo ratings yet

- Budding Scientist - Discovering Language HICHAM OUAZENEDocument2 pagesBudding Scientist - Discovering Language HICHAM OUAZENESara Chehidi Eps BendrefNo ratings yet