Professional Documents

Culture Documents

Efficient Steel Conference

Uploaded by

Juan HernanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Efficient Steel Conference

Uploaded by

Juan HernanCopyright:

Available Formats

THE STEEL CONFERENCE

Hints on Using Joists

Efficiently

By Tim Holtermann, S.E., P.E.; Drew Potts, P.E.; Bob Sellers, P.E.; and Walt Worthley, P.E.

Proper coordination between structural engineers and joist suppliers can make

steel joists more structurally efficient and cost-effective.

teel joists and joist girders are which section was used for the overall will have minimal or no effect on the

S an efficient framing system for

support of floors and roofs in a

wide variety of buildings.

They are easy to use and pro-

vide a great deal of flexibility in their use

for many different loads, spans, shapes,

or other special conditions. However, it is

building structure will ensure that the

joists are designed to the same load com-

binations. If a different set of load combi-

nations is required, it should be specified

on the contract drawings.

It is important for the specifying pro-

fessional to provide net uplift values

girder. But for uplift reactions greater

than 25% of the gravity reaction, the

uplift can control member selections, and

lower values on the girders could create a

savings.

Another note about joist girders: The

presumption is that the design load spec-

important that the design requirements where the joist manufacturer needs to ified includes an allowance for the self-

established by the specifying profes- consider uplift in the joist or joist girder weight of the girder. If this is not the case,

sional (Structural Engineer of Record) be design. If the uplift forces shown on the it needs to be clearly noted on the con-

clearly conveyed and understood by the contract drawings are displayed as gross tract documents.

joist manufacturer so that the joist design uplift, the joist manufacturer may conser- For joists that have more than a nomi-

is safe and economical. This paper dis- vatively design for the full force without nal double pitch, an unbalanced loading

cusses a number of topics and the coordi- deducting any dead load, which is not case may need to be considered. This is

nation and options for a safe, efficient, cost effective, or will need to verify a net not automatically covered by the SJI

and cost-effective design. uplift value. Many contract drawings do specifications, so the specifying profes-

The Steel Joist Institute (SJI) is the gov- not show the dead loads used in design, sional should provide the necessary

erning body for joist manufacturers. For and even if they do, it is the specifying instructions on the contract drawings.

more general information about steel professional’s judgment call if some of For earthquake loads, the joist manu-

joists or the Institute, or to obtain contact the dead load should be considered col- facturer will use different load combina-

information for a joist manufacturer, lateral and not be deducted from the tions for E or Em loads, so the contract

please visit www.steeljoist.org. gross uplift. drawings need to make a clear distinc-

Joist girders are typically designed for tion between the two types of loads.

Loads and Load Combinations the uplift reactions of the joists sitting on

The joist manufacturer will design the them, but in fact they are considered as Axial Loads and End Moments

joists for the load combinations from the part of the main wind force resisting sys- Standard K-Series, LH, DLH-Series

design code specified on the contract tem (MWFRS), which would result in and joist girders are designed in accor-

drawings. It should be noted that the cur- lower uplift values than if they were con- dance with the latest SJI specifications as

rent IBC 2003 offers two different load sidered “components and cladding.” simply supported underslung joists/joist

combinations for use with ASD design: When is it an advantage to try to use girders, which support symmetrically

Basic Load Combinations (Section lower uplift values on a joist girder? If the placed gravity loads applied to the top

1605.3.1) and Alternate Basic Load Com- uplift forces are less than 25% of the typ- chord. Occasionally it is desirable to

binations (Section 1605.3.2). Specifying ical girder gravity load, then the uplift extend and connect the bottom chord to

Tim Holtermann is Corporate Drew Potts is Engineering Man- Bob Sellers is Engineering Man- Walt Worthley is Chief Engineer

Engineering Manager for Canam ager for New Columbia Joist. ager for Socar, Inc., a steel joist for Valley Joist-West.

Steel Corporation. manufacturer.

April 2005 • Modern Steel Construction

the supporting column so the joist/joist umn. Top plates or tie angles/rods should K-Series joist or a 4”-deep seat could be

girder and column together form a rigid always be specified for joist-to-joist con- used on an LH-Series joist. When the

frame supporting gravity and wind/seis- nections when supported by joist girders. joists are installed at a slope, the mini-

mic loads. Axial loads or end moments If fillet welds are used for transferring the mum required bearing seat depth might

may be induced into the joists/joist gird- lateral forces from the bottom chord to the have to be increased. Most manufactur-

ers when joists/joist girders are used as supporting columns, reasonable weld ers’ catalogs have a table that gives the

part of the rigid frame, moment frame, or thicknesses should be used to create the minimum required bearing seat depths

other bracing systems. Joist/joist girder most efficient bottom chord design – 1/8” for a given slope. Referring to these

load diagrams or schedules are used to fillet for K-Series and 3/16” fillet for LH- tables and specifying the minimum bear-

specify the magnitude and direction of Series, if possible. ing seat depth in accordance with these

the moments and axial forces for each For axial loads, there can be a cost sav- tables will help to reduce detailing, man-

load case that is required to be consid- ings for making the load paths clear or ufacturing, and possibly erection costs. It

ered. The diagrams or schedules should indicating where the axial load is accu- will also reduce the number of RFIs from

distinguish between, and show, both the mulating along the length of a joist. the joist manufacturer.

live load and wind/seismic moments for Deck is often used in the bracing sys- When the loads for a top chord exten-

the most efficient and timely design. tem as a diaphragm and the accommo- sion of a given length are greater than the

Also, the specifying professional should dating loads may need to be routed from values given in the “Top Chord Extension

ensure that the contract drawings state the deck into the supporting beam or joist Load Table” or “Extended End Load

that all dead loads are to be applied girder through the joist seats. When the Table,” it is an indication that a 2.5”-deep

before the bottom chord extensions are lateral stiffness of the joist seat is not suf- seat will not work. So what bearing seat

welded to the column, thereby eliminat- ficient to transfer the required lateral depth should be specified? A good rule of

ing the moment generated by the dead loads, steel tubes or channel sections thumb (in most cases) is that the depth of

load. The joists/joist girders are checked could be applied between the joists to the bearing seat in inches should be equal

for the specified load cases and the effect transfer the lateral load from the deck to to the length of the extension in feet.

of the moments and axial chord forces, the supporting member. As an example, consider a joist exten-

and the design of the chords and webs, sion with a length of 5’-6”; the load on the

plus the quantity and spacing of the bot- Top Chord Extensions joist and extension is 280 plf, and there is

tom chord braces, is adjusted accord- Top chord extensions are commonly a 1,000 lb concentrated load at the end of

ingly. used to create eaves or awnings. They the extension.

To transfer the moments and chord can be either simple (S Type), where only The equivalent uniform load on the

forces from the bracing systems or the top chord is extended past the bear- extension is: 280 + (2 x 1000)/5.5 = 644

columns into the joists/joist girders, suit- ing seat, or reinforced (R Type), where plf.

able connections are required. The speci- both the top chord and the bearing seat From the “Extended End Load Table

fying authority should be knowledgeable are extended. The SJI standard specifica- (R Type),” the maximum load on a 5’-6”

of the inter-relationships between the tion has tables for “Top Chord Extensions extension is 375 plf for a Type R12

joists/joist girders, columns, and connec- and Extended Ends” that provide the extended end. Therefore, a 2.5”-deep

tions to obtain a cost effective design. load capacity for various lengths of types bearing seat will not work for this joist.

Minimizing fabrication and erection costs S1 through S12 and R1 through R12 Based on the above, the bearing seat

of the connections and reducing the spe- extensions. It should be noted that depth should be increased to 5”. Note: If

cial requirements for the joists/joist gird- although a simple top chord extension the joist had to be installed at a slope, the

ers (seat stiffeners, chord reinforcements, can be as long as 4’-6”, the load rating for bearing seat depth may have to be fur-

etc.) will produce the most economical this extension is only 113 plf. ther increased to account for the slope.

design. Generally for single story build- The Structural Engineer of Record

ings, the most cost effective method of should review the “Top Chord Extension Joist Substitutes

transferring the moments and axial loads Load Table” and “Extended End Load Joist substitutes are now included as

from the bracing systems or columns is Table” to ensure that an extension can be part of the SJI K-Series standard specifi-

through the joist/joist girder bearing manufactured for the length and loads cation. These are very economical and

seats, provided that the forces are not too required for their project. If there are con- should be specified when the length of

large. The top chord must be designed to centrated loads or snow drift loads on the the joist is 8’ or less. The SJI has three joist

accommodate the axial force and bending extension, they need to be resolved into substitute designations: 2.5K1, 2.5K2, and

moment that is developed due to the an equivalent uniform load and added to 2.5K3. The spans for these joist substi-

force coming in through the bottom of the the dead and live loads on the extension. tutes are 4’ to 8’. The specifying profes-

joist/joist girder bearing seat. This begins This will allow the engineer to properly sional should refer to the “2.5 Inch K-

to significantly affect the joist design once size and specify the extension needed. Series Joist Substitutes” load table for the

the axial force exceeds 5 kips for K-Series The top chord extensions given in the particular joist substitute that satisfies the

joists, 10 kips for LH, DLH-Series joists, SJI standard specification can be used for project requirements. Some joist manu-

and 20 kips for joist girders. For larger either K-Series or LH, DLH-Series joists. facturers do offer joist substitutes in

axial loads, a better force path would The SJI “standard” bearing seat depths up to 5” and lengths up to 10’. If a

need to be created by modifying the basic depths are 2.5” for K-Series joists, 5” for joist substitute must be longer than 8’, it

connection to include the use of a top LH, DLH-Series joists, and 7.5” for joist may need to have a bearing seat deeper

plate, tie angles/rods, or knife plates from girders. However, it should be under- than 2.5”. The depth of the joist substitute

the joist/joist girder to the supporting col- stood that a 5”-deep seat can be used on a

Modern Steel Construction • April 2005

should be the same depth as the joist

bearing seats.

Bridging

The traditional image of horizontal

bridging rows is a pair of aligned angles

at the same location on the top and bot-

tom chords. However, it is not essential

or required that the top and bottom

chord rows align. In fact, there can be

cost savings if the spacing of the bridging

rows is varied according to the structural

needs. This is particularly true in regions

with high uplift values. The specifying

Top chord extension profiles.

professional should avoid dimensioning

specific bridging line locations on the

contract drawings to allow the joist man-

ufacturer to optimize the bridging layout. Load on vertical

In fact, many contract drawings simply

state, “bridging as required per SJI.” SJI Uniform Loading

When selecting the joist designations

for a project, the lightest joist may not be

the cheapest if the lighter joist requires

erection stability bridging (bolted cross

bridging) and a slightly heavier joist does Primary Diagonals Web Members

not. All joists in the shaded portions of

the load tables require erection stability

bridging (bolted cross bridging). Verticals or Redundant Web Members

Retrofit Joists The secondary web members, often referred to as "verticals" or "redundants," must be designed

When the retrofit of an existing struc- to support the top chord load, plus a portion of the top chord force as a bracing load.

ture requires that the joist capacities be

increased, adding new additional inter-

mediate joists may be more cost effective connection to the existing deck. There- KCS-Series Joists

than modifying or extensively reinforc- fore, an alternative is to call for extra When exact locations of the point

ing existing joists. If the deck will be bridging rows, and to coordinate with loads are not available to the specifying

replaced in the area of the new joists, the the joist manufacturer so that the joist professional, a KCS-Series joist is an

procedures are essentially the same as for design considers only those bridging alternative that provides flexibility

new construction. But if the metal deck- rows as lateral support points. within a moment and shear envelope. By

ing will not be removed, there are a num- evaluating two possible locations for

ber of special considerations to be made: Point Loads point loads, the end of the span and the

➜ The new joists can be provided with a When joists will be used to support mid-span, a design envelope can be

field bolted splice at mid-span to non-uniform, concentrated loads, such as established. With maximum moment and

allow each half to be raised inde- roof top units, a number of options are shear values, a KCS-Series joist can be

pendently and then joined together available to provide the required joist selected that will perform satisfactorily

in the air. capacity. This section will outline those regardless of the locations of the loads.

➜ The camber of the new joists should options and provide a relative price com- However, there are a number of issues

be reduced or eliminated to attempt parison. pertaining to design that need to be

to match the current as-built deck understood and considered when select-

profile. Loads and Locations Known ing KCS joists. Below is a brief explana-

➜ It is common to reduce the joist bear- If the exact magnitude and location of tion of how a KCS joist design differs

ing seat depth slightly, and then call the point loads are known to the specify- from that of a K-Series joist. Then, spe-

for field shimming to the required ing professional, the most efficient joist cific items are addressed illustrating the

height. This allows for tolerances that design will be obtained if a load diagram impact of the use of KCS joists.

may vary from the existing to the new is provided or the loads and locations are A KCS joist is a modified K-Series

construction. clearly shown on the contract drawings. joist. The K-Series standard specification

➜ The lateral support of the new joist Because every joist manufacturer custom requires the diagonal web members be

top chord needs to be addressed. Typ- designs all the joists for the specific proj- designed for the shear resulting from the

ically, the metal deck is attached at a ect, there is no cost savings if the specify- published uniform load or a minimum of

maximum spacing of 36” on center to ing professional attempts to select a 25% of the SJI end reaction, whichever is

laterally support the top chord. But it larger standard designation joist to cover greater. The primary modification to the

may not be possible to make a welded the additional loads. K-Series joist specification is that the web

April 2005 • Modern Steel Construction

TC Compression = M 550 plf

cap/deff

TC force = Horizontal Component

Vcap + 0.005(TC Comp.)

Shear = Vcap

Placement +M max

V max Angle

BC Tension = Mcap/deff

Horizontal -M max

Component

The chords of a KCS-Series joist are designed for the axial force— The end panels of the top chord of a KCS-Series joist are designed for

compression in the top chord and tension in the bottom chord— the combined effects of the axial force resulting from the horizontal com-

resulting from dividing the published maximum moment by the effec- ponent of the end web and bending calculated using an assumed four

tive depth of the joist. span continuous beam model loaded with 550 plf.

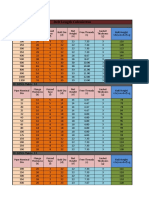

RELATIVE PRICE COMPARISON

TRAVEL/

TRAVEL/ TRAVEL/

LOAD KCS/ ADD LOAD

UNIFORM WITH POINT ADD LOAD ADD LOAD

CASE 1: KCS FIELD WITH FIELD REINF.

LOAD LOADS @ PANEL WITH FIELD

2 @ 300# STRUTS LOCAL

POINT STRUT

BENDING

8 ELEMENTS

COST $239 $247 $355 $410 $253 $308 $260

$239 + $340

% 100% 103% 149% 172% 106% 129% 109% 242%

Cost comparisons for two traveling loads of

TRAVEL/

LOAD KCS/

TRAVEL/ TRAVEL/

ADD LOAD 300 lb, or two at 1,200 lb.

UNIFORM WITH POINT ADD LOAD ADD LOAD

CASE 2: KCS FIELD WITH FIELD REINF.

LOAD LOADS @ PANEL WITH FIELD

2 @ 1200# STRUTS LOCAL

POINT STRUT

BENDING

22 ELEMENTS

COST $239 $281 $401 $456 $292 $347 $308

$239 + $680

% 100% 118% 168% 191% 122% 145% 129% 385%

members are designed for a constant bending calculated using an assumed Traveling Loads or Add Loads

shear value regardless of position within four span continuous beam model Another possibility for providing flex-

the joist, thus the KCS designation. The loaded with 550 plf. It should be noted ibility in the placement of point loads is

secondary web members, often referred that the top chords of KCS joists, as with to specify a traveling, added load that

to as “verticals” or “redundants,” must K-Series joists, are not designed for any could occur anywhere along the joist

be designed to support the top chord bending between the panel points except span. The joist manufacturer will model

load, plus a portion of the top chord force in the end panel as described above. A the joist with the loads in a large number

as a bracing load. The primary web mem- KCS joist cannot support a concentrated of possible locations so that the maxi-

bers, except the end web, of a KCS-Series load between panel points. A field mum possible shear and moment is cal-

joist are designed for 100% of the pub- applied member must be installed at all culated for each individual element of

lished shear capacity as a compressive loads that are not at panel points. the joist. There are two possibilities for

load. Only the end web is designed as a Because of this approach, the chord the type of traveling load being specified:

tension member for the force that results and web sizes for KCS joists will rarely It could be applied at any panel point

from the published shear capacity. change, regardless of length. A 30KCS5 (such that local bending between panel

The chords of a KCS-Series joist are that has a 30’span will have the same point is not considered), or it could be

designed for the axial force—compres- member sizes as one that has a 60’ span. applied anywhere along the span (such

sion in the top chord and tension in the With the chord sizes established, a that local bending is considered and field

bottom chord—resulting from dividing moment of inertia is calculated and pub- added struts would not be required). The

the published maximum moment by the lished in the tables. This information specifying professional needs to clearly

effective depth of the joist. This design provides the specifying professional the indicate the desired type on the contract

force is used for all the bottom chord pan- stiffness that can be used for checking drawings, as well as an indication of the

els and all top chord panels, except the deflection and analyzing lateral frame chord to which the traveling load will be

first and last. SJI recognizes that the max- action. applied.

imum shear and moment capacities can- Another advantage of a KCS-Series The table shows the cost compar-

not develop simultaneously in the end joist is that if the loads ever change over isons for two traveling loads of 300 lb, or

panel. The end panels of the top chord the life of the structure, the moment and two at 1,200 lb. Three comparisons are

are designed for the combined effects of shear capacities are clearly known, mak- made for each loading case: Loads

the axial force resulting from the hori- ing it easy to evaluate new loading con- applied at panel points only, loads

zontal component of the end web and ditions. applied at panel points for the joist

Modern Steel Construction • April 2005

design but field added struts used at the

actual locations, or loads applied any-

where along the span with local bending

considered. In general, for something

like a roof top unit that will have a frame

that may not correspond to joist panel

lengths, it is cost effective to require the

design for anywhere along the span. But

for hanging loads, such as sprinkler

lines, that have the field flexibility to be

hung only at panel points, the "at any

panel point" option makes sense.

The chart demonstrates that the

specification of a traveling, added load

can be a cost effective alternative and

shows that the costs of having flexibility

in the placement of the loads is not sig-

nificantly greater than the cost of a joist

designed for the loads at a known loca-

tion.

Field Reinforcement

To complete the cost comparison in

the table, the estimated costs of rein-

forcing the joist that was designed only

for uniform loads so that it can support

the point loads is considered. This col-

umn of the chart shows the number of

overstressed joist elements for this

example and the cost of the original joist

plus the cost of the field reinforcement.

It should be noted that the actual field

costs can vary greatly depending on

location and conditions. However, the

cost of the field reinforcing will be sev-

eral multiples of the original joist cost,

and it is clear that it is far more expen-

sive than other costs shown to build the

original joist with additional capacity. ★

This paper has been edited for space consider-

ations. To learn more about using joists effi-

ciently, read the complete text online at

www.modernsteel.com or in the 2005

NASCC Proceedings.

April 2005 • Modern Steel Construction

You might also like

- Staad TutorialDocument58 pagesStaad TutorialSritoko83% (6)

- Design Guide For Cold-Formed Steel TrussesDocument22 pagesDesign Guide For Cold-Formed Steel Trusseseng_ali_khalafNo ratings yet

- Sixteen tips for fostering collaboration on splice designDocument4 pagesSixteen tips for fostering collaboration on splice designKamal HalawiNo ratings yet

- Top DriveDocument6 pagesTop DriveRenny Gracezifa BandasoNo ratings yet

- AD135Document3 pagesAD135Mayur WaghelaNo ratings yet

- Design Guide Joist Girder Rev4 Final 11sep06Document60 pagesDesign Guide Joist Girder Rev4 Final 11sep06Тодор ИлиескиNo ratings yet

- Guidelines For Seismic Design of Liquid Storage TanksDocument106 pagesGuidelines For Seismic Design of Liquid Storage Tanksjpdavila205No ratings yet

- CFSEI Tech Note X Bracing L001-09Document8 pagesCFSEI Tech Note X Bracing L001-09Jane EyreNo ratings yet

- ASTM C 932 - Stanadard Specification For Surface Applied Bonding Compound For Exterioir Plastering PDFDocument8 pagesASTM C 932 - Stanadard Specification For Surface Applied Bonding Compound For Exterioir Plastering PDFibrahimNo ratings yet

- Presentation GirderDocument53 pagesPresentation GirderIrfan KhanNo ratings yet

- Value Engineering For Steel ConstructionDocument9 pagesValue Engineering For Steel ConstructionvNo ratings yet

- Tolerating Tolerances: Understanding Construction Tolerances in Steel StructuresDocument3 pagesTolerating Tolerances: Understanding Construction Tolerances in Steel StructuresteedNo ratings yet

- Extended End-Plate Stiffener PDFDocument2 pagesExtended End-Plate Stiffener PDFaams_sNo ratings yet

- Guide to Operating an 11′′-5000psi Double Ram BOPDocument29 pagesGuide to Operating an 11′′-5000psi Double Ram BOPJuan Felipe Garza GNo ratings yet

- Flexible Riser (Abdul Rahman)Document5 pagesFlexible Riser (Abdul Rahman)Subsea_TeamNo ratings yet

- Tilting Pad Design PaperDocument16 pagesTilting Pad Design PaperTomas Andres Alfaro DiazNo ratings yet

- PSC Two Span Bridge Design TutorialDocument37 pagesPSC Two Span Bridge Design TutorialSony JsdNo ratings yet

- Concrete Construction Article PDF - Shoring BasicsDocument5 pagesConcrete Construction Article PDF - Shoring BasicsMark GreerNo ratings yet

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- OCDI (Japan)Document664 pagesOCDI (Japan)lazy cat75% (8)

- FHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored SystemsDocument304 pagesFHWA GEOTECHNICAL ENGINEERING CIRCULAR NO. 4 Ground Anchors and Anchored Systemsv100% (4)

- PSC I-Girder Bridge Design in AASHTO-LRFDDocument177 pagesPSC I-Girder Bridge Design in AASHTO-LRFDsandipNo ratings yet

- EM 1110-2-2901 Tunnels and Shafts in RockDocument236 pagesEM 1110-2-2901 Tunnels and Shafts in Rockxhifrah100% (3)

- EM 1110-2-2901 Tunnels and Shafts in RockDocument236 pagesEM 1110-2-2901 Tunnels and Shafts in Rockxhifrah100% (3)

- API RP 1102 SpreadsheetDocument5 pagesAPI RP 1102 SpreadsheetBehroozNo ratings yet

- Wind Turbine Foundation Design ConsiderationsDocument14 pagesWind Turbine Foundation Design ConsiderationsClaire GregoryNo ratings yet

- Lighting PlanDocument5 pagesLighting PlanAnandababuNo ratings yet

- Programme Narrative of Roads and Infrastructure in West Bay Block A 2500Document5 pagesProgramme Narrative of Roads and Infrastructure in West Bay Block A 2500Santhosh PalaniappanNo ratings yet

- Deflection LimitDocument12 pagesDeflection LimitPiyush Bhardwaj100% (2)

- Hints On Using Joists: EfficientlyDocument5 pagesHints On Using Joists: EfficientlyDemçe FlorjanNo ratings yet

- EFFICIENT USE OF STEEL JOISTSDocument9 pagesEFFICIENT USE OF STEEL JOISTSinsane88No ratings yet

- SteelWise Joists FactsDocument2 pagesSteelWise Joists FactsvNo ratings yet

- Detail Design of Bridge Piers On Pile FoDocument98 pagesDetail Design of Bridge Piers On Pile FoMukovhe MuvhaliNo ratings yet

- Skewed and Curved Steel I-Girder Bridge Fit: Technical ResourceDocument4 pagesSkewed and Curved Steel I-Girder Bridge Fit: Technical ResourceMario Guevara Ubidia- IngenieroCivilNo ratings yet

- Selecting Steel Joists and Joist GirdersDocument5 pagesSelecting Steel Joists and Joist GirdersHyunkyoun JinNo ratings yet

- Pages From 177344845 Aashto LRFD 4th 2007Document2 pagesPages From 177344845 Aashto LRFD 4th 2007vrajan1988No ratings yet

- Clase Dise o Anclajes PDFDocument59 pagesClase Dise o Anclajes PDFFran Barrera AlbornozNo ratings yet

- 05aDocument41 pages05aBridge Iit At RanchiNo ratings yet

- 272003-C-StructuralComponents-structural Capasity of PileDocument5 pages272003-C-StructuralComponents-structural Capasity of PileVirendra Kumar PareekNo ratings yet

- Composite PDFDocument4 pagesComposite PDFYami YugiNo ratings yet

- Preliminary STEEL STRUCTURE sizingDocument2 pagesPreliminary STEEL STRUCTURE sizingbaban patilNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document8 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!JitendraNo ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFYan Naung KoNo ratings yet

- C CodesStand Schneider Jan11Document3 pagesC CodesStand Schneider Jan11Magdy BakryNo ratings yet

- GN - 1.04 - Bearing Guidance Notes-SCIDocument7 pagesGN - 1.04 - Bearing Guidance Notes-SCIraaaaajjjjjNo ratings yet

- Chapter 1Document8 pagesChapter 1Saker MohamedNo ratings yet

- Balanced Cantilever BridgesDocument30 pagesBalanced Cantilever BridgesPacha Khan KhogyaniNo ratings yet

- EJ Fisher BracingwithJoistsDocument6 pagesEJ Fisher BracingwithJoistsGabby KenNo ratings yet

- Or Less: How To Determine The Best Connections For Steel Joists and Metal DeckDocument4 pagesOr Less: How To Determine The Best Connections For Steel Joists and Metal DeckMinh Tâm TrầnNo ratings yet

- STR-M - Joist Girder Moment Connections SJIDocument4 pagesSTR-M - Joist Girder Moment Connections SJIFWICIPNo ratings yet

- Anchor Rod Edge DistanceDocument2 pagesAnchor Rod Edge Distancewudongxiao3953No ratings yet

- Precast Concrete Lifting Anchor SystemDocument4 pagesPrecast Concrete Lifting Anchor SystemRachmat Hidayat SapwariNo ratings yet

- Chapter-2 (Steel Design)Document22 pagesChapter-2 (Steel Design)danica ledesmaNo ratings yet

- Launching of Pre Stressed Girder by James R LibbyDocument19 pagesLaunching of Pre Stressed Girder by James R LibbyhammadhouseNo ratings yet

- Release Notes Csi Bridge V 2100Document10 pagesRelease Notes Csi Bridge V 2100thekrauser96No ratings yet

- Steel Interchange: Drift LimitsDocument2 pagesSteel Interchange: Drift Limitsmaxeytm_839061685No ratings yet

- Practical Cost-Saving Ideas for Welding DesignDocument3 pagesPractical Cost-Saving Ideas for Welding Designmaxeytm_839061685No ratings yet

- Pile Structural CapacityDocument6 pagesPile Structural CapacitybuddhikaNo ratings yet

- Anchor Rod Edge DistanceDocument2 pagesAnchor Rod Edge DistancedongxiaoNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011 PDFDocument10 pagesConfinementreinforcement RCcolumns ICJAug2011 PDFSamuel megersaNo ratings yet

- Hollow Core Building BrochureDocument18 pagesHollow Core Building BrochureWahyu Wawan Tulit SetiawanNo ratings yet

- EgegDocument25 pagesEgegNguyễn Sơn LâmNo ratings yet

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Document2 pagesSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNo ratings yet

- 2012 10 Application of Axial Loads in Connection DesignsDocument7 pages2012 10 Application of Axial Loads in Connection DesignsDak KaizNo ratings yet

- Drill String and Casing Design For Horizontal and ExtendedDocument4 pagesDrill String and Casing Design For Horizontal and ExtendedYuga Agung PratamaNo ratings yet

- Design Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Document21 pagesDesign Example 4 Reinforced Concrete Parking Garage: 2012 IBC SEAOC Structural/Seismic Design Manual, Vol. 3Mofasa ENo ratings yet

- Mdot RFP Res Req2566 Or19-002 Qa2 636553 7Document12 pagesMdot RFP Res Req2566 Or19-002 Qa2 636553 7Tony ParkNo ratings yet

- CN Chap 04 - Design of Rectangular Beams and One-Way SlabsDocument38 pagesCN Chap 04 - Design of Rectangular Beams and One-Way Slabshussain ghaziNo ratings yet

- 2.3. Purlin System Specific Design PDFDocument6 pages2.3. Purlin System Specific Design PDFMuhammad FirdausNo ratings yet

- Confinementreinforcement RCcolumns ICJAug2011Document10 pagesConfinementreinforcement RCcolumns ICJAug2011joshuaNo ratings yet

- American Headway Starter WBDocument3 pagesAmerican Headway Starter WBJuan HernanNo ratings yet

- Acceptability of Seismic Stoppers StressesDocument2 pagesAcceptability of Seismic Stoppers StressesJuan HernanNo ratings yet

- 2Document5 pages2kannanNo ratings yet

- 2010 CJ-Series Standard SpecifictionDocument30 pages2010 CJ-Series Standard SpecifictionVrangalov PeroNo ratings yet

- Structures Congress 2006 PresentationDocument100 pagesStructures Congress 2006 PresentationJuan HernanNo ratings yet

- VULCRAFT DeckDocument116 pagesVULCRAFT DeckJuan HernanNo ratings yet

- Essential RequirementsDocument259 pagesEssential RequirementsJuan Hernan100% (1)

- Sps ExampleDocument3 pagesSps Exampleeuthan100% (1)

- Grout - Estogrout UW - Data Sheet - 120404Document2 pagesGrout - Estogrout UW - Data Sheet - 120404Dana IrmawanNo ratings yet

- Stramit Monoclad: Product Technical ManualDocument8 pagesStramit Monoclad: Product Technical Manualchillerz69No ratings yet

- Failure Analysis Design Handout TopicsDocument2 pagesFailure Analysis Design Handout TopicsYash SaksenaNo ratings yet

- e-LAB Mechanics of Materials (BFC 21201) Semester II 2020/2021 - Lab BriefingDocument28 pagese-LAB Mechanics of Materials (BFC 21201) Semester II 2020/2021 - Lab Briefingmuhammad aminuddin bin khalidNo ratings yet

- Tulasi Sitaula - ThemeDocument7 pagesTulasi Sitaula - ThemeRam Chandra Optional Kaphle100% (2)

- Isolation Facility Model 3Document1 pageIsolation Facility Model 3Romel TorresNo ratings yet

- Cost Breakdown TerchaDocument251 pagesCost Breakdown TerchaMohammed GagiNo ratings yet

- Part 7Document5 pagesPart 7api-149208964No ratings yet

- Excessive Retardation in Concrete: P.Senthamil SelvanDocument4 pagesExcessive Retardation in Concrete: P.Senthamil SelvanSelvanNo ratings yet

- HvacDocument331 pagesHvacBojan Suresh Kumar100% (1)

- Jepretan Layar 2023-05-25 Pada 14.42.40Document50 pagesJepretan Layar 2023-05-25 Pada 14.42.40Triwijayanto DesprasetyaNo ratings yet

- KAT-A 5023 Klamflex VARIplus-RFA Flangeadaptor Edition01 28-05-2014 EN AIeditDocument3 pagesKAT-A 5023 Klamflex VARIplus-RFA Flangeadaptor Edition01 28-05-2014 EN AIeditSonny LuuNo ratings yet

- CatalougeDocument15 pagesCatalougeBarbara OrtigozaNo ratings yet

- Cost EstimateDocument1 pageCost EstimateCire OmalinNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Upgrading Infrastructure of SIDCO Industrial Estate in MetturDocument26 pagesUpgrading Infrastructure of SIDCO Industrial Estate in Mettursk.md.easin.AliNo ratings yet

- Europa Valve Non Slam Check ValvesDocument16 pagesEuropa Valve Non Slam Check ValvesBryan KellyNo ratings yet

- UntitledDocument42 pagesUntitledShafkat SaminNo ratings yet

- Bolt Length Calculation: IS 6392-Table 11Document3 pagesBolt Length Calculation: IS 6392-Table 11sumit_b123No ratings yet

- Ind PamDocument47 pagesInd PamAbhishek PandaNo ratings yet

- Design considerations for pipe support spacingDocument1 pageDesign considerations for pipe support spacingdas_joydebNo ratings yet

- Ranchi Building Bye LawsDocument76 pagesRanchi Building Bye Lawsbiswashree10No ratings yet

- Case Study Sc14 en v01 Steel University ChallengeDocument5 pagesCase Study Sc14 en v01 Steel University ChallengeJatin BangaliNo ratings yet