Professional Documents

Culture Documents

FAT Procedure & Checklist

FAT Procedure & Checklist

Uploaded by

ARSHI ASLAMCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FAT Procedure & Checklist

FAT Procedure & Checklist

Uploaded by

ARSHI ASLAMCopyright:

Available Formats

PETROKEMYA Arabian Electro-Velocity

Industrial

Petrochemical Co.

Contracting Co.

Nordson BKG Document Number EVICCO-PK-FAT-P-00

Revision Number 0

Münster Revision Date

Project Title:Screen Changer Replacement in Line B (GPPS) Project No: 4300328934

FAT Procedure

OBJECTIVE:

Factory acceptance test (FAT) for screen changer will be done at the equipment manufacturing

site of the Nordson in Germany before shipping. A proper FAT can help to minimize the

problems occur during installation of the equipment at site.

PURPOSE:

To evaluate the SREEEN CHANGER after the assembly process by verifying that it is built and

operating in accordance with design specification. FAT ensure that the components and controls

are working properly according to the functionality of equipment itself.

PREPARATION:

Before FAT begins, EVICCO will align with OEM and present the FAT procedure to PK for

review and approval. As per the approved procedure & checklist FAT will be conducted.

PROCEDURE:

This procedure includes a clear explanation on what we are going to do (verification list), the

acceptance criteria, punch list and required signature upon FAT completion and acceptance.

For the FAT there will be a live stream session in Nordon facility which will be limited to

maximum 15 minutes.

During the FAT, Nordson representative will present/check the most important data’s together

with Petrokemya like:

Dimension Checking (Extrusion height)

Equipment marking or tagging

Surface preparation and painting

Color

Safety devices installed

Control panel and instrument checking

Operation test as applicable

Painting of the machine

OEM recommendation:

For the electrical points, we would recommend to open the control cabinet so that we can

have visual inspection of the inner part’s.

And we make a functional test of the SPS control unit due to a test run of the automatic

modus.

We will check screen size.

It also include placing the screen meshes and removing to understand the fitmet.

FAT Procedure Page 1

PETROKEMYA Arabian Electro-Velocity

Industrial

Petrochemical Co.

Contracting Co.

Nordson BKG Document Number EVICCO-PK-FAT-P-00

Revision Number 0

Münster Revision Date

Project Title:Screen Changer Replacement in Line B (GPPS) Project No: 4300328934

FAT Procedure

MACHINE DETAIL:

Below is the detail of machine upon which FAT will be conducted.

Machine: Screen Changer

Make: Nordson

Type: K-SWE-300

Serial No: 20-234557/0010

Year of Construction: 2020

DOCUMENTS:

FAT Checklist no: FAT-EVICCO-PK-CL-00 (With FAT procedure document)

OEM internal electrical & Mechanical certification (Submitted to PK)

Provisional Documents (With machine)

Approved Drawing

CONCLUSION:

FAT is typically conducted in order to assess any discrepancies and non-conformities, as well as

develop a process for how they are to be handled. Deviation or abnormalities observed during

testing will be recorded in a punch list and corrected prior to shipment.

FAT Procedure Page 2

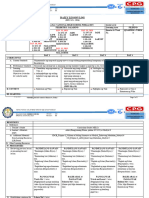

PETROKEMYA Arabian Electro-Velocity Industrial

Petrochemical Co. Contracting Co.

Nordson BKG

Münster Document Number EVICCO-PK-FAT-CL-00

Project Title : Screen Changer Replacement in Line B

Project No : 4300328934

(GPPS)

FAT Check List

Location: Munster Germany Method: Live Streaming

Date: ------------------------------- Time: 15 Minutes

ACCEPTANCE CRITERIA

TEST REMARKS

Item Parameters

Model : Machine

A) Equipment Marking & Type: BKG® NorCon ™ Melt Filter - K-SWE-30

Tagging Machine / Job No.: 20-234557/0010

Year of construction: 2020

Extrusion height 1880 ±25 mm

Inlet adaptor size 190.1 ⁺⁰∙⁰⁵, 271 ±0.3, 393.7 ⁺⁰∙²

Outlet adapter size 190.1 ⁺⁰∙⁰⁵, 250 ᴴ⁷, 480 ⁺⁰∙²

Width 580 mm

B) Dimensions Checking

Overall Dimension 3579.75 x 1264 mm

Weight 5974.90 kg

Screen Size Measurement

Screen meshes fitment Placing & Removing

Housing + adaptor Heat resistance black / silver

Screen Changer 9006 RAL

E-motor / drive 9005 RAL

C) Painting

Support cart 9006 RAL / verzinkt / galvanized

Connection box 7035 RAL

Terminal boxes 7035 RAL

Warning Sign All warning signs

D) Safety Safety Devices All safety devices

Safety Guard All safety guard

Electrical Testing

Mechanical Testing

E) Operation Test

Hydraulic Testing

Control & Instrument Testing

Witness By

CONCERN: NORDSON EVICCO PK

Name:

Signature:

Date:

You might also like

- General Conditions of Passenger and Baggage CarriageDocument51 pagesGeneral Conditions of Passenger and Baggage CarriageŞəmsəddin CəfərovNo ratings yet

- Site Acceptance Test PlanDocument12 pagesSite Acceptance Test PlanUmar Adamu83% (6)

- P27-Factory Acceptance Test Report - HV SWGR - 0Document49 pagesP27-Factory Acceptance Test Report - HV SWGR - 0caigithe852456100% (4)

- Factory Acceptance Test ProtocolDocument28 pagesFactory Acceptance Test ProtocolShabbir Hussain Palitanawala100% (6)

- The FAT Test ProcedureDocument1 pageThe FAT Test Procedurenisha_khanNo ratings yet

- Punch Points For Piping EngineersDocument8 pagesPunch Points For Piping EngineersVignesh MohanNo ratings yet

- Biz Orgs Attack OutlineDocument5 pagesBiz Orgs Attack OutlineSam Hughes100% (2)

- SAT Plan & Procedure VMSDocument47 pagesSAT Plan & Procedure VMSMGHIRBI HAYKELNo ratings yet

- Contractor Management ProcedureDocument13 pagesContractor Management ProcedureARSHI ASLAMNo ratings yet

- FAT DocumentDocument4 pagesFAT DocumentKhaled Kamal100% (1)

- FAT Procedure Rev.1Document9 pagesFAT Procedure Rev.1Rahul Deva100% (1)

- Procedure For Calibration of Machines Welding PDFDocument3 pagesProcedure For Calibration of Machines Welding PDFravi00098100% (1)

- Power Cable Inspection ChecklistDocument1 pagePower Cable Inspection ChecklistjoshmalikNo ratings yet

- Mels Constuction Limitada: Commercial Management Mechanical Completion CertificateDocument1 pageMels Constuction Limitada: Commercial Management Mechanical Completion CertificateDeonNo ratings yet

- Contractor Quality Control Plan For Electrical Equipment InstallationDocument7 pagesContractor Quality Control Plan For Electrical Equipment Installationhasan_6764896160% (1)

- E202 - Instr Inspection Test Plan Template Rev 00 11.11Document10 pagesE202 - Instr Inspection Test Plan Template Rev 00 11.11Arbaaz Khan100% (1)

- Master Document MRB Index Rev SDocument10 pagesMaster Document MRB Index Rev SSalmanNo ratings yet

- E&I Quality PlanDocument9 pagesE&I Quality PlanJithuRajNo ratings yet

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentesutjiadiNo ratings yet

- Kirloskar Dry Type Transformer MQPDocument6 pagesKirloskar Dry Type Transformer MQPNaresh RajuNo ratings yet

- On Comparative Analysis of Financial Statement of Pepsi Co & Coca Cola.Document7 pagesOn Comparative Analysis of Financial Statement of Pepsi Co & Coca Cola.Saikat BhattacharjeeNo ratings yet

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For ElectricalkhoerulNo ratings yet

- Factory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic GuideDocument13 pagesFactory Acceptance Test (FAT) of A PLC Panel - A Step-by-Step Basic Guidenzar HasanNo ratings yet

- Checklist For On-Off ValvesDocument5 pagesChecklist For On-Off Valvesmilton1987No ratings yet

- Section 25 50 52 - INSTRUMENT CALIBRATION AND COMMISSIONINGDocument13 pagesSection 25 50 52 - INSTRUMENT CALIBRATION AND COMMISSIONINGAhmad DagamsehNo ratings yet

- Inward Material Inspection Report: Project Name: Job Code: LocationDocument2 pagesInward Material Inspection Report: Project Name: Job Code: LocationTarun GodiyalNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Fat ProcedureDocument16 pagesFat ProcedureAngeloluigi MerelliNo ratings yet

- ITPDocument7 pagesITPmetroroadNo ratings yet

- I&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Document16 pagesI&C Inspection and Test Plan - NWC Dhurma Pump Station, Pp11, Pp12, Pp13Mohd Sami UddinNo ratings yet

- ITP's and ITR's A Necessary - Monster - PDFDocument5 pagesITP's and ITR's A Necessary - Monster - PDFshastri85No ratings yet

- 12 Fat SatDocument18 pages12 Fat SatSteve JobsNo ratings yet

- 34-SAMSS-913 Instrumentation and Thermocouple CableDocument21 pages34-SAMSS-913 Instrumentation and Thermocouple CablenavaronefraNo ratings yet

- Testing CertificationDocument2 pagesTesting Certificationmanox007No ratings yet

- Factory Acceptance Test PDFDocument2 pagesFactory Acceptance Test PDFStephanie0% (3)

- E2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13Document27 pagesE2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13rosy_vereniceNo ratings yet

- SATR-J-6601 Rev 0 PDFDocument4 pagesSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Document13 pagesQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNo ratings yet

- LOG-563-03 Receiving Inspection Checklist Rev.1Document1 pageLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniNo ratings yet

- Factory Acceptance Test FAT ProtocolDocument1 pageFactory Acceptance Test FAT ProtocolBalakrishnan S NadarNo ratings yet

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- Inspection Report For Installation of JB, Juncation BoxDocument1 pageInspection Report For Installation of JB, Juncation BoxnayumNo ratings yet

- 6 Fire Protection SystemDocument1,320 pages6 Fire Protection SystemedmondevangelistacorpuzNo ratings yet

- Mechanical Completion Check Sheet Electrical: Lighting & Power CircuitDocument2 pagesMechanical Completion Check Sheet Electrical: Lighting & Power CircuitYadira Centanaro GutierrezNo ratings yet

- Pressure Switch Calibration FormDocument1 pagePressure Switch Calibration FormAli AkbarNo ratings yet

- I-007 DP Transmitter Calibration CheckDocument1 pageI-007 DP Transmitter Calibration CheckAr RahmanNo ratings yet

- q22 001 Fat Procedure Mt1 SK 4910 B ADocument18 pagesq22 001 Fat Procedure Mt1 SK 4910 B APham Thai Tuyen100% (1)

- UFGS 01 33 00 Submittal ProceduresDocument36 pagesUFGS 01 33 00 Submittal Proceduresrhunter2010No ratings yet

- ELSTERDocument4 pagesELSTERManuel GerardoNo ratings yet

- This Checklist Is To Be Used For The Commissioning of Plant or EquipmentDocument2 pagesThis Checklist Is To Be Used For The Commissioning of Plant or EquipmentAnonymous v6ybIxZFNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch Checklistgeorge stanley paceteNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- 020101N OMNI Serial Ethernet Modbus Mux Module Model 68 6209 Setup and InstallationDocument35 pages020101N OMNI Serial Ethernet Modbus Mux Module Model 68 6209 Setup and Installationserie1984No ratings yet

- Design Specifications - Validation - ARAMCODocument5 pagesDesign Specifications - Validation - ARAMCOMohanNo ratings yet

- DHB Pipe Line Tester 80 80L 82Document2 pagesDHB Pipe Line Tester 80 80L 82smab2162094No ratings yet

- SATR-J-6913 Rev 0 PDFDocument6 pagesSATR-J-6913 Rev 0 PDFAdel KlkNo ratings yet

- Elect-Ttip-05 - Inspection and Test Plan For Ring Main Unit (Rmu) - R1Document1 pageElect-Ttip-05 - Inspection and Test Plan For Ring Main Unit (Rmu) - R1Muhammad IrfanNo ratings yet

- THE THIRD PART INSPECTION FOR VALVES - OdtDocument8 pagesTHE THIRD PART INSPECTION FOR VALVES - OdtVelibor StokicNo ratings yet

- Instrumentation Switch ChecklistDocument9 pagesInstrumentation Switch ChecklistIñaki EseberriNo ratings yet

- Initial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Document7 pagesInitial Product/Process Change Notification: Document #:IPCN23483XA Issue Date:01 Jul 2021Douglas AlbertNo ratings yet

- WO 2626 - PO 4504180804 - General Inspection - PGCDocument75 pagesWO 2626 - PO 4504180804 - General Inspection - PGCMatheus Fabrício TeixeiraNo ratings yet

- NGMSA TQ Fence Levels 122Document2 pagesNGMSA TQ Fence Levels 122Sehna SerajNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Program of The Contractor For Boiler ProjectDocument4 pagesProgram of The Contractor For Boiler ProjectARSHI ASLAMNo ratings yet

- First Aid - Sample ProcedureDocument5 pagesFirst Aid - Sample ProcedureARSHI ASLAMNo ratings yet

- Excavation and Trenching Safety Program Construction Material Handeling ProgramDocument9 pagesExcavation and Trenching Safety Program Construction Material Handeling ProgramARSHI ASLAMNo ratings yet

- FAT Procedure & ChecklistDocument3 pagesFAT Procedure & ChecklistARSHI ASLAM100% (3)

- PDFDocument1 pagePDFVivekPalleeri33% (3)

- The Production of Specialty RubberDocument2 pagesThe Production of Specialty RubberfebiantiNo ratings yet

- Chirag Gupta - CV - Chirag GuptaDocument1 pageChirag Gupta - CV - Chirag GuptasaternjewelsNo ratings yet

- ParCor Chapter3 Part2 BuenaventuraDocument17 pagesParCor Chapter3 Part2 BuenaventuraAnonn100% (4)

- MGT400 GroupAssignment2 Husniyah Anis Farah HudaDocument12 pagesMGT400 GroupAssignment2 Husniyah Anis Farah HudaHusniyah HalimiNo ratings yet

- Bài Thi Online Topic 6Document3 pagesBài Thi Online Topic 6linhdo242007No ratings yet

- VCBHJNDocument96 pagesVCBHJNMihiri MadushaniNo ratings yet

- Eep Msree Lec 3 WaccDocument19 pagesEep Msree Lec 3 WaccRamendra KumarNo ratings yet

- Thesis For Business Management-The Level of Effectiveness of Customer Relationship Management of Starbucks Baguio To Retain Customer LoyaltyDocument22 pagesThesis For Business Management-The Level of Effectiveness of Customer Relationship Management of Starbucks Baguio To Retain Customer LoyaltyJoana Marie Tolete100% (2)

- Rudra Singh 98 Tyco Edp Exp 6Document3 pagesRudra Singh 98 Tyco Edp Exp 6tanmay ghoraiNo ratings yet

- RBAC Round 2 Case StudyDocument18 pagesRBAC Round 2 Case StudyK60 Vũ Ngọc YếnNo ratings yet

- 21 Douglas Douglas Cano MoyesDocument15 pages21 Douglas Douglas Cano Moyesnegev2005No ratings yet

- Id-17241065 Internship ReportDocument41 pagesId-17241065 Internship ReportParvez AfnaanNo ratings yet

- 2 Google XRay LinkedIn 2020 748893069Document23 pages2 Google XRay LinkedIn 2020 748893069A GentlemenNo ratings yet

- InventoryDocument10 pagesInventoryGirlie Ann JimenezNo ratings yet

- Four Season Tart The Problem and Its BacDocument13 pagesFour Season Tart The Problem and Its BacErin Louise Arnaiz TubigNo ratings yet

- Module 1 - Intro To Lab ManagementDocument3 pagesModule 1 - Intro To Lab ManagementReah Jayzel AlkuinoNo ratings yet

- QMS-02 Issue 2 Rev 1 Procedure For Enquiry and Contract ReviewDocument16 pagesQMS-02 Issue 2 Rev 1 Procedure For Enquiry and Contract ReviewbanglvhNo ratings yet

- Capital Markets Infrastructure: An Industry Reinventing ItselfDocument40 pagesCapital Markets Infrastructure: An Industry Reinventing ItselfahmedNo ratings yet

- Tech Mahindra: Submitted To: DR M SriramDocument9 pagesTech Mahindra: Submitted To: DR M SriramAnuj SohaniNo ratings yet

- 2011 Verizon Foundation Tax Package PDFDocument302 pages2011 Verizon Foundation Tax Package PDFArlanda JacksonNo ratings yet

- DLL - Q2 - Fil8 - Week 8Document6 pagesDLL - Q2 - Fil8 - Week 8Felibeth SaladinoNo ratings yet

- Tutuna Ine FinalsDocument132 pagesTutuna Ine FinalsAnuar LoboNo ratings yet

- Case 83 - Rose Packing Co., Inc vs. Court of AppealsDocument6 pagesCase 83 - Rose Packing Co., Inc vs. Court of AppealsGlance CruzNo ratings yet

- Cir vs. Air India DigestDocument3 pagesCir vs. Air India Digestkarlonov100% (2)

- Unit 1 DiscussionDocument4 pagesUnit 1 DiscussionSimran Pannu100% (1)

- Because Cooking Souffl S Is Incredibly Difficult The Supply of Souffl SDocument2 pagesBecause Cooking Souffl S Is Incredibly Difficult The Supply of Souffl Strilocksp SinghNo ratings yet