Professional Documents

Culture Documents

Pages From SIMABUS Tubular Busbar Accesories-2

Uploaded by

asi midobarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From SIMABUS Tubular Busbar Accesories-2

Uploaded by

asi midobarCopyright:

Available Formats

28

5 TJR 82 T_ Bolted couplers

Bolted joints for tubular conductors

T

5 TJR 82 T100 CHARACTERISTICS

Bolted joint for Al Tube 100 O/D • From 60kV to 550kV

• EN & NEMA compliant

5 TJR 82 T141 • Aluminium Alloy & Stainless steel fasteners

Bolted joint for Al Tube 5’’ O/D

APPLICATIONS

• Main & reserve Busbar

• Mechanical/electrical joint of Aluminium tubular conductors

ADVANTAGES

• Economic solution

• Easy to install (no weldment at site)

• Corrosion resistant

Metric 80 90 100 120 125 140 150 160 200 220 250

Busbar Size

IPS 3" 3 "1/2 5" 6"

T (mm) 80 88.9 90 100 101.6 120 125 140 141.3 150 160 168.2 200 220 250

Design guide Span « L »

L/3 Max

Bolted couplers must be installed at busbar location

where the bending moment on the concerned span is

null or minor.

The figures in front indicate the two typical bus system

configurations depending on the boundary conditions

provided by the connection type.

The first figure illustrates a Fix/Sliding bus configura- Sliding/Fix Bus system

tion where the fix connector (or support) allows minor (Torque free at the fix end)

deflection of the tube (due to the applied forces, ie:

dead weight, wind, short-circuit...). In that case the

coupler will be installed at the closest possible location

to the fix connector without exceeding 1/3 of the span Span « L »

length.

L/3

The second figure illustrates a Fix/Sliding bus configu-

ration too but here the fix connector is such as it pos-

sibly transfers torque to the connected equipment. In

that case the coupler must be installed closest as

possible to the third length of the tube and at the fix

connector side where the bending moment in the tube

is null or almost null.

For any other specific bus system configuration,

please contact us. Our Engineers can run a calcula-

tion in order to recommend the best connections’ set

configuration. Sliding/Fix Bus system

(Anchorage at the fix end)

You might also like

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Prysmian Separable Connectors v1.03Document12 pagesPrysmian Separable Connectors v1.03Muhammad SyaifulhaqNo ratings yet

- Spec Sheet - Auto Arc 130Document4 pagesSpec Sheet - Auto Arc 130Hobart Welding ProductsNo ratings yet

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenFrom EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenRating: 4 out of 5 stars4/5 (2)

- Teknomega - Bar SupportsDocument10 pagesTeknomega - Bar SupportsSundaresan SabanayagamNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- GET7005J Busway Pub 9-12-10Document44 pagesGET7005J Busway Pub 9-12-10Man MadhanNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- 10A CutoutsDocument16 pages10A Cutoutsbuaran2023No ratings yet

- Sicat ContactDocument8 pagesSicat ContactDHARMENDRANo ratings yet

- Coren Project 2Document18 pagesCoren Project 2Nwokolo Austine Chuks100% (3)

- 10A - Cutouts AB CHANCEDocument16 pages10A - Cutouts AB CHANCELuis MartinezNo ratings yet

- Safety Competency TrainingDocument21 pagesSafety Competency TrainingsemajamesNo ratings yet

- 124 - Bench Am5k Manual Standard 11-05-06Document100 pages124 - Bench Am5k Manual Standard 11-05-06Ayman MaezaNo ratings yet

- Tension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsDocument4 pagesTension Wheel Assemblies: Sicat 8WL5070 / 8WL5078 For Overhead Contact Line SystemsVictor Manuel BonettoNo ratings yet

- Series 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointDocument7 pagesSeries 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointChristian UhreNo ratings yet

- Cooper Dual Element Bayonet Fuse LinkDocument4 pagesCooper Dual Element Bayonet Fuse LinkDominic SantiagoNo ratings yet

- LT 65650131r4.4 20220329 EX100 200 SpecDocument4 pagesLT 65650131r4.4 20220329 EX100 200 SpecArani Davila TineoNo ratings yet

- 01-Overview of TRDDocument131 pages01-Overview of TRDsugind sNo ratings yet

- Interchangeability: Power Systems, IncDocument2 pagesInterchangeability: Power Systems, IncalvaroferroNo ratings yet

- Expansion Junction 1Document1 pageExpansion Junction 1kojjasNo ratings yet

- Separable Connectors & Bushings - Interface C: DescriptionDocument3 pagesSeparable Connectors & Bushings - Interface C: DescriptionMario TNo ratings yet

- Cooper Loadbreak Elbow 500287Document8 pagesCooper Loadbreak Elbow 500287denzil_1000No ratings yet

- Raychem Screened Elbow/Straight Separable Connectors Rses/RsssDocument2 pagesRaychem Screened Elbow/Straight Separable Connectors Rses/RsssGiovany Vargas QuirozNo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsJan MaksNo ratings yet

- Installation, Testing and Jointing of LT and HT Power Cables Up To 33 KVDocument7 pagesInstallation, Testing and Jointing of LT and HT Power Cables Up To 33 KVanjum araNo ratings yet

- Industrial: Rane OntrolDocument8 pagesIndustrial: Rane OntrolRam PatelNo ratings yet

- Cleat WiringDocument8 pagesCleat WiringHaseeb NawazNo ratings yet

- Acoplamientos TSK PDFDocument4 pagesAcoplamientos TSK PDFBenicio Joaquín Ferrero BrebesNo ratings yet

- Ampact Wedge Tap CatalogDocument84 pagesAmpact Wedge Tap CatalogKarneekVyasNo ratings yet

- CSE Cables - Voltage Drop CalculationsDocument2 pagesCSE Cables - Voltage Drop Calculationsjay512100% (1)

- Catalogue Wetown Busway SeriesDocument46 pagesCatalogue Wetown Busway SeriesLuis Carpio100% (2)

- 0521 - 2009 - 381333 - 270c MANUAL ATSDocument12 pages0521 - 2009 - 381333 - 270c MANUAL ATSronychavesNo ratings yet

- Brosjyre GSSB EnglishDocument3 pagesBrosjyre GSSB Englishrol_sonNo ratings yet

- Catalogue CentralizerDocument7 pagesCatalogue CentralizerNicolas Collet-BeillonNo ratings yet

- Installation, Testing and Jointing of LT and HT Power Cables Up To 33 KVDocument7 pagesInstallation, Testing and Jointing of LT and HT Power Cables Up To 33 KValitopan9900No ratings yet

- KAT0815-0001-E Single Pole Insulated Conductor RailDocument36 pagesKAT0815-0001-E Single Pole Insulated Conductor RailirinaNo ratings yet

- Standard Weldable Patterns: Vishay Micro-MeasurementsDocument3 pagesStandard Weldable Patterns: Vishay Micro-Measurementshuicho_ponchoNo ratings yet

- LV Insulated Overhead LinesDocument59 pagesLV Insulated Overhead Linesyavuz772No ratings yet

- Elastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresDocument4 pagesElastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresVictor Manuel BonettoNo ratings yet

- ACA Clamps&ConnectorsDocument4 pagesACA Clamps&ConnectorsvenkyeeeNo ratings yet

- Electrical Wiring Industrial Canadian 5th Edition Herman Solutions ManualDocument5 pagesElectrical Wiring Industrial Canadian 5th Edition Herman Solutions ManualKimCoffeyjndf100% (39)

- 7TKK000608 - Surge Arresters - TDS - DGTDocument4 pages7TKK000608 - Surge Arresters - TDS - DGTAva AlonserNo ratings yet

- Catalog - Conductor Rail 815 SeriesDocument32 pagesCatalog - Conductor Rail 815 SeriesyongkiNo ratings yet

- Ti - in 0041 RocsDocument22 pagesTi - in 0041 RocsGopalakrishnanNo ratings yet

- Ezform Cables CatalogDocument19 pagesEzform Cables CatalogradianfmNo ratings yet

- C2 25kvDocument12 pagesC2 25kvLuis MurilloNo ratings yet

- Cable Accessories: Systems, IncDocument4 pagesCable Accessories: Systems, IncLuis MurilloNo ratings yet

- Rotax 912 Electrical SystemDocument12 pagesRotax 912 Electrical SystemMarian GrigoreNo ratings yet

- ABB Spectra GET-7005 20210811 10 DigitalDocument60 pagesABB Spectra GET-7005 20210811 10 DigitalDodongNo ratings yet

- Ameron CatalogeDocument7 pagesAmeron CatalogeRachmat MaulidiNo ratings yet

- LineTrapsAir Core, Dry TypeDocument8 pagesLineTrapsAir Core, Dry TypeSINU0607IITEEENo ratings yet

- LT 7 TractorDocument4 pagesLT 7 Tractorgringo73234No ratings yet

- Electrical Control Panel Design Project ReportDocument30 pagesElectrical Control Panel Design Project ReportRakesh YadavNo ratings yet

- Bondstrand Series 2400 Fiberglass Pipe and FittingsDocument6 pagesBondstrand Series 2400 Fiberglass Pipe and FittingsIsmailNo ratings yet

- Raychem Terminations For GIS and TransformerDocument1 pageRaychem Terminations For GIS and Transformerrasheed313No ratings yet

- C&S Bus DuctDocument4 pagesC&S Bus DuctSudalai Muthu100% (1)

- TS - TROLLEY SYSTEM 63 - 250A: Components and AccessoriesDocument20 pagesTS - TROLLEY SYSTEM 63 - 250A: Components and AccessoriesGustavo J Perez MNo ratings yet

- 14B Overhead SwitchesDocument28 pages14B Overhead SwitchesRhiannon HaynesNo ratings yet

- Payment Procedurte FIDIC 1999Document5 pagesPayment Procedurte FIDIC 1999asi midobarNo ratings yet

- Balancing Reasonable and Unreasonable Transmission Line RoutesDocument1 pageBalancing Reasonable and Unreasonable Transmission Line Routesasi midobarNo ratings yet

- Pages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 4Document1 pagePages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 4asi midobarNo ratings yet

- Fidic Letters by ContractorDocument77 pagesFidic Letters by ContractorMajid Hassen83% (54)

- Pages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 5Document1 pagePages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 5asi midobarNo ratings yet

- Structural Engineering of Transmission LinesDocument1 pageStructural Engineering of Transmission Linesasi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-333Document1 pagePages From SIMABUS Tubular Busbar Accesories-333asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-555Document1 pagePages From SIMABUS Tubular Busbar Accesories-555asi midobarNo ratings yet

- Pages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 3Document1 pagePages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 3asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-41Document1 pagePages From SIMABUS Tubular Busbar Accesories-41asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-444Document1 pagePages From SIMABUS Tubular Busbar Accesories-444asi midobarNo ratings yet

- Pages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 1Document1 pagePages From Structural Engineering of Transmission Lines by Peter Catchpole, Buck Fife 1asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-21Document1 pagePages From SIMABUS Tubular Busbar Accesories-21asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-222Document1 pagePages From SIMABUS Tubular Busbar Accesories-222asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-51Document1 pagePages From SIMABUS Tubular Busbar Accesories-51asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-31Document1 pagePages From SIMABUS Tubular Busbar Accesories-31asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories111Document1 pagePages From SIMABUS Tubular Busbar Accesories111asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-4Document1 pagePages From SIMABUS Tubular Busbar Accesories-4asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories 22Document1 pagePages From SIMABUS Tubular Busbar Accesories 22asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-5Document1 pagePages From SIMABUS Tubular Busbar Accesories-5asi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-23Document1 pagePages From SIMABUS Tubular Busbar Accesories-23asi midobarNo ratings yet

- The Electro-Mechanical Design of Rigid A PDFDocument10 pagesThe Electro-Mechanical Design of Rigid A PDFXabi AlonsoNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-3Document1 pagePages From SIMABUS Tubular Busbar Accesories-3asi midobarNo ratings yet

- Aluminium Tubular Busbars For HV SubstatDocument5 pagesAluminium Tubular Busbars For HV Substatasi midobarNo ratings yet

- Pages From SIMABUS Tubular Busbar Accesories-1Document1 pagePages From SIMABUS Tubular Busbar Accesories-1asi midobarNo ratings yet

- Alumimium Bus Bar Calculation 4000ADocument11 pagesAlumimium Bus Bar Calculation 4000Aivan(D3)No ratings yet

- Chiawa Bridge EIADocument142 pagesChiawa Bridge EIAJohn Banda100% (1)

- Astm D4024 00Document3 pagesAstm D4024 00Anghelo AlcaldeNo ratings yet

- Synthèse Partielle OutriggerDocument5 pagesSynthèse Partielle OutriggerPetouStarNo ratings yet

- AATS Technical Services ProfileDocument6 pagesAATS Technical Services Profileimzee25No ratings yet

- bs7671 Iee On Site GuideDocument184 pagesbs7671 Iee On Site Guidemigzx95% (19)

- American Wide Flange BeamsDocument4 pagesAmerican Wide Flange BeamsMang KulasNo ratings yet

- Press Brake BendingDocument12 pagesPress Brake BendingGopu PushpangadhanNo ratings yet

- FFO Unit 5 Pipe Fitting and Valves.Document20 pagesFFO Unit 5 Pipe Fitting and Valves.Dnyaneshwar SarodeNo ratings yet

- Oilwell Cement Standards - An UpdateDocument7 pagesOilwell Cement Standards - An UpdateisnainarNo ratings yet

- Postmodernism Architecture: Postmodern Architecture Is A Style or MovementDocument10 pagesPostmodernism Architecture: Postmodern Architecture Is A Style or MovementAlcris CarinoNo ratings yet

- PEACE CORPS Overseas Request For Quotation (RFQ) For Services BuildingDocument3 pagesPEACE CORPS Overseas Request For Quotation (RFQ) For Services BuildingAccessible Journal Media: Peace Corps DocumentsNo ratings yet

- Excel Project Tracker FullDocument8 pagesExcel Project Tracker FullRiyaz BasheerNo ratings yet

- Ead - 330030 00 06.01 Fastener For Wall CladdingDocument26 pagesEad - 330030 00 06.01 Fastener For Wall CladdingRaine HopeNo ratings yet

- AlSi10Mg-M270 Material Data Sheet 07-09 enDocument4 pagesAlSi10Mg-M270 Material Data Sheet 07-09 eninam758388No ratings yet

- UBBL 1984 Code ExplainedDocument102 pagesUBBL 1984 Code ExplainedFirdaus RamliNo ratings yet

- Tank Manual: Training Course For TANK Software (Based On API 650, 11 Ed., Add.1)Document100 pagesTank Manual: Training Course For TANK Software (Based On API 650, 11 Ed., Add.1)Hirad EghbalianNo ratings yet

- Effects of Processing Parameters of Infrared Based Automated F 2023 CompositDocument11 pagesEffects of Processing Parameters of Infrared Based Automated F 2023 CompositGUANCI ZHUNo ratings yet

- Jacking Force CalculationDocument7 pagesJacking Force CalculationSajjad AnwarNo ratings yet

- Welding: 5.2.1. Reinforcement and BackingDocument16 pagesWelding: 5.2.1. Reinforcement and BackingakankwasaNo ratings yet

- Construction Safety Form SubmissionDocument2 pagesConstruction Safety Form SubmissionRuel BariaNo ratings yet

- Produced by an Autodesk Student VersionDocument1 pageProduced by an Autodesk Student VersionSoumia GuptaNo ratings yet

- Viraj Catalouge-2Document21 pagesViraj Catalouge-2Vinod GuptaNo ratings yet

- Conclusion: ReferencesDocument1 pageConclusion: ReferencesKNo ratings yet

- Limit State of Collapse-TorsionDocument34 pagesLimit State of Collapse-Torsionmdaashu100% (1)

- ACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Document14 pagesACI 3 - 08 Rec Sec. MX - Q-Torsion Design Rev06 02-May-2013Andy SunjayaNo ratings yet

- Problem 9 - Column Interaction DiagramDocument9 pagesProblem 9 - Column Interaction DiagramRey Joseph IglesiaNo ratings yet

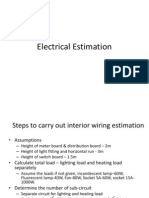

- Electrical Estimation StepsDocument9 pagesElectrical Estimation Stepssonapyacha0% (1)

- Nichias Gasket Tombo1995Document3 pagesNichias Gasket Tombo1995Richard SmithNo ratings yet

- UndrainedShearStrength PDFDocument6 pagesUndrainedShearStrength PDFarslanpasaNo ratings yet

- Karaikudi Our TNPSC CESE AE Civil Result in 2019 Exam 436 + Selections Out of 573 PostsDocument12 pagesKaraikudi Our TNPSC CESE AE Civil Result in 2019 Exam 436 + Selections Out of 573 PostsGokul ParthibanNo ratings yet