Professional Documents

Culture Documents

Refrigeration Lab Report: Ali Rida Bachir SID 8104461

Uploaded by

NARE EDMUNDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refrigeration Lab Report: Ali Rida Bachir SID 8104461

Uploaded by

NARE EDMUNDCopyright:

Available Formats

Refrigeration Lab Report

Ali Rida Bachir

SID 8104461

Abstract:

In this experiment, a refrigeration unit (R634) was studied. The unit was allowed to operate

normally while different parameters were measured such as temperatures, pressures and flow

rates. The results were tabulated and used to construct the thermodynamic cycle on the P-h

chart. As well as asses its performance by measuring the isentropic efficiency which was 59.9%

and the COPR (coefficient of performance) = 1.949 .

Introduction:

Refrigeration is the process of transferring energy from a low energy domain to a high energy

domain. According to the second law of thermodynamics, heat cannot be transferred from a cold

location to a hotter one unless work is introduced to the process. The devices that apply this

process are called refrigerators. Refrigerators are cyclic devices that operate on the vapour –

compression cycle (reverse cycle of heat engines) involving four processes; Evaporation,

Compression, Condensation and Expansion. For that it requires four components; Compressor

(to raise temperature and pressure), Condenser (exchange heat with surrounding), Expansion

valve/Throttle (to lower pressure and temperature), Evaporator (absorbs heat from

refrigerated area) shown in Figure 1. The purpose of a refrigerator is to maintain the

refrigerated space at low temperature by removing heat from it. The working fluid in

refrigerators is called the refrigerant it absorbs heat isothermally from a low temperature

source in the amount of ‘QL’ (from refrigerated area at evaporator) then rejects heat

isothermally to a high temperature sink in the amount of ‘QH’ (to the surrounding at condenser).

The objective of this report is to identify and analyse the processes in each component, record

data such as pressure and temperature at different locations as well as studying the

refrigerant’s phases (thermodynamic states) (Figure 2) to construct the refrigeration cycle on a

real pressure enthalpy chart provided by SOLVAY. The chart is for refrigerant Solkane® SES36.

Solkane® refrigerants are superior as they are nontoxic, ozone friendly, completely recyclable

and easy to handle.

Apparatus used:

The apparatus used for this experiment was a refrigeration

cycle demonstration unit R634. It consists of a bench

mounted vapour compression refrigeration cycle

demonstration unit using a hermetic compressor and water

cooled flooded glass condenser and evaporator. A float-

controlled expansion device controls the flow of refrigerant

(Solkane SES36). Internal electrical and mechanical safety

devices allow for unsupervised operation by students.

Instruments that allow the measure of pressures

temperature as well as flow rates are fitted in the machine.

(© 2011, P.A. Hilton Ltd).

F IGURE 1 DEMONSTRATION UNIT R634

(2011, P.A. H ILTON L TD ).

Experimental procedure:

1. Firstly, the cooling water and mains supply to the unit are

turned on.

2. Make sure the valves are in normal operation. This

ensures that the vapour is drawn by the compressor and

the condensed liquid goes to the evaporator.

3. Set the condenser cooling water flow rate to 6 g/s.

4. Set the evaporator water flow rate to 10 g/s.

5. Turn on the main switch. The compressor will start

working. If the unit is working normally, we should see

two internal lamps light up.

6. Set the refrigerant flow rate to 1 g/s. F IGURE 2 VALVES POSITIONS FOR NORMAL OPERATION.

7. Let the unit to run for 15 to 20 minutes to allow

everything to stabilize. (time taken to stabilize may depend on surrounding conditions)

8. Record all parameters in data sheet.

Results:

The results obtained from recordings and calculations are tabulated below respectively:

T ABLE 1 THESE VALUES ARE VALID AT ROOM TEMPERATURE OF 21O C WHILE P ATM WAS TAKEN AS 100 K N/M 2

QUANTITY MEASURED RECORDED VALUE UNIT

Evaporator gauge/absolute pressure Pe -68/32 kN/m2

Evaporator inlet/outlet water temp. 15.6/13.2 oC

Evaporator refrigerant temp. 3.5 oC

Evaporator water flow rate 10 g/s

Condenser gauge/absolute pressure Pc 53/153 kN/m2

Condenser inlet/outlet water temp. 16/21.9 oC

Condenser refrigerant temp. 33.5 oC

Condenser water flow rate 6 g/s

Compressor discharge temp. 69.6 oC

Compressor power input 170 Watts

Refrigerant mass flow rate 1 g/s

Expansion valve inlet temp. 26.1 oC

T ABLE 2 TEMPERATURES WERE CONVERTED TO SI UNIT KELVIN - (C P = 4.18 K J/KG.K )

FORMULAE/QUANTITY VALUE UNIT

Q’c (Qh) = m’c . CP . (t1-t2) 0.148 KJ/s

Q’e (QL)= m’e . CP . (t3-t4) 0.1 KJ/s

𝜻 (pressure ratio abs.) = PC/Pe 0.0478 -

COPR = (h1-h4)/(h2-h1) 1.949 -

Isentropic efficiency 0.559(55.9%) -

Power output =m’ref . (h2-h1) 59 J/s

Pmech (Given) 170 J/s

Discussion:

Points 1 ⟶2, the compression process takes place.

The refrigerant enters the compressor as a low

temperature and pressure vapour saturated SATURATED

(ideally) or super-heated and is discharged as a

high temperature and pressure super-heated

vapour. The change in internal energy is 𝛥h1,2=Win,

compression process is assumed to be adiabatic.

Win

Points 2⟶3, condensation process takes place. The

high temperature and pressure vapour passes

through the condenser where it rejects heat to the

surrounding environment and condenses into a

saturated liquid (ideally) at constant pressure and

temperature. In reality, the refrigerant is allowed

to condense beyond the saturated liquid state into

F IGURE 3 MAIN COMPONENTS SHOWN WITH FLOW AND STATE

the sub-cooled liquid state. That is to ensure

OF REFRIGERANT ( IDEALLY )

complete phase transformation. The change in

internal energy 𝛥h2,3 is equal to the heat rejected Qc . Critical point

Points 3⟶4, the expansion process takes place. The

high-pressure liquid goes through the expansion

valve that causes a significant drop in the T1

temperature and pressure of the refrigerant. The 3 2

process is assumed to be adiabatic since its rapid and T2

no work is done. Change in internal energy 𝛥h=0 .

Points 4⟶1, when the pressure of the liquid is

lowered it starts evaporating. The energy that 4 1

evaporates the refrigerant comes from cooling

everything down (e.g. pipes). As it passes through

the evaporator (refrigerated area/region), the

refrigerant is a mix of liquid and vapour, the energy

it absorbs is in the amount of Qe continues to evaporate F IGURE 4 IDEAL PRESSURE VS . ENTHALPY EXAMPLE CHART

the refrigerant until it is in the saturated vapour state SHOWING PHASES OF THE FLUID

(ideally), in reality, it is allowed to evaporate until a super-heated vapour is obtained. That is to

ensure 100% conversion to vapour before it enters the compressor since liquids are

incompressible (assumed to be as they require a lot of pressure to accomplish a little

compression).

Pmech (given) was measured using the electrical supply to the compressor.

Pmech > Poutput is an expected inaccuracy as the energy provided to the compressor is not fully

used into compressing the refrigerant vapour. Most of the energy is lost due to a lot of factors

mainly:

- The quality of the refrigerant vapour.

- Thermal losses through conduction and convection.

- Vibrations (sound).

- Some of the Kinetic energy of the compressor is transformed into heat.

- Hysteresis loses due to heat exchange between cylinder and refrigerant vapour.

On the other hand, other major errors affected the results of the experimental data including:

- Readings of the P-h chart were inaccurate as the copy provided was a photograph.

- External influences such as vibrations and room temperature which was assumed.

- Inaccurate reading of values by the machine

- Pressure losses due to imperfect seals.

- Thermal losses throughout the system.

h1 h2’

h3,4 h3’4’ h2

F IGURE 4 SHOWING THE PLOTTED CYCLE ON THE REAL P- H CHART

Conclusion:

In conclusion, as for the efficiency of the compressor, 44.1% of the power input is lost due to

natural occurrences and poor insulation. Moreover, refrigerant Solkane SES36 is not suitable for

an ideal cycle.

References:

Gkanas, E. 2018, thermodynamics [online lecture] module 207MAE. Coventry University

available from <https://cumoodle.coventry.ac.uk/course/view.php?id=53600>

[september23 June 2018].

Cengel & Boles, Y. M. 1989, thermodynamics: an engineering approach, 5th edition,

McGraw-Hill, London.

James M. Watterson. 2018, a simple guide to understanding compressors, 222 East 46th

Street, New York, NY 10017.

You might also like

- Lab Heat PumpDocument9 pagesLab Heat PumpShahran IezzatNo ratings yet

- Lab 5 Refrigeration-1Document9 pagesLab 5 Refrigeration-1Ahmed MaqsoodNo ratings yet

- R & AC Lab ManualDocument30 pagesR & AC Lab ManualShashankNo ratings yet

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 pagesBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNo ratings yet

- Chemical Engg Thermodynamics Lab List of ExperimentsDocument32 pagesChemical Engg Thermodynamics Lab List of ExperimentsGee DevilleNo ratings yet

- Study performance water chillerDocument12 pagesStudy performance water chillerபிரேம் ஆனந்த்No ratings yet

- Vapour Compression Refrigeration PDFDocument5 pagesVapour Compression Refrigeration PDFjose100% (1)

- Lesson 8 - Refrigeration CycleDocument17 pagesLesson 8 - Refrigeration CycleCameronNo ratings yet

- Vapor Compression Refrigeration Test Rig Lab Manual LatestDocument12 pagesVapor Compression Refrigeration Test Rig Lab Manual LatestAshish VermaNo ratings yet

- Refrigration and Air Conditioning MDTDocument10 pagesRefrigration and Air Conditioning MDTSudhir KoliNo ratings yet

- User Manual SPP MUETDocument18 pagesUser Manual SPP MUETAlyan YousafNo ratings yet

- Refrigeration - Test - Rig Lab ManualDocument6 pagesRefrigeration - Test - Rig Lab ManualSandeep SainiNo ratings yet

- Vapour Compression Cycle Performance as Refrigerator & Heat PumpDocument7 pagesVapour Compression Cycle Performance as Refrigerator & Heat Pumptatoo1No ratings yet

- Lab Refrigeration N Cooling TowerDocument21 pagesLab Refrigeration N Cooling TowerShahran IezzatNo ratings yet

- Lab 3Document28 pagesLab 3Afiqah FaiqahNo ratings yet

- Vapor compression refrigeration COP testDocument12 pagesVapor compression refrigeration COP testAshish Verma50% (2)

- Experiment No. 1Document4 pagesExperiment No. 1subhamgupta7495100% (1)

- Experiment of Refrigeration and Air ConditioningDocument30 pagesExperiment of Refrigeration and Air ConditioningNitin KumarNo ratings yet

- Exp 1 Refrigeration CycleDocument23 pagesExp 1 Refrigeration CycleAnonymous T7vjZG4otNo ratings yet

- Lab Report 560751c42519eDocument16 pagesLab Report 560751c42519eNadiaNo ratings yet

- HVAC Cooling WaterDocument54 pagesHVAC Cooling WaterShiyamraj Thamodharan100% (1)

- T2. Air Conditioning StudyDocument8 pagesT2. Air Conditioning StudyHaha WoNgNo ratings yet

- Study Refrigeration Cycle PerformanceDocument10 pagesStudy Refrigeration Cycle PerformanceMeor Fitri SE100% (1)

- Thermodynamics Lab ManualDocument9 pagesThermodynamics Lab ManualEr Shankar Singh Dhami100% (2)

- Heat Pump and RefrigertorDocument10 pagesHeat Pump and RefrigertordohlalaNo ratings yet

- Refrigeration UnitDocument6 pagesRefrigeration UnitNur Amira JasminNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsSiddhant Vishal ChandNo ratings yet

- RefrigerationDocument6 pagesRefrigerationriniz92No ratings yet

- Refrigerator Test R1Document9 pagesRefrigerator Test R1GHyukendo Shaddiq AkhbarNo ratings yet

- Refrigeration and Air Conditioning: Lecture # 3Document38 pagesRefrigeration and Air Conditioning: Lecture # 3Owais AzharNo ratings yet

- Lecture 6 RefrigerationDocument65 pagesLecture 6 RefrigerationRamon Gerald AsiloNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant (Lecture)Document56 pagesPerformance and Efficiency Test of A Refrigeration Plant (Lecture)Anonymous xjV1llZS75% (4)

- (CARNOT CYCLE) Lab Report On Cooling and Heating Effects in An Air Conditioning SystemDocument12 pages(CARNOT CYCLE) Lab Report On Cooling and Heating Effects in An Air Conditioning SystemUmer Qureshi0% (1)

- Performance and Efficiency Test of Refrigeration PlantDocument52 pagesPerformance and Efficiency Test of Refrigeration PlantIvy Joy UbinaNo ratings yet

- Air Conditioning Lab Final1Document20 pagesAir Conditioning Lab Final1haziqNo ratings yet

- Window - Air - Conditioning - Test - Rig Lab ManualDocument6 pagesWindow - Air - Conditioning - Test - Rig Lab ManualSandeep SainiNo ratings yet

- MEHB321 Lab Manual Heat Transfer ThermoDocument24 pagesMEHB321 Lab Manual Heat Transfer ThermoDinesh RaviNo ratings yet

- Duyuru2018 Refrigeration CycleDocument4 pagesDuyuru2018 Refrigeration CycleGaurav KeshriNo ratings yet

- Air Cycle Refrigeration SystemDocument30 pagesAir Cycle Refrigeration SystemtsegayNo ratings yet

- AWP LabDocument11 pagesAWP LabAmirul HusniNo ratings yet

- MM321 Lab 1 Report 2020Document5 pagesMM321 Lab 1 Report 2020JnrNo ratings yet

- Refregent and CryogenicsDocument7 pagesRefregent and CryogenicsViren ParwaniNo ratings yet

- Variation In Refrigeration Coefficient Of PerformanceDocument17 pagesVariation In Refrigeration Coefficient Of PerformanceSyahirzabidiNo ratings yet

- Heat Pump Lab ExperimentDocument19 pagesHeat Pump Lab Experimentakmal100% (2)

- Refrigeration CycleDocument8 pagesRefrigeration CycleMohamed HassanainNo ratings yet

- Types of Refrigeration SystemsDocument16 pagesTypes of Refrigeration SystemsmeriiNo ratings yet

- Experiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsDocument8 pagesExperiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsMuhammad Al-baihaqiNo ratings yet

- Experiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsDocument8 pagesExperiment 4 Heat Pump: 1 CLB20703 Chemical Engineering ThermodynamicsHafizie HashimNo ratings yet

- 803 Rac (Me-803) Exp. ManualDocument47 pages803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToNo ratings yet

- Compound Vapor Refrigeration System ExamplesDocument65 pagesCompound Vapor Refrigeration System Examplesm_alodat6144100% (1)

- Cet-1 Question Bank2 For StudentsDocument20 pagesCet-1 Question Bank2 For StudentsSruthi ChallapalliNo ratings yet

- Table of Content Heat Pump ExperimentDocument16 pagesTable of Content Heat Pump ExperimentDaniel Razak0% (1)

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- Refrigeration Cycle Efficiency and ComponentsDocument8 pagesRefrigeration Cycle Efficiency and ComponentsJames TheeNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Applied Thermodynamics Second Semester 2020Document24 pagesApplied Thermodynamics Second Semester 2020NARE EDMUNDNo ratings yet

- Lecture 3.1.2 - Organic Chemical Processes - Characterization of PolymersDocument13 pagesLecture 3.1.2 - Organic Chemical Processes - Characterization of PolymersNARE EDMUNDNo ratings yet

- Phase Equilibria 1: Problem Formulation (Chapter 6) : Live Your Life. Create Your DestinyDocument32 pagesPhase Equilibria 1: Problem Formulation (Chapter 6) : Live Your Life. Create Your DestinyNARE EDMUNDNo ratings yet

- Cmp33bt Manual 2015Document16 pagesCmp33bt Manual 2015NARE EDMUNDNo ratings yet

- Thermodynamics - Applied III (TDA301T)Document10 pagesThermodynamics - Applied III (TDA301T)NARE EDMUNDNo ratings yet

- Lesson 3 2020 Size Reduction - CommunitionDocument47 pagesLesson 3 2020 Size Reduction - CommunitionNARE EDMUNDNo ratings yet

- Chemical Process Variables-1Document48 pagesChemical Process Variables-1NARE EDMUNDNo ratings yet

- Live Your Life. Create Your Destiny.: Department of Chemical, Metallurgical & Materials EngineeringDocument42 pagesLive Your Life. Create Your Destiny.: Department of Chemical, Metallurgical & Materials EngineeringNARE EDMUNDNo ratings yet

- Thermodynamics - Applied III (TDA301T)Document10 pagesThermodynamics - Applied III (TDA301T)NARE EDMUNDNo ratings yet

- The Most Vital Text BookDocument35 pagesThe Most Vital Text BookNARE EDMUNDNo ratings yet

- Chap 2Document54 pagesChap 2kamlesh1714No ratings yet

- Ntirho KayaDocument9 pagesNtirho KayaNARE EDMUNDNo ratings yet

- Instrumentation Job Interview Preparation GuideDocument11 pagesInstrumentation Job Interview Preparation GuideJignesh Banava100% (1)

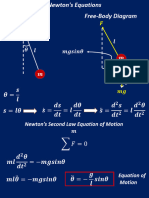

- Simple Pendulum Modelling Simulation 1686477167Document12 pagesSimple Pendulum Modelling Simulation 1686477167durssiNo ratings yet

- Glass Parapet Fixing Design SheetDocument2 pagesGlass Parapet Fixing Design SheetjudeNo ratings yet

- Comparison of ASME B31.1 and B31.3 piping codesDocument4 pagesComparison of ASME B31.1 and B31.3 piping codesPranpath Narupantawart100% (1)

- Catalogo de Partes Xpulse 200 FiDocument100 pagesCatalogo de Partes Xpulse 200 FiRafael Angel Berdugo MuñozNo ratings yet

- WK 12CDocument4 pagesWK 12COmar SanchezNo ratings yet

- VW Evrovan MaintenanceDocument142 pagesVW Evrovan MaintenanceNick P100% (1)

- 11.lube Oil SystemDocument22 pages11.lube Oil Systempepenapao1217100% (1)

- Design and Analysis of High Pressure Door With Stiffened PlateDocument12 pagesDesign and Analysis of High Pressure Door With Stiffened PlateSyed Faiz Quadri100% (1)

- PME 111 - OBE Curriculum - Reservoir Rock and Fluid PropertiesDocument3 pagesPME 111 - OBE Curriculum - Reservoir Rock and Fluid PropertiesMd. Mizanur RahmanNo ratings yet

- Time Domain Flutter Analysis of AGARD 445.6 WingDocument11 pagesTime Domain Flutter Analysis of AGARD 445.6 WingVarghese MathewNo ratings yet

- Free Fall NotesDocument2 pagesFree Fall NotesTrah NurNo ratings yet

- Chapter 5 ActuatorsDocument41 pagesChapter 5 Actuatorszul hilmiNo ratings yet

- C36 Combi Full ManualDocument52 pagesC36 Combi Full ManualEricHeatNo ratings yet

- R RA AD Diia AT TO OR RS SDocument4 pagesR RA AD Diia AT TO OR RS Slovac1No ratings yet

- Wellhead Adapter ListDocument6 pagesWellhead Adapter ListtaufikNo ratings yet

- Afterburners Systems of Turbine EnginesDocument5 pagesAfterburners Systems of Turbine EnginesAzmah EskandriNo ratings yet

- Pedal Powered Hacksaw 2Document7 pagesPedal Powered Hacksaw 2Jefry RithikNo ratings yet

- Free Standing 7.5Document35 pagesFree Standing 7.5Arif WidyatmokoNo ratings yet

- TXT PRO RACING 2011 Trial Bike ManualDocument56 pagesTXT PRO RACING 2011 Trial Bike Manualaustin holmesNo ratings yet

- Unit 4& 5Document9 pagesUnit 4& 5hariharanbook0% (1)

- Basic Concepts in Relativity and Early Quantum Theory - Resnick & HallidayDocument353 pagesBasic Concepts in Relativity and Early Quantum Theory - Resnick & HallidayFernando Espinosa100% (1)

- Heavy duty fire sand bucket specificationsDocument2 pagesHeavy duty fire sand bucket specificationsAntonio Pedro Varela TavaresNo ratings yet

- 03 066 01 0 02 PDFDocument89 pages03 066 01 0 02 PDFJan AhmedNo ratings yet

- Mihir Industrial TrainingDocument27 pagesMihir Industrial Trainingcewaja2731No ratings yet

- Rack and Pinion Steering DesigningDocument19 pagesRack and Pinion Steering DesigningAudrian Louven Realubit Sabado0% (2)

- Technical Service Information: Automatic Transmission Service GroupDocument4 pagesTechnical Service Information: Automatic Transmission Service GroupByung C KimNo ratings yet

- Mastering Physics - Change of Phase (Temperature), Sound LabDocument10 pagesMastering Physics - Change of Phase (Temperature), Sound LabpalparasNo ratings yet

- Structural Calculation 3 Storey Residential House Part 1Document10 pagesStructural Calculation 3 Storey Residential House Part 1Joefer Cuetara100% (1)

- Ref 87 - TCVN 6767 - 3Document28 pagesRef 87 - TCVN 6767 - 3Nguyễn NgọcNo ratings yet