Professional Documents

Culture Documents

RMF Titan Desiccant Breathers 20170331 en

Uploaded by

alaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RMF Titan Desiccant Breathers 20170331 en

Uploaded by

alaaCopyright:

Available Formats

Titan Desiccant Breathers

THE TOUGHEST DESICCANT BREATHER ON THE MARKET

The Titan series operate by the same efficient procedure as the other air conditioners within the RMF Systems range. The

difference is the housing of the Titan Desiccant Breather, which is made out of the strongest polymer to optimally function

under the most harsh environments. Due to the integrated inner core the desiccant breather is also lighter.

Highest efficiency This prevents atmospheric contact

in a single process between the air and the ZR Gel

The Titan Desiccant Breather under static conditions, increasing

reduces contamination of your oils the lifetime of the drying agent.

by removing solid particles (down

to 3µ) and moisture from the air in a Serviceable and non-toxic

single process. This process prevents All desiccant breathers are

contamination and oxidation of the completely serviceable, RMF

oil and components, resulting in Systems can provide you with spare

a prolonged service life of the oil filter elements or refills of the

and equipment and less down time. non-toxic and non-carcinogenic ZR

Reducing the total cost of ownership gel granules.

for your equipment.

Easy mounting

Integrated anti-splash device The desiccant breathers are

The Titan Desiccant Breather comes compatible with almost all hydraulic

standard with an integrated and lubricating fluids applications,

anti-splash device to eliminate because of the wide variety of

oil from the equipment reservoir mounting plates.

reaching the air filter and ZR Gel.

Optional check valves can be added.

These valves are fitted in opposing

directions, opening whilst in- or

exhaling.

Anti-splash device

Benefits

1 Reduces cost of ownership

2 Reduces oxidation of the oil and bearing surfaces

3 Prolongs the life of the equipment and oil (additive package)

4 Minimizes equipment downtime

Titan Desiccant Breathers

TECHNICAL SPECIFICATIONS

TYPE 96 SERIES 121 SERIES

Total weight ± 1,1 kg ± 2 kg

Dimensions D x H ± 100 x 243 mm ± 130 x 267 mm

ZR gel volume 600 cc 1.000 cc

Water adsorption 172 gram 288 gram

Maximum air flow without

700 l/min 1.500 l/min

check valves (0,01 bar)

Maximum air flow with

300 l/min 400 l/min

check valves (0,01 bar)

Adsorption material Non-toxic & Non-carcinogenic ZR gel 3-6 mm

Operating temperature - 40 °C + 90 °C

Housing material Copolyester

FLUID COMPATIBILITY

Mineral Oils: H, HL, HLP, HVLP OK

HEES Synthetical ester OK Titan Desiccant Breathers

Other fluids Contact RMF Systems

Ordering Code

TDB

PRODUCT CONNECTION

TDB -Titan Desiccant Breather TDB96 connections

34B - 3/4’’ BSPP male

34N - 3/4’’ NPT male

DIMENSION 1B - 1’’ BSPP male

96 1N - 1’’ NPT male

121

TDB121 connections

1B - 1’’ BSPP male

© 2017 RMF Systems 20170331EN

DRYING AGENT 1N - 1’’ NPT male

R - ZR Gel without check valves 114B - 1 1/4’’ BSPP male

RV - ZR Gel with check valves EXAMPLE: 114N - 1 1/4’’ NPT male

TDB96RV - 34B

Coenecoop 71 | 2741 PH | Waddinxveen | the Netherlands | T: +31 182 30 28 88 | E: info@rmfsystems.com | W: www.rmfsystems.com

You might also like

- Titan Desiccant Breathers: BenefitsDocument2 pagesTitan Desiccant Breathers: BenefitsMhs EngineerNo ratings yet

- NC750 - Service OnesheetDocument4 pagesNC750 - Service OnesheetReşatNo ratings yet

- 2016 Chemistry Solutions GBDocument8 pages2016 Chemistry Solutions GBWillie Cheong Han YangNo ratings yet

- Data Sheet TRAP BreatherDocument2 pagesData Sheet TRAP BreatherMAMI RAKOTOMAHANINANo ratings yet

- Filters, Regulators, and Lubricators: Air Preparation Equipment FiltersDocument18 pagesFilters, Regulators, and Lubricators: Air Preparation Equipment FiltersElsonMilanNo ratings yet

- Brosure - FO Flow Meter2Document4 pagesBrosure - FO Flow Meter2dhawallaNo ratings yet

- Danfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZDocument11 pagesDanfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZclopez5556No ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- RycoHoseCatalog 97Document1 pageRycoHoseCatalog 97Zayuri MaldonadoNo ratings yet

- n25 ManualDocument12 pagesn25 ManualRikshita Agarwal100% (1)

- 17078EN TLMP SeriesDocument2 pages17078EN TLMP Seriesxuanphuong2710No ratings yet

- Variable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T ADocument64 pagesVariable Displacement Axial Piston Pumps: Edition: 04/01.2012 Replaces: MVP 03 T AGERALD SIMONNo ratings yet

- SKF Multipoint Automatic Lubricator TLMP Series: Reliable Relubrication of Multiple Lubrication PointsDocument2 pagesSKF Multipoint Automatic Lubricator TLMP Series: Reliable Relubrication of Multiple Lubrication Pointsatanas kolevNo ratings yet

- Danfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZDocument19 pagesDanfoss Reciprocating Compressors: MT / MTZ / MPZ / NTZclopez5556No ratings yet

- Ds04108bf Data Sheet (Nm4-108b)Document2 pagesDs04108bf Data Sheet (Nm4-108b)johnnygabrielNo ratings yet

- Precision Meters & AccessoriesDocument8 pagesPrecision Meters & Accessoriessupernaveed88No ratings yet

- Max Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range ToDocument4 pagesMax Flow: 100 GPM (379 LPM) : SP80/90 Spin-On Filters Working Pressures To: Rated Static Burst To: Flow Range Tofrancis_15inNo ratings yet

- TLMP 2017Document2 pagesTLMP 2017ANo ratings yet

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- Specification Sheet: Centrifuge For Petrol and Mineral OilsDocument3 pagesSpecification Sheet: Centrifuge For Petrol and Mineral Oilsh8pb8jzyhgNo ratings yet

- Pump CatalogAC PowerDocument8 pagesPump CatalogAC Powernadir belaghitNo ratings yet

- QTN 2336Document2 pagesQTN 2336shahkunal11No ratings yet

- Introduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownDocument51 pagesIntroduction To Condition Monitoring - STLE Toronto Section March 19 2024 Ken BrownKenneth John BrownNo ratings yet

- PMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Document159 pagesPMC Hydraulics - Hoses - Fittings - Catalogue - 2019 - 01 - EN - v2Bouslimi SouhaibNo ratings yet

- 4660 LubricationDocument16 pages4660 LubricationCAT CYLINDERNo ratings yet

- EN V6007 S762 KnifeGate Web 20220706Document8 pagesEN V6007 S762 KnifeGate Web 20220706password2002No ratings yet

- Single Seat Valves SVP Select Sudmo Leaflet v2110 enDocument2 pagesSingle Seat Valves SVP Select Sudmo Leaflet v2110 enMark JonesNo ratings yet

- Nem-sd5-Mas-00!00!0087 Supplier Submission Bearing HM (Mie - Naite)Document52 pagesNem-sd5-Mas-00!00!0087 Supplier Submission Bearing HM (Mie - Naite)Ly Thanh HaNo ratings yet

- Quick Release Snap Type CouplingDocument1 pageQuick Release Snap Type Couplingpeters petersNo ratings yet

- 115NZ NZCDocument4 pages115NZ NZCOdicoNo ratings yet

- Manual Z Long Life 75W80 TDSDocument2 pagesManual Z Long Life 75W80 TDSVusal HasanovNo ratings yet

- Triple Crown A-HOOV-TB001-E v10 HRDocument9 pagesTriple Crown A-HOOV-TB001-E v10 HRIGOR ARSENIONo ratings yet

- LUBEWORKS-Catalogue BrochureDocument4 pagesLUBEWORKS-Catalogue Brochureventas freyreNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- Flyer Digital Filter Suite enDocument5 pagesFlyer Digital Filter Suite enemmsh71No ratings yet

- Breathers Mar-20-06 PDFDocument8 pagesBreathers Mar-20-06 PDFOscar NavarroNo ratings yet

- ATSL1-150: Data SheetsDocument3 pagesATSL1-150: Data SheetsCALGERINo ratings yet

- MTZ36-4VM - Danfoss CompressorDocument3 pagesMTZ36-4VM - Danfoss CompressorAnca SterianNo ratings yet

- Oilsampling 2011-07 PDFDocument5 pagesOilsampling 2011-07 PDFJolito RamosNo ratings yet

- Technology: The Oil Sample. Where Oil Analysis BeginsDocument8 pagesTechnology: The Oil Sample. Where Oil Analysis BeginsTheerayoot PoomchaiNo ratings yet

- Lubricant eDocument26 pagesLubricant eMeliza Torres BerrioNo ratings yet

- Micro FiltrationDocument7 pagesMicro FiltrationEdwin CaleñoNo ratings yet

- Depliant Walcom USA - Bonding Ott 23 - TD3 FiltriDocument2 pagesDepliant Walcom USA - Bonding Ott 23 - TD3 FiltriSalvatore GuarinoNo ratings yet

- LD Brochure LetterDocument6 pagesLD Brochure LetterJackNo ratings yet

- NM6-110E Data SheetDocument3 pagesNM6-110E Data SheetDedi WahyudiNo ratings yet

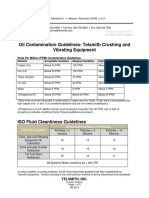

- Oil Contamination GuidelinesDocument2 pagesOil Contamination Guidelinescarlos martinezNo ratings yet

- Des-Case Sales Sheet LMS LT SeriesDocument6 pagesDes-Case Sales Sheet LMS LT SeriesGiovanny MosqueraNo ratings yet

- Check ValvesDocument8 pagesCheck ValvesNat FloresNo ratings yet

- Castrol Syntrans Transaxle 75W-90: DescriptionDocument2 pagesCastrol Syntrans Transaxle 75W-90: DescriptionDylan GirdlestoneNo ratings yet

- Doosan RSP2 FDocument3 pagesDoosan RSP2 FPartsHeavy HeavyPartsNo ratings yet

- Nevastane SLDocument4 pagesNevastane SLronnysiguasNo ratings yet

- Electric Motor Bearing Grease: LGHQ 2Document2 pagesElectric Motor Bearing Grease: LGHQ 2estebang956No ratings yet

- Bladder Accumulators Type Asa: 3.5.1 Technical DataDocument14 pagesBladder Accumulators Type Asa: 3.5.1 Technical DataCricri CriNo ratings yet

- Regular Grade Anti-Seize & Lubricating Compound: Never SeezDocument2 pagesRegular Grade Anti-Seize & Lubricating Compound: Never SeezGregory Alan Francisco IINo ratings yet

- tsf2 h2 Coalescing Filter Data Sheet enDocument4 pagestsf2 h2 Coalescing Filter Data Sheet enCLAUDIA RAMIREZ SAUCEDONo ratings yet

- Hydraulic TRAP Breather TechnologyDocument8 pagesHydraulic TRAP Breather TechnologyFernandoPelozioNo ratings yet

- CF Catalog PDFDocument15 pagesCF Catalog PDFHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Catalogo Filtros Highfil PDFDocument190 pagesCatalogo Filtros Highfil PDFAriel Taboada ZapataNo ratings yet

- ALMURBAT General PresentationDocument14 pagesALMURBAT General PresentationalaaNo ratings yet

- Brochure Air-Conditioners 20180306 enDocument20 pagesBrochure Air-Conditioners 20180306 enalaaNo ratings yet

- RMF Brochure Engels Rev20190506Document24 pagesRMF Brochure Engels Rev20190506alaaNo ratings yet

- Brochure GOLU 20160321 enDocument12 pagesBrochure GOLU 20160321 enalaaNo ratings yet

- D 30-Series 20161019 enDocument1 pageD 30-Series 20161019 enalaaNo ratings yet

- 3210 02 02 Student GuideDocument4 pages3210 02 02 Student GuideKenneth WevoyaNo ratings yet

- Mellors Inorganic ChemistryDocument936 pagesMellors Inorganic ChemistryMichael WilliamsNo ratings yet

- Q13&14Document2 pagesQ13&14Izzah HzmhNo ratings yet

- Igcse Phy 04Document2 pagesIgcse Phy 04Kamrul Hasan SagarNo ratings yet

- 06 Lecture 6 CES Edupack ProgrammeDocument12 pages06 Lecture 6 CES Edupack Programmeaaroncete14No ratings yet

- Mat & Sat - 06Document32 pagesMat & Sat - 06RamNagalNo ratings yet

- Topic 26 Air and WaterDocument1 pageTopic 26 Air and WaterCarolus WisnuNo ratings yet

- Solution Manual - Chemistry-4th Ed. (McMurry)Document546 pagesSolution Manual - Chemistry-4th Ed. (McMurry)Abdullah Raza Khan82% (17)

- THE TRANSPORT OF ATOMIC DEBRIS FROM OPERATION UPSHOT-KNOTHOLE - U.S. Atomic Energy CommissionDocument201 pagesTHE TRANSPORT OF ATOMIC DEBRIS FROM OPERATION UPSHOT-KNOTHOLE - U.S. Atomic Energy Commissionscribd3No ratings yet

- Che 411A: Fluid Mechanics: Sourc E TopicDocument24 pagesChe 411A: Fluid Mechanics: Sourc E TopicChristine Mae Vea100% (1)

- Bradford AssayDocument7 pagesBradford AssayTiara CahyadiNo ratings yet

- 2022-JEE Advanced Booster Test-2 SolutionsDocument14 pages2022-JEE Advanced Booster Test-2 SolutionsDivyansh SinghNo ratings yet

- Stability Design of Coastal StructuresDocument96 pagesStability Design of Coastal StructuresshreevardhanNo ratings yet

- JPST - Volume 8 - Issue 1 - Pages 32-44Document13 pagesJPST - Volume 8 - Issue 1 - Pages 32-44Sanjay singhNo ratings yet

- Use of Mattsson's Solution of PH 7.2 To Evaluate The Stress-Corrosion Cracking Susceptibility of Copper-Zinc AlloysDocument3 pagesUse of Mattsson's Solution of PH 7.2 To Evaluate The Stress-Corrosion Cracking Susceptibility of Copper-Zinc AlloysGrato Jr SingcoNo ratings yet

- Design Co2 EvaporatorsDocument7 pagesDesign Co2 EvaporatorsYutt Watt100% (1)

- Manual MaDocument21 pagesManual MaSergio RecabarrenNo ratings yet

- Birla Instritute of Technology & Science, Pilani, Pilani Campus Chemical Engineering DepartmentDocument2 pagesBirla Instritute of Technology & Science, Pilani, Pilani Campus Chemical Engineering DepartmentVaibhav SharmaNo ratings yet

- The Mole and Chemical Calculations: Pure ChemistryDocument2 pagesThe Mole and Chemical Calculations: Pure Chemistryyuxiang32No ratings yet

- Design and Development of Carvedilol Gastroretentive Floating Drug Delivery Systems Using Hydrophilic Polymers and in Vitro CharacterizationDocument8 pagesDesign and Development of Carvedilol Gastroretentive Floating Drug Delivery Systems Using Hydrophilic Polymers and in Vitro CharacterizationPRASANTA KUMAR MOHAPATRANo ratings yet

- Advanced Quantum Field Theory Roberto CasalbuoniDocument261 pagesAdvanced Quantum Field Theory Roberto Casalbuoniapi-3797403100% (1)

- Raghu Engineering College: AutonomousDocument12 pagesRaghu Engineering College: Autonomousganesh chowdaryNo ratings yet

- ANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFDocument8 pagesANSWER MPSM Johor Kimia Kertas 3 Set 2 2018 PDFSiti Hajar Abd HamidNo ratings yet

- Overview of The Availability and Utilization of Kaolin As A Potential Raw Material in Chemicals & Drugs Formulation in NigeriaDocument6 pagesOverview of The Availability and Utilization of Kaolin As A Potential Raw Material in Chemicals & Drugs Formulation in Nigeriawilolud6720100% (1)

- Informational Passages RC - Voyagers 1 and 2Document1 pageInformational Passages RC - Voyagers 1 and 2andreidmannnNo ratings yet

- Energy Balances On A Nonreactive Systems: Chapter 8, FelderDocument76 pagesEnergy Balances On A Nonreactive Systems: Chapter 8, Feldermuhammad izzulNo ratings yet

- Venturi MeterDocument15 pagesVenturi MeterFatimah BadruddinNo ratings yet

- Neutron Radiography: What Is NDT?Document4 pagesNeutron Radiography: What Is NDT?mohamedNo ratings yet

- 1 Polymerization: An OverviewDocument17 pages1 Polymerization: An OverviewJoão Vitor SahadiNo ratings yet

- Unit 2: Molecular and Ionic Compound Structure and PropertiesDocument7 pagesUnit 2: Molecular and Ionic Compound Structure and PropertiesTAHA GABRNo ratings yet