Professional Documents

Culture Documents

Eye & Eye Turnbuckles

Eye & Eye Turnbuckles

Uploaded by

Konstantinos SynodinosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eye & Eye Turnbuckles

Eye & Eye Turnbuckles

Uploaded by

Konstantinos SynodinosCopyright:

Available Formats

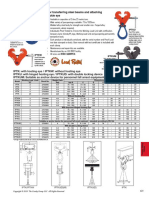

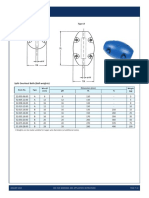

Eye & Eye Turnbuckles

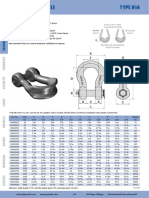

• End fittings are Quenched and Tempered or Normalized, bodies heat treated by normalizing.

• Hot Dip galvanized steel.

• Turnbuckle eyes are forged elongated, by design, to maximize easy attachment in system and minimize

stress in the eye. For turnbuckle sizes 6 mm through 64 mm, a shackle one size smaller can be reeved

through eye.

• Modified UNJ thread on end fittings for improved fatigue properties. Body has UNC thread

• TURNBUCKLES RECOMMENDED FOR STRAIGHT OR IN-LINE PULL ONLY.

• Lock Nuts available for all sizes (see page 198).

• Comprehensive end fitting data provided on page 195.

• Fatigue Rated.

• Meets or exceeds all requirements of ASME B30.26 including identification, ductilit , design factor, proof load

HG - 226 and temperature requirements. Importantly, these turnbuckles meet other critical performance requirements

Eye & Eye

including fatigue life, impact properties and material traceability, not addressed by ASME B30.26.

Accessories

Meets the performance requirements of

Rigging

Federal Specifications FF- -791b, Type

1 Form 1 - CLASS 4, and ASTM F-1145,

except for those provisions required of the

contractor. For additional information, see

page 476.

HG-226 Eye & Eye

Thread Working

Diameter & Load Weight Dimensions (mm)

Take Up HG-226 Limit Each J K M N X

(mm) Stock No. (t)* (kg) A Open Closed Open Closed R S Closed BB

† 6.35 x 102 1031252 .23 .13 6.35 303 202 314 213 20.6 8.64 44.6 103

† 7.94 x 114 1031270 .36 .22 7.94 354 239 368 253 24.1 11.2 55.8 116

† 9.53 x 152 1031298 .54 .34 9.53 446 294 463 311 28.7 13.5 62.9 155

12.7 x 152 1031314 1.00 .78 12.7 506 354 529 376 35.8 18.0 90.4 153

12.7 x 305 1031350 1.00 1.19 12.7 819 514 841 536 35.8 18.0 89.9 314

15.9 x 152 1031378 1.59 1.25 15.9 552 399 577 425 45.7 22.4 110 153

15.9 x 305 1031412 1.59 1.87 15.9 865 560 891 586 45.7 22.4 110 315

19.1 x 152 1031430 2.36 1.91 19.1 590 438 622 470 53.1 25.4 130 156

19.1 x 305 1031476 2.36 2.78 19.1 905 600 937 632 53.1 25.4 129 320

19.1 x 457 1031494 2.36 3.55 19.1 1210 753 1242 785 53.1 25.4 130 471

22.2 x 305 1031519 3.27 4.01 22.2 932 627 970 665 60.5 31.8 147 309

22.2 x 457 1031537 3.27 5.22 22.2 1249 792 1287 830 60.5 31.8 147 473

25.4 x 152 1031555 4.54 4.36 25.4 666 514 711 559 76.2 36.3 165 157

25.4 x 305 1031573 4.54 5.88 25.4 971 666 1016 711 76.2 36.3 165 309

25.4 x 457 1031591 4.54 7.40 25.4 1276 819 1321 864 76.2 36.3 165 462

25.4 x 610 1031617 4.54 9.14 25.4 1596 987 1641 1031 76.2 36.3 164 631

31.8 x 305 1031635 6.89 9.01 31.8 1070 766 1127 822 91.2 46.2 216 306

31.8 x 457 1031653 6.89 10.8 31.8 1375 918 1432 975 91.2 46.2 216 459

31.8 x 610 1031671 6.89 12.6 31.8 1694 1085 1751 1141 91.2 46.2 216 625

38.1 x 305 1031699 9.71 13.0 38.1 1124 819 1187 882 104 53.8 240 313

38.1 x 457 1031715 9.71 15.4 38.1 1428 971 1492 1035 104 53.8 240 465

38.1 x 610 1031733 9.71 17.9 38.1 1749 1139 1813 1203 104 53.8 240 633

44.5 x 457 1031779 12.7 23.0 44.5 1457 1000 1534 1076 118 60.5 253 467

44.5 x 610 1031797 12.7 26.4 44.5 1762 1153 1838 1229 118 60.5 253 619

51.0 x 610 1031813 16.8 37.9 50.8 1922 1313 2011 1402 148 68.3 331 622

63.5 x 610 1031831 27.2 67.4 63.5 2011 1402 2113 1503 165 79.2 350 625

70.0 x 610 1031859 34.0 79.1 69.9 2066 1456 2180 1571 178 82.6 383 626

*Proof Load is 2.5 times the Working Load Limit. Ultimate Load is 5 times the Working Load Limit. † Mechanical Galvanized

Copyright © 2019 The Crosby Group LLC All Rights Reserved 191

You might also like

- Piping Inspector's Handbook (Rev 2)Document10 pagesPiping Inspector's Handbook (Rev 2)praveentien100% (1)

- Engr 113 Group 13 Final ReportDocument16 pagesEngr 113 Group 13 Final Reportapi-507203933100% (1)

- Torque-Tension Chart For Metric Fasteners PDFDocument1 pageTorque-Tension Chart For Metric Fasteners PDFmhd abdouNo ratings yet

- Scheme of MVW Spray SystemDocument1 pageScheme of MVW Spray SystemankushbahaleNo ratings yet

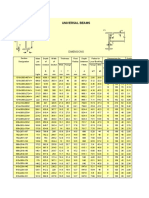

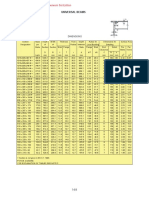

- Section TableDocument52 pagesSection TableNurin Irdina RoslanNo ratings yet

- British and European SectionsDocument89 pagesBritish and European SectionsgenergiaNo ratings yet

- 1.5D Bend Calculation Per B31.1-2018Document84 pages1.5D Bend Calculation Per B31.1-2018Amit SharmaNo ratings yet

- Blue BookDocument241 pagesBlue Bookeng_muhammad88No ratings yet

- GI Sheet Kg-m2Document1 pageGI Sheet Kg-m2farshan296015100% (1)

- Minimum Thread Engagement With Respect To Material StrengthDocument10 pagesMinimum Thread Engagement With Respect To Material StrengthDarío CostasNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Raft Design Bheri-2and3 BHKDocument19 pagesRaft Design Bheri-2and3 BHKMilan KarkiNo ratings yet

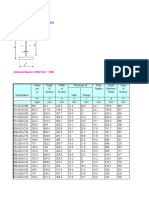

- Sections: Universal Columns (UC) EurocodeDocument2 pagesSections: Universal Columns (UC) EurocodeRajesh RNo ratings yet

- Sectional Properties of SteelDocument72 pagesSectional Properties of Steeladera1No ratings yet

- Lamp Flag Fence Post DesignDocument16 pagesLamp Flag Fence Post DesignJupiter AbianNo ratings yet

- Steel Section Table ConciseDocument36 pagesSteel Section Table ConciseVance KangNo ratings yet

- Torque Calculation For HT BoltsDocument2 pagesTorque Calculation For HT BoltsMadhava PadiyarNo ratings yet

- Flexible PipeDocument17 pagesFlexible PipeAnonymous dSFbLxc9100% (1)

- Manual RF Baghouse CollectorDocument24 pagesManual RF Baghouse Collectorheroj83100% (1)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Stochastic Fatigue, Fracture and Damage AnalysisDocument37 pagesStochastic Fatigue, Fracture and Damage AnalysisVinayaga Murthy GNo ratings yet

- COBIM - S10 - Energy - Analysis - v1 PDFDocument23 pagesCOBIM - S10 - Energy - Analysis - v1 PDFUkashaRaufNo ratings yet

- ILO 152 Lifting GearDocument18 pagesILO 152 Lifting GearADL123100% (1)

- Jaw & Jaw TurnbucklesDocument1 pageJaw & Jaw TurnbucklesSavin TimofteNo ratings yet

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDocument1 pageJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyGustavo ArancibiaNo ratings yet

- HG 225Document1 pageHG 225Claudio Alvarado ArayaNo ratings yet

- Eye Bolt DetailDocument1 pageEye Bolt Detailshalinimanjunath2020No ratings yet

- Crosby Eye Bolt G 291Document1 pageCrosby Eye Bolt G 291pandiangvNo ratings yet

- Turnbuckle Eye To EyeDocument1 pageTurnbuckle Eye To EyeNed VasicNo ratings yet

- Crosby - HG-228 Jaw Jaw Turnbuckles SpecsDocument1 pageCrosby - HG-228 Jaw Jaw Turnbuckles SpecsSalmanNo ratings yet

- Z-Section Dimensions & Properties - MetsecDocument3 pagesZ-Section Dimensions & Properties - Metsecadil_khan648No ratings yet

- Jaw & Eye Turnbuckles: All Rights Reserved 188Document1 pageJaw & Eye Turnbuckles: All Rights Reserved 188agustinNo ratings yet

- G-277 Cancamo CrosbyDocument1 pageG-277 Cancamo CrosbyDavid Borja HuarachiNo ratings yet

- cjv92 82sa cjpf96 SCDocument3 pagescjv92 82sa cjpf96 SCrnd.ptcwiNo ratings yet

- Uc COLUMNSDocument4 pagesUc COLUMNSmiteshpatel191No ratings yet

- Hot Roled SectionsDocument58 pagesHot Roled Sectionsmohamed AlasadyNo ratings yet

- BOLT LOADS Metric 5.6 PDFDocument1 pageBOLT LOADS Metric 5.6 PDFJorge Ivan Monsalve GalvisNo ratings yet

- Universal Beam Section PropertiesDocument4 pagesUniversal Beam Section Propertiesloft diamondNo ratings yet

- Bearing CalalougeDocument9 pagesBearing CalalougeRakesh GairolaNo ratings yet

- Universal Columns (UC), Section Properties Dimensions & PropertiesDocument8 pagesUniversal Columns (UC), Section Properties Dimensions & PropertiesSuresh Babu100% (1)

- BS Section PDFDocument96 pagesBS Section PDFUpendra WalinjkarNo ratings yet

- Sections: Universal Beams (UB)Document18 pagesSections: Universal Beams (UB)rezetane mohamed amineNo ratings yet

- Torque-Tension Relationship For Metric Stainless Steel Fasteners A2 and A4-70 Feb 2016Document1 pageTorque-Tension Relationship For Metric Stainless Steel Fasteners A2 and A4-70 Feb 2016Mohammad TaushifNo ratings yet

- Universal Beams Advance UKB: DimensionsDocument10 pagesUniversal Beams Advance UKB: DimensionszulaikhaNo ratings yet

- Parallel Flanges Channels - Steel DimensionsDocument1 pageParallel Flanges Channels - Steel DimensionsAxiv The GreatNo ratings yet

- Universal Beams To BS4 Part 1 - 1993Document3 pagesUniversal Beams To BS4 Part 1 - 1993Aristotle MedinaNo ratings yet

- Universal BeamDocument2 pagesUniversal BeamP HRNo ratings yet

- Tata Steel Section Ciold and Hot Section PDFDocument96 pagesTata Steel Section Ciold and Hot Section PDFSyedNo ratings yet

- Suntech Thrust Pad Cata 18-19Document16 pagesSuntech Thrust Pad Cata 18-19ARKA technocorpNo ratings yet

- P201: Handbook of Structural Steelwork 3rd Edition: Universal BeamsDocument44 pagesP201: Handbook of Structural Steelwork 3rd Edition: Universal Beamsmbhanusagar.keynesNo ratings yet

- Uk Sections Datasheets 100723Document20 pagesUk Sections Datasheets 100723pkdscdubaiNo ratings yet

- Weight Per Meter of Weld Metal For Fillet Welds and Elements of Common Butt Joints (KG/M) Steel InstructionsDocument1 pageWeight Per Meter of Weld Metal For Fillet Welds and Elements of Common Butt Joints (KG/M) Steel InstructionsTAMILNo ratings yet

- Appendix GDocument1 pageAppendix GRealino PradoNo ratings yet

- Handbook - Calculations10Document1 pageHandbook - Calculations10Anonymous 7IKdlmNo ratings yet

- List & Properties of UK Strcutral Steel Shapes No Sheet DescriptionDocument65 pagesList & Properties of UK Strcutral Steel Shapes No Sheet DescriptionThắngg TrịnhhNo ratings yet

- Grid Cable Dia Calculation SheetDocument6 pagesGrid Cable Dia Calculation SheetdrravijainNo ratings yet

- Equal Leg Angles EN 10056-1 - 1998Document1 pageEqual Leg Angles EN 10056-1 - 1998Axiv The GreatNo ratings yet

- Hercules Laminated Elastomeric BearingsDocument7 pagesHercules Laminated Elastomeric BearingsjohnsonNo ratings yet

- Steel Cable 6x36-Galvanised-WS-IWRCDocument2 pagesSteel Cable 6x36-Galvanised-WS-IWRCAnca GeaninaNo ratings yet

- Metric Catalog 2022-1 - 220825 - 114343 228-232Document5 pagesMetric Catalog 2022-1 - 220825 - 114343 228-232taztika putriNo ratings yet

- Phân Tích EFADocument5 pagesPhân Tích EFAAn PhúcNo ratings yet

- Pengukuran Cros RugukDocument18 pagesPengukuran Cros RugukabdullahmahifalNo ratings yet

- Ball Mill Capacity Dimensions Paul o AbbeDocument2 pagesBall Mill Capacity Dimensions Paul o AbbeAnonymous QLRaOLNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections Datasheetsمحمد متوليNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsYaziq NabilNo ratings yet

- Synodinos Wire Rope SlingsDocument1 pageSynodinos Wire Rope SlingsKonstantinos SynodinosNo ratings yet

- Crosby McKissick Snatch BLocks 2t To12tDocument1 pageCrosby McKissick Snatch BLocks 2t To12tKonstantinos SynodinosNo ratings yet

- Dyform 8 PI: High Performance Crane Ropes BenefitsDocument2 pagesDyform 8 PI: High Performance Crane Ropes BenefitsKonstantinos SynodinosNo ratings yet

- Closed Spelter SocketsDocument2 pagesClosed Spelter SocketsKonstantinos SynodinosNo ratings yet

- Crosby Instructions Chain Slings 1Document1 pageCrosby Instructions Chain Slings 1Konstantinos SynodinosNo ratings yet

- Crosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookDocument1 pageCrosby Grade 100 SHUR-LOC Handle Hooks: Shur-Loc Handle Swivel Hook With Bearing Shur-Loc Handle Eye HookKonstantinos SynodinosNo ratings yet

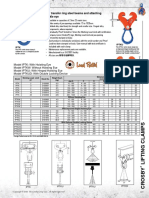

- For Transferring Steel Beams and Attaching Tackle Eye: IptkuDocument1 pageFor Transferring Steel Beams and Attaching Tackle Eye: IptkuKonstantinos SynodinosNo ratings yet

- Ropeblock - Snatch Blocks S Series With Hook - MetricDocument1 pageRopeblock - Snatch Blocks S Series With Hook - MetricKonstantinos SynodinosNo ratings yet

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDocument1 pageCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosNo ratings yet

- Threaded Rod M33 (3.5) 10.9Document4 pagesThreaded Rod M33 (3.5) 10.9Konstantinos SynodinosNo ratings yet

- All Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsDocument1 pageAll Breaking Loads Are in Metric Tonnes. To Maximize The Benefits of The Improved Strength of The Chain, Only Use Compatible Trawlex FittingsKonstantinos SynodinosNo ratings yet

- Pewag SVW - SVSW - SvsuwDocument1 pagePewag SVW - SVSW - SvsuwKonstantinos SynodinosNo ratings yet

- Diepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeDocument1 pageDiepa X53 K: Ordinary Lay Non-Rotation Resistant Wire RopeKonstantinos SynodinosNo ratings yet

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 pagesType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosNo ratings yet

- Important Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsDocument1 pageImportant Safety Information - Read & Follow: Warning Forged Eye Bolt Warnings & Application InstructionsKonstantinos SynodinosNo ratings yet

- Important - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingDocument1 pageImportant - Read and Understand These Instructions Before Using Eye Bolts. Regular Nut & Shoulder Nut Eye Bolt - Installation For In-Line LoadingKonstantinos SynodinosNo ratings yet

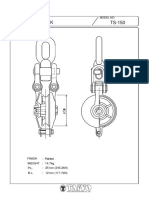

- 05 Snatch Block (Ts150)Document1 page05 Snatch Block (Ts150)Konstantinos SynodinosNo ratings yet

- To Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Document1 pageTo Remove Lifting Point: Table 1 Working Load Limit 4:1 (T) UNC Bolt Size (In.) Effective Thread Projection Length (In.)Konstantinos SynodinosNo ratings yet

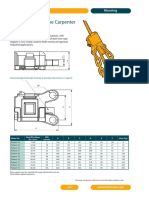

- Stopper: A3-10032 Wire Rope CarpenterDocument1 pageStopper: A3-10032 Wire Rope CarpenterKonstantinos SynodinosNo ratings yet

- Western Manila Rope Blocks Western Standard Steel BlocksDocument1 pageWestern Manila Rope Blocks Western Standard Steel BlocksKonstantinos SynodinosNo ratings yet

- Product Sheet HDTP 13.03.2019Document1 pageProduct Sheet HDTP 13.03.2019Konstantinos SynodinosNo ratings yet

- Thiele TWN100-TWN1001Document2 pagesThiele TWN100-TWN1001Konstantinos SynodinosNo ratings yet

- For Transfer Ring Steel Beams and Attaching Tackle EyeDocument1 pageFor Transfer Ring Steel Beams and Attaching Tackle EyeKonstantinos SynodinosNo ratings yet

- Python Compac27Document2 pagesPython Compac27Konstantinos SynodinosNo ratings yet

- Split Overhaul BallsDocument1 pageSplit Overhaul BallsKonstantinos SynodinosNo ratings yet

- Elaskon 30 Spray SDS GB-en v2,0Document9 pagesElaskon 30 Spray SDS GB-en v2,0Konstantinos SynodinosNo ratings yet

- Midas Civil RSI Analysis Step by Step v2Document28 pagesMidas Civil RSI Analysis Step by Step v2asraful.adalderNo ratings yet

- Heat Transfer Analyses by "Nite Element and Boundary Element Methods. A Bibliography (1997) 1998)Document12 pagesHeat Transfer Analyses by "Nite Element and Boundary Element Methods. A Bibliography (1997) 1998)chrissbansNo ratings yet

- Kingspan Multideck&Structural Decks Technical Handbook UAE enDocument56 pagesKingspan Multideck&Structural Decks Technical Handbook UAE enWaleed IbrahimNo ratings yet

- 6 Ceramics - Structure, Properties, Classification and ApplicationDocument9 pages6 Ceramics - Structure, Properties, Classification and ApplicationInah OtreraNo ratings yet

- CJ WL Electrical Lighting Schedule C04 CIDocument11 pagesCJ WL Electrical Lighting Schedule C04 CIalberttendoy2158No ratings yet

- Avinash Document ProjectDocument90 pagesAvinash Document ProjectBajibabu IndurthiNo ratings yet

- Wrought MetalsDocument168 pagesWrought MetalsDr. Vikram SusilNo ratings yet

- FIS-Finishes Schedule - R1Document4 pagesFIS-Finishes Schedule - R1meghadurganNo ratings yet

- BPL SL 1300 Solar Lantern SpecsDocument3 pagesBPL SL 1300 Solar Lantern SpecsGuruNo ratings yet

- Brick Tiles - Brick Wall Tiles - Brick Tile Quality - Brick Tile Specifications - GharExpert PDFDocument22 pagesBrick Tiles - Brick Wall Tiles - Brick Tile Quality - Brick Tile Specifications - GharExpert PDFSelvaraj VillyNo ratings yet

- Response of CMT Welded Aluminum AA5086-H111 To AA6061-T6 Plate With AA4043 Filler For BallisticDocument7 pagesResponse of CMT Welded Aluminum AA5086-H111 To AA6061-T6 Plate With AA4043 Filler For BallisticAnurag yadavNo ratings yet

- Case StudyDocument23 pagesCase Studysatyam gupta100% (1)

- Teck Thai Jewelry Supply Ltd. Teck Thai Jewelry Supply LTDDocument184 pagesTeck Thai Jewelry Supply Ltd. Teck Thai Jewelry Supply LTDaku_capriNo ratings yet

- Class 10 ElectricityDocument16 pagesClass 10 ElectricityTapas BanerjeeNo ratings yet

- Die Attach Materials For High Temperature Applications - A ReviewDocument22 pagesDie Attach Materials For High Temperature Applications - A ReviewHanLe DuyNo ratings yet

- A Comparison of Canadian, Mexican, and United States Steel Design StandardsDocument15 pagesA Comparison of Canadian, Mexican, and United States Steel Design Standardsfred flintstoneNo ratings yet

- Vivax HR Acp18cofm50aeeiDocument110 pagesVivax HR Acp18cofm50aeeiDrazen HajlingNo ratings yet

- Epsilone BrochureDocument12 pagesEpsilone BrochureGeorges BaderNo ratings yet

- API RP 572 QuizDocument17 pagesAPI RP 572 Quizamalhaj2013No ratings yet

- Thread Pipe NippleDocument1 pageThread Pipe NippleJuditaNo ratings yet

- Henan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium GreaseDocument1 pageHenan Dongsen Lubrication Technology Co., LTD: Multipurpose Calcium Greasesunhell1611No ratings yet

- 18 - 2017 - Covering Material PDFDocument4 pages18 - 2017 - Covering Material PDFvjdj100% (1)

- Pipe Policy in KeralaDocument28 pagesPipe Policy in Keralajoyhjones4250% (1)