0% found this document useful (0 votes)

405 views12 pagesCable Suspended Roof Structureppt Compress

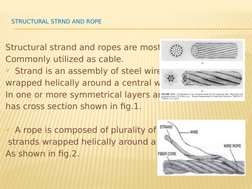

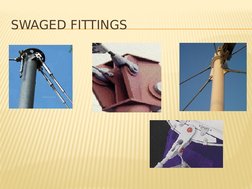

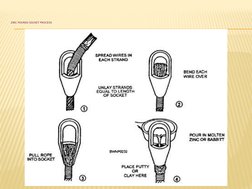

The document discusses the analysis, design, and construction of cable suspended roof structures. It covers three main topics: (1) the analysis of cable suspended roof structures, (2) construction aspects including the use of structural strands and ropes for cables, cable fittings, and cable placement and tensioning, and (3) the design of cable roof structures.

Uploaded by

Yousif MustafaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

405 views12 pagesCable Suspended Roof Structureppt Compress

The document discusses the analysis, design, and construction of cable suspended roof structures. It covers three main topics: (1) the analysis of cable suspended roof structures, (2) construction aspects including the use of structural strands and ropes for cables, cable fittings, and cable placement and tensioning, and (3) the design of cable roof structures.

Uploaded by

Yousif MustafaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Analysis of Cable Suspended Roof Structure

- Construction Aspects of Cable Suspended Roofs