Professional Documents

Culture Documents

CSW Rolls Requirements: Your Best Start in End-Unwrapping

Uploaded by

Antonio Henrique BandeiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CSW Rolls Requirements: Your Best Start in End-Unwrapping

Uploaded by

Antonio Henrique BandeiraCopyright:

Available Formats

CSW Rolls Requirements

Requirements

Paper: Dry (storage), “Kraft” paper 70-80 gr/m2, preferable 70 gr/m2. Paper thickness

max. 0.1 mm

Bag: Pre-made bag with open side folded (180 degrees), ends have to be packed with

looseness.

Orientation Ends: All facing the same direction, according to the drawing below.

Closure: Water based paper tape or glued with Hot Melt glue only.

Flaps: 180 degree folded in the direction of the glued seam, see example next page.

Striping detection: If the machine is equipped with striping detection, the striping should be located

according to the drawing on the next page, and nowhere else.

Samples: Samples requested for test trials free house CSW Deventer 6 weeks before delivery

ex works (number of rolls depending on ma-

chine type, end supplier and diameter ends).

Deviations: Please do not hesitate to send us samples in

case of deviations to these requirements.

CSW reserves the right to update these requirements based on practical experience.

Roll lengths L

Machine Type Roll Length variation Standard Roll Length Range (L)*

Mini-Multifeeder (MMF) No 800 - 1,200

Mini Multifeeder (MMF) Yes 1,025 - 1,200

Multifeeder No 800 - 1,200

Multifeeder Yes 1,025 - 1,200

Multifeeder–S Yes 1,025 - 1,200

* Other roll-lengths on request

your best start in end-unwrapping

CSW Rolls Requirements

Roll Lengths L

Examples good and wrong closures

1. Correct

Hot melt glue is used.

2. Wrong

Plastic white tape is used.

3. Correct

Paper tape is used correctly.

4. Wrong

Plastic transparant tape is used.

5.

For your specific requirements please contact your CSW representative, call +31 (0) 570 678 700

or find your local CSW representative on www.cswbv.com/your-agency.

CSW Machinery B.V.

Rigastraat 16, 7418 EW Deventer

The Netherlands

+31 (0)570 678700

sales@cswbv.nl

WWW.CSWBV.COM

You might also like

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterNo ratings yet

- Lenz Katalog EnglDocument112 pagesLenz Katalog EnglXray UandNo ratings yet

- Pre-Twister: For Use Before Stranding MachinesDocument2 pagesPre-Twister: For Use Before Stranding Machinesماريا قراجةNo ratings yet

- Ganges Internationale - ELE - TXT - v2.3 PDFDocument11 pagesGanges Internationale - ELE - TXT - v2.3 PDFArunkumar vNo ratings yet

- Shell MESC Number 774133.010.1 (NEAREST)Document2 pagesShell MESC Number 774133.010.1 (NEAREST)Ehsan Ur Rehman100% (1)

- EH1200 300-1200 500 pg1157 enDocument3 pagesEH1200 300-1200 500 pg1157 enSirajeddine YounessNo ratings yet

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Document8 pages600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardNo ratings yet

- CR SeriesDocument11 pagesCR SeriesphamNo ratings yet

- Regitz-Consulting GMBH: Do More For LessDocument7 pagesRegitz-Consulting GMBH: Do More For LessLaboratoryNo ratings yet

- V-Blocks / Vises / Angle Plates / Cylindrical Squares Squares / Parallels / Straight EdgesDocument34 pagesV-Blocks / Vises / Angle Plates / Cylindrical Squares Squares / Parallels / Straight EdgesdiegomilitojNo ratings yet

- Offerfor 19 Inchand 20 Inch LCDmonitorDocument4 pagesOfferfor 19 Inchand 20 Inch LCDmonitorapi-3744743100% (2)

- WCB High Quality China Factory Price Tadano Crane Single Row Slewing Ring Swing BearingDocument80 pagesWCB High Quality China Factory Price Tadano Crane Single Row Slewing Ring Swing BearingWCB BEARINGNo ratings yet

- Pressure Water Line MatlsDocument4 pagesPressure Water Line MatlsDusngi MoNo ratings yet

- H V Price List New 2023Document29 pagesH V Price List New 2023dasdaNo ratings yet

- CCTV Surveillance System Price ProposalDocument2 pagesCCTV Surveillance System Price ProposalIB CorporationNo ratings yet

- Psl Fo Yale Ahmadul Hasan Ref Reza Ahamed Sir Md Imran Hossain 11 March 2024Document1 pagePsl Fo Yale Ahmadul Hasan Ref Reza Ahamed Sir Md Imran Hossain 11 March 2024Md. Imran HossainNo ratings yet

- Category Comments Surface Finish: H Z C C H Z 15°Document10 pagesCategory Comments Surface Finish: H Z C C H Z 15°Mikel1020No ratings yet

- Jaw Coupling PDFDocument4 pagesJaw Coupling PDFhibhavuNo ratings yet

- Catalogo Hommel KellerDocument52 pagesCatalogo Hommel KellerHibozoNo ratings yet

- EN 10143 steel sheet dimensions tolerancesDocument2 pagesEN 10143 steel sheet dimensions tolerancesAdolfoDeLaGarzaNo ratings yet

- Servo Magazine - July 2017 PDFDocument68 pagesServo Magazine - July 2017 PDFtony445100% (1)

- Nvent CADDY 3 Quot Single Pipe Conduit Rigid Universal Sway Brace ElectrogalvanizedDocument4 pagesNvent CADDY 3 Quot Single Pipe Conduit Rigid Universal Sway Brace ElectrogalvanizedMARCO RODRIGUEZNo ratings yet

- Shaker ScreensDocument8 pagesShaker ScreensmarboudNo ratings yet

- Project Virtual ProductionDocument6 pagesProject Virtual ProductionLeon SakiNo ratings yet

- Anchor Aps-V Elematic Tec TD en 01Document1 pageAnchor Aps-V Elematic Tec TD en 01Kasia GosławskaNo ratings yet

- Worldpoly Catalogue 2008Document24 pagesWorldpoly Catalogue 2008alejandroNo ratings yet

- PTFE Mesh: Material SpecificationsDocument1 pagePTFE Mesh: Material SpecificationsAhmed SaidNo ratings yet

- Pfaff Classic Style Fashion Sewing Machine Instruction ManualDocument52 pagesPfaff Classic Style Fashion Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Von RudenDocument4 pagesVon RudenNeeraj SharmaNo ratings yet

- Uster OfferDocument18 pagesUster OfferArif ApuNo ratings yet

- Gauges / Pin Gauges / Thread and Tolerance Tables: Schut For PrecisionDocument19 pagesGauges / Pin Gauges / Thread and Tolerance Tables: Schut For PrecisionVishwanadhNo ratings yet

- Gauges / Pin Gauges / Thread and Tolerance Tables: Schut For PrecisionDocument19 pagesGauges / Pin Gauges / Thread and Tolerance Tables: Schut For PrecisionVishwanadh100% (1)

- Purchase Order for CPVC FittingsDocument2 pagesPurchase Order for CPVC FittingsIshan GoelNo ratings yet

- Opposite Party QuoteDocument4 pagesOpposite Party QuoteAnithaDurai1990No ratings yet

- MDQ23137 R00Document5 pagesMDQ23137 R00SUSOVAN BISWASNo ratings yet

- N XD 3 2 1 XD XD XD: TurningDocument3 pagesN XD 3 2 1 XD XD XD: TurningAlejandro Alvarez AlvaradoNo ratings yet

- ProductivityDocument7 pagesProductivityفتحى أحمد100% (2)

- CBB21 Metallized Polypropylene Film Capacitor SpecsDocument4 pagesCBB21 Metallized Polypropylene Film Capacitor SpecsWilson DuranNo ratings yet

- Symmetrical Quick Couplers For Excavators June 2011 EditionDocument5 pagesSymmetrical Quick Couplers For Excavators June 2011 EditionpmpintoisqNo ratings yet

- Operation Manual: Pneumatic Ribbon CoderDocument6 pagesOperation Manual: Pneumatic Ribbon CoderLuis Enrique Barreto GarciaNo ratings yet

- AVR Maintenance ReportDocument4 pagesAVR Maintenance ReportMudassirNo ratings yet

- Deep Hole Drlling On Maching Centres BOTEKDocument2 pagesDeep Hole Drlling On Maching Centres BOTEKmapalptsNo ratings yet

- Rotmax Offer BRT (10) 200407eid ParryDocument2 pagesRotmax Offer BRT (10) 200407eid Parryapi-3725163No ratings yet

- Atac Nuline Cone Plate Viscometer Data Sheet Rev 02Document2 pagesAtac Nuline Cone Plate Viscometer Data Sheet Rev 02frox123No ratings yet

- SWT 2000 LeafletDocument4 pagesSWT 2000 LeafletphucgenjiNo ratings yet

- Standard Belt Cross SectionsDocument26 pagesStandard Belt Cross Sectionsagung badoNo ratings yet

- CCCL Offer (14) (BRT) ConDocument1 pageCCCL Offer (14) (BRT) Conapi-3725163No ratings yet

- Plummer Block & Sleeve)Document4 pagesPlummer Block & Sleeve)vinodsnNo ratings yet

- ASR Thread & AccessoriesDocument11 pagesASR Thread & AccessoriesMD FaysalNo ratings yet

- M e Hyd PVT LTDDocument7 pagesM e Hyd PVT LTDRasheshNo ratings yet

- Lifting and Lashing Point Collection: - For Bolting, For Welding, Simply StrongDocument44 pagesLifting and Lashing Point Collection: - For Bolting, For Welding, Simply StrongMelissa MillsNo ratings yet

- Vishay Escc ActivitiesDocument12 pagesVishay Escc Activitiesritchie ritchieNo ratings yet

- Line Shafts: You Can Rely On Us!Document12 pagesLine Shafts: You Can Rely On Us!skidamdnevnoNo ratings yet

- CR..A SeriesDocument13 pagesCR..A SeriesphamNo ratings yet

- Quotation t1920EW011Document3 pagesQuotation t1920EW011pulakjaiswal85No ratings yet

- Multilayer Ceramic Chip Capacitors: C Series Commercial Grade General (Up To 50V)Document55 pagesMultilayer Ceramic Chip Capacitors: C Series Commercial Grade General (Up To 50V)blokolbNo ratings yet

- Maple Leaf Cement Factory Limited 03-10-23Document1 pageMaple Leaf Cement Factory Limited 03-10-23anm bNo ratings yet

- Technical Contract for 0.5-4X1300 Slitting LineDocument12 pagesTechnical Contract for 0.5-4X1300 Slitting LineTjNo ratings yet

- 2020-51 MDB 160A X 13 PCS EzcDocument3 pages2020-51 MDB 160A X 13 PCS Ezcmohammedhavzy7No ratings yet

- YJOT Weight BarsDocument2 pagesYJOT Weight BarsDiego CorderoNo ratings yet

- Design Report For Aca PurposeDocument321 pagesDesign Report For Aca PurposeKokat AbiNo ratings yet

- Design Procedure of Gear Box For Automobile and Machine ToolsDocument10 pagesDesign Procedure of Gear Box For Automobile and Machine ToolsNAGU20090% (1)

- Mechanical Properties of Materials: Tensile TestDocument6 pagesMechanical Properties of Materials: Tensile Test張席郕No ratings yet

- Beams, Steel I Beams, Structural Beams, Wide FlangeDocument4 pagesBeams, Steel I Beams, Structural Beams, Wide Flangeanon_795652448No ratings yet

- Pneumatic Vice: An OverviewDocument13 pagesPneumatic Vice: An OverviewPrabhav KulkarniNo ratings yet

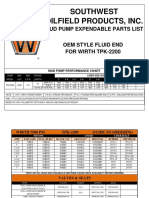

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListDocument2 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListKapil Patwa100% (1)

- Table of Contents OverviewDocument50 pagesTable of Contents OverviewAnthony WaaliaNo ratings yet

- Design Examples: Design Code: ACI 318-05 Design DataDocument4 pagesDesign Examples: Design Code: ACI 318-05 Design DataHafez Taheri100% (2)

- BOSCH Basic Mechanical ElementsDocument1 pageBOSCH Basic Mechanical ElementsJavi GGNo ratings yet

- WR426FN WR426F WR426FN WR400F: (5NG1) (5NG2) (5NG4) (5GS9)Document69 pagesWR426FN WR426F WR426FN WR400F: (5NG1) (5NG2) (5NG4) (5GS9)dan equihuaNo ratings yet

- MOS (Installation of Ceramic Tile) REV2Document3 pagesMOS (Installation of Ceramic Tile) REV2Don Roseller DumayaNo ratings yet

- Beast Wear Parts 2-22Document36 pagesBeast Wear Parts 2-22Mauricio ZapataNo ratings yet

- EST120-QP (1)Document3 pagesEST120-QP (1)Owsu KurianNo ratings yet

- Boundary WallDocument1 pageBoundary WallgohilnarendraNo ratings yet

- Cablofil Data Centre Accessories For Steel Wire Cable TraysDocument8 pagesCablofil Data Centre Accessories For Steel Wire Cable TraysMohamed AdelNo ratings yet

- 814649-1 09 RUKO Core Drilling Machines enDocument50 pages814649-1 09 RUKO Core Drilling Machines enBogdan AndreiNo ratings yet

- GHH Product Brochure enDocument16 pagesGHH Product Brochure entomescu_sorinNo ratings yet

- RH200 Cooling SystemDocument14 pagesRH200 Cooling SystemLuis jopi100% (3)

- Jack Hydraulic, Aircraft, 5-Ton Type A-5 PART NO. 53D22020 NSN 1730-00-540-2343 (EIC: N/A)Document35 pagesJack Hydraulic, Aircraft, 5-Ton Type A-5 PART NO. 53D22020 NSN 1730-00-540-2343 (EIC: N/A)mecambNo ratings yet

- Static Load Calculations & Code Requirements for Welded StructuresDocument6 pagesStatic Load Calculations & Code Requirements for Welded StructuresNayan RamyaNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- TRANE wcc030 - 3 PHASE MODEL ONLYDocument28 pagesTRANE wcc030 - 3 PHASE MODEL ONLYJoseph David0% (1)

- BN - 20038 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A4)Document3 pagesBN - 20038 Hexalobular Socket Pan Head Machine Screws Fully Threaded (A4)MSD ENGRNo ratings yet

- Victaulic General Catalog G-103Document248 pagesVictaulic General Catalog G-103Muhsen Khan100% (1)

- Pmqe441eng 220219Document190 pagesPmqe441eng 220219Gleidson Djalma100% (1)

- Ceiling MaterialsDocument14 pagesCeiling Materialschristian benitezNo ratings yet

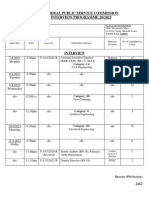

- Interview Prog No.20-2023Document3 pagesInterview Prog No.20-2023Abdullah EjazNo ratings yet

- Pdvsa: Manual de Ingenieria de DiseñoDocument4 pagesPdvsa: Manual de Ingenieria de DiseñoDAVID SOTONo ratings yet

- UntitledDocument37 pagesUntitledDiesel RuizNo ratings yet