Professional Documents

Culture Documents

Chapter 4 - Bolted Connections

Chapter 4 - Bolted Connections

Uploaded by

John Philip Molina NuñezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 4 - Bolted Connections

Chapter 4 - Bolted Connections

Uploaded by

John Philip Molina NuñezCopyright:

Available Formats

Chapter 4 – Bolted Connections

Discussion:

I. Types of Bolts

1. Unfinished Bolt - Known in construction circles by several names—ordinary, common,

machine, or rough—unfinished bolts are characterized chiefly by the rough appearance of

the shank. They are classified by the ASTM as A302 bolts and are made from carbon steels

with stress-strain characteristics similar to those of A-36 steel.

2. High Strength Bolt – Also known as High Strength Friction Grip Bolt (HSFG). They are made

from medium-carbon heat treated steel and from alloy steel and have tensile strengths

greater than those of ordinary bolts. They are designated as A325 and A490 bolts.

II. Types of Bolted Connections

1. Slip-Critical or Friction Type Connection - The high-strength bolt clamps the connected parts

in such a way that the shearing force is resisted by the friction between the parts, not by the

shear on the body of the bolts. This is often denoted on drawings as “SC”

2. Bearing Type Connection - A bolted connection that assumes that shear forces are

transmitted by the bolt bearing against the sides of the holes in the connected material. Often

denote on drawings with an “X”.

III. Sizes and Types of holes for bolts

1. Oversized Holes – they are used in all plies of connection as long as the applied load does not

exceed the allowable slip resistance. They should not be used in bearing type connection.

2. Short-Slotted Holes – they are used regardless of the direction of the applied load if the

permissible slip resistance is larger than the applied force. If the load be applied in a direction

normal to the slot, these holes maybe used in any bearing type connections.

3. Long-Slotted Holes – they are used in only one of the connected parts of friction type or

bearing type connections. For friction type these holes maybe used in any direction but for

bearing type connections the load must be normal to the axis of the slotted holes. If long-

slotted holes are used in an outer ply, they will need to be covered by plate washers.

IV. Types of Bolted Connections

V. Bolted Connection Failure Modes

VI. Minimum Spacing and Edge Distance

VII. Design Shear and Tension Strength of Bolt

∅𝑹𝒏 = ∅𝑭𝒏 𝑨𝒃 𝒇𝒐𝒓 𝑳𝑹𝑭𝑫

𝑹 𝒏 𝑭 𝒏 𝑨𝒃

= 𝒇𝒐𝒓 𝑨𝑺𝑫

𝛀 𝛀

Where

φ = 0.75

Ω = 2.0

Rn = Nominal shear strength or nominal tension strength of the bolt, kN

Fn = Nominal shear stress (Fnv) or nominal tension stress (Fnt), kPa

Ab = Nominal unthreaded body area of bolt, mm 2

VIII. Bearing Strength of Bolt Holes

For NSCP 2015:

1. For a bolt connection with standard, oversized, and short-slotted holes, independent of the

direction of loading, or a long-slotted hole with the slot parallel to the direction of the bearing

force:

i. When deformation at the bolt hole at service load is a design consideration

𝑹𝒏 = 𝟏. 𝟐𝑳𝒄 𝒕𝑭𝒖 ≤ 𝟐. 𝟒𝒅𝒕𝑭𝒖

ii. When deformation at the bolt hole at service load is not a design consideration

𝑹𝒏 = 𝟏. 𝟓𝑳𝒄 𝒕𝑭𝒖 ≤ 𝟑. 𝟎𝒅𝒕𝑭𝒖

2. For a bolt in a connection with long-slotted holes with the slot perpendicular to the direction

of force:

𝑹𝒏 = 𝟏. 𝟎𝑳𝒄 𝒕𝑭𝒖 ≤ 𝟐. 𝟎𝒅𝒕𝑭𝒖

Where

φ = 0.75

Ω = 2.0

d = nominal bolt diameter, mm

Fu = specified minimum tensile strength of the connected material, MPa

Lc = clear distance, in the direction of the force, between the edge of the hole and the edge

of the adjacent hole or edge of the material, mm

t = thickness of connected material

For connections, the bearing resistance shall be taken as the sum of the bearing resistances

of the individual bolts.

For NSCP 2001

Bearing Capacity of Bolts

𝑻 = 𝟏. 𝟐𝑭𝒖 𝒅𝒕

Exercise Problems:

1. A bolted bearing type connection shown in the figure consists of 16 mm x 150 mm steel plates with

22 mm diameter A325 bolts and A572 Grade 50 plate material with standard holes (F y = 345.6 MPa).

Minimum tensile strength Fu = 449.3 MPa. Allowable shearing stress Fv = 207 MPa for bolt threads

excluded from shear plane. Diameter of hole is 3 mm bigger than bolt diameter.

a. Determine the tensile capacity of the bearing

type connection if the bolt threads are excluded

from the shear plane.

b. Determine the tensile capacity of the bearing

type connection if the bolt threads are included

in the shear plane. Allowable shear stress Fv =

145 MPa

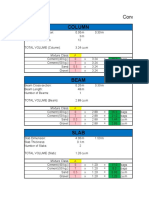

2. Two plates each with thickness t = 16 mm are bolted together with 6-22 diameter bolts forming a

lap connection. Bolt spacing are as follows S 1 = 40 mm, S2 = 80 mm, S3 = 100 mm.

Bolt hole diameter = 25 mm

Allowable stress:

Shear stress of the bolt: Fv = 120 MPa

Tensile strength Fu = 400 MPa

Calculate the permissible tensile load P under the

following conditions.

a. Based on shear capacity of bolts.

b. Based on bearing capacity of bolts.

c. Based on block shear strength.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Investigation 11B: Inelastic CollisionsDocument4 pagesInvestigation 11B: Inelastic CollisionsNIVALE BAXENDELLNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spooky Tesla Spirit Radio - 17 Steps (With Pictures) - InstructablesDocument53 pagesSpooky Tesla Spirit Radio - 17 Steps (With Pictures) - InstructablesMsuttonNo ratings yet

- Chapter One - Introduction To Steel StructuresDocument8 pagesChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezNo ratings yet

- Chapter 3 - Engineering ManagementDocument6 pagesChapter 3 - Engineering ManagementJohn Philip Molina NuñezNo ratings yet

- Chapter 5 - Engineering ManagementDocument5 pagesChapter 5 - Engineering ManagementJohn Philip Molina NuñezNo ratings yet

- Chapter 4 - Engineering ManagementDocument5 pagesChapter 4 - Engineering ManagementJohn Philip Molina NuñezNo ratings yet

- Chapter 2 - Engineering ManagementDocument6 pagesChapter 2 - Engineering ManagementJohn Philip Molina NuñezNo ratings yet

- Column: Concrete EstimatorDocument19 pagesColumn: Concrete EstimatorJohn Philip Molina NuñezNo ratings yet

- Exercise 4 (2nd Sem)Document11 pagesExercise 4 (2nd Sem)Jan VegaNo ratings yet

- CT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncDocument3 pagesCT-1205C-SMT Datasheet - MAGNETIC BUZZER INDICATOR - CUI IncrstramirezNo ratings yet

- TS TT TU TV: Paragon Twin Screw CompressorsDocument16 pagesTS TT TU TV: Paragon Twin Screw Compressorsfernando lopesNo ratings yet

- Calibres ETA 775xDocument42 pagesCalibres ETA 775xRoberto CalveloNo ratings yet

- Namma Kalvi 11th Maths Book Back and Creative Questions em 219385Document209 pagesNamma Kalvi 11th Maths Book Back and Creative Questions em 219385Think BetterNo ratings yet

- Rocket PropulsionDocument29 pagesRocket PropulsionPrajwal Vemala Jagadeeshwara100% (1)

- Quick Start Guide - ATV212: Check The Delivery of The DriveDocument4 pagesQuick Start Guide - ATV212: Check The Delivery of The DriveDella Ayu OktaNo ratings yet

- Lab Report 4 MM322Document6 pagesLab Report 4 MM322JnrNo ratings yet

- Csir - Net - JRF Physical SCIENCEDocument58 pagesCsir - Net - JRF Physical SCIENCEmpsing1133No ratings yet

- Esr 2818 PowersDocument16 pagesEsr 2818 PowersmurdicksNo ratings yet

- Gear TrainDocument26 pagesGear Trainraaz1007No ratings yet

- Four Step Rule and Formulas For DifferentiationDocument7 pagesFour Step Rule and Formulas For DifferentiationRosanna RosalesNo ratings yet

- 201 Lab 7. Work and EnergyDocument9 pages201 Lab 7. Work and EnergydermaNo ratings yet

- Companion ASME Vol. III-ch1Document22 pagesCompanion ASME Vol. III-ch1Siddhartha GaubaNo ratings yet

- Assignment 1 PDFDocument1 pageAssignment 1 PDFHarjot SinghNo ratings yet

- SsovgasvalvesDocument12 pagesSsovgasvalvesTin Aung KyiNo ratings yet

- THU-002-Michel Ravers, Kaneka Belgium NVDocument19 pagesTHU-002-Michel Ravers, Kaneka Belgium NVŞafakNo ratings yet

- P-Block Elements and Their Compounds - I: Module - 6Document33 pagesP-Block Elements and Their Compounds - I: Module - 6TeachingTrainingCoaching KnowledgeSharingSessionNo ratings yet

- Illuminated Assessment Cabinet Colorbox: Product DescriptionDocument2 pagesIlluminated Assessment Cabinet Colorbox: Product DescriptionFany BacNo ratings yet

- Datasheet Water Level Sensor V1Document3 pagesDatasheet Water Level Sensor V1Adamas BagasNo ratings yet

- Science 7 - Q1 To Q4Document4 pagesScience 7 - Q1 To Q4Romne Ryan PortacionNo ratings yet

- ESAB Rebel EMP 215icDocument4 pagesESAB Rebel EMP 215icEDUARDO ALCANTARA JRNo ratings yet

- 40QB/QD Series: Floor Standing Split SystemDocument2 pages40QB/QD Series: Floor Standing Split SystemalexmilarNo ratings yet

- Cutler Hammer 1MCB1000R BrochureDocument42 pagesCutler Hammer 1MCB1000R BrochureHoku's NickNo ratings yet

- A New Model of Thermal Conductivity For LiquidsDocument5 pagesA New Model of Thermal Conductivity For LiquidsJosemar Pereira da SilvaNo ratings yet

- Daftar Harga LampuDocument14 pagesDaftar Harga LampuGallery MediaNo ratings yet

- Product Specification: LanguageDocument22 pagesProduct Specification: LanguageCharles BernabéNo ratings yet

- SEMI-circular ArchDocument5 pagesSEMI-circular ArchQeemi QeemiNo ratings yet