Professional Documents

Culture Documents

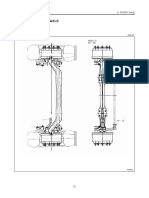

Instruction For Removal and Installation of Brake Assembly and Air Gap Adjustments

Uploaded by

ivan ivanaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction For Removal and Installation of Brake Assembly and Air Gap Adjustments

Uploaded by

ivan ivanaCopyright:

Available Formats

Instruction

For removal and installation of brake assembly

And air gap adjustments.

I. Air gap adjustment

As a result of brake wear during operation, upon replacement of brake assembly or some of its parts such

as the magnetic core (pos.4) or fan disc (pos.8), air gap adjustment between the magnetic core (pos.4) and

the anchor (position 6) shall be performed.

The air gap shall not exceed 0.8 mm.

Regular checks and adjustment after every 100000 cycles of operation is recommended, or at least once

annually.

The factory setting of the distance between core (pos.4) and anchor (pos. 6) is within 0.3 mm - 0.5 mm.

Attention: Before attempting any check or adjustment of the brake turn off motor power supply.

1. Unwind the screws (pos.1) and remove motor fan cover (pos.12);

2. Check the fan (pos.8) for brake lining wear (pos.7). If its thickness is less than 1 mm, replace the fan.

3. Using feeler gauge, check the air gap between the core (pos.4) and anchor (pos.6) at four points at 90 °

along the anchor circumference.

The results of the measurements shall be within 0.3mm - 0.8mm.

If not, make the following adjustments:

1. 1. Unwind the safety screw (pos.10) of the special nut (pos.9).

2. The air gap is adjusted by slightly winding or unwinding the special nut (pos.9). Check again if the space

between the core (pos.4) and the anchor (pos.6) is within 0.3 mm - 0.5 mm. If so, secure the special nut

against self-unwinding by winding the safety screw.

3. Place the fan cover (pos.12) and tighten the screws (pos.1).

II. Dismantling the brake assembly

Attention: Before attempting any check or adjustment of the brake turn off motor power supply.

1. Unwind the screws (pos.1) and remove the motor fan cover (pos.12);

2. Unwind the safety screw (pos.10) of the special nut (pos.9).

3. Unscrew the special nut (pos.9);

4. Carefully remove the brake fan with the lining (pos.8);

5. Remove carefully the anchor (pos.6);

6. Remove the springs (pos.11);

7. Disconnect and remove the cable [3] feeding the magnet [4] from the motor terminal box.

8. Unscrew and remove the bolts (pos.5) fixing the core (pos.6) to the rear bearing shield of the

motor .

Thus, brake assembly consisting of special nut, fan with lining, anchor, springs, magnet, and screws with

hexagon socket for attaching the magnet to the rear shield of the motor is dismantled..

Change brake unit with a new one, or replace damaged parts only, and assemble in reverse order.

III. Assembly of brake unit

1. Mount the magnet (pos.4) to the rear shield of the motor by winding the screws (pos.5);

Attention: The screws must be secured against self-unwinding with medium strength thread

protector, such as Loctite 243 for example.

2. Place the springs (pos.11) into the holes of the magnet;

You might also like

- Section 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModelDocument10 pagesSection 1.13 Gear Case Exhaust Gas Recirculation (EGR) ModeldanyNo ratings yet

- Corolla 1.8 - 1Document4 pagesCorolla 1.8 - 1Diego496No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Suzuki GSX-R1000 2005-2006Document6 pagesSuzuki GSX-R1000 2005-2006Mr. TNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Cat 936eDocument5 pagesCat 936eAlberto Ferradás100% (1)

- Engine Manual Rx-8Document326 pagesEngine Manual Rx-8Jose Ignacio Morales Barreda100% (2)

- Ac Compressor ServicingDocument25 pagesAc Compressor Servicingsonny1234100% (1)

- Caterpiller 3508 SettingsDocument11 pagesCaterpiller 3508 SettingsHalit Yalçınkaya88% (16)

- Sturmey Archer Hub TechnicalDocument8 pagesSturmey Archer Hub TechnicalbobnunleyNo ratings yet

- Service - Service Manual Code 950 - 994 - 653Document49 pagesService - Service Manual Code 950 - 994 - 653CristianNo ratings yet

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarNo ratings yet

- Alineacion CatDocument4 pagesAlineacion CatAndrea Zalamea100% (1)

- Direccion Asistida Mazda PDFDocument56 pagesDireccion Asistida Mazda PDFGabriel Balcazar100% (1)

- Ancient Indian ArchitectureDocument86 pagesAncient Indian ArchitectureRishika100% (2)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Document9 pagesFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNo ratings yet

- Fuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Document9 pagesFuel Injection Pump Housing and Governor (New Scroll Fuel System Effective in Production With 10X5411-UP, 45V36536-UP)Hammam al HammamNo ratings yet

- Toyota Matrix L4 2008Document16 pagesToyota Matrix L4 2008Gesco EscobarNo ratings yet

- Awc Src3 Manual. 1Document5 pagesAwc Src3 Manual. 1ghionoiucNo ratings yet

- LymphomaDocument20 pagesLymphomaChairul Adilla Ardy100% (1)

- Nursing Case Study - 1 - (Acs)Document32 pagesNursing Case Study - 1 - (Acs)nidhiNo ratings yet

- Landis System 3200 Software User's ManualDocument135 pagesLandis System 3200 Software User's ManualjoshibocanegraNo ratings yet

- Week 2 Day 1 GRADE 8Document2 pagesWeek 2 Day 1 GRADE 8Anonymous yElhvOhPnNo ratings yet

- Boston Consultancy Group Matrix MM101Document8 pagesBoston Consultancy Group Matrix MM101Gift Simau100% (2)

- Super X Transmission RemovalDocument29 pagesSuper X Transmission RemovallNo ratings yet

- Clutch ManualDocument16 pagesClutch ManualCO BDNo ratings yet

- TR Service Manual Compresor Sanden PDFDocument7 pagesTR Service Manual Compresor Sanden PDFAnthony PozoNo ratings yet

- Group 10 Rear AxleDocument42 pagesGroup 10 Rear AxleTaha RdmanNo ratings yet

- Bullet 4 Speed Clutch Dismantling and ReassemblingDocument4 pagesBullet 4 Speed Clutch Dismantling and ReassemblingJon SmithNo ratings yet

- Timing Belt: Service and Repair Timing Belt Removal and InstallationDocument3 pagesTiming Belt: Service and Repair Timing Belt Removal and InstallationJosé Carlos da silvaNo ratings yet

- Meritor Spindle NutDocument5 pagesMeritor Spindle NutPhrag MannsteinNo ratings yet

- 11susp. Tras y Parte Trasera Suzuki IntruderDocument22 pages11susp. Tras y Parte Trasera Suzuki Intruderbenjapana100% (2)

- Ont Axle 2 PDFDocument34 pagesOnt Axle 2 PDFFrezgi BirhanuNo ratings yet

- 4 Wheel DriveDocument43 pages4 Wheel DriveSelmirije2No ratings yet

- Tilton 98-1231 MC Rebuild KitDocument1 pageTilton 98-1231 MC Rebuild KitHaruki Tavares TutiaNo ratings yet

- Suzuki GSX-R1000 2009-2010Document6 pagesSuzuki GSX-R1000 2009-2010Mr. TNo ratings yet

- خطوات فك عمودمولد جي ايهDocument7 pagesخطوات فك عمودمولد جي ايهخالدNo ratings yet

- Section 10 - Power Take-OffDocument19 pagesSection 10 - Power Take-OffMiller Andres ArocaNo ratings yet

- Propeller ShaftDocument13 pagesPropeller Shaftmika DataNo ratings yet

- Military 14 Bolt Axle ManualDocument29 pagesMilitary 14 Bolt Axle ManualCAP History Library67% (6)

- WEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishDocument2 pagesWEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishadalcomjesusNo ratings yet

- Overhauling The Flywheel CoverDocument1 pageOverhauling The Flywheel CoverIanNo ratings yet

- Cat3512camshaft TimingDocument4 pagesCat3512camshaft TimingEfrain FlorezNo ratings yet

- Sti Timing Belt InstructionsDocument19 pagesSti Timing Belt InstructionsPablo DpNo ratings yet

- Cancerul de Col UterinDocument16 pagesCancerul de Col UterinAndreiNo ratings yet

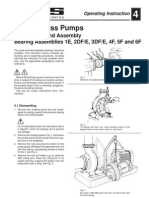

- ABS Process Pumps: Dismantling and Assembly Bearing Assemblies 1E, 2DF/E, 3DF/E, 4F, 5F and 6FDocument8 pagesABS Process Pumps: Dismantling and Assembly Bearing Assemblies 1E, 2DF/E, 3DF/E, 4F, 5F and 6FHector Eduardo Fernandez VarelaNo ratings yet

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- Timing Belt: 2000 Acura Integra GS Coupe L4 1.8L Dohc MfiDocument10 pagesTiming Belt: 2000 Acura Integra GS Coupe L4 1.8L Dohc MfiVicctor PiñaNo ratings yet

- Reductor Llantas Ro-56Document39 pagesReductor Llantas Ro-56DavidNo ratings yet

- Torque Converter, Transmission and Transfer GearsDocument4 pagesTorque Converter, Transmission and Transfer GearschanlinNo ratings yet

- Focus C Max 16 Ti Timing Belt Fitting GuideDocument2 pagesFocus C Max 16 Ti Timing Belt Fitting GuideRiyadh BoucennaNo ratings yet

- 5379X 5382X Diff Rebuild 0Document2 pages5379X 5382X Diff Rebuild 0coldtotouchNo ratings yet

- Sci Mop Bombas Espuma Cgp80 - ChemguardDocument13 pagesSci Mop Bombas Espuma Cgp80 - Chemguarddiuska13No ratings yet

- 5 Differential PTO Assembly RepairDocument17 pages5 Differential PTO Assembly RepairfirinmusaNo ratings yet

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocument8 pages2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNo ratings yet

- AA03118 - Torqueo de CauchosDocument4 pagesAA03118 - Torqueo de CauchosJose A. Basanta H.No ratings yet

- Steering Gear Manual Rack and PinionDocument4 pagesSteering Gear Manual Rack and PinionJeferson SilvaNo ratings yet

- 2005 Volkswagen PASSAT: - L4 - 1.8 FI - GASDocument4 pages2005 Volkswagen PASSAT: - L4 - 1.8 FI - GASRussell Leon LoydNo ratings yet

- Isc 300Document37 pagesIsc 300AwanNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Spec Sheet For Forklift Boom 3638T24Document3 pagesSpec Sheet For Forklift Boom 3638T24ivan ivanaNo ratings yet

- MGV25S: Gearless Type Traction Sheave (MM) Dimensions (MM) Ø D F A B C E MGV25SDocument7 pagesMGV25S: Gearless Type Traction Sheave (MM) Dimensions (MM) Ø D F A B C E MGV25Sivan ivanaNo ratings yet

- Analysis and Optimization Design of Welded I-Girder of The Single-Beam Bridge CraneDocument7 pagesAnalysis and Optimization Design of Welded I-Girder of The Single-Beam Bridge Craneivan ivanaNo ratings yet

- 19 2610 PDFDocument1 page19 2610 PDFivan ivanaNo ratings yet

- UputstvoDocument1 pageUputstvoivan ivanaNo ratings yet

- Newer Version Already InstalatedDocument1 pageNewer Version Already Instalatedivan ivanaNo ratings yet

- PS3 Sampleqs Soln PDFDocument9 pagesPS3 Sampleqs Soln PDFivan ivanaNo ratings yet

- BP Valjci PDFDocument20 pagesBP Valjci PDFivan ivanaNo ratings yet

- Formal Language and Automata TheoryDocument18 pagesFormal Language and Automata TheoryAyan DuttaNo ratings yet

- Imran Index 1Document11 pagesImran Index 1api-387022302No ratings yet

- Pakistan: Nation-State, State-Nation or Multinational State?Document12 pagesPakistan: Nation-State, State-Nation or Multinational State?Asif KhanNo ratings yet

- Literature Review of Centella AsiaticaDocument6 pagesLiterature Review of Centella Asiaticaea3vk50y100% (1)

- CHED - NYC PresentationDocument19 pagesCHED - NYC PresentationMayjee De La CruzNo ratings yet

- Embedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GDocument4 pagesEmbedded Modules: Pci Express Minicard and Lga Modules High-Speed Multi-Mode 3GYaSeregaNo ratings yet

- Finalizing The Accounting ProcessDocument2 pagesFinalizing The Accounting ProcessMilagro Del ValleNo ratings yet

- Database NotesDocument4 pagesDatabase NotesKanishka SeneviratneNo ratings yet

- Review of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Document2 pagesReview of The Householder's Guide To Community Defence Against Bureaucratic Aggression (1973)Regular BookshelfNo ratings yet

- Ernst Bloch Principle of Hope PDFDocument2 pagesErnst Bloch Principle of Hope PDFAdamNo ratings yet

- 24 - Mubangizi-WHOPQP GMP Inspections UpdatesDocument17 pages24 - Mubangizi-WHOPQP GMP Inspections UpdatessamxuNo ratings yet

- Bourbon Explorer 500 Series Commercial LeafletDocument6 pagesBourbon Explorer 500 Series Commercial LeafletDaniel ZhangNo ratings yet

- 2CSE60E14: Artificial Intelligence (3 0 4 3 2) : Learning OutcomesDocument2 pages2CSE60E14: Artificial Intelligence (3 0 4 3 2) : Learning OutcomesB. Srini VasanNo ratings yet

- Industrial Development Economic Growth in Andhra PradeshDocument9 pagesIndustrial Development Economic Growth in Andhra PradeshMurali Krishna ReddyNo ratings yet

- Geometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewDocument3 pagesGeometry Sparkcharts Geometry Sparkcharts: Book Review Book ReviewAyman BantuasNo ratings yet

- Chapter 3 - Instructional PlanningDocument30 pagesChapter 3 - Instructional PlanningMadelyne BenitezNo ratings yet

- Management of Developing DentitionDocument51 pagesManagement of Developing Dentitionahmed alshaariNo ratings yet

- Economic GrowthDocument15 pagesEconomic GrowthANJULI AGARWALNo ratings yet

- Caps 5Document4 pagesCaps 5shheNo ratings yet

- Login ManagerDocument17 pagesLogin ManagerMahakaal Digital PointNo ratings yet

- The Awakened Goat: Playable RaceDocument2 pagesThe Awakened Goat: Playable RacePJ FlandersNo ratings yet

- Dr. Shikha Baskar: CHE154: Physical Chemistry For HonorsDocument22 pagesDr. Shikha Baskar: CHE154: Physical Chemistry For HonorsnishitsushantNo ratings yet

- EBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFDocument44 pagesEBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFYaw Antwi-AddaeNo ratings yet

- Fender Re-Issue 62 Jazzmaster Wiring DiagramDocument1 pageFender Re-Issue 62 Jazzmaster Wiring DiagrambenitoNo ratings yet