Professional Documents

Culture Documents

Fault Code 800116 Hydraulic Temperature High 2017

Fault Code 800116 Hydraulic Temperature High 2017

Uploaded by

Justice MachiwanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fault Code 800116 Hydraulic Temperature High 2017

Fault Code 800116 Hydraulic Temperature High 2017

Uploaded by

Justice MachiwanaCopyright:

Available Formats

SANDVIK MOBILE CRUSHERS & SCREENS

FAULT CODE 800116 HYDRAULIC TEMPERATURE HIGH

1 Hydraulic temp high SL 8 4 2020

Rev 2 – 01-10-18

SAFETY FIRST

Sandvik‘s objective is zero harm to our

people, the environment we work in,

our customers and our suppliers.

PROTECTIVE FIRST AID

ALARM

EQUIPMENT KIT

EMERGENCY EMERGENCY ASSEMBLY

NUMBER EXIT POINT

PSYCHOLOGICAL

SAFETY

2 Hydraulic temp high SL 8 4 2020

GLOBAL INTERNAL CONTROLS

Control leads to

The Way We All Operate compliance !

Ensure

compliance

We all need to

with all relevant

be compliant

internal and

external rules

and regulation

Conducting

business with

‘Power of ethics and

Sandvik’ are integrity

the guidelines

for all

employees

3 Hydraulic temp high SL 8 4 2020

QUALITY FOCUS

ZERO DEFECTS TO CUSTOMER

Sandvik aims to be THE preferred and

recurrent supplier in Mobile Crushing and

Screening

4 Hydraulic temp high SL 8 4 2020

HEALTH AND SAFETY

5 Hydraulic temp high SL 8 4 2020

FAULT CODE 800116 HYDRAULIC TEMPERATURE HIGH

SYSTEM LOGIC 2017

Hydraulic temperature

Error code Error message Description Action

116 Hydraulic oil temp High Hydraulic temp high Engine shutdown

6 Hydraulic temp high SL 8 4 2020

FAULT CODE 800116 HYDRAULIC TEMPERATURE HIGH

COMPONENT LOCATION

Hydraulic Oil Temperature Sensor

Mounted the hydraulic tank, this sensor monitors the

temperature of the oil during operation.

7 Hydraulic temp high SL 8 4 2020

FAULT CODE 800116 HYDRAULIC TEMP WARNING

HOW TO BYPASS SENSORS

Tip Grid Setting Sensor Bypass

Screen Enable/Disable

(QA Only)

Sensor Selection

Time & Date Settings Advance/Next

(Move Right)

Page 2 Sensor Selection

Pressure Sensors Previous

(Move Left)

Hydraulic temperature

ESC OK

SANDVIK:Hydraulic temperature warning SL 8 4 2020

8

Scroll Sensor Set Points Adjust Sensor Set Points

FAULT CODE 800116 HYDRAULIC TEMP WARNING

Icon

HOW TO BYPASS SENSORS White – Active

Red - Disabled

Sensor Enable/Disable

Sensor Selection

(Scrolls along shown sensors)

Sensor Bypass

In the event that a sensor is not fitted to a particular model or becomes

damaged during machine operation, the sensor may be bypassed to allow the

machine to continue processing.

To do this, firstly select the desired sensor by pressing the middle right button

(the top right icon will change highlighting the sensor selected).

Then using the top right hand button, deactivate the sensor (selection

Stockpile Sensor displayed as icon next to button).

Note; the icon will turn red at the top right of the display screen when

deactivated by placing the red cross over the selected icon bar charts.

Belt Speed Sensor

Hydraulic Temperature Sensor

9 SANDVIK:Hydraulic temperature warning SL 8 4 2020

FAULT CODE 800116 HYDRAULIC TEMP WARNING

COMPONENT TESTING 2017

• Check the operation of the Oil Cooler and that the

cooler matrix is clean.

• Check the hydraulic circuit for internal leakage

• Pin 1 white and purple wire, Pin 2 Green and brown

wire

• The resistance should be between 4 and 20 mA Or

Pin 20 and 25 of 35pin plug of in out module

• As the oil heats up the current will alter between 4 and 20 mA

• 0’C = 4mA

• 100’C = 20mA

• To test use a thermometer to compare the temperature

displayed on the screen

• Remove the sensor and place in boiling water water the

reading resistance across the sensor should be 20 mA ,

place the sensor in cold water the sensor should be slightly

above 4mA

• Check the wiring to the sensor for damage and replace as

required.

10 SANDVIK: Hydraulic temperature warning SL 8 4 2020

ROCKTECHNOLOGY.SANDVIK

11 Hydraulic temp high SL 8 4 2020

You might also like

- QJ341 HydraulicDocument48 pagesQJ341 HydraulicJustice Machiwana100% (4)

- TrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Document99 pagesTrioTC51 Instruction Manual 20120920 (SN. 316, 320 - 324, 344)Justice Machiwana100% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Qs332 Machine MasterDocument8 pagesQs332 Machine MasterJustice MachiwanaNo ratings yet

- GE Carescape V100 Monitor - Service ManualDocument178 pagesGE Carescape V100 Monitor - Service ManualGIGNo ratings yet

- SINOCARE BP MONITOR AES-U181 User ManualDocument24 pagesSINOCARE BP MONITOR AES-U181 User ManualNell Almazan100% (1)

- SW-65A-0316-00 SW-65A - EngishDocument20 pagesSW-65A-0316-00 SW-65A - Engishmani nadar100% (1)

- 19 - Practice Exercise 2.3 - AnswerDocument2 pages19 - Practice Exercise 2.3 - AnswerCARL WENDELL BAYOCOT100% (1)

- Ficha Técnica Eli-FlexDocument2 pagesFicha Técnica Eli-FlexGhislaine SousaNo ratings yet

- RENASYS GO Service Manual PI03899 Final 1374229048Document24 pagesRENASYS GO Service Manual PI03899 Final 1374229048Huy Trần ThiệnNo ratings yet

- METTLER - Toledo Seven2Go S2-S8 - CatalogDocument4 pagesMETTLER - Toledo Seven2Go S2-S8 - CatalogDao Quang AiNo ratings yet

- Inventory Stocktake Procedure (FMPM)Document16 pagesInventory Stocktake Procedure (FMPM)Justice Machiwana100% (1)

- 703US-0002 Blood Pressure MonitorDocument15 pages703US-0002 Blood Pressure Monitorwwwkajtek797No ratings yet

- Cyclops L User Guide - Issue 1 (23-05-2014) LRDocument76 pagesCyclops L User Guide - Issue 1 (23-05-2014) LRFerec XalikovNo ratings yet

- Raw Cashew Moisture Tester: Operating ManualDocument24 pagesRaw Cashew Moisture Tester: Operating ManualSIVARAMANJAGANATHANNo ratings yet

- Cyclops L User GuideDocument74 pagesCyclops L User Guidealbert RNo ratings yet

- 01 Industrial Automation ControllersDocument29 pages01 Industrial Automation ControllersNirjhar BhatnaagarNo ratings yet

- Omni - VSDocument2 pagesOmni - VSalexanderNo ratings yet

- 33-0019 6002 CIE User ManualDocument20 pages33-0019 6002 CIE User ManualEmilioGastónNo ratings yet

- 3 2 7manualDocument12 pages3 2 7manualpuri ghibahNo ratings yet

- Manual Termometro Infrarrojo Klein Tools IR5Document17 pagesManual Termometro Infrarrojo Klein Tools IR5Pablo Orellana TapiaNo ratings yet

- Presentation - InstrumentationDocument57 pagesPresentation - Instrumentationmahesh4975No ratings yet

- Covidien Bed SIde Spo2 Monitoring SystemDocument2 pagesCovidien Bed SIde Spo2 Monitoring SystemShriji HealthcareNo ratings yet

- Vibration Meter Model VB450: User GuideDocument7 pagesVibration Meter Model VB450: User GuideManuel Morales EncinasNo ratings yet

- WS Datasheet 150 ControllerDocument2 pagesWS Datasheet 150 ControllerfranssoafourieNo ratings yet

- Manual Riken Keiki SD-1Document17 pagesManual Riken Keiki SD-1Pablo ZapateroNo ratings yet

- Medidor de Conductividad de MesaDocument112 pagesMedidor de Conductividad de MesaDavid EguezNo ratings yet

- Starter 5000 Bench PH Meter En-11Document84 pagesStarter 5000 Bench PH Meter En-11Celeynes RTNo ratings yet

- FT 63 - Smoke DetectorDocument5 pagesFT 63 - Smoke DetectorDarwin LeònNo ratings yet

- SVM 7200 Life Scope Vital Signs Spec SheetDocument2 pagesSVM 7200 Life Scope Vital Signs Spec Sheetmelek saadiNo ratings yet

- Rishmulti 12s 18sDocument10 pagesRishmulti 12s 18schopadeswapnil859No ratings yet

- 【New Epc】Lsf Qj4149 - 1 (English)Document36 pages【New Epc】Lsf Qj4149 - 1 (English)prachan.nasomNo ratings yet

- Sensor PLCDocument103 pagesSensor PLCapi-3834854100% (2)

- 3300/15 Dual Vibration Monitor: Operation ManualDocument25 pages3300/15 Dual Vibration Monitor: Operation ManualLinh LyNo ratings yet

- Fault Code 800106 Low Engine Oil Pressure 2017Document10 pagesFault Code 800106 Low Engine Oil Pressure 2017Justice MachiwanaNo ratings yet

- General CatalougeDocument176 pagesGeneral CatalougeAshu PrajapatiNo ratings yet

- Control Method For Temperature: Panel CutoutDocument2 pagesControl Method For Temperature: Panel CutoutThuyên NguyễnNo ratings yet

- Octave V4 Installation Manual Rev02 English August 2017Document16 pagesOctave V4 Installation Manual Rev02 English August 2017Randy De PedroNo ratings yet

- 01.SP2nd Manual v2.2 EnglishDocument19 pages01.SP2nd Manual v2.2 EnglishSijo JoyNo ratings yet

- CMCP620V (T) ManualDocument22 pagesCMCP620V (T) ManualbottiotherNo ratings yet

- Independence User Manual DNADocument64 pagesIndependence User Manual DNAJafar JilaniNo ratings yet

- Ds 212Document24 pagesDs 212M. SalmanNo ratings yet

- Masibus Vibration Meter Vm908Document2 pagesMasibus Vibration Meter Vm908Govindarajan ChandrasekaranNo ratings yet

- Teledyne Oil in Water Analyzer Operating Instruction PDFDocument46 pagesTeledyne Oil in Water Analyzer Operating Instruction PDFKarthik BNo ratings yet

- Pruftechnik Rotalign Touch Operation User S Manual 30Document30 pagesPruftechnik Rotalign Touch Operation User S Manual 30hrstga100% (1)

- Buku Manual (Inggris)Document15 pagesBuku Manual (Inggris)Surta DevianaNo ratings yet

- Philips - LCD - 215vw9 - Envision - p851 Manual Service PDFDocument53 pagesPhilips - LCD - 215vw9 - Envision - p851 Manual Service PDFcarlosavictoriaNo ratings yet

- Hilti PD 4 Laser Range MeterDocument15 pagesHilti PD 4 Laser Range MeterRaman IyerNo ratings yet

- Liftlog 1000: TitleDocument26 pagesLiftlog 1000: TitleJONHHY NGUYEN DANGNo ratings yet

- Food Service Infrared Thermometer: Instruction ManualDocument12 pagesFood Service Infrared Thermometer: Instruction ManualVincent LecoursNo ratings yet

- Tende Vav-Iw Brochure-EnDocument4 pagesTende Vav-Iw Brochure-EnhassanmohachiNo ratings yet

- Driver Safety Awareness and Assistance SDocument6 pagesDriver Safety Awareness and Assistance SArvin Dexter De CastroNo ratings yet

- Benchtop Conductivity Meter 70 Series Laqua Instruction ManualDocument16 pagesBenchtop Conductivity Meter 70 Series Laqua Instruction Manualsan san moeNo ratings yet

- Rsud Bhakti Dharma Husada Surabaya Lembar Kerja Inspeksi Dan Pemeliharaan (Preventive Maintenance)Document1 pageRsud Bhakti Dharma Husada Surabaya Lembar Kerja Inspeksi Dan Pemeliharaan (Preventive Maintenance)Dodik E. PrasetyoNo ratings yet

- Brochure Valve-Sense ExDocument15 pagesBrochure Valve-Sense Expruttipong.cNo ratings yet

- V100 目錄含規格spec (標案)Document6 pagesV100 目錄含規格spec (標案)許善智No ratings yet

- 3b Sentry - ControllerDocument4 pages3b Sentry - Controllerpabloperezmtz1No ratings yet

- Mud System SensorsDocument14 pagesMud System SensorsMohamad TayeaNo ratings yet

- Line of Sight Remote Control PDFDocument24 pagesLine of Sight Remote Control PDFJose Luis Arroyo MauricioNo ratings yet

- Patent Health Monitoring System 1Document19 pagesPatent Health Monitoring System 1imtiaj.amadershomoyNo ratings yet

- Conductimetyro PDFDocument14 pagesConductimetyro PDFFrancia PulgarinNo ratings yet

- 2004 LegacyDocument28 pages2004 LegacyMVPNo ratings yet

- EC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCDocument8 pagesEC20 Pocket Conductivity Tester Instruction Manual: Apera Instruments, LLCThomas GalindoNo ratings yet

- Multisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsFrom EverandMultisensor Instrumentation 6σ Design: Defined Accuracy Computer-Integrated Measurement SystemsNo ratings yet

- Bangs - History of Methodist Church Vol 1Document298 pagesBangs - History of Methodist Church Vol 1Justice MachiwanaNo ratings yet

- Inspecting The BushingDocument1 pageInspecting The BushingJustice MachiwanaNo ratings yet

- Tract 21 Tabernacle 6-22 RevDocument1 pageTract 21 Tabernacle 6-22 RevJustice MachiwanaNo ratings yet

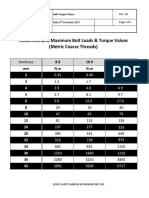

- 16 - Torque Chart BoltDocument1 page16 - Torque Chart BoltJustice MachiwanaNo ratings yet

- 17 - Dcn8015enDocument4 pages17 - Dcn8015enJustice MachiwanaNo ratings yet

- Adventist SongsDocument36 pagesAdventist SongsJustice MachiwanaNo ratings yet

- QJ341 Standard OpDocument16 pagesQJ341 Standard OpJustice MachiwanaNo ratings yet

- MS Word Assignment Question - OlympicsDocument1 pageMS Word Assignment Question - OlympicsJustice MachiwanaNo ratings yet

- QJ341 OperationsDocument250 pagesQJ341 OperationsJustice Machiwana100% (1)

- Manual InstallationDocument19 pagesManual InstallationJustice MachiwanaNo ratings yet

- QA451Document242 pagesQA451Justice MachiwanaNo ratings yet

- CRSH-OI-0004ENG TC-Series Cone Crushers Operation Instruction Manual - NOV2012Document72 pagesCRSH-OI-0004ENG TC-Series Cone Crushers Operation Instruction Manual - NOV2012Justice Machiwana100% (1)

- TC 51 PressureDocument1 pageTC 51 PressureJustice MachiwanaNo ratings yet

- DB460 Use & Maintenance ManualDocument252 pagesDB460 Use & Maintenance ManualJustice MachiwanaNo ratings yet

- Operation and Maintenance ManualDocument290 pagesOperation and Maintenance ManualJustice Machiwana100% (1)

- TC51SC Cone Crusher Parts Manual TC51-441-AU1156Document31 pagesTC51SC Cone Crusher Parts Manual TC51-441-AU1156Justice Machiwana100% (1)

- QH Red Code 110 DEF Level CriticalDocument7 pagesQH Red Code 110 DEF Level CriticalJustice MachiwanaNo ratings yet

- Toggle SystemDocument4 pagesToggle SystemJustice MachiwanaNo ratings yet

- QH Red Code 114 Fines Conveyor Speed CriticalDocument16 pagesQH Red Code 114 Fines Conveyor Speed CriticalJustice Machiwana100% (1)

- Manual User Series NzsDocument140 pagesManual User Series NzsJustice MachiwanaNo ratings yet

- QH Red Code 101 Machine Stop PressedDocument12 pagesQH Red Code 101 Machine Stop PressedJustice Machiwana100% (1)

- Phys1122 202200Document8 pagesPhys1122 202200Amritraj DashNo ratings yet

- Checklist For Valve Spec PDFDocument1 pageChecklist For Valve Spec PDFJAVID TAJHIZ MAHANNo ratings yet

- MC111 Piping Vibration D FrikkenDocument4 pagesMC111 Piping Vibration D FrikkenHerdiana KristiNo ratings yet

- Structural Analysis ProjDocument13 pagesStructural Analysis ProjVigo 89No ratings yet

- UAV Thermal Imaging For Unexploded Ordnance DetectDocument19 pagesUAV Thermal Imaging For Unexploded Ordnance DetectTrịnh Doãn TúNo ratings yet

- Chiller Performance ParametersDocument3 pagesChiller Performance ParametersMohamad ChaudhariNo ratings yet

- Chapter 4 Tasks - Essential Questions Group 3Document12 pagesChapter 4 Tasks - Essential Questions Group 3Sofiah Marshialyn PepitoNo ratings yet

- SOURSERVICE 4v 1210Document8 pagesSOURSERVICE 4v 1210LucasNo ratings yet

- C-P-T Fractionalization by Juven WangDocument8 pagesC-P-T Fractionalization by Juven WangAnonymous 4wofkS90XTNo ratings yet

- Linear Time Invariant (LTI) Systems: Level-1Document18 pagesLinear Time Invariant (LTI) Systems: Level-1kalyanNo ratings yet

- Membrane System Design For Multicomponent Gas Mixtures Via MINLP (Qi and Henson) - 00Document19 pagesMembrane System Design For Multicomponent Gas Mixtures Via MINLP (Qi and Henson) - 00Bima SetyaputraNo ratings yet

- Estimation TheoryDocument8 pagesEstimation Theoryemma698No ratings yet

- Feb 5th, Fatigue Failure & Dynamic Loading - Part 1 PDFDocument74 pagesFeb 5th, Fatigue Failure & Dynamic Loading - Part 1 PDFTrentNo ratings yet

- Final-Report-On-Internship Namuna-ThapaliyaDocument20 pagesFinal-Report-On-Internship Namuna-ThapaliyaMorning KalalNo ratings yet

- Complete SOM ESE Mains 2021 Study Material With Video Lectures Mechanical & CivilDocument94 pagesComplete SOM ESE Mains 2021 Study Material With Video Lectures Mechanical & CivilNaveenYadavNo ratings yet

- INAO Problems 2008-2014Document151 pagesINAO Problems 2008-2014Science Olympiad Blog100% (5)

- Thermo-Economic and Exergy Assessment and Optimization of Performance of A Hydrogen Production System by Using Geothermal EnergyDocument20 pagesThermo-Economic and Exergy Assessment and Optimization of Performance of A Hydrogen Production System by Using Geothermal Energyjoasobral100% (1)

- (UPOU) PHYSICS Pre-TestDocument14 pages(UPOU) PHYSICS Pre-TestMon Belle AmourNo ratings yet

- ENR301 Experiment 2: Specific Heat: Student Number: 21811522Document11 pagesENR301 Experiment 2: Specific Heat: Student Number: 21811522alibeneshaqNo ratings yet

- NotesPart1 myTUTorDocument161 pagesNotesPart1 myTUTorMpho PopsNo ratings yet

- ENG Sir Chandrasekhara Venkata Raman An Illuminating LifeDocument86 pagesENG Sir Chandrasekhara Venkata Raman An Illuminating LifePreeti ChaudhryNo ratings yet

- The Influence of Temperature On Breakdown VoltageDocument9 pagesThe Influence of Temperature On Breakdown Voltagezona amrullohNo ratings yet

- Lelm 404Document26 pagesLelm 404Arohan BuddyNo ratings yet

- Fiziks: Forum For Csir-Ugc Jrf/Net, Gate, Iit-Jam, Gre in Physical SciencesDocument12 pagesFiziks: Forum For Csir-Ugc Jrf/Net, Gate, Iit-Jam, Gre in Physical SciencesAryA JackNo ratings yet

- The Elements of Realistic Drawing Ebook From The Drawing Source PDFDocument52 pagesThe Elements of Realistic Drawing Ebook From The Drawing Source PDFyassine mafrax100% (1)

- Research Paper On Solid MechanicsDocument8 pagesResearch Paper On Solid Mechanicsfvg4bacd100% (1)

- IB Physics - Formulae Not in The Data BokletDocument8 pagesIB Physics - Formulae Not in The Data BokletLaurus NagNo ratings yet

- The Particle Nature of Matter. Home Work Solutions: 4.1 Problem 4.10 (In The Text Book)Document12 pagesThe Particle Nature of Matter. Home Work Solutions: 4.1 Problem 4.10 (In The Text Book)Dhias Pratama LazuarfyNo ratings yet