Professional Documents

Culture Documents

What Is Process Engineering

Uploaded by

mulerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is Process Engineering

Uploaded by

mulerCopyright:

Available Formats

What is Process Engineering?

Process engineering is a complex and continuously changing field – so it

can be quite difficult to understand exactly what a process engineer does

on a day-to-day basis. However, it’s all in the name!

Process engineers are responsible for the design, implementation, control, and

optimisation of industrial processes. In this article, we’ll take a deep look at

process engineering, and discuss everything you need to know about this

field. From the basics about what process engineering is, to typical industries

served by process engineering companies, job responsibilities, tools used and

much more.

Process engineering, as touched upon above, is a field that’s primarily

interested in processes – especially continuous processes within the chemical,

agricultural, petrochemical, mineral food, and pharmaceutical industries.

Process engineering is the means by which raw materials are turned into some

kind of end product or commodity. Process engineers are responsible for

designing the processes that allow for the creation of some kind of product –

as well as their optimisation to ensure that there is minimal waste during the

process, and profits are maximised.

To this end, process engineering is a very complex engineering specialisation.

Process engineers must create and develop product specifications, develop

equipment requirements, implement manufacturing strategies, and monitor all

of the processes they develop – to ensure maximum productivity.

These processes vary from simple mechanical processes – such as the

stamping of metal or CNC machining of plastic components – to complex

biochemical reactions, and everything in-between. While process engineers do

develop new, innovative processes for new facilities, they are also often

involved in the analysis, upgrading, and modification/optimisation of

equipment and processes that are already being used by a company.

Process engineering is an inherently cross-departmental discipline. Process

engineers usually must work with people from every sector of the

manufacturing industry – including R&D staff, production personnel,

operations personnel, management, and even customers, in some cases.

What Process Engineers Do – Basic Job Responsibilities

Now that the basics of process engineering have been discussed, it’s time to

explore the roles and responsibilities of process engineers in more detail.

The role of the process engineer will differ in each company, so this is not a

comprehensive list – just a general overview of the different areas of expertise

in which an engineer will be expected to work.

Research and development – Many process engineers spend a large

portion of their time on research and development; finding new

technologies that can enhance current processes, and stimulate higher

productivity in manufacturing.

Simulating new processes with software – Because overhauling a

process is a very expensive and risky task, new processes must be simulated

using advanced software that mimics real-world conditions – ensuring that

a potential process improvement is worth the risk.

Equipment monitoring – Process engineers who are focused on

operations often monitor equipment to ensure that it is functioning

correctly, and running according to the standards they put in place when

designing the process.

Writing and editing documentation – Documentation for all existing

processes must be written up and edited regularly, to ensure that all new

hires and other personnel can understand the best practices and standards

of each individual process.

Risk assessments of current equipment/processes – Process

engineers are responsible for assessing current processes and equipment to

determine risk of malfunction/failure, employee/personnel injury, and much

more.

Continual evaluation of all processes and equipment – Most process

engineers are expected to monitor and evaluate all extant processes and

equipment, and develop more streamlined, economical processes – if at all

possible.

New equipment installation – Senior process engineers are often

responsible for overseeing the installation of new equipment, and making

sure that it is installed according to the process specifications.

Troubleshooting production problems – Engineers often work with

specialist process technicians to resolve issues with production and

processes.

Overseeing processes and operations personnel – Process engineers

in management roles typically have at least some control over the oversight

and management of operations personnel and floor workers.

Data collection/interpretation – Process engineers analyse, collect,

interpret, and compile data–based reports based on data from the

manufacturing floor.

Presentation of data findings – Senior process engineers may be

responsible for presenting and explaining data findings to C-suite executive

and other high-level business personnel.

Budgeting responsibilities – Process engineers may either have input

on the manufacturing budget, or be solely responsible for stay on-budget,

in some cases.

You might also like

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsFrom EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsNo ratings yet

- Structured What If Technique A Complete Guide - 2020 EditionFrom EverandStructured What If Technique A Complete Guide - 2020 EditionNo ratings yet

- TKS 4155 Perancangan Pabrik: General Site ConsiderationsDocument35 pagesTKS 4155 Perancangan Pabrik: General Site ConsiderationsDavid BonjolNo ratings yet

- Project Charter TemplateDocument3 pagesProject Charter TemplateSarvesh DaradeNo ratings yet

- Plant LayoutDocument15 pagesPlant LayoutXyz YxzNo ratings yet

- QA Course TotalDocument32 pagesQA Course Totalafic219473No ratings yet

- Introduction to Document ManagementDocument30 pagesIntroduction to Document Managementbose_lowe11No ratings yet

- Premises As Per GMPDocument15 pagesPremises As Per GMPdivvelaNo ratings yet

- Complete Magnetic Filtration Mini-CatalogDocument19 pagesComplete Magnetic Filtration Mini-Catalog15 FFNo ratings yet

- AACHC Emergency Shutdown Procedures Template 4-25-14Document9 pagesAACHC Emergency Shutdown Procedures Template 4-25-14bertan dağıstanlıNo ratings yet

- Lecture 2 Process Engineering - 2016Document56 pagesLecture 2 Process Engineering - 2016Yazhou ZhouNo ratings yet

- GMP Requirements for Ophthalmic Preparations SeminarDocument57 pagesGMP Requirements for Ophthalmic Preparations Seminarvkguptajss100% (1)

- EIGA (2008) - Comparison of EP, USP & JP For Medicinal GasDocument21 pagesEIGA (2008) - Comparison of EP, USP & JP For Medicinal GashuynhhaichauchauNo ratings yet

- Environmental Control System A Complete Guide - 2020 EditionFrom EverandEnvironmental Control System A Complete Guide - 2020 EditionNo ratings yet

- Oxygen USPDocument2 pagesOxygen USPMartha Lucia Roa FonsecaNo ratings yet

- Validation Master Plan Example - LongDocument31 pagesValidation Master Plan Example - LongJayesh kolheNo ratings yet

- Bioprocessing Technology for Production of Biopharmaceuticals and BioproductsFrom EverandBioprocessing Technology for Production of Biopharmaceuticals and BioproductsClaire KomivesNo ratings yet

- Process Selection Written ReportDocument11 pagesProcess Selection Written Reportkarina gayosNo ratings yet

- GMP Facilities Set Up V2Document17 pagesGMP Facilities Set Up V2FakhriyahNur IbrahimNo ratings yet

- Torbeck, L - Validation With Designed of Experiments (APRESENTAÇÃO)Document39 pagesTorbeck, L - Validation With Designed of Experiments (APRESENTAÇÃO)Luis Gustavo PachecoNo ratings yet

- Pre-job Safety Briefing RequirementsDocument5 pagesPre-job Safety Briefing Requirementsliveconnectionz2820% (1)

- Giz2012 en Comparison of Eu GMP Guidelines With Who Guidelines PDFDocument70 pagesGiz2012 en Comparison of Eu GMP Guidelines With Who Guidelines PDFMr ThanhNo ratings yet

- Mettler Toledo Validation Manual 2Document2 pagesMettler Toledo Validation Manual 2Almir Pepeljak100% (1)

- Reliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsFrom EverandReliability Analysis and Plans for Successive Testing: Start-up Demonstration Tests and ApplicationsNo ratings yet

- Full Proposal Template - Tech Tranfer Simple FormatDocument15 pagesFull Proposal Template - Tech Tranfer Simple FormatSaddam Ali KhanNo ratings yet

- Vial washing for parenteral drugsDocument2 pagesVial washing for parenteral drugsAnas Abandeh100% (1)

- HPF 002 04 Entry and Exit Procedure in CNC Grade D Area and ManufacturingDocument52 pagesHPF 002 04 Entry and Exit Procedure in CNC Grade D Area and ManufacturingDarlenis RodriguezNo ratings yet

- TQM Class NotesDocument7 pagesTQM Class NotesCainan OjwangNo ratings yet

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- Process Validation of Polyherbal Cough Syrup FormulationDocument7 pagesProcess Validation of Polyherbal Cough Syrup FormulationBhavesh NayakNo ratings yet

- Clean RoomDocument16 pagesClean RoomApoloTrevinoNo ratings yet

- Beximco Pharma MGT 210Document36 pagesBeximco Pharma MGT 210Romi SikderNo ratings yet

- LabX Bro eDocument12 pagesLabX Bro eWalter BurtonNo ratings yet

- Design of ExperimentsDocument18 pagesDesign of ExperimentsniltonlizaNo ratings yet

- Non Destructive Container Closure Integrity Testing PDFDocument40 pagesNon Destructive Container Closure Integrity Testing PDFChang Woo JongNo ratings yet

- Techniques for Downstream process for Biologic Drugs and VaccinesFrom EverandTechniques for Downstream process for Biologic Drugs and VaccinesNo ratings yet

- PMP Exam Tips On Time Management, Third EditionDocument5 pagesPMP Exam Tips On Time Management, Third EditionWilliam Luque Lds100% (1)

- Learn Process Design Fundamentals & Equipment SizingDocument4 pagesLearn Process Design Fundamentals & Equipment SizingMojtabaPMNo ratings yet

- One 2 One Cross Contamination FinalDocument9 pagesOne 2 One Cross Contamination FinalBlank BacktobasicNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Poster Ispe PDFDocument1 pagePoster Ispe PDFHadiantoNo ratings yet

- Change ControlDocument2 pagesChange Controlbhavik_meghaniNo ratings yet

- BPOG's ProtocolDocument11 pagesBPOG's ProtocolRadha Krishna B VNo ratings yet

- PhEn602 Spring09 Notes8 PDFDocument69 pagesPhEn602 Spring09 Notes8 PDFFaisal Abbas100% (1)

- Plant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Document19 pagesPlant Performance & Efficiency Monitoring: Introduction & Familiarization Module - Part 1Youcef NasriNo ratings yet

- 04 Breakout B-Control Strategy-Key MessagesDocument21 pages04 Breakout B-Control Strategy-Key MessagesOskar LazaroNo ratings yet

- Lyophilization Process 1622495344Document7 pagesLyophilization Process 1622495344maheshNo ratings yet

- Cold Chain 101 The First Steps: Andrew GibsonDocument20 pagesCold Chain 101 The First Steps: Andrew GibsonYCNo ratings yet

- What Is Good Engineering PracticeDocument4 pagesWhat Is Good Engineering PracticesarifinNo ratings yet

- Environmental Monitoring Risk AssessmentDocument22 pagesEnvironmental Monitoring Risk AssessmentMarcelo CarvalhoNo ratings yet

- Materials Selection in Oil and Gas-An OverviewDocument15 pagesMaterials Selection in Oil and Gas-An OverviewAli AliNo ratings yet

- WP Gmp-En AnshDocument12 pagesWP Gmp-En AnshFelix ShihNo ratings yet

- Column Chromatography OverviewDocument8 pagesColumn Chromatography Overviewyasa karyadaNo ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- HighlightsDocument1 pageHighlightsmulerNo ratings yet

- Excellent Leadership Skills and Multi-Tasking Strengths. Demonstrated Ability To Improve Store Operations, Increase Top Line Sales, and Reduce CostsDocument1 pageExcellent Leadership Skills and Multi-Tasking Strengths. Demonstrated Ability To Improve Store Operations, Increase Top Line Sales, and Reduce CostsmulerNo ratings yet

- KASAHUN KEFYALW Gypsum Project BackgroundDocument2 pagesKASAHUN KEFYALW Gypsum Project BackgroundmulerNo ratings yet

- Store Manager Japan Car Center, New YorkDocument1 pageStore Manager Japan Car Center, New YorkmulerNo ratings yet

- Key Success and Risk Factor: 1.1. Beneficiaries of The ProjectDocument2 pagesKey Success and Risk Factor: 1.1. Beneficiaries of The ProjectmulerNo ratings yet

- Executive Summary: 1.1. The CompanyDocument2 pagesExecutive Summary: 1.1. The CompanymulerNo ratings yet

- ChemicalDocument3 pagesChemicalmulerNo ratings yet

- ProcessDocument2 pagesProcessmulerNo ratings yet

- Executive Summary: 1.1. The CompanyDocument2 pagesExecutive Summary: 1.1. The CompanymulerNo ratings yet

- Hand Sanitizer: Advantages and FeaturesDocument2 pagesHand Sanitizer: Advantages and FeaturesmulerNo ratings yet

- TecnologyDocument3 pagesTecnologymulerNo ratings yet

- Project ProposalDocument4 pagesProject ProposalmulerNo ratings yet

- LSY Cement Screw Conveyor for SaleDocument1 pageLSY Cement Screw Conveyor for SalemulerNo ratings yet

- What Process Engineers Do - Basic Job ResponsibilitiesDocument2 pagesWhat Process Engineers Do - Basic Job ResponsibilitiesmulerNo ratings yet

- Hand Sanitizer: Advantages and FeaturesDocument2 pagesHand Sanitizer: Advantages and FeaturesmulerNo ratings yet

- 12WHO-recommended Hand Rub Formulations: 12.1. General RemarksDocument24 pages12WHO-recommended Hand Rub Formulations: 12.1. General RemarksmulerNo ratings yet

- Cement Screw Conveyor: Advantages and FeaturesDocument2 pagesCement Screw Conveyor: Advantages and FeaturesmulerNo ratings yet

- What Is Process EngineeringDocument3 pagesWhat Is Process EngineeringmulerNo ratings yet

- LSY Cement Screw Conveyor for SaleDocument1 pageLSY Cement Screw Conveyor for SalemulerNo ratings yet

- LSY Cement Screw Conveyor for SaleDocument1 pageLSY Cement Screw Conveyor for SalemulerNo ratings yet

- SpefiDocument1 pageSpefimulerNo ratings yet

- NoteDocument1 pageNotemulerNo ratings yet

- SpefiDocument1 pageSpefimulerNo ratings yet

- 1Document3 pages1mulerNo ratings yet

- Hibbsword SlideshowDocument34 pagesHibbsword SlideshowAnwar SoewandiNo ratings yet

- What Is Process EngineeringDocument1 pageWhat Is Process EngineeringmulerNo ratings yet

- Give A Spoken or Written Account of Something That One Has Observed, Heard, Done, or InvestigatedDocument1 pageGive A Spoken or Written Account of Something That One Has Observed, Heard, Done, or InvestigatedmulerNo ratings yet

- NoteDocument1 pageNotemulerNo ratings yet

- PeripheralDocument1 pagePeripheralmulerNo ratings yet

- Proprac ReportDocument201 pagesProprac ReportJames Jr BalaNo ratings yet

- Gyprock 513 Party Wall 201407Document28 pagesGyprock 513 Party Wall 201407eusufiqbal100% (1)

- Assignment ProblemsDocument3 pagesAssignment ProblemsKaushik SreenivasNo ratings yet

- Data Sustainability HalalDocument260 pagesData Sustainability HalalAldila AmeliaNo ratings yet

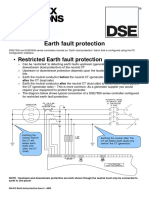

- 056-019 Earth Fault Protection PDFDocument2 pages056-019 Earth Fault Protection PDFmigas_migue2856No ratings yet

- Elements of Aeroelastic Design: Xie ChangchuanDocument21 pagesElements of Aeroelastic Design: Xie ChangchuanAbaziz Mousa OutlawZzNo ratings yet

- Management of Intelligent Buildings System (IBMSDocument28 pagesManagement of Intelligent Buildings System (IBMSPradeep PunterNo ratings yet

- International Prospectus: StudentDocument75 pagesInternational Prospectus: StudentRinla BabuNo ratings yet

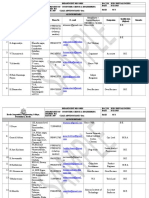

- Final Year Students Hostel Allotment ListDocument3 pagesFinal Year Students Hostel Allotment ListSwapnil Gade007No ratings yet

- CE 100 Orientation GuideDocument26 pagesCE 100 Orientation GuideTyn MaturanNo ratings yet

- Chapter 1 QB SenDocument7 pagesChapter 1 QB Sen14SYCMIIIShruti DawangeNo ratings yet

- Sample-Problems For Flexure, Shear and Floor FramingDocument24 pagesSample-Problems For Flexure, Shear and Floor FramingMaan Valencia - RevillaNo ratings yet

- PEEN4006 Petroleum Geomechanics Semester 2 2016 Bentley Campus INTDocument8 pagesPEEN4006 Petroleum Geomechanics Semester 2 2016 Bentley Campus INTekeneNo ratings yet

- Acharya N.G. Ranga Agricultural University: Administrative Office: Lam, Guntur - 522 034, A.PDocument6 pagesAcharya N.G. Ranga Agricultural University: Administrative Office: Lam, Guntur - 522 034, A.PDavidNo ratings yet

- Alumni Details 2007 BatchDocument5 pagesAlumni Details 2007 Batchrevathyjayabaskar0% (3)

- Porite Yangzhou Technology & Industry Co., LTDDocument5 pagesPorite Yangzhou Technology & Industry Co., LTDsamNo ratings yet

- Unit-IV - Voli. 2 Polyphase TransformersDocument74 pagesUnit-IV - Voli. 2 Polyphase Transformersvasu_koneti5124No ratings yet

- VAL-030 Equipment Specification and Qualification SampleDocument2 pagesVAL-030 Equipment Specification and Qualification SampleVizit31No ratings yet

- Prateek Nigam M.tech Updated CVDocument4 pagesPrateek Nigam M.tech Updated CVkkp0650No ratings yet

- Reliability Based Design of Utility Pole Structures Prepared by Reliability Based Design Committee of The Structural Engineering InstituteDocument119 pagesReliability Based Design of Utility Pole Structures Prepared by Reliability Based Design Committee of The Structural Engineering InstituteTharach Janesuapasaeree100% (3)

- Design and Analysis of A Micro Tunnel Boring Machines (TBM)Document7 pagesDesign and Analysis of A Micro Tunnel Boring Machines (TBM)thauwui86No ratings yet

- Offshore Site Investigation and Geotechnics: Integrated Geotechnologies - Present and FutureDocument690 pagesOffshore Site Investigation and Geotechnics: Integrated Geotechnologies - Present and FutureSharon_SKNo ratings yet

- TIPL - Company ProfileDocument25 pagesTIPL - Company ProfileHarisNo ratings yet

- Tarpon Energy Services - Electrical, Instrumentation, Construction & Maintenance SolutionsDocument8 pagesTarpon Energy Services - Electrical, Instrumentation, Construction & Maintenance SolutionsVinzoKeiNo ratings yet

- Three Core Cables To BS 6622Document8 pagesThree Core Cables To BS 6622rose chenNo ratings yet

- 60950-1 Vs gb4943 1 2011Document11 pages60950-1 Vs gb4943 1 2011awalleNo ratings yet

- Chapter 4 Part 1 - Truss Method of JointsDocument13 pagesChapter 4 Part 1 - Truss Method of JointsMuhammad Sumair KhanNo ratings yet

- G 7Document8 pagesG 7Phiw TabuzoNo ratings yet

- 1620828341bwubrochureall PageDocument38 pages1620828341bwubrochureall PageBog heiseiNo ratings yet

- CORP CustomerStory Cikoni LetterDocument2 pagesCORP CustomerStory Cikoni LetterADITYA DEVOLNo ratings yet