Professional Documents

Culture Documents

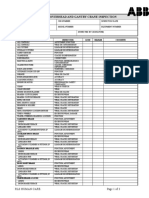

Lifting equipment inspection requirements

Uploaded by

Quality controllerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting equipment inspection requirements

Uploaded by

Quality controllerCopyright:

Available Formats

PDO SP-2275

Specification for Lifting and Hoisting Equipment Inspection and Testing Requirements. Version: 01.

5.6 General Requirements of Flat and Round Synthetic Webbing Slings

* Webbing sling safety factor shall not be less than 7:1.

* A protective sleeve shall be fitted to the soft eye of flat webbing slings.

* Single ply webbing sling thickness shall be minimum of 2mm thickness.

* The Effective Working Length (EWL of a flat woven webbing sling shall not differ from the nominal length

by more than 3 % of the nominal length, in case of round slings 2% of the nominal length.

* Information label shall contain, WLL, reference standard number (EN 1492-1 & 2 or equivalent), the

material used, mode factors of straight, basket & choked hitches and serial number/identification number.

* Webbing slings shall not be exposed to Ultra violet rays

6 Rejection Criteria’s for Lifting accessories

The table below shows the most common rejection criteria, however, if any, specific criteria for acceptance

of a particular item shall be at the discretion of the lifting inspector and standard requirements. The

following criteria need to be considered for rejection

*Hard stamping with sharp edged stamps or hard stamps in low stress area.

#*Wear and Elongation in excess of 5% of the Original dimension. In case of wire rope slings maximum

elongation is 4% allowed.

@Loss of diameter exceeds 5% of the Original diameter.

**Wire breaks shall not exceed 5% of wires in 10 diameter length and 3 or more wires in one lay length. In

case number of wires in the sling is not known, then 5 wires in any 6 diameters.

Ψ Increase of hooks throat opening distance in excess of 10%.

You might also like

- API 5B Updates (16th Edition)Document9 pagesAPI 5B Updates (16th Edition)Albert Tu100% (1)

- Crane inspection checklistDocument1 pageCrane inspection checklistshaikh_nazar75% (8)

- API Spec 6A 21st Edition ChangesDocument43 pagesAPI Spec 6A 21st Edition ChangesQuality controller83% (6)

- Portable Electrical Equipment Register and InspectionDocument1 pagePortable Electrical Equipment Register and Inspectionsalman100% (1)

- ANSI ASME B1.5 Acme StandardDocument123 pagesANSI ASME B1.5 Acme StandardRagesh VVNo ratings yet

- Compactor Daily Inspection ChecklistDocument1 pageCompactor Daily Inspection ChecklistThandabantu Magengelele33% (3)

- Temporary Building and Porta Cabin Safety Inspection ChecklistDocument3 pagesTemporary Building and Porta Cabin Safety Inspection ChecklistHabib ur rahman0% (1)

- Api 6a 21 Ed Summary of ChangesDocument2 pagesApi 6a 21 Ed Summary of ChangesQuality controller100% (3)

- L6.17 Mobile Welding Machine Inspection ChecklistDocument2 pagesL6.17 Mobile Welding Machine Inspection Checklistom prakash100% (4)

- CR 10 (2) D Safety Harness Inspector TEMPLATEDocument1 pageCR 10 (2) D Safety Harness Inspector TEMPLATELiam Du Piesanie0% (1)

- Beam Clamp Inspection ChecklistDocument1 pageBeam Clamp Inspection ChecklistTrust EmmaNo ratings yet

- Visual Inspection ChecklistDocument2 pagesVisual Inspection ChecklistAbdallah QtaishatNo ratings yet

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocument1 pageChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (2)

- Shackle Checklist FormDocument1 pageShackle Checklist FormРашад ИбрагимовNo ratings yet

- Backhoe-Loader Daily Inspection ChecklistDocument1 pageBackhoe-Loader Daily Inspection ChecklistMartine OtienoNo ratings yet

- Hydraulic Jack Inspection ChecklistDocument1 pageHydraulic Jack Inspection ChecklistHario Pramudito100% (1)

- Draft Offshore ChecklistDocument2 pagesDraft Offshore Checklistmohamad nur saufiNo ratings yet

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- Certificate of Visual Examination and Mpi: Description of Equipment Crane HookDocument12 pagesCertificate of Visual Examination and Mpi: Description of Equipment Crane HookMichael OkwuwaNo ratings yet

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- F020 Register of Lifting EquipmentDocument1 pageF020 Register of Lifting EquipmentvladNo ratings yet

- 99 Top IELTS CollocationsDocument1 page99 Top IELTS Collocationsamirlove20667% (6)

- Flange Gasket, Bolt, Wrench and Torque Reference ChartDocument13 pagesFlange Gasket, Bolt, Wrench and Torque Reference Chartrlk2806100% (1)

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDocument1 pageHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNo ratings yet

- Steel Wire Rope Sling Safety ChecklistDocument1 pageSteel Wire Rope Sling Safety ChecklistImad ChaudharyNo ratings yet

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Tower Crane ChecklistDocument1 pageTower Crane ChecklistbeshoyNo ratings yet

- MOBILE CRANE CHECKLISTDocument2 pagesMOBILE CRANE CHECKLISTAnuraj100% (1)

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- INSPECTION OF CRADLE / RSPDocument1 pageINSPECTION OF CRADLE / RSPBineesh100% (3)

- 5 Full Body Harness Safety Belt Check List 22.6.15-1Document2 pages5 Full Body Harness Safety Belt Check List 22.6.15-1ankitNo ratings yet

- Crane Jib Check ListDocument1 pageCrane Jib Check ListsawkariqbalNo ratings yet

- Pre-Use Welding ChecklistDocument2 pagesPre-Use Welding ChecklistNuno LopesNo ratings yet

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 pageTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- 06 Portable Grinding MachineDocument1 page06 Portable Grinding MachineGyanendra Narayan NayakNo ratings yet

- Form Inspection Premob - Quarterly (1) - 2Document26 pagesForm Inspection Premob - Quarterly (1) - 2Ryan RhamdhaniNo ratings yet

- Checklist of Gas Cutting SetDocument3 pagesChecklist of Gas Cutting SetSafety DeptNo ratings yet

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDocument1 page006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnNo ratings yet

- Wire Rope Inspection Checklist FormDocument1 pageWire Rope Inspection Checklist FormРашад ИбрагимовNo ratings yet

- CHECKLIST - Fire Equipment Inspection - Hose ReelsDocument1 pageCHECKLIST - Fire Equipment Inspection - Hose Reelsle papi100% (1)

- HSE-025. Pre-Entry ExcavatorDocument3 pagesHSE-025. Pre-Entry ExcavatorMithlesh SinghNo ratings yet

- Boom Placer Inspection ChecklistDocument1 pageBoom Placer Inspection ChecklistMyo LwinNo ratings yet

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Webbing SlingDocument1 pageWebbing SlingTrust Emma100% (1)

- Crane Inspection FormDocument2 pagesCrane Inspection FormWisnu Suryo Andriyanto AndriyantoNo ratings yet

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 pageCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarNo ratings yet

- Check List For Welding MachinesDocument1 pageCheck List For Welding MachinesSaravanan JambunathanNo ratings yet

- Tripod Inspection Form - FillableDocument1 pageTripod Inspection Form - FillablehienleeNo ratings yet

- Crane InspectionDocument2 pagesCrane InspectionAdhy DarmawanNo ratings yet

- Equipment Inspection ChecklistsDocument43 pagesEquipment Inspection ChecklistsBassam HSENo ratings yet

- Crane ChecklistDocument3 pagesCrane ChecklistAbdul Rehman SheikhNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- Pilling Machine ChecklistDocument3 pagesPilling Machine Checklisttanoycomet100% (1)

- Fire Extinguisher Inspection, Maintenance and Testing ProceduresDocument5 pagesFire Extinguisher Inspection, Maintenance and Testing ProceduresSumathi Sundaram SundaramNo ratings yet

- Mobile Crane Certification and Inspection ReportDocument2 pagesMobile Crane Certification and Inspection ReportRafael LecuNo ratings yet

- Gantry Crane Rail Inspection Form NAVFACDocument6 pagesGantry Crane Rail Inspection Form NAVFACTracy JohnsonNo ratings yet

- SL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ADocument2 pagesSL - No Description of Activity Inspection by Records Remark SUB Vendor Vendor Oif/Tpia 1 2 ASuraj Shetty100% (1)

- EOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormDocument1 pageEOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormHassan Abdullah100% (2)

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Suds Wire Rope Grips Din741Document1 pageSuds Wire Rope Grips Din741Gerardo LobosNo ratings yet

- Crane Wire RopeDocument32 pagesCrane Wire RopeRajmohan Babu100% (3)

- NOV Grant Prideco Drilling Connection Inspection GuideDocument4 pagesNOV Grant Prideco Drilling Connection Inspection GuidetheinmoeNo ratings yet

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFDocument3 pagesField Inspection Procedure For Used GPDS Connections Revision 03 PDFJohn Dolan0% (1)

- Wire Rope Terminations 22Document33 pagesWire Rope Terminations 22Luffy11No ratings yet

- FIP XT XTM PC 9.9 2009feb11 ExtDocument5 pagesFIP XT XTM PC 9.9 2009feb11 ExtSAntiago MorenoNo ratings yet

- Breakout - NCR Writing and ClosureDocument30 pagesBreakout - NCR Writing and ClosureMichael HicksNo ratings yet

- List of Connectors PDFDocument3 pagesList of Connectors PDFYojan Sebastian MastropieroNo ratings yet

- 651 - Burst Pressure Versus Casing Wear Calculation DDDocument4 pages651 - Burst Pressure Versus Casing Wear Calculation DDQuality controllerNo ratings yet

- Writing Vocabulary To Describe ChartsDocument4 pagesWriting Vocabulary To Describe ChartsQuality controllerNo ratings yet

- API 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingDocument10 pagesAPI 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingQuality controller0% (1)

- Control Plan TemplateDocument1 pageControl Plan TemplaterajarajanNo ratings yet

- Report Writing SamplesDocument7 pagesReport Writing SamplesQuality controllerNo ratings yet

- API Tubing and Casing Dimensions GuideDocument45 pagesAPI Tubing and Casing Dimensions GuideRyan LlanetaNo ratings yet

- GRR Study MSA TemplateDocument21 pagesGRR Study MSA TemplateaadmaadmNo ratings yet

- API Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure Gerdes 2010Document8 pagesAPI Box Boreback Stress Relief With Truncated Threads Can Cause Premature Connection Fatigue Failure Gerdes 2010Quality controllerNo ratings yet

- API Spec 7-1 Drill Stem ManufacturingDocument1 pageAPI Spec 7-1 Drill Stem ManufacturingQuality controller0% (1)

- Electromagnetic SpectrumDocument3 pagesElectromagnetic SpectrumQuality controllerNo ratings yet

- Accceptance CriteriaDocument4 pagesAccceptance CriteriaQuality controllerNo ratings yet

- Electromagnetic SpectrumDocument3 pagesElectromagnetic SpectrumQuality controllerNo ratings yet

- Asme B89 1 13 2001Document27 pagesAsme B89 1 13 2001Quality controllerNo ratings yet

- ASME B1.8-1988 Stub Acme Screw Threads (B1.8 - 1988)Document42 pagesASME B1.8-1988 Stub Acme Screw Threads (B1.8 - 1988)Quality controllerNo ratings yet

- WPS & PQRDocument84 pagesWPS & PQRjoseph.maquez24100% (4)

- Vtes Vtes Vtes Vtes Vtes Vtes Vtes Vtes: Api Spec Q1 ReviewDocument8 pagesVtes Vtes Vtes Vtes Vtes Vtes Vtes Vtes: Api Spec Q1 ReviewQuality controller100% (1)

- Ansi B89.1.10M-2001Document26 pagesAnsi B89.1.10M-2001arabcal100% (1)

- ARAMCO Engineering - Standard - Selection of Flanges, Stud Bolts, and GasketsDocument17 pagesARAMCO Engineering - Standard - Selection of Flanges, Stud Bolts, and GasketsQuality controllerNo ratings yet

- API Flange Bolt & Ring Chart for Oil & Gas Piping SystemsDocument1 pageAPI Flange Bolt & Ring Chart for Oil & Gas Piping SystemsPrasetiyo SholehNo ratings yet

- API Spec 7-1 Drill Stem ManufacturingDocument1 pageAPI Spec 7-1 Drill Stem ManufacturingQuality controller0% (1)

- API Spec 7-1 Drill Stem ManufacturingDocument1 pageAPI Spec 7-1 Drill Stem ManufacturingQuality controllerNo ratings yet

- API Spec 5CT IntroductionDocument37 pagesAPI Spec 5CT IntroductionChandrasekhar Sonar100% (2)