Professional Documents

Culture Documents

364 Pre Job Check List High Pressure Hydro Jetting Rev 000

Uploaded by

asan100%(1)100% found this document useful (1 vote)

356 views2 pagesThe document is a pre-job checklist for high pressure hydro jetting that outlines safety requirements and equipment needs. It lists training requirements for employees, safety equipment, work hours limits, break requirements, work area barricading and signage, illumination, equipment securing, containment arrangements, pressure rated hoses and fittings, flexible lancing and pipe cleaning specifications, and shotgun requirements. Compliance with the checklist is meant to ensure work is performed safely.

Original Description:

Original Title

434765072 364 Pre Job Check List High Pressure Hydro Jetting Rev 000 Xls (1)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a pre-job checklist for high pressure hydro jetting that outlines safety requirements and equipment needs. It lists training requirements for employees, safety equipment, work hours limits, break requirements, work area barricading and signage, illumination, equipment securing, containment arrangements, pressure rated hoses and fittings, flexible lancing and pipe cleaning specifications, and shotgun requirements. Compliance with the checklist is meant to ensure work is performed safely.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

356 views2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000

Uploaded by

asanThe document is a pre-job checklist for high pressure hydro jetting that outlines safety requirements and equipment needs. It lists training requirements for employees, safety equipment, work hours limits, break requirements, work area barricading and signage, illumination, equipment securing, containment arrangements, pressure rated hoses and fittings, flexible lancing and pipe cleaning specifications, and shotgun requirements. Compliance with the checklist is meant to ensure work is performed safely.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

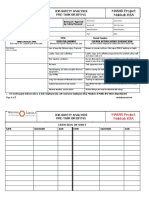

Pre Job Check List

High Pressure Hydro Jetting

Client Equipment Serviced

Location Date

Shift Pressure Intended

Method Proposed

FLEXIBLE LANCE AUTOMATED

SHOT GUN

OR PIPE CLEANING CLEANING

Sr Description YES NO N/A Remarks

TRAINING REQUIREMENTS

1 Employees are adequately trained to perform this specific task.

SAFETY REQUIREMENTS

1 All employees have proper safety and personal protective

equipment for the job.

2 The equipment operator has the ability to control the pump

pressure and flow.

3 Employees will not be required to work more than 12 hours in the

shift.

4 Jetters must be given frequent breaks and rest time to relax after

one hour working continuously.

WORK LOCATION REQUIREMENTS

Equipment setup/location

1 Barricade is extended aroundis out of major personnel traffic area

the hydroblast

and is a safe distance from operating equipment as

equipment.

2 required for

3 personnel

Signs are and operation

adequately safety.

placed.

If hydroblasting equipment cannot be adequately spaced from

4 process equipment or personnel traffic, additional sturdy

barriers/panels are installed to provide protection.

5 Hoses properly protected & barricaded & they do not present a

tripping hazard.

6 Illumination at the work location

7 Equipment to be cleaned is unable to move and secured as

necessary.

CONTAINMENT

1 Arrangements are in place to ensure that the material being

blasted is contained of being disposed of properly.

EQUIPMENT REQUIREMENTS

Hoses and fittings are of the correct

1 All hoses are joined by threaded female pressure rating and in good

condition. couplings, of the correct

2 pressure rating.

3 No quick

Hoses connect

have fittings

the Safe are used.

working pressure marked and visible.

4 Hoses have safety bridges (restraining devices) across couplings.

5 Hoses are free of damaged wire braids.

6 All pressure control valves have a guard to prevent inadvertent

actuation.

Pumping unit is equipped with safety relief devices and have

7

been checked.

8 The pump suction filter is clean and rated correctly.

FLEXIBLE LANCING AND PIPE CLEANING REQUIREMENTS

1 The starter bar length is at least 300mm.

A deflector shield has been placed at the outlet end of the tube

2

bundle.

The starter bar has a mark 300mm from the end to indicate

3

nozzle location.

4 An

Theanti-withdrawal

starter bar anddevice

tube nozzle are ofto

is attached the correct

the pressure

inlet flange rating.

to prevent

5 the nozzle from

The line mole has a mark 50mm from the end of the nozzle to

coming out

6 indicate of the pipe.

nozzle

The line mole extension exceeds the inside diameter of the pipe

location.

7

being cleaned, for pipes exceeding 500mm.

Page 1 of 2

SHOTGUN REQUIREMENTS

1 The shotgun

gun barrel

has is at least one

1.2mcontrol

long. valves to control water flow

2 and pressure,

3 and

The two

pumpcontrol valves

pressure where necessary.

regulator/unloader will unload the pump.

Supervisor Name & signature Hamza

Doc.No. RE/HSE/HPHJ/FM 364 * Date Issued : 10.02.2011 * Revision No. 000

RE364 - 0

Page 2 of 2

You might also like

- SB - 55 - Manbasket ENDocument1 pageSB - 55 - Manbasket ENlê ngọc tùng0% (1)

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchieNo ratings yet

- Work Permit Request For HydrotestingDocument3 pagesWork Permit Request For HydrotestingZeyad Rezk50% (2)

- Part II - 08 Abrasive BlastingDocument5 pagesPart II - 08 Abrasive Blastingsalah abddayemNo ratings yet

- JSA For ONGC PhotographyDocument1 pageJSA For ONGC PhotographyPanchdev KumarNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Maeda-Onaka, Joint Venture: Generic Lifting PlanDocument4 pagesMaeda-Onaka, Joint Venture: Generic Lifting PlanJaycee Pagador100% (1)

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Bar Cutting MachineDocument1 pageBar Cutting Machinesaurav roy100% (1)

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Rescue unconscious person from confined mud tankDocument1 pageRescue unconscious person from confined mud tankPaul100% (1)

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 pageCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarNo ratings yet

- Jsa For Ut TestDocument2 pagesJsa For Ut Testnasar_mahsood50% (2)

- Welfare Facilities - ChecklistDocument2 pagesWelfare Facilities - Checklistyahiya100% (4)

- Suspended personnel platform checklistDocument1 pageSuspended personnel platform checklistmark lester caluzaNo ratings yet

- JSA #28 - Use of Hand ToolsDocument1 pageJSA #28 - Use of Hand ToolsSubham SohalNo ratings yet

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Catalyst Filling & SeggregationDocument3 pagesCatalyst Filling & SeggregationMohammed MinhajNo ratings yet

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- F020 Register of Lifting EquipmentDocument1 pageF020 Register of Lifting EquipmentvladNo ratings yet

- Job Safety Analysis: 1. Removing Spool From Existing Pipe LinesDocument5 pagesJob Safety Analysis: 1. Removing Spool From Existing Pipe Lineskaremkoko100% (1)

- JSA - Paintng in Confined SpaceDocument6 pagesJSA - Paintng in Confined SpaceJohnNo ratings yet

- Sand Blasting & Painting Risk AssessmentDocument6 pagesSand Blasting & Painting Risk AssessmentNaveed Ahmed Get-Info100% (1)

- Night Shift Work Inspection ChecklistDocument1 pageNight Shift Work Inspection Checklistazer Azer100% (2)

- Banksman Training On 27122016Document12 pagesBanksman Training On 27122016Lau Yock Wing100% (1)

- 14.lifting Operations & Lifting EquipmentDocument28 pages14.lifting Operations & Lifting EquipmentbabadapbadapNo ratings yet

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANINo ratings yet

- Water Tank Cleaning TRADocument5 pagesWater Tank Cleaning TRAyehia sayedNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- HSE Training Module: Lifting OperationsDocument46 pagesHSE Training Module: Lifting OperationsChiheb KaanicheNo ratings yet

- Breaker Machine Safety ChecklistDocument1 pageBreaker Machine Safety ChecklistNair R RakeshNo ratings yet

- HSE-BMS-013 Color Coding and InspectionDocument30 pagesHSE-BMS-013 Color Coding and InspectionSatya Naidu100% (1)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Confined Space Rescue Plan FormDocument7 pagesConfined Space Rescue Plan FormZulham SurbaktiNo ratings yet

- Job Hazard AnalysisDocument9 pagesJob Hazard Analysisananthu.uNo ratings yet

- JsaDocument5 pagesJsaMohd AzrinNo ratings yet

- Chemical Hazard Bulletin: OPT D 1127Document1 pageChemical Hazard Bulletin: OPT D 1127HaleemUrRashidBangashNo ratings yet

- Job Safety Analysis: Touch Up PaintDocument3 pagesJob Safety Analysis: Touch Up PaintMuhammad Umar GondalNo ratings yet

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisNo ratings yet

- Blinding and De-blinding Safety EssentialsDocument42 pagesBlinding and De-blinding Safety EssentialsMayur NaikNo ratings yet

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- H2S-Exam Safety Trainer ExamDocument2 pagesH2S-Exam Safety Trainer Examreda mesbah0% (1)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Safe Excavation ProceduresDocument3 pagesSafe Excavation Proceduresbabu541No ratings yet

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- Synthetic Sling Inspection FormDocument1 pageSynthetic Sling Inspection FormpakistaniNo ratings yet

- JSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityDocument7 pagesJSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityRaditya PramudyaNo ratings yet

- General Instruction ManualDocument1 pageGeneral Instruction ManualGeorge ZormpasNo ratings yet

- Ladder Inspection Checklist: General Condition OK Needs Repair Not ApplicableDocument1 pageLadder Inspection Checklist: General Condition OK Needs Repair Not ApplicableWaqas KhanNo ratings yet

- Pre Job Check List for High Pressure Hydro JettingDocument4 pagesPre Job Check List for High Pressure Hydro Jettingfrancis50% (2)

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document4 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000Narendra singh UKNo ratings yet

- Manual Instalacion y Operación Bomba Spring - MS1Document56 pagesManual Instalacion y Operación Bomba Spring - MS1JUAN DAVID BALDION BONILLANo ratings yet

- Admin 4 2 R0Document2 pagesAdmin 4 2 R0Stephen MalobaNo ratings yet

- Jet Flusher Pre Start ChecklistDocument1 pageJet Flusher Pre Start ChecklistasanNo ratings yet

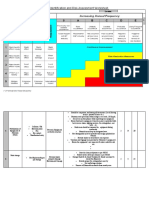

- 2 - Hazards Indentification Plan CheckedDocument28 pages2 - Hazards Indentification Plan Checkedasan100% (1)

- 2 - Hazards Indentification PlanDocument27 pages2 - Hazards Indentification PlanasanNo ratings yet

- Inter Q AnsDocument9 pagesInter Q AnsasanNo ratings yet

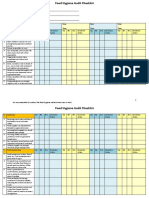

- 4b PPE ChecklistDocument3 pages4b PPE Checklistasan100% (1)

- Implement Health & Safety StandardsDocument13 pagesImplement Health & Safety StandardsasanNo ratings yet

- WAHTicket ExpiryDocument1 pageWAHTicket ExpiryasanNo ratings yet

- UNDRR Hazard-Report DIGITALDocument89 pagesUNDRR Hazard-Report DIGITALRASHEED YUSUFNo ratings yet

- Memo Nov22Document2 pagesMemo Nov22asanNo ratings yet

- Types of Physical and Health HazardsDocument37 pagesTypes of Physical and Health HazardsasanNo ratings yet

- Cap 1484 Mar17Document58 pagesCap 1484 Mar17asanNo ratings yet

- Pre Shutdown ChecklistDocument12 pagesPre Shutdown ChecklistasanNo ratings yet

- Procedure/Method Statement: Risk AssessmentDocument29 pagesProcedure/Method Statement: Risk AssessmentasanNo ratings yet

- How to Write a Memo: Formatting, Examples & Templates (40chDocument46 pagesHow to Write a Memo: Formatting, Examples & Templates (40chasanNo ratings yet

- Confined Space Entry PermitDocument1 pageConfined Space Entry PermitasanNo ratings yet

- Hand Tools HIRADocument4 pagesHand Tools HIRAasanNo ratings yet

- Notes IGC-I PortraitDocument38 pagesNotes IGC-I PortraitasanNo ratings yet

- GD 2008Document8 pagesGD 2008asanNo ratings yet

- NFPA DiamondDocument7 pagesNFPA DiamondasanNo ratings yet

- Carelink Evacplan ChecklistDocument5 pagesCarelink Evacplan ChecklistasanNo ratings yet

- AccidentDocument5 pagesAccidentasanNo ratings yet

- Name of Licensed Premises: - License No.: - Check by (Name)Document7 pagesName of Licensed Premises: - License No.: - Check by (Name)atherNo ratings yet

- 2006 Turki Andijani Siddiqui ERP Trends in Saudi ArabiaDocument11 pages2006 Turki Andijani Siddiqui ERP Trends in Saudi ArabiaasanNo ratings yet

- Glossary of Chemical Safety TermsDocument56 pagesGlossary of Chemical Safety TermsasanNo ratings yet

- First Aid at Work PDFDocument41 pagesFirst Aid at Work PDFwertyuioNo ratings yet

- COSHH Risk Assessment FormDocument6 pagesCOSHH Risk Assessment FormasanNo ratings yet

- Safety Meeting Attendance and Discussion RegisterDocument2 pagesSafety Meeting Attendance and Discussion RegisterasanNo ratings yet

- Accident RateDocument6 pagesAccident RateasanNo ratings yet

- First Aid Risk Assessment PDFDocument4 pagesFirst Aid Risk Assessment PDFAmin UllahNo ratings yet

- Water Treatment Plant SchematicDocument3 pagesWater Treatment Plant SchematicRhys PalmaNo ratings yet

- Ficha Tecnica de Valvula de Seguridad 19KGGA150Document1 pageFicha Tecnica de Valvula de Seguridad 19KGGA150mynor8josh8juarezNo ratings yet

- Turboprop EnginesDocument17 pagesTurboprop EnginesMukesh ChaubeyNo ratings yet

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- Need For Surge Tank in Hydro Electric Power PlantDocument5 pagesNeed For Surge Tank in Hydro Electric Power PlantAmrit SinghaNo ratings yet

- Quality Procedure For Pressure Test (Hydro) : QCP-HP110Document9 pagesQuality Procedure For Pressure Test (Hydro) : QCP-HP110AAISATNo ratings yet

- Scavenging & TurbochargingDocument25 pagesScavenging & TurbochargingSayem kaifNo ratings yet

- Bladder Tank Manual F-2012020-2Document24 pagesBladder Tank Manual F-2012020-2Dianita Nieto100% (2)

- C4 - Components in Hydraulic SystemDocument64 pagesC4 - Components in Hydraulic SystemKubheran SelvathuraiNo ratings yet

- Hand Pump 06.07.2023Document1 pageHand Pump 06.07.2023menan PatelNo ratings yet

- Flow in ConduitsDocument29 pagesFlow in ConduitsEngr Sabiul AlamNo ratings yet

- Fluid Mechanics Objective Type QuestionsDocument151 pagesFluid Mechanics Objective Type Questionshumbleavi100% (1)

- DS-System-Design-Manual-iCOM Touch EN-NA-SL-18827-R12-15 PDFDocument192 pagesDS-System-Design-Manual-iCOM Touch EN-NA-SL-18827-R12-15 PDFjuanmanuel2020No ratings yet

- Report On Gas Turbine Power PlantDocument22 pagesReport On Gas Turbine Power Plantgayatri57% (7)

- Air Compressor & Refrigeration EfficienciesDocument31 pagesAir Compressor & Refrigeration EfficienciesAbubakkar SiddiqNo ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselslourenceNo ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Piping Latest Aramco QuestionsDocument2 pagesPiping Latest Aramco Questionschandu666creator0% (1)

- EQUIPMENT INSPECTION STATUS UPDATE FOR PELLETIZER & ISBLDocument45 pagesEQUIPMENT INSPECTION STATUS UPDATE FOR PELLETIZER & ISBLnkvonNo ratings yet

- Kaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesDocument10 pagesKaishan-Kaitain-Screw-Compressor-Direct-Couple-ISO-50Hz - JN SeriesSwapnil PatadeNo ratings yet

- Piping Material Specification for Polymer ChipsDocument8 pagesPiping Material Specification for Polymer ChipsMARCONo ratings yet

- GEA FES GS Series Screw Compressor PackagesDocument2 pagesGEA FES GS Series Screw Compressor PackagesVadimNo ratings yet

- Start Two Stage Ammonia Plant Et 2015-02-23Document80 pagesStart Two Stage Ammonia Plant Et 2015-02-23dachoko8750% (2)

- Bernoulli's Theorem DemonstrationDocument21 pagesBernoulli's Theorem DemonstrationDafiMabo100% (2)

- Bombas ParkerDocument6 pagesBombas ParkerDaniel ValladaresNo ratings yet

- Aerodynamics in CarsDocument20 pagesAerodynamics in CarssaifpawaskarNo ratings yet

- Resistance and Equivalent Length of FittingsDocument5 pagesResistance and Equivalent Length of FittingsGlishna Peushan WidanapathiranaNo ratings yet

- Medenus Safety Shut Off Valve PI - S104 - EN - FP3 - KleinDocument20 pagesMedenus Safety Shut Off Valve PI - S104 - EN - FP3 - Kleinanas ins10No ratings yet

- Assignment-1 Hydropower Plant: TheoryDocument40 pagesAssignment-1 Hydropower Plant: TheoryarunNo ratings yet

- Fox 3-RFP Rapid Filling Preventor With MeshDocument2 pagesFox 3-RFP Rapid Filling Preventor With MeshSpoonful BurnsideNo ratings yet