Professional Documents

Culture Documents

Hazard Identification and Risk Assessment For Pipe Lowering

Uploaded by

Achalere Shekhar KashinathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification and Risk Assessment For Pipe Lowering

Uploaded by

Achalere Shekhar KashinathCopyright:

Available Formats

NRP PROJECTS PVT LTD

Hazard Identification and Risk Assessment

for

PIPE LOWERING

Project : Report No :

Client : Location :

Consultant : Date :

HIRA Meeting Attendance Sheet

Sl.No Name Designation Signature Remarks

General Safety Precautions / Instructions.

1. Adhere strictly to work permit System and HSE Manual and HSE Regulations.

2. Follow NRP Emergency Procedure, identify the escape routes and be aware about the nearest and safest Marshaling Point.

3. Conduct a Tool Box Talk at the workplace prior to commencement of work and discuss the Task Risk Assessment content on daily basis.

4. Ensure the use of Job Specific PPE's at all the time & Maintain good housekeeping on daily basis before, during and after the work.

5. Close supervision at all locations and activities to ensure compliance with Method Statement. Only Competent personnel shall be involved in the activity

6. HSE Officer/Assistant shall be available at all times at the workplace area.

7. In case of any emergency Inform to Tel. No.

8. Approved Job procedure and JSA shall be maintained along with the permit.

9. Ensure that first aid box and fire extinguishers are available at Site.

10. Spotlights on HSE with regards to activities performed shall be displayed on site bulletin board and must be followed strictly.

11. Check Tools & equipment's for soundness prior to use and All Electrical/mechanical tools& Equipment must be certified/approved

12. Frequent Joint Site visit shall be conducted by all concerns to ensure Safe working environment and good housekeeping.

13. Appropriate reliever shall be assigned in the absence of key persons.

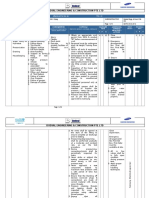

Risk Rating Risk

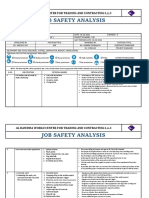

S.No Activity Hazards / Causes Effects Risk Rating Existing Controls Additional Control Rating

S P R S P R

1 Pipe Lowering 1. Hydraulic Failure 1. Personnal 3 C M 1. Ensure Valid registration, Third party 1 A L 1. Competent person to be L

Injury Certificate for all side booms and hydra. assigned in site for the

monitoring.

2. All lifting tackles are to be

2. Trench Collapse 2. Property inspected visually by supervisor.

Damage 2. First aid box shall be provided

3. Ensure that all lifting tackles have at site.

3. Pipe move/roll valid 3rd party certification.

4. Pipe may hit the 4. Follow proper Job ergonomics, 3. Emergency vehicle shall be

person during Workers must take frequent breaks to avoid provided.

shifting/lowering fatigue.

5. Keep the work place and swing

area and access clear of any obstruction.

6. Experienced back signal man and

sound alarm when equipments move or lift.

7. Display Safety Signage for work

and swing area.

8. Use stable ladder for below grade

work

9. Trained and experienced riggers shall be

deployed.

10. Tools, equipments and machineries shall

not be kept in trench during lowering.

11. Workmen shall not be allowed inside the

trench during pipe lowering

12. Unauthorised entry shall be restricted.

13. Proper signal shall be given to the all

operators by the experienced and trained

signal man.

14. Damaged lifting tools shall not be used.

15. Hydra/Side boom shall keep away from

the edge of the trench to avoid the trench

collapse.

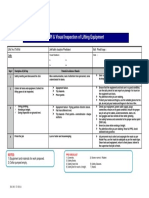

RISK POTENTIAL MATRIX QUALITATIVE

PROBABILITY

A B C D E

Frequent /Almost

Severity People Assets Environment Reputation Rare Possible Likely Often

certain

Multiple fatalities or Extensive Massive International

5.Catastrophic permanent total

damage. effect. impact. HIGH

disability

Single fatality or

Major National

4. Severe permanent total Major effect.

damage. impact.

disability

Major injury or health Localized Considerable

3. Critical

effects

Local damage.

effect. impact. MEDIUM

2. Marginal Minor injury or health Minor Minor effect. Minor impact.

effects damage.

LOW

Slight injury or health

1. Negligible effects Slight damage. Slight effect. Slight impact.

You might also like

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeepNo ratings yet

- TFU-Risk Assessment RA-11 - Use of Grooving & Threading MachinesDocument1 pageTFU-Risk Assessment RA-11 - Use of Grooving & Threading Machinesarshin wildanNo ratings yet

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDocument7 pagesCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- ISC-JSA Installation of Portable CabinDocument4 pagesISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JSA-049 Valves & Support Installation and DismantlingDocument4 pagesJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- JSA for Holiday TestingDocument4 pagesJSA for Holiday TestingMohammed Minhaj67% (3)

- JSA for TIE in on Chiller piping south of general officeDocument4 pagesJSA for TIE in on Chiller piping south of general officemyo lwinNo ratings yet

- JSA For HDPE Liner Fusion Welding PDFDocument4 pagesJSA For HDPE Liner Fusion Welding PDFHaleemUrRashidBangash67% (3)

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- Radiography JSADocument2 pagesRadiography JSAVipul ShankarNo ratings yet

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- JSA For NDTDocument4 pagesJSA For NDTMohammed Minhaj50% (2)

- Jsa Non Destructive TestingDocument2 pagesJsa Non Destructive Testingghulammohyuddin100% (1)

- (EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)Document10 pages(EDIT) F-SAF-0046.11 Bolt Torquing Risk Assessment (Generic)ainun mardiah75% (4)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- JSA For PiggingDocument3 pagesJSA For PiggingMohammed Minhaj86% (7)

- Pipe Rack Erection JSADocument8 pagesPipe Rack Erection JSARohit Thorat100% (2)

- Jsa For RadiographyDocument3 pagesJsa For Radiographyjithin shankarNo ratings yet

- JSA - Cathodic ProtectionDocument4 pagesJSA - Cathodic ProtectionAkash ShuklaNo ratings yet

- DOCUMENT Piping Insulation Installation and Dismantle Work JHADocument12 pagesDOCUMENT Piping Insulation Installation and Dismantle Work JHAAmirHakimRusli100% (1)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Job Safety Analysis for HDPE Pipe InstallationDocument12 pagesJob Safety Analysis for HDPE Pipe InstallationtusharDJNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- GRP PIPING INSTALLATION SWMSDocument13 pagesGRP PIPING INSTALLATION SWMSKhuda Buksh100% (1)

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Job Safety Analysis: Touch Up PaintDocument3 pagesJob Safety Analysis: Touch Up PaintMuhammad Umar GondalNo ratings yet

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- JHA For PWHT WorkDocument2 pagesJHA For PWHT WorkAzmi Fauzi77% (13)

- Hydrotest & Pneumatic Test - TRADocument6 pagesHydrotest & Pneumatic Test - TRAOws Anish100% (3)

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- JSA-055 Hydro-TestDocument24 pagesJSA-055 Hydro-TestOmar Dhieb100% (7)

- Risk Assess JSA Bolt Tightening 012Document7 pagesRisk Assess JSA Bolt Tightening 012Abdeldjalil Ferhati100% (2)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- Pipe Lowering JHADocument6 pagesPipe Lowering JHASalam AlkataluniNo ratings yet

- Confined Space Entry and Exit LogDocument2 pagesConfined Space Entry and Exit LogDinesh Kanukollu100% (4)

- JSA of MPI InspectionDocument1 pageJSA of MPI Inspectionengmuhmud100% (1)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneNo ratings yet

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- JSA - Fire Proofing WorksDocument5 pagesJSA - Fire Proofing WorksAnis Uddin100% (3)

- Jsa For Air Flushin & Mech. Cleaning of PipesDocument17 pagesJsa For Air Flushin & Mech. Cleaning of PipesKhuda Buksh100% (2)

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- 9.JSA For Night Work Activity - Rev 01Document7 pages9.JSA For Night Work Activity - Rev 01ibrahim80% (10)

- JHA - Handrails and GratingsDocument10 pagesJHA - Handrails and GratingsVidyesh Nair67% (3)

- Job Safety Analysis for Grout Placement and Coating Concrete FoundationDocument5 pagesJob Safety Analysis for Grout Placement and Coating Concrete Foundationmuhammad zaman50% (2)

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDocument5 pagesJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument2 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha Bennasr100% (2)

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- HDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateDocument7 pagesHDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateAchalere Shekhar Kashinath80% (10)

- JSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Document7 pagesJSA For Ship Repairing Welding Cutting and Grinding Activity 21.08.2023Sebin VargheseNo ratings yet

- Installation and Disassembly of Catwalk SOPDocument7 pagesInstallation and Disassembly of Catwalk SOPDQE040 HSSENo ratings yet

- HSE Supervisor:Name: Name:Signature:_________________ SignatureDocument2 pagesHSE Supervisor:Name: Name:Signature:_________________ SignaturekhurramNo ratings yet

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- HDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateDocument7 pagesHDD (Horizontal Directional Drilling) WORK: Project: Report No: Client: Location: Consultant: DateAchalere Shekhar Kashinath80% (10)

- Radiography TestDocument5 pagesRadiography TestAchalere Shekhar KashinathNo ratings yet

- Hazard Identification and Risk Assessment For Grit Blasting & CoatingDocument4 pagesHazard Identification and Risk Assessment For Grit Blasting & CoatingAchalere Shekhar KashinathNo ratings yet

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- HS-RA-05 - Lifting Fitting Precast UnitsDocument3 pagesHS-RA-05 - Lifting Fitting Precast UnitsAchalere Shekhar KashinathNo ratings yet

- HS-RA-05 - Lifting Fitting Precast UnitsDocument3 pagesHS-RA-05 - Lifting Fitting Precast UnitsAchalere Shekhar KashinathNo ratings yet

- OHTA 505 Student Manual Final Q5o721Document267 pagesOHTA 505 Student Manual Final Q5o721prashantagarwal787_4No ratings yet

- Fuel Truck Driver SOPDocument2 pagesFuel Truck Driver SOPSugan Byang PradhanNo ratings yet

- EH&S Organizational ChartDocument1 pageEH&S Organizational Chartpankajbhatt376No ratings yet

- Overtime Work Permit FormDocument1 pageOvertime Work Permit FormToha Hilpan HamimNo ratings yet

- Monthly HSE report summaryDocument5 pagesMonthly HSE report summaryNiraNo ratings yet

- Stop Card 2 Kelompok 5Document1 pageStop Card 2 Kelompok 5Reza IsnawanNo ratings yet

- SD13097 - Silcor Primer BS - (KOR)Document11 pagesSD13097 - Silcor Primer BS - (KOR)nlmiNo ratings yet

- Excavation and TrenchingDocument28 pagesExcavation and TrenchingParth PatelNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- TWINNING PROJECT EG07/AA/EN10 - Integrated Waste and Hazardous Substances Management SystemDocument24 pagesTWINNING PROJECT EG07/AA/EN10 - Integrated Waste and Hazardous Substances Management SystemAsala CosmeticsNo ratings yet

- Reducing employee exposure to physical hazardsDocument2 pagesReducing employee exposure to physical hazardsJames Erroll CruzNo ratings yet

- Ethylene Glycol MSDSDocument8 pagesEthylene Glycol MSDSMohamed Youssef MOHAMED MAHMOUD HELLESNo ratings yet

- JHA No.: 0022396 Job Hazard AnalysisDocument7 pagesJHA No.: 0022396 Job Hazard AnalysisFirdausDaliNo ratings yet

- 1 Identification: Acc. To OSHA HCSDocument16 pages1 Identification: Acc. To OSHA HCSmhrdd222No ratings yet

- Key Performance Indicators For OSHDocument2 pagesKey Performance Indicators For OSHAo no dākusaidoNo ratings yet

- Colour +25 STD MSDSDocument11 pagesColour +25 STD MSDSSakthi VelayuthanNo ratings yet

- Monthly ESH Report & StatisticsDocument5 pagesMonthly ESH Report & StatisticsEngr.Syed AmjadNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument7 pagesSafety Data Sheet: Section 1. IdentificationBerdi Nak GbaNo ratings yet

- Msds Lifebuoy in - Handwash Antibac Frag FreeDocument18 pagesMsds Lifebuoy in - Handwash Antibac Frag FreePIPIT FITRIANINo ratings yet

- Safe Handling of ChemicalsDocument26 pagesSafe Handling of ChemicalsnagarajanNo ratings yet

- Accident Investigation ReportDocument3 pagesAccident Investigation ReportKhan Mohammad Mahmud HasanNo ratings yet

- Suncorp FAQ FinalDocument2 pagesSuncorp FAQ FinalSam AbdulrahimNo ratings yet

- HR Compliance LawsDocument1 pageHR Compliance LawsKabeer SharmaNo ratings yet

- Rates of Minimum Wages for Security GuardsDocument1 pageRates of Minimum Wages for Security GuardsAdhavan M AnnathuraiNo ratings yet

- Occupational Health and SafetyDocument8 pagesOccupational Health and Safetygroup oneNo ratings yet

- Larif Jauhari, Kuat Prabowo, Arfia FridiantiDocument9 pagesLarif Jauhari, Kuat Prabowo, Arfia Fridianti181OOO199 Indah SimanjuntakNo ratings yet

- Sept 2018. XBLR3103. eTUTOR. OSH LEGISLATIONDocument13 pagesSept 2018. XBLR3103. eTUTOR. OSH LEGISLATIONAnis SyuhadaNo ratings yet

- Safety Data Sheet: SECTION 1: IdentificationDocument9 pagesSafety Data Sheet: SECTION 1: IdentificationPalacios Marina SandraNo ratings yet

- En UsDocument12 pagesEn UsYudhi NapitupuluNo ratings yet

- 1.weekly HSE Walkthrough Report - 07 SEPTEMBER 2023Document5 pages1.weekly HSE Walkthrough Report - 07 SEPTEMBER 2023Shahzaib.raja2000No ratings yet