Professional Documents

Culture Documents

JOB SAFETY ANALYSIS Grout Placement, Curing and Coating

Uploaded by

muhammad zamanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JOB SAFETY ANALYSIS Grout Placement, Curing and Coating

Uploaded by

muhammad zamanCopyright:

Available Formats

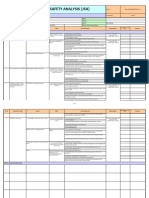

JOB SAFETY ANALYSIS (JSA) WORKSHEET

Date: 09 Dec 2018 JSA Number: 6347-JSA--0014

Department Name: HSE Division/Unit Name VRU Facility: Bulk Plant

Job Title/Description: Grout Placement and Curing and Coating Concrete foundation

Equipment’s and Tools to be used: Light duty electric chipping hammer, Mixer machine, Mixing Container, Trowel & Grout Float,

chisel, hammer and Power Generator, Bitumen Paint, Paint roller, Hand Tools.

PPEs to be used: Hard Hat, Safety Glass, Safety Rubber Shoes, Respiratory Mask, Face Shield, Disposable Coverall, Rubber Gloves dust mask.

Name(s) of Individuals Performing JSA: Rana Maqsood khawar Ayub (HSE Incharge)

Signature: _______________________ _____________________

Critical Steps Hazard(s) Controls/Recommended Action

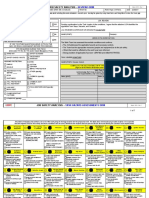

Secure the material on Pickup to avoid

falling of materials.

Access and egress routes and signs.

Transportation of Bitumen, Cement and grout Unsafe Movement of Pickup.

material to main site. Must comply with speed limit of 20kph.

Must be assisted by a banks man and a

functional reverses alarm.

Traffic management plan shall be

followed.

Make sure proper manual handling

Loading and unloading of material manually. Unsafe Manual handling back injury. techniques.

Do not lift the load beyond your capacity

Saudi Aramco: Company General Use

i.e. not more than 20kg.

Lift the load close to your body.

Store the load at proper designated place t

site.

Chemical storage procedure shall be

followed.

Chemical storage procedure shall be

Chemical hazard. followed.

Use chemical mast to avoid inhalation of

Inhalation chemical dust.

Use respiratory mask to avoid the effects

of vapors i.e. drowsiness and dizziness

Storage & Mixing of Grout Hazardous Vapour’s

hazard.

Keep container at well ventilated place.

Do not breath Vapor, Fumes, Spray

Do not empty into drains.

Make sure proper eye and skin protection

Irritation to eye and skin when exposed to chemical see the CHB or

MSDS for reference.

Use proper inspected mixer machine.

Electrical hazard Make sure daily visual inspection of

Machine shall be carried out at daily bases.

Electrical wire shall be inspected. Do not use

Saudi Aramco: Company General Use

damage wire.

Color code shall be done.

Use rubber gloves and rubber shoes.

Avoid sitting at wet surface.

Use proper hand gloves.

Placing the grout Damage to hand skin Do not expos directly to the chemical.

Read the manufacturer specification for the

Batter understanding.

Eye irritation Use proper eye protection. In case of

continuous irritation visit the clinic for

Treatment.

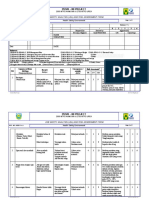

Curing On completion grout area shall be watered

Slip, trip, fall Make sure use of proper safety shoes to avoid slip

trip and falling on the same level.

Using burlap can cause fire hazard. Make

Sure no hot work in the area especially welding

Fire hazard cutting and grinding.

Do not smoke in the area.

Keep the burlap wet all time.

Dispose properly after use.

Store burlap at a dry ventilated place at site

storage area

Coating and painting the surface by using Read CHB/MSDS for batter understanding.

Bitumen Mixing (Chemical hazard) Use rubber gloves, rubber shoes, disposable cover

all and respiratory system to avoid inhalation

Of fumes and vapors of chemical.

Wash eye hand hands with soap before meal

Saudi Aramco: Company General Use

The disposal of chemical shall comply to

Disposal of raw material Waste disposal plan.

The disposal shall be according to the

Saudi Aramco standards.

Maintain good housekeeping all the time

before, during and after finishing the job.

Turn equipment off after its used.

Assign helpers for regular housekeeping.

Housekeeping is the responsibility of

everybody working at site.

All workers must participate to keep the

working area clean.

Secure all materials tools shall be

Housekeeping Slip, Trip and Falls appropriately stored in designated places.

Chemical Spills

Clean up spills or any chemical leak.

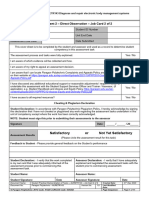

In case of emergency stop the work

Isolate/switch off any machine or

Equipment Unplug any electrical tool.

Evacuate Go to Nearest area assembly/

mustered point.

Follow the emergency communication protocol

system. Stay at assembly area

Until all clear alarm.

A new permit shall be issued for the job.

Saudi Aramco: Company General Use

Instructions

1. Use as many lines as needed to list the critical steps. Be specific.

2. There may be more than one hazard per step. List each hazard.

3. Identify the proper control for addressing each hazard. The preferred priorities are engineering, administrative (procedures) and then PPE.

4. Identify any recommended actions required, e.g., develop a new procedure or perform an industrial hygiene assessment. Assign a responsible party

for any required actions.

5. List each type of PPE needed for the task. Be specific.

6. Identify key steps as “STOP WORK TRIGGERS” (in the “Controls” column) if there are any conditions, job changes or distractions that will

prompt personnel to stop all work activities associated with the job until further assessment is conducted or additional controls are implemented.

Normal Approvals Name Signature Date

SAPMT HSE Representative

SAPMT Construction Representative

Proponent Representative

Saudi Aramco: Company General Use

You might also like

- ACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207Document3 pagesACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207msohaibaziz50% (4)

- Concreting Job Safety Analysis (JSA)Document2 pagesConcreting Job Safety Analysis (JSA)sudam kumar raut90% (20)

- JSA For PiggingDocument3 pagesJSA For PiggingMohammed Minhaj86% (7)

- ISC-JSA Installation of Portable CabinDocument4 pagesISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Jha RoofingDocument4 pagesJha Roofingahmadhatake100% (1)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JSA For WrappingDocument6 pagesJSA For WrappingMohammed Minhaj100% (2)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDocument12 pagesSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNo ratings yet

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- JHA - Handrails and GratingsDocument10 pagesJHA - Handrails and GratingsVidyesh Nair67% (3)

- TEIPL-JSA-058 Carpentry Wood WorkDocument3 pagesTEIPL-JSA-058 Carpentry Wood Workba ratnaparkheNo ratings yet

- Chemical Hazard Bulletin No. 0188: OxygenDocument2 pagesChemical Hazard Bulletin No. 0188: Oxygenshinto LawrenceNo ratings yet

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDocument3 pagesJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (2)

- JSA - Installation of U G PipingDocument11 pagesJSA - Installation of U G PipingOws Anish100% (1)

- Jsa Working at Height (Maintenance & Cleaning)Document2 pagesJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (1)

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 pagesULSADO-JSA - Installation of Temporary Fence GateKelvin TanNo ratings yet

- JSA For Cement Plaster at Office ExtensionDocument4 pagesJSA For Cement Plaster at Office ExtensionMohammed Minhaj50% (2)

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Job Safety Analysis Foundation WorkDocument3 pagesJob Safety Analysis Foundation WorkMihirdutta75% (4)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Demolition PDFDocument2 pagesDemolition PDFvinothNo ratings yet

- Jsa For ScaffoldingDocument3 pagesJsa For Scaffoldingsoubhagya100% (4)

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- JSA GroutingDocument2 pagesJSA GroutingSyazWyn100% (5)

- Example Risk Assessment For Motor Vehicle Repair WorkshopDocument6 pagesExample Risk Assessment For Motor Vehicle Repair WorkshopaymenmoatazNo ratings yet

- Reinforcing - Bar - Couplers UK IRE Edition PDFDocument28 pagesReinforcing - Bar - Couplers UK IRE Edition PDFilovevinaNo ratings yet

- Reinforcing - Bar - Couplers UK IRE Edition PDFDocument28 pagesReinforcing - Bar - Couplers UK IRE Edition PDFilovevinaNo ratings yet

- 11 - HSE Management SystemDocument37 pages11 - HSE Management SystemMohammed AffrozeNo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- 12-JSA Pipe Erection Work - Existing Pipe RackDocument4 pages12-JSA Pipe Erection Work - Existing Pipe RackSwaminathan ThayumanavanNo ratings yet

- JHA Chain HoistDocument1 pageJHA Chain HoistKrishna Patil100% (2)

- JHA 08 On Erection of Roofing SheetsDocument3 pagesJHA 08 On Erection of Roofing SheetsAkhilesh KumarNo ratings yet

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Document1 pageJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- 002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFDocument8 pages002 Job Safety Analysis For Excavation, Backfilling and Compaction Activities at SAOO GOSPs Rev 03 PDFHaleemUrRashidBangash100% (1)

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho50% (2)

- 02concreting & Block Bricks Work JSADocument3 pages02concreting & Block Bricks Work JSAJayendra Patel100% (1)

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Form JSA Lifting CraneDocument6 pagesForm JSA Lifting CraneYeti Srinurhayati100% (1)

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeepNo ratings yet

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- Mivan Risk AssessmentDocument3 pagesMivan Risk AssessmentBineeshNo ratings yet

- JSA PaintingDocument1 pageJSA PaintingjonesNo ratings yet

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- JSA For Brick WorkDocument3 pagesJSA For Brick Workwahyu nugroho83% (6)

- Jsa For Brick WorkDocument4 pagesJsa For Brick WorkSushil Kumar YadavNo ratings yet

- Rohan Abuilders (India) PVT - LTD: Job Hazard AnalysisDocument2 pagesRohan Abuilders (India) PVT - LTD: Job Hazard AnalysisMc Evans Magallanes100% (1)

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement WorkDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Reinforcement Workba ratnaparkhe67% (3)

- JSA FOR Using The LadderDocument4 pagesJSA FOR Using The Laddertnssbhaskar100% (1)

- Jsa Insulation WorkDocument19 pagesJsa Insulation WorkM M PRADHAN100% (2)

- Jsa 035Document10 pagesJsa 035Mohammad Anwar Hossain100% (1)

- Cooling Tower BiomateDocument8 pagesCooling Tower BiomateJavid AaqibNo ratings yet

- Jsa For Admin BuildingDocument5 pagesJsa For Admin Buildingmohamed yasinNo ratings yet

- Technical Query: King Salman International Complex For Maritime Industries and Services (MYP) CONTRACT 6600042823 (IK)Document3 pagesTechnical Query: King Salman International Complex For Maritime Industries and Services (MYP) CONTRACT 6600042823 (IK)muhammad zamanNo ratings yet

- Concrete Surface Preparation Part 3Document6 pagesConcrete Surface Preparation Part 3muhammad zamanNo ratings yet

- Concrete Surface Preparation Part 3Document6 pagesConcrete Surface Preparation Part 3muhammad zamanNo ratings yet

- List and Quantity of MaterialDocument59 pagesList and Quantity of Materialmuhammad zamanNo ratings yet

- Primavera P6 Is Used For Project ManagementDocument8 pagesPrimavera P6 Is Used For Project Managementmuhammad zamanNo ratings yet

- Fire FightingDocument3 pagesFire Fightingmuhammad zamanNo ratings yet

- Iso 45001 - 6.1.1Document2 pagesIso 45001 - 6.1.1dnmuleNo ratings yet

- HSE DocsDocument30 pagesHSE DocsAbubakr MohamedNo ratings yet

- JSA EmployeesDocument2 pagesJSA EmployeesburhanNo ratings yet

- Excavation Safety Dos and DontsDocument4 pagesExcavation Safety Dos and DontsVidya SagarNo ratings yet

- JSA For Insulation of VesselDocument6 pagesJSA For Insulation of Vesselyc safetyNo ratings yet

- Hazard Identification - MethodDocument12 pagesHazard Identification - Methodrnp2007123No ratings yet

- Att Job Safety Assessment (Jsa) Rev F Dated 9-22-15Document2 pagesAtt Job Safety Assessment (Jsa) Rev F Dated 9-22-15Brandon Moore0% (1)

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- JSA External Window Cleaning To 2 Story Building Full ReportDocument13 pagesJSA External Window Cleaning To 2 Story Building Full Reportsoumya ranjan beheraNo ratings yet

- Job Safety Analysis: Sample Written Program ForDocument27 pagesJob Safety Analysis: Sample Written Program ForniienNo ratings yet

- Jsa Ndt-BuildingDocument5 pagesJsa Ndt-BuildingFirdaus RidzuanNo ratings yet

- JSA WorkingWithHazardousSubstancesDocument2 pagesJSA WorkingWithHazardousSubstancesCristina RicanNo ratings yet

- P:XYZ Contractor/Forms/Site Specific Steel Erection Plan and ChecklistDocument5 pagesP:XYZ Contractor/Forms/Site Specific Steel Erection Plan and ChecklistocnszNo ratings yet

- Epci For Keera Metering Station Project Master Schedule CONTRACT NO.: CON/EEES/16/009Document3 pagesEpci For Keera Metering Station Project Master Schedule CONTRACT NO.: CON/EEES/16/009ardodotNo ratings yet

- Tataouine Gas Project Tataouine Branch Line: Risk Assessment ProcedureDocument16 pagesTataouine Gas Project Tataouine Branch Line: Risk Assessment ProcedureMoaatazz NouisriNo ratings yet

- 28 Job Safety AnalysisDocument7 pages28 Job Safety Analysisashish_kamat100% (3)

- Jsa-Rhi-Arz-0-051 Asu - Lube Oil FlushingDocument5 pagesJsa-Rhi-Arz-0-051 Asu - Lube Oil FlushingBadredine FarahNo ratings yet

- SHE Regulation 2020 With Attachment (Approved)Document212 pagesSHE Regulation 2020 With Attachment (Approved)Ainur RohmanNo ratings yet

- FUEL TANK FOUNDATION FoundationDocument7 pagesFUEL TANK FOUNDATION FoundationMohammed HamzaNo ratings yet

- 009-Civil-Ms Concrete Works PDFDocument27 pages009-Civil-Ms Concrete Works PDFKöksal PatanNo ratings yet

- XIX Paper 59Document15 pagesXIX Paper 59DarmawanNo ratings yet

- JSA - Turning Spectacle BlindDocument4 pagesJSA - Turning Spectacle BlindJJ WeldingNo ratings yet

- Job Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityDocument7 pagesJob Safety Analysis: Removing Porta Cabin & Loading at Trailor's ActivityMuhammad TariqNo ratings yet

- JHA For Pipe Work-01.09Document3 pagesJHA For Pipe Work-01.09Anonymous Xb3zHio100% (1)

- JSA Box UpDocument7 pagesJSA Box Upimam dianiNo ratings yet

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDocument4 pagesJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- AURETR143 Student Assessment 2 Job Card 2.v1.0Document11 pagesAURETR143 Student Assessment 2 Job Card 2.v1.0jjacoba42No ratings yet

- Behavior Based Safety HandoutsDocument7 pagesBehavior Based Safety HandoutsAnsarNo ratings yet