Professional Documents

Culture Documents

JSA Mobile Cranes

Uploaded by

Amanya DickallansOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JSA Mobile Cranes

Uploaded by

Amanya DickallansCopyright:

Available Formats

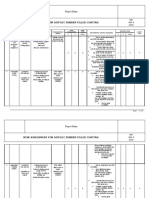

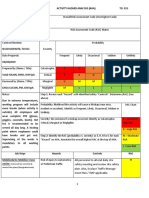

JOB SAFETY ANALYSIS

COMPANY/ PROJECT NAME or ID/ LOCATION ( City, State) DATE NEW

4/18/15 REVISED PAGE 1 of 2

WORK ACTIVITY (Description):

MOBILE CRANES

DEVELOPMENT TEAM POSITION / TITLE REVIEWED BY: POSITION / TITLE

Dave Ruzich Safety Coordinator

MINIMUM REQUIRED PERSONAL PROTECTIVE EQUIPMENT ( SEE CRITICAL ACTIONS FOR TASK-SPECIFIC REQUIREMENTS)

REFLECTIVE VEST GOGGLES AIR PURIFYING GLOVES Cut-resistant

HARD HAT FACE SHIELD RESPIRATOR OTHER Chaps

LIFELINE / HARNESS HEARING PROTECTION SUPPLIED RESPIRATOR

SAFETY GLASSES SAFETY SHOES PPE CLOTHING

¹JOB STEPS ²POTENTIAL HAZARDS ³CRITICAL ACTIONS TO MITIGATE HAZARDS

Mobilize crane onsite: Work area should be delineated & proper signage stating

Crane will be escorted & moved Risk of injury to Un-Authorized personnel & signs posted clearing the set

into place (designated area) by Automotive or up area the night before.

the P/M (Traffic & Pick Plan). Pedestrian traffic.

Use pilot cars to get crane and trucks to building.

Follow Traffic Control Plan (TCP) when pulling the crane

onsite (flaggers, cones, signage closing area down

including sidewalks and roads).

Verify TCP to ensure all areas in the plan are secure & free

of un-authorized personnel.

Ensure proper PPE for all adjacent personnel.

Mark off swing path with caution tape where live load &

turret will be swinging

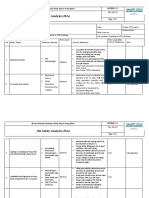

Inspections: Risk of injury from Inspection of Operators / Oilers certification (to ensure

Crane Operator License equipment failure or current).

Annual/ Pre-Shift Crane operator error.

Inspection Inspection of Crane certs. & other crane safety equipment.

Rigging Equipment Inspection

Verify the correct crane with what was submitted.

Inspection or Rigging equipment.

Risk of injury due to Be aware of overhead obstructions & your surrounding at

Crane set up: unstable ground all times.

Lay down outrigger pads &

extend outriggers Ensure all areas are maintained & free of un-authorized

personnel

Ensure swing radius is accurate.

Ensure pads are stable for out riggers

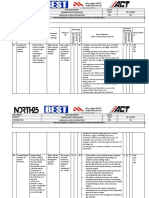

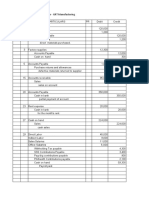

JOB SAFETY ANALYSIS

Hoisting Material: Risk of injury from falling objects Be aware of overhead obstructions & your surrounding at all

Picking material, tools or times.

equipment from rigging area to Keep visual or audio contact with rigger (pick up & landing

the unloading zone. points) at all times.

Please identify the material or

equipment being lifted. Once pick occurs, sound air horn prior to swing.

1. Structural Steel

2. Steel Siding All loads shall be tagged lined

¹ Each Job or Operation consists of a set of steps. Be sure to list all the steps in the sequence that they are performed. Specify the equipment or other details to set

the basis for the associated hazards in Column 2

² A hazard is a potential danger. What can go wrong? How can someone get hurt? Consider, but do not limit, the analysis to: Contact - victim is struck by or strikes

an object; Caught - victim is caught on, caught in or caught between objects; Fall - victim falls to ground or lower level (includes slips and trips); Exertion - excessive

strain or stress / ergonomics / lifting techniques; Exposure - inhalation/skin hazards. Specify the hazards and do not limit the description to a single word such as

"Caught"

³ Aligning with the first two columns, describe what actions or procedures are necessary to eliminate or minimize the hazards. Be clear, concise and specific. Use

objective, observable and quantified terms. Avoid subjective general statements such as, "be careful" or "use as appropriate".

You might also like

- The Hazard Identification and Risk Assessment for the Pacaltsdorp Substation Fence Installation ProjectDocument10 pagesThe Hazard Identification and Risk Assessment for the Pacaltsdorp Substation Fence Installation ProjectemmyNo ratings yet

- Manhole Construction SafetyDocument13 pagesManhole Construction SafetyTaiwo Oshin100% (1)

- CASE 1 Planning For Rise of Cloud Computing at MicrosoftDocument3 pagesCASE 1 Planning For Rise of Cloud Computing at MicrosoftVarunKeshariNo ratings yet

- Ma'aden Aluminium JSA for Backfilling, Grading and CompactionDocument3 pagesMa'aden Aluminium JSA for Backfilling, Grading and Compactionshoaib akhtarNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

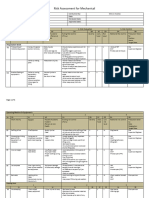

- Risk Assessment For Mechanical: Preparation WorkDocument3 pagesRisk Assessment For Mechanical: Preparation Workahmedalderbi801No ratings yet

- Civil EHS Risk Assessment - 1. ExcavationDocument2 pagesCivil EHS Risk Assessment - 1. Excavationshamshu123No ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Risk Assessment For Installation of Drainage Pipes PDF FreeDocument17 pagesRisk Assessment For Installation of Drainage Pipes PDF FreeMalik RizwanNo ratings yet

- Risk Assessment For Acrylic Rubber Filled CoatingDocument6 pagesRisk Assessment For Acrylic Rubber Filled CoatingKalid Jmal100% (2)

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- Concrete ChippingDocument3 pagesConcrete ChippingAbhijit ParasharNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- 02 RISK ASSESMENT For Constraction Vehicle Movement at SiteDocument1 page02 RISK ASSESMENT For Constraction Vehicle Movement at SiteVIRUPAKSHA KOOLINo ratings yet

- Daily JSA - Fence Post InstallationDocument5 pagesDaily JSA - Fence Post Installationshoaib akhtarNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Risk Assessment for Precast InstallationDocument11 pagesRisk Assessment for Precast InstallationSajid ShahNo ratings yet

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- EMP - Environmental Risk RegisterDocument23 pagesEMP - Environmental Risk RegisterNaveen ChaudharyNo ratings yet

- HSE Hazards and Effects Management for Wood Cutting MachinesDocument7 pagesHSE Hazards and Effects Management for Wood Cutting Machinessaravana.bNo ratings yet

- Swms For LV, MV Cable Laying 17.12.22Document5 pagesSwms For LV, MV Cable Laying 17.12.22Md Shahbaz AlamNo ratings yet

- Risk Assessment of Cable Tray InstallationDocument10 pagesRisk Assessment of Cable Tray Installationfayaz fayazhotmail.comNo ratings yet

- Surface Preparation SWMSDocument11 pagesSurface Preparation SWMSAmit SinghNo ratings yet

- Back FillingDocument1 pageBack FillingRohit SinghNo ratings yet

- Installation of Seismic Stoppers and Elastomeric BearingsDocument51 pagesInstallation of Seismic Stoppers and Elastomeric BearingsPlanning C7100% (1)

- HAZARD IDENTIFICATION AND RISK ASSESSMENTDocument31 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarNo ratings yet

- GeneralDocument7 pagesGeneralsujith s pNo ratings yet

- C/M or P Excavation SafetyDocument1 pageC/M or P Excavation SafetyHafiz SabriNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Hazard Risk Assessment and Control at Godrej Project SiteDocument11 pagesHazard Risk Assessment and Control at Godrej Project SiteRajput AmitNo ratings yet

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Risk Assessment For Production and ErectionDocument14 pagesRisk Assessment For Production and ErectionFurqan FarrukhNo ratings yet

- Batching Plant Project: Initial Environmental Examination (Iee) ReportDocument16 pagesBatching Plant Project: Initial Environmental Examination (Iee) ReportavieNo ratings yet

- Jsa-Rp-001 Site Preparation and General EarthworksDocument20 pagesJsa-Rp-001 Site Preparation and General Earthworksibaig1970No ratings yet

- Best Hse FileDocument5 pagesBest Hse FileGilbert GillNo ratings yet

- Risk Assessment for EarthworksDocument1 pageRisk Assessment for EarthworkskumarNo ratings yet

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- RA - For Precast ChambersDocument5 pagesRA - For Precast ChambersKallem RajashekarNo ratings yet

- RA 002 - Mechanical ExcavationDocument2 pagesRA 002 - Mechanical ExcavationZaki Abdullah ALQweaenNo ratings yet

- Mie Hse Jha 004 Installation of TransformerDocument5 pagesMie Hse Jha 004 Installation of TransformerMd Gulam SafiNo ratings yet

- Risk Assessment - Sheet Piling DraftDocument8 pagesRisk Assessment - Sheet Piling DraftSinaNo ratings yet

- AHA-002, Geotechnical WorkDocument5 pagesAHA-002, Geotechnical WorkBuddhikaNo ratings yet

- Risk Assessment - Rev01 8 4 2020-2Document14 pagesRisk Assessment - Rev01 8 4 2020-2shaibaz chafekar100% (1)

- High Risk Job Safety Analysis: Contractor ArgonneDocument13 pagesHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNo ratings yet

- Health, Safety and Environment Plan for Westown Residence Block 41 ConstructionDocument64 pagesHealth, Safety and Environment Plan for Westown Residence Block 41 ConstructionمصطفىمحمدNo ratings yet

- Job Safe Practices for Overhead Crane Operation (JSP 08Document4 pagesJob Safe Practices for Overhead Crane Operation (JSP 08Farooq MohammadNo ratings yet

- Precast Erection JSWDocument6 pagesPrecast Erection JSWPrabhakaran GurunathanNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Electric Risk AssessmentDocument10 pagesElectric Risk AssessmentThandabantu MagengeleleNo ratings yet

- RA For Cable Pulling and WiringDocument11 pagesRA For Cable Pulling and Wiringnikhilsingh1087No ratings yet

- SS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Document5 pagesSS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Farhat SetharNo ratings yet

- Risk Assessment-1 PDFDocument17 pagesRisk Assessment-1 PDFDayanandaNo ratings yet

- Temporary Structure Erection Work Risk AssessmentsDocument2 pagesTemporary Structure Erection Work Risk Assessmentshussein aliNo ratings yet

- Working at Height Risk AssessmentDocument3 pagesWorking at Height Risk AssessmentAmpala Vanan100% (1)

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetYounis KhanNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Unsafe MEWP Operation ReviewDocument2 pagesUnsafe MEWP Operation ReviewAbdulKatherNo ratings yet

- JSA Mobile Crane Pipe Installation Tandem LiftDocument3 pagesJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisNo ratings yet

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- AGRASOC ReviewerDocument30 pagesAGRASOC ReviewerSabrina YuNo ratings yet

- Ez Mill: Low-Cost Portable Hammer Mill Helps Small FarmersDocument37 pagesEz Mill: Low-Cost Portable Hammer Mill Helps Small FarmersANIME CHANNo ratings yet

- Sap Fi Budget Balance ReportsDocument58 pagesSap Fi Budget Balance ReportsPallavi ChawlaNo ratings yet

- Worked Solution (Formula Solution)Document2 pagesWorked Solution (Formula Solution)Amit Bansal AMYTHNo ratings yet

- Just Dial Limited Letter of OfferDocument68 pagesJust Dial Limited Letter of Offervarun_bhuNo ratings yet

- Quality Function Deployment in House-Building MarketDocument10 pagesQuality Function Deployment in House-Building MarketMarvi HarsiNo ratings yet

- Nigeria, Ghana, Kenya, Egypt and South Africa - Software Engineer (1 - 5)Document11 pagesNigeria, Ghana, Kenya, Egypt and South Africa - Software Engineer (1 - 5)Ajiboye JosephNo ratings yet

- GST Filing in IndiaDocument13 pagesGST Filing in IndiaKriti vardhanNo ratings yet

- Bsa - Finman - SyllabusDocument13 pagesBsa - Finman - SyllabusAbdulmajed Unda MimbantasNo ratings yet

- Operations Management (Zheng) SU2016 PDFDocument9 pagesOperations Management (Zheng) SU2016 PDFdarwin12No ratings yet

- The Application of Machine Learning and Deep LearnDocument20 pagesThe Application of Machine Learning and Deep LearnFran MoralesNo ratings yet

- Comprehensive Exam Case Analysis Lester Limheya FinalDocument36 pagesComprehensive Exam Case Analysis Lester Limheya FinalXXXXXXXXXXXXXXXXXXNo ratings yet

- Batangas State University Managerial Economics Article Site Author Date PublishedDocument3 pagesBatangas State University Managerial Economics Article Site Author Date PublishedBen TorejaNo ratings yet

- Social Support For Expatriates Through Virtual Platforms: Exploring The Role of Online and Offline ParticipationDocument33 pagesSocial Support For Expatriates Through Virtual Platforms: Exploring The Role of Online and Offline ParticipationAniss AitallaNo ratings yet

- Booking Invoice - M06AI23I17058515 - LTADocument1 pageBooking Invoice - M06AI23I17058515 - LTANishant DuggalNo ratings yet

- Chapter 2 The Concept of Audit Syllabus 2023Document88 pagesChapter 2 The Concept of Audit Syllabus 2023nguyenanleybNo ratings yet

- DTC 22-23 - Digital Transformation Strategy PDFDocument13 pagesDTC 22-23 - Digital Transformation Strategy PDFDebrian SaragihNo ratings yet

- Agency: Classification of Agents On The Basis of Authority On The Basis of Nature of WorkDocument8 pagesAgency: Classification of Agents On The Basis of Authority On The Basis of Nature of WorkATBNo ratings yet

- Solution Manufacturing Prob. GRT ManufacturingDocument15 pagesSolution Manufacturing Prob. GRT ManufacturingCarmi FeceroNo ratings yet

- Commentary: Ophthalmic Increasing Operations ofDocument2 pagesCommentary: Ophthalmic Increasing Operations ofDurval SantosNo ratings yet

- The Platinum Card®: Page 1 of 4Document4 pagesThe Platinum Card®: Page 1 of 4Emma ChanNo ratings yet

- App Store Marketing GuidelinesDocument19 pagesApp Store Marketing GuidelinesMichelle KoueiterNo ratings yet

- Business Implications of Sustainability Practices in Supply ChainsDocument25 pagesBusiness Implications of Sustainability Practices in Supply ChainsBizNo ratings yet

- Firming Up Inequality: How Rising Between-Firm Dispersion Contributed to Rising U.S. Earnings InequalityDocument50 pagesFirming Up Inequality: How Rising Between-Firm Dispersion Contributed to Rising U.S. Earnings InequalitySiti Nur AqilahNo ratings yet

- L&T Elastomeric Bearing ApprovalDocument2 pagesL&T Elastomeric Bearing ApprovalSubarnarekha HL BridgeNo ratings yet

- Sample Special Power of Attorney PAG-IBIG FUNDDocument2 pagesSample Special Power of Attorney PAG-IBIG FUNDRizal RamosNo ratings yet

- Exercise 1 Key PDF Cost of Goods Sold InvenDocument1 pageExercise 1 Key PDF Cost of Goods Sold InvenAl BertNo ratings yet

- Variable Life Insurance: Anniversary StatementDocument3 pagesVariable Life Insurance: Anniversary StatementKim RamosNo ratings yet

- Child Nutrition Procurement 2022Document91 pagesChild Nutrition Procurement 2022Jesse VillarrealNo ratings yet