Professional Documents

Culture Documents

Upload Product Entity Product PdfEn

Uploaded by

Ahmed AbuoelnagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upload Product Entity Product PdfEn

Uploaded by

Ahmed AbuoelnagaCopyright:

Available Formats

Acrylic 900

Description & Acrylic 900 is a ready for use putty, based on high quality acrylic co-polymer resins which have excellent filling properties

Features: without shrinkage or cracking even at high film thickness, with good adherence to smooth substrate & easy to sand.

{Conforms to Egyptian standard specification No. 6623/2008}

Recommended Recommended for internal & external use on all new surfaces such as concrete surfaces, cement and wood surfaces…..etc.

use:

Technical Color White

Specifications: (1)

Solid Content by weight 77% ±2

Specific Gravity (2) 1.8 ± 0.05 gm./cm³

Thinner Ready for use

Flash Point Non Flammable

Viscosity at 25˚ Thick Putty

*Spreading rate M²/kg. ( Theoretically ) 2-3 M²/kg.

*The actual Spreading rate depends on many factors such as porosity of substrate, surface preparation & application means.

Usage Condition: Atmosphere must be free from dust during use and drying, surface temperature should not be less than 5°C.

Application Data: Used Tools Filling knife

Surface Preparation The Surfaces must be dry and clean, free from grease, oil, dust

and must be remove any contamination before coating

Recommended Product No. of Coats

Coating System: GL Nile 29/ GL Nile 290 1

Acrylic 900 2

Geltex 20000, Super platen 6000, 2

Super Day-tone 3030 , ….etc.

Drying Time: - Initial drying time 30 - 60 min.

(at 25°c & 50% R.H): - Recoating time 3 - 4 hrs.

- Final drying time 12 hrs.

Storage & Validity: - Keep the sealed original container at a good ventilation place away from direct sun light, heat and accordance to local

laws, the product validity is 24 month from production date.

Packaging: - Product is available in a Kilo, Gallon, Drum & Bag package (For more information, please refer to the company price list).

Handling: - Handle with care, stir well before use.

Health and Safety: - Ensure good ventilation during application. Avoid inhalation of solvent or paint dust and avoid paint contact with skin

and eye.

- To get complete information about safety and health precaution you should return to the health and safety instructions.

Note:

The information contained in these pages is the best information that we have, it's based on laboratory tests and practical experience, including that the product is

used under conditions beyond our control, so we cannot ensure anything except the product quality and we reserve the right to change information and data given

without prior notice.

Issued at March 2013

These Technical Specifications canceled previously published Specifications

22 Reference

(1) ASTM D1259-85 /(2) ASTM D1475-98

You might also like

- Upload Product Entity Product PdfEnDocument1 pageUpload Product Entity Product PdfEnMohamed HamamaNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- Acrylic Sunscreen Sealer: Technical Data SheetDocument1 pageAcrylic Sunscreen Sealer: Technical Data SheetShaijan JosephNo ratings yet

- Polyfoam SS45Document71 pagesPolyfoam SS45BavishNo ratings yet

- Sikadur - 43 TaDocument3 pagesSikadur - 43 TaSylvester WafulaNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- Sikadur®-32 IN: Product Data SheetDocument3 pagesSikadur®-32 IN: Product Data SheetDeep GandhiNo ratings yet

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocument4 pagesSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNo ratings yet

- Aquaarm Topguard Aquaarm Topguard Aquaarm TopguardDocument2 pagesAquaarm Topguard Aquaarm Topguard Aquaarm TopguardmadhavNo ratings yet

- Silicone U - TDSDocument2 pagesSilicone U - TDShadeer youns0% (1)

- 282MEDocument2 pages282MEdutt0784No ratings yet

- Select Hi Gloss Enamel - 0939Document3 pagesSelect Hi Gloss Enamel - 0939Jimmy GeorgeNo ratings yet

- Sikagrout® - 295Document3 pagesSikagrout® - 295Ayman ZakariaNo ratings yet

- ResiGard TAS 2022-08-18 06 - 13 - 14Document3 pagesResiGard TAS 2022-08-18 06 - 13 - 14Sridhar RajajiNo ratings yet

- Ken Kyd 200 SPDocument2 pagesKen Kyd 200 SPDany Muhammad FNo ratings yet

- Royale High Gloss Enamel - 4926Document3 pagesRoyale High Gloss Enamel - 4926PraveenNo ratings yet

- Loctite 596™: SurfacesDocument2 pagesLoctite 596™: Surfaces楼淼森No ratings yet

- En GBDocument4 pagesEn GBNithin MathaiNo ratings yet

- Sigma Shield 1200Document5 pagesSigma Shield 1200Ventas IMSNo ratings yet

- Sikafloor - 89: 2-Part Water Based Epoxy CoatingDocument4 pagesSikafloor - 89: 2-Part Water Based Epoxy CoatingEaswar KumarNo ratings yet

- TDS Weberdry 360 PUDocument3 pagesTDS Weberdry 360 PUMahmoudFarhatNo ratings yet

- Sikagard®-62: Product Data SheetDocument4 pagesSikagard®-62: Product Data Sheetantonsugiarto20_7049No ratings yet

- KCC Silicone Koreseal sl819 7717Document4 pagesKCC Silicone Koreseal sl819 7717mapuphamNo ratings yet

- Berger QAD Enamel PDFDocument2 pagesBerger QAD Enamel PDFMuthuKumarNo ratings yet

- Pds Maestro Alkyd Primer 12070 En-GbDocument2 pagesPds Maestro Alkyd Primer 12070 En-GbHari BabuNo ratings yet

- Bituprime: Bituminous Roofing PrimerDocument2 pagesBituprime: Bituminous Roofing PrimerJalil TahirNo ratings yet

- Sikatop - 107 Sealid 221102 105735Document4 pagesSikatop - 107 Sealid 221102 105735Andre SitumeangNo ratings yet

- Sikagrout 201 - Pds en PDFDocument3 pagesSikagrout 201 - Pds en PDFswastika putuNo ratings yet

- Sikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerDocument2 pagesSikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerBruno AlfanoNo ratings yet

- Sikagrout®-200 PT Id: Product Data SheetDocument3 pagesSikagrout®-200 PT Id: Product Data SheetCbeztNo ratings yet

- En GBDocument3 pagesEn GBChayma HamdiNo ratings yet

- Product Data Sheet: G 2100 - Silicone SealantDocument2 pagesProduct Data Sheet: G 2100 - Silicone SealantShahid BhattiNo ratings yet

- Sikagard-62 UkDocument4 pagesSikagard-62 Ukbassem kooliNo ratings yet

- Sikagrout - 200 PtidDocument3 pagesSikagrout - 200 Ptidfandy sipataNo ratings yet

- Bitushield: Field of ApplicationDocument2 pagesBitushield: Field of ApplicationFandy SipataNo ratings yet

- Technical Data Sheet Jazeera Maxim Tex JA-26002: DescriptionDocument3 pagesTechnical Data Sheet Jazeera Maxim Tex JA-26002: DescriptionAhmad BougeisNo ratings yet

- 12X34 10130DSC12X34 Gori 34 Decking Stain TDS (En) #8248Document3 pages12X34 10130DSC12X34 Gori 34 Decking Stain TDS (En) #8248Ajith SomaratneNo ratings yet

- Aquaarm Spu SPL Ver 8 1Document3 pagesAquaarm Spu SPL Ver 8 1Paladi RaviNo ratings yet

- Sikadur 55 LP inDocument3 pagesSikadur 55 LP inRUDRA KARMAKARNo ratings yet

- Pentens: Ceramic Coating Description Technical & Physical DataDocument2 pagesPentens: Ceramic Coating Description Technical & Physical Datarobi setiawanNo ratings yet

- ShaliProtek PuR 40Document3 pagesShaliProtek PuR 40Rana MahatoNo ratings yet

- 283MEDocument2 pages283MEdutt0784No ratings yet

- Sigacoat 111: Technical Data SheetDocument2 pagesSigacoat 111: Technical Data SheetAmirhossein LotfiNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Sikafloor - 290 PrimerDocument4 pagesSikafloor - 290 PrimerMaha MuflehNo ratings yet

- Soudaflex Construction FCDocument2 pagesSoudaflex Construction FCAvijitSinharoyNo ratings yet

- Sikaseal - 105Document3 pagesSikaseal - 105Nader ToutounjiNo ratings yet

- EasyPro Alkyd Prime 2019Document2 pagesEasyPro Alkyd Prime 2019Raja SNo ratings yet

- Sikagard® PU UR (W) : Product Data SheetDocument3 pagesSikagard® PU UR (W) : Product Data SheetAMIT HALDERNo ratings yet

- Asian Paints SmartCare Flexi Seal PUDocument4 pagesAsian Paints SmartCare Flexi Seal PUNational WaterproofingNo ratings yet

- 58860Document2 pages58860Mohamed NouzerNo ratings yet

- Ceramic-Polymer 232 Spray Version - Ds - PDSDocument3 pagesCeramic-Polymer 232 Spray Version - Ds - PDSANIBALLOPEZVEGANo ratings yet

- En - Silcoset 152 TDS - 2Document1 pageEn - Silcoset 152 TDS - 2Андрей МошкинNo ratings yet

- Waterproofing - Sikafloor - Proseal-22Document3 pagesWaterproofing - Sikafloor - Proseal-22CC Cost AdvisoryNo ratings yet

- Masterseal TC 254 - TdsDocument2 pagesMasterseal TC 254 - TdsHanyNo ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- Berger QAD EnamelDocument2 pagesBerger QAD EnamelMuthuKumarNo ratings yet

- Magik 3217 Ul Classified Acrylic Sealant Anti Fungal Duct SealantDocument2 pagesMagik 3217 Ul Classified Acrylic Sealant Anti Fungal Duct SealantAhamed IbrahimNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- 1 Input Data: Profis Anchor 2.7.3Document7 pages1 Input Data: Profis Anchor 2.7.3Ahmed AbuoelnagaNo ratings yet

- Conbextra GP PDFDocument4 pagesConbextra GP PDFPrabowo SandiNo ratings yet

- Isolated Footing P OnlyDocument14 pagesIsolated Footing P OnlyAhmed AbuoelnagaNo ratings yet

- Proplast RC50 - TDSDocument2 pagesProplast RC50 - TDSAhmed AbuoelnagaNo ratings yet

- Isolated Footing P & MDocument4 pagesIsolated Footing P & MAhmed AbuoelnagaNo ratings yet

- Flo-Grout PC100 - TDSDocument2 pagesFlo-Grout PC100 - TDSAhmed AbuoelnagaNo ratings yet

- List of Prequalified Asphalt Plants and Approved Asphalt Mixes For PWA ProjectsDocument14 pagesList of Prequalified Asphalt Plants and Approved Asphalt Mixes For PWA ProjectsAhmed AbuoelnagaNo ratings yet

- SilverSchmidt - Sales Flyer - English - HighDocument4 pagesSilverSchmidt - Sales Flyer - English - HighAhmed AbuoelnagaNo ratings yet

- Isolated Footing P & MDocument4 pagesIsolated Footing P & MAhmed AbuoelnagaNo ratings yet

- Parex PRC 1Document1 pageParex PRC 1Ahmed AbuoelnagaNo ratings yet

- Isolated Footing P OnlyDocument14 pagesIsolated Footing P OnlyAhmed AbuoelnagaNo ratings yet

- Torsion Design For Freestand Stair BeamDocument2 pagesTorsion Design For Freestand Stair BeamAhmed AbuoelnagaNo ratings yet

- Design by Ahmed TabazaDocument149 pagesDesign by Ahmed TabazaAlaa SalimNo ratings yet

- Isolated Footing DesignDocument7 pagesIsolated Footing DesignChristopher Joshua MartinezNo ratings yet

- Sample Structural Investigation ReportDocument16 pagesSample Structural Investigation Reportmr. one100% (1)

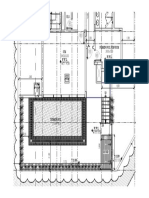

- Ar-02-Ground Floor Plan PDFDocument1 pageAr-02-Ground Floor Plan PDFAhmed AbuoelnagaNo ratings yet

- Marmocasa Profile RevisedDocument90 pagesMarmocasa Profile RevisedAhmed AbuoelnagaNo ratings yet

- 1 Input Data: WWW - Hilti.usDocument5 pages1 Input Data: WWW - Hilti.usAhmed AbuoelnagaNo ratings yet

- 174 - 00A000-R11-ModelDocument1 page174 - 00A000-R11-ModelAhmed AbuoelnagaNo ratings yet

- Preliminary Design of ShellsDocument7 pagesPreliminary Design of ShellsSarish KumarNo ratings yet

- Penstocks Catalogue PDFDocument19 pagesPenstocks Catalogue PDFAhmed AbuoelnagaNo ratings yet

- Marmocasa Profile RevisedDocument90 pagesMarmocasa Profile RevisedAhmed AbuoelnagaNo ratings yet

- 174 - 00a000-R09-Sec PDFDocument1 page174 - 00a000-R09-Sec PDFAhmed AbuoelnagaNo ratings yet

- 174 - 00A000-R11-Model PDFDocument1 page174 - 00A000-R11-Model PDFAhmed AbuoelnagaNo ratings yet

- Plastic ProcessingDocument35 pagesPlastic ProcessingCIPET KORBA TESTING100% (1)

- Welding CalculatorDocument4 pagesWelding CalculatorVbzNo ratings yet

- Potential Suppliers in Latvia For The Automotive Industry 2013 20130527 152118Document32 pagesPotential Suppliers in Latvia For The Automotive Industry 2013 20130527 152118Fredie IsaguaNo ratings yet

- Material Capabilities: Sintered Materials Other MaterialsDocument1 pageMaterial Capabilities: Sintered Materials Other MaterialsVíctor DominguezNo ratings yet

- YedaiDocument4 pagesYedaiAbel SánchezNo ratings yet

- Anjuman College of Engineering & TechnologyDocument12 pagesAnjuman College of Engineering & TechnologyZaky MuzaffarNo ratings yet

- Design and Development Mini Compression Molding For Teaching and LearningDocument7 pagesDesign and Development Mini Compression Molding For Teaching and LearningNeemsNo ratings yet

- Technical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum RangeDocument4 pagesTechnical Data Sheet Bright Acid Tin Process: Solution Composition: Optimum Rangeshanmukha MechanicalNo ratings yet

- item8-LNT NiCro60.20Document1 pageitem8-LNT NiCro60.20VVan TanNo ratings yet

- FIFI Pump Overhaul KitDocument1 pageFIFI Pump Overhaul KitBui Trung KienNo ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- Aeration Industries International, Inc. Aire-O Microfloat DAF Case StudyDocument6 pagesAeration Industries International, Inc. Aire-O Microfloat DAF Case StudyDileep C DileepNo ratings yet

- CSWIP 3.1 Multiple Choice Questions - Paper 3 - ProProfs QuizDocument9 pagesCSWIP 3.1 Multiple Choice Questions - Paper 3 - ProProfs QuizJawed Akhter100% (2)

- LECTURE 15-1: Synthesis and Preparation of Nanomaterials (Crystalline and Thinfilm)Document30 pagesLECTURE 15-1: Synthesis and Preparation of Nanomaterials (Crystalline and Thinfilm)Sk. Laila AyeshaNo ratings yet

- Tech-Macro Brochure-EN-23-2Document40 pagesTech-Macro Brochure-EN-23-2cadoantinhthuong1975No ratings yet

- Perancangan Dan Analisis Rangka Mesin: Desktop CNC MillingDocument9 pagesPerancangan Dan Analisis Rangka Mesin: Desktop CNC MillingBuruh PaculNo ratings yet

- Waterproofing Materials Commonly Applied To Commercial BuildingDocument21 pagesWaterproofing Materials Commonly Applied To Commercial BuildingBer Salazar Jr100% (1)

- Assignment 2Document5 pagesAssignment 2divyansh vermaNo ratings yet

- Activated SludgeDocument11 pagesActivated SludgeMuhammad Hafizh AzhariNo ratings yet

- Untitled 1Document3 pagesUntitled 1AmanNo ratings yet

- Cutting Force Thrust ForceDocument1 pageCutting Force Thrust ForcepmagrawalNo ratings yet

- 5.7 ETP & Textile Industry-13-44Document32 pages5.7 ETP & Textile Industry-13-44manoj gowdaNo ratings yet

- Welding & Hot Dip Galvanizing PDFDocument9 pagesWelding & Hot Dip Galvanizing PDFויליאם סן מרמיגיוסNo ratings yet

- Handmade Haven: Farmhouse X DeskDocument15 pagesHandmade Haven: Farmhouse X Deskgunay cakmakNo ratings yet

- Decora Stucco Putty: Product DescriptionDocument2 pagesDecora Stucco Putty: Product DescriptionMuthuKumar100% (1)

- Astm A517 GR B: General Product DescriptionDocument2 pagesAstm A517 GR B: General Product Descriptionjuan vargas tarazonaNo ratings yet

- Cast IronDocument27 pagesCast IronSanthoshsharma Devaraju100% (1)

- 15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Document3 pages15ifiziegftenioneers Standard Specification For Surface Preparation and Protective Coating 6-79-0020 Rev. 0Chinmay DaveNo ratings yet

- CK 60 PDFDocument3 pagesCK 60 PDFtaban89No ratings yet

- G Tooling System en PDFDocument194 pagesG Tooling System en PDFBandi DevaNo ratings yet