Professional Documents

Culture Documents

Select Hi Gloss Enamel - 0939

Uploaded by

Jimmy GeorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Select Hi Gloss Enamel - 0939

Uploaded by

Jimmy GeorgeCopyright:

Available Formats

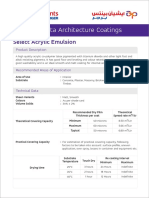

Technical Data Architecture Coatings

Select Hi Gloss Enamel

Product Description

A lead free enamel based on suitably modified alkyd containing titanium dioxide and other high

grade pigments to provide a tough, durable and hardwearing full gloss finish. It has excellent flow,

film build-up, hiding power, and is suitable as a decorative and protective coating.

Recommended Areas of Application

Area of Use : Interior & Exterior

Substrate : Metal, Timber, Masonry.

Technical Data

Sheen Variants : High Gloss, smooth.

Colours : As per shade card.

Volume Solids

(Based on ASTM D2697) : 37% ± 2%

Recommended Dry Film Theoretical

Thickness per coat Spread rate m²/ ltr

Theoretical Covering Capacity Minimum 25 Microns 14.8 m²/Ltr

Maximum 35 Microns 10.57 m²/Ltr

Typical 30 Microns 12.33 m²/Ltr

Practical Covering Capacity : For estimation of practical covering capacity, following

factors to be taken into account surface profile, uneven

application, overspray, losses in container and equipment etc.

Substrate Re coating Interval

Temperature Touch Dry

Minimum Maximum

Drying time 25°C 4 Hours 24 Hours Indefinite

35°C 2 Hours 18 Hours Indefinite

45°C 1½ Hours 12 Hours Indefinite

Application Data

Method of application : Brush, roller and airless spray application.

Thinner : TH-1

Thinning ratio (by vol.) : Use 5% to 10% for ease of application depending on the

method of application.

Surface Preparation

The performance of this coating is directly related to the degree of surface preparation.

• Ensure surface is clean, dry and free from all contaminants.

Steel

• Remove rust, if any, by sand blasting to Swedish Standard Sa 2 or by mechanical abrading.

Timber

• Wood may be treated further with Berger Wood Preservative.

Masonry

• Surface must be sound and free from laitance. Remove laitance by wire brush or sweep blast.

Application Details

• Ensure adequate ventilation during application and drying.

• Do not apply when humidity exceeds 80% and condensation is likely.

• Surface temperature should be 3°C or more above dew point.

Note: Use of Alkyd systems on masonry necessitates extra precautions such as, adequate

ventilation and light during and for a length of time after application.

Airless Spray : Tip Size : 0.22 – 0.30 mm (0.009 – 0.011 in)

Tip Pressure : 90 – 130 Kg /cm2 (1300 – 1800 psi)

Conventional Spray : Use normal spray equipment.

Brush or Roller : Apply an even coat taking care to avoid runs and sags. More than one

coat will be required.

Typical Paint System

Steel

1 Coat x Luxaprime 1400

1 Coat x Alkyd Undercoat

2 Coats x Select Hi-Gloss Enamel

Masonry

1 Coat x Alkyd Primer

1 Coat x Alkyd Undercoat

2 Coats x Select Hi-Gloss Enamel

Timber

1 Coat x Wood Primer

1 Coat x Alkyd Undercoat

2 Coats x Select Hi-Gloss Enamel.

Storage, Safety Information And Precautions

Kindly refer to the Safety Data Sheet (MSDS) for further information on safety measures.

Storage : Store the container with the lid tightly closed in an upright position, in a cool,

dry place, well ventilated space and keep away from sources of heat and ignition.

Keep out of reach of children and away from eatables.

Shelf Life : Upto 12 months

Flash Point : 38°C

Disposal : Left-over paint/drums should not be disposed in soil/drains. Consumers should

consult a local recycling agency for proper disposal of paint/drums or dispose as per

applicable statutory regulation.

Safety Precautions

• Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls,

goggles, dust masks and gloves. Use a barrier cream.

• Ensure that there is adequate ventilation in the area where the product is being applied. Do not

breathe vapour or spray.

First Aid

Eyes : In the event of accidental splashes, flush eyes with warm water immediately and

obtain medical advice.

Skin : Wash skin thoroughly with soap and water or an approved industrial cleaner. DO NOT

USE solvent or thinners.

Inhalation : Remove to fresh air, loosen collar and keep patient rested.

Ingestion : In case of accidental ingestion, DO NOT INDUCE VOMITTING. Obtain immediate medical

attention.

Disclaimer

The information provided in this data sheet is not intended to be complete. It is the responsibility of the user to ensure that the product

used is suitable for the purpose it is meant to serve. In view of various factors affecting the performance of the coating, we cannot

assume responsibility for the product performance, nor do we accept any liability arising from use of this product, unless specifically agreed

to in writing by us. The information provided in the data sheet may be modified by us without notice.

This Technical Data Sheet supersedes those previously issued with immediate effect

Version No: 04/19

You might also like

- Pds - Royale Atmos (Rev-02) (2) - 9824Document3 pagesPds - Royale Atmos (Rev-02) (2) - 9824Jhan Carlos ZapataNo ratings yet

- Royale High Gloss Enamel - 4926Document3 pagesRoyale High Gloss Enamel - 4926PraveenNo ratings yet

- Berger Royale Semi-Gloss EnamelDocument3 pagesBerger Royale Semi-Gloss Enamelbhima irabattiNo ratings yet

- Asian - Select Acrylic EmulsionDocument3 pagesAsian - Select Acrylic Emulsionguru sathya bharathyNo ratings yet

- Select Fine Texture - 4878Document2 pagesSelect Fine Texture - 4878arunbavaNo ratings yet

- PDS-Supreme Eggshell - Silk Version 1Document2 pagesPDS-Supreme Eggshell - Silk Version 1Moin AltafNo ratings yet

- Jotashield ColourXtreme Matt (I)Document3 pagesJotashield ColourXtreme Matt (I)محمد عزتNo ratings yet

- Pds Maestro Alkyd Primer 12070 En-GbDocument2 pagesPds Maestro Alkyd Primer 12070 En-GbHari BabuNo ratings yet

- Jotashield ColourXtreme Silk (I)Document3 pagesJotashield ColourXtreme Silk (I)محمد عزتNo ratings yet

- Transolac Undercoat 321Document2 pagesTransolac Undercoat 321mido medoNo ratings yet

- TDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Document5 pagesTDS - Chemflake Classic - English (Uk) - Issued.25.10.2013Khaled GamalNo ratings yet

- Epilux Concrete Primer - 8377Document2 pagesEpilux Concrete Primer - 8377SandipNo ratings yet

- 3 - PC 7049 - Apcodur MioDocument3 pages3 - PC 7049 - Apcodur Miosujay AvatiNo ratings yet

- TDS - Penguard Midcoat - Issu.26.11.2010 PDFDocument4 pagesTDS - Penguard Midcoat - Issu.26.11.2010 PDFvitharvanNo ratings yet

- Penguard Stayer - English (Uk) - Issued.06.12.2007Document3 pagesPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- 283MEDocument2 pages283MEdutt0784No ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- SiTech Putty English TDSDocument3 pagesSiTech Putty English TDSMahmoud MahalawyNo ratings yet

- Product Data Sheet: Transpoxy Masterbond 4.68Document2 pagesProduct Data Sheet: Transpoxy Masterbond 4.68rajeshNo ratings yet

- Gardex Premium Gloss: Technical Data SheetDocument3 pagesGardex Premium Gloss: Technical Data SheetBhayu Senoaji Dwi PrimasanjoyoNo ratings yet

- Penguard Primer Datasheet " Azadjotun"Document3 pagesPenguard Primer Datasheet " Azadjotun"AzadAhmadNo ratings yet

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Document3 pagesMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS Tankguard 412 English (Uk) Issued.22.05.2009Document4 pagesTDS Tankguard 412 English (Uk) Issued.22.05.2009Ahmed NabilNo ratings yet

- Alkydprimer - English (Uk) - Issued.06.12.2007Document3 pagesAlkydprimer - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- TDS - Penguard Tie Coat 100 - English (Uk) - Issued.26.11.2010 PDFDocument3 pagesTDS - Penguard Tie Coat 100 - English (Uk) - Issued.26.11.2010 PDFNPTNo ratings yet

- Pilot II: Technical DataDocument4 pagesPilot II: Technical DataMohamed FarhanNo ratings yet

- pm002 4446Document2 pagespm002 4446Dhanush Kumar RamanNo ratings yet

- TDS CleanStarDocument3 pagesTDS CleanStarMearg NgusseNo ratings yet

- TDS - Pilot II - English (Uk) - Issued.12.03.2012 PDFDocument4 pagesTDS - Pilot II - English (Uk) - Issued.12.03.2012 PDFNPTNo ratings yet

- (Firemask) sq476 2465Document3 pages(Firemask) sq476 2465Rosdin IsmailNo ratings yet

- PC 1752 - Asian Bituminous CoatingsDocument3 pagesPC 1752 - Asian Bituminous CoatingsRamesh BabuNo ratings yet

- CapaPlus Silk, Matt AE enDocument4 pagesCapaPlus Silk, Matt AE enShaik J MohamedNo ratings yet

- ALKYDPRIMERDocument3 pagesALKYDPRIMERMoh. Emil SyamsudinNo ratings yet

- Bengalac Aluminium: Technical DataDocument3 pagesBengalac Aluminium: Technical Dataabdelhamid ghazalaNo ratings yet

- Bengalac Red Oxide PrimerDocument3 pagesBengalac Red Oxide PrimerNagendra BurabattulaNo ratings yet

- Jazeera Acrythane 60Document3 pagesJazeera Acrythane 60salam nazarNo ratings yet

- Marathon XHB - English (Uk) - Issued.06.12.2007Document3 pagesMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- 282MEDocument2 pages282MEdutt0784No ratings yet

- Berger Coating StandardsDocument9 pagesBerger Coating StandardsHariHaranNo ratings yet

- Transpoxy Tankguard 118 ESDocument5 pagesTranspoxy Tankguard 118 ESFadi MagdyNo ratings yet

- Etch Primer Is 5666Document3 pagesEtch Primer Is 5666Er Aftab ShaikhNo ratings yet

- TDS-ANODESHIELD ICCP-EnglishDocument4 pagesTDS-ANODESHIELD ICCP-EnglishthirdNo ratings yet

- TDS 0004 FlexoPrime 202003Document3 pagesTDS 0004 FlexoPrime 202003Mearg NgusseNo ratings yet

- Durosan 02 INT MATT (I) : Technical Data SheetDocument3 pagesDurosan 02 INT MATT (I) : Technical Data Sheetمحمد عزتNo ratings yet

- JOTUN DECO Jotashield Extreme MattDocument3 pagesJOTUN DECO Jotashield Extreme MattWeasley RonNo ratings yet

- Penguard Midcoat: Technical DataDocument3 pagesPenguard Midcoat: Technical DataMohamed FarhanNo ratings yet

- Durosan 02 Matt Datasheet " AzadJotun"Document3 pagesDurosan 02 Matt Datasheet " AzadJotun"AzadAhmadNo ratings yet

- Product Technical Data Glass Flake Epoxy PaintDocument2 pagesProduct Technical Data Glass Flake Epoxy PaintSudheesh SudhakaranNo ratings yet

- Jotashield ColourLast Matt (I)Document3 pagesJotashield ColourLast Matt (I)محمد عزتNo ratings yet

- Thermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Document3 pagesThermoplastic Road Marking Paint: Product Code: TTP 1 & TTP 2Veera PandiNo ratings yet

- TDS+ +Gardex+Primer+ +english+ (Uk) + +issued.12.03.2009Document3 pagesTDS+ +Gardex+Primer+ +english+ (Uk) + +issued.12.03.2009mas danNo ratings yet

- Lembar Data Keselamatan Bahan CatDocument3 pagesLembar Data Keselamatan Bahan CatMuhamad AsikNo ratings yet

- Zinc Chromate Primer PDFDocument2 pagesZinc Chromate Primer PDFWanda WibisanaNo ratings yet

- Hydro Anti Stick ClearDocument3 pagesHydro Anti Stick Clearwali_crocNo ratings yet

- Tankguard Holding Primer: Technical DataDocument4 pagesTankguard Holding Primer: Technical DataTra ThanhNo ratings yet

- Chemclear - English (Uk) - Issued.10.01.2008Document3 pagesChemclear - English (Uk) - Issued.10.01.2008Mohamed FaragNo ratings yet

- Interline 1012+ds+engDocument4 pagesInterline 1012+ds+engSUBHOMOYNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- QD Thinner - TDocument3 pagesQD Thinner - TJimmy GeorgeNo ratings yet

- Fenomastic WonderwallDocument12 pagesFenomastic WonderwallJimmy GeorgeNo ratings yet

- Crystal Reports ActiveX Designer - SDS - RPT - SDB - VMZ - EngDocument9 pagesCrystal Reports ActiveX Designer - SDS - RPT - SDB - VMZ - EngJimmy GeorgeNo ratings yet

- MSDS - HAND SANITIZER - LiquidDocument3 pagesMSDS - HAND SANITIZER - LiquidJimmy GeorgeNo ratings yet

- Company Name Primary SectorDocument681 pagesCompany Name Primary SectorJimmy GeorgeNo ratings yet

- Safety Data Sheet: 01 Identification of The Substance/mixture and of The Company UndertakingDocument6 pagesSafety Data Sheet: 01 Identification of The Substance/mixture and of The Company UndertakingJimmy GeorgeNo ratings yet

- Heat Stress Prevention ProgramDocument6 pagesHeat Stress Prevention ProgramJimmy GeorgeNo ratings yet

- Cover Letter TemplateDocument1 pageCover Letter TemplateBlue BirdNo ratings yet

- Middle East Healthcare Directory Database Excel Format SampleDocument1 pageMiddle East Healthcare Directory Database Excel Format SampleJimmy GeorgeNo ratings yet

- Dubaibusinessdirectory SampleDocument4 pagesDubaibusinessdirectory SampleJimmy George100% (1)

- Instrumentation Engineer - Tojo TomDocument3 pagesInstrumentation Engineer - Tojo TomJimmy GeorgeNo ratings yet

- Cover Letter 2012 ExampleDocument1 pageCover Letter 2012 ExampleliviuzamanNo ratings yet

- SamplehhDocument4 pagesSamplehhJimmy GeorgeNo ratings yet

- KA FormDocument6 pagesKA FormJimmy GeorgeNo ratings yet

- SamplehhDocument4 pagesSamplehhJimmy GeorgeNo ratings yet

- Jimmy George - Electrical Engineer-ResumeDocument2 pagesJimmy George - Electrical Engineer-ResumeJimmy GeorgeNo ratings yet

- Recruitment Agencies in Dubai-1Document1 pageRecruitment Agencies in Dubai-1Usman JamilNo ratings yet

- HR Email Id DubaiDocument98 pagesHR Email Id DubaiJimmy George61% (72)

- Dynamic Stochastic General Equilibrium (Dsge) Modelling:Theory and PracticeDocument34 pagesDynamic Stochastic General Equilibrium (Dsge) Modelling:Theory and PracticeRSNo ratings yet

- Geometry of Middle SurfaceDocument29 pagesGeometry of Middle SurfaceParth ShahNo ratings yet

- Tunnel Thru The Air Correct Starting PointDocument2 pagesTunnel Thru The Air Correct Starting Pointkhit wong54% (13)

- Egcuwa - Butterworth Profile PDFDocument84 pagesEgcuwa - Butterworth Profile PDFsbuja7No ratings yet

- FINALby REDAZADocument3 pagesFINALby REDAZANoreen RedazaNo ratings yet

- Assignment 1: InstructionsDocument6 pagesAssignment 1: InstructionsAsim MughalNo ratings yet

- Proforma - Attendance PercentageDocument6 pagesProforma - Attendance Percentageraja93satNo ratings yet

- Deber Modelación de AguasDocument2 pagesDeber Modelación de AguasLiz VillamarNo ratings yet

- Basic Measurement PiezoeletricDocument6 pagesBasic Measurement PiezoeletricALEX_INSPETORNo ratings yet

- English: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyDocument24 pagesEnglish: Quarter 2 - Module 1 Listening Strategies Based On Purpose, Familiarity With The Topic, and Levels of DifficultyMary Ysalina100% (3)

- All The Words I Should Have Said - Rania NaimDocument167 pagesAll The Words I Should Have Said - Rania NaimNan Nan100% (2)

- Electrical Circuits 2 AssignmentDocument5 pagesElectrical Circuits 2 Assignmentangelo dedicatoriaNo ratings yet

- CH 3 Around The Table Negotiations 1 By: Hadaitulalh BaqriDocument14 pagesCH 3 Around The Table Negotiations 1 By: Hadaitulalh BaqriHadait Ullah Baqri80% (5)

- Crafting The Service Environment: Text Book Chapter 10Document25 pagesCrafting The Service Environment: Text Book Chapter 10Sneha DussaramNo ratings yet

- BrusselsDocument1 pageBrusselskmiqdNo ratings yet

- Rockmass Strength PropertiesDocument32 pagesRockmass Strength PropertieskannonzkNo ratings yet

- Bootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFDocument21 pagesBootstrap 3 All Classes List Cheat Sheet Reference PDF (2020) PDFHoney ShineNo ratings yet

- Remote Sensing GeologyDocument438 pagesRemote Sensing GeologyStalin Bryan100% (2)

- Highlands FM: Jacqueline LawrenceeDocument14 pagesHighlands FM: Jacqueline LawrenceeLydia LaizaNo ratings yet

- Reference Manual - Model 6487 Picoammeter/Voltage SourceDocument338 pagesReference Manual - Model 6487 Picoammeter/Voltage SourceRanilson AngeloNo ratings yet

- Market Size Estimation WhitepaperDocument10 pagesMarket Size Estimation WhitepaperAmit AshishNo ratings yet

- Impact On OrganizationsDocument14 pagesImpact On OrganizationsogakhanNo ratings yet

- Quarter 3-LP-Eng10-Lesson3Document4 pagesQuarter 3-LP-Eng10-Lesson3Cynthia LuayNo ratings yet

- Sogc AssignmentDocument2 pagesSogc Assignmentapi-573219210No ratings yet

- Basics On Piping LayoutDocument11 pagesBasics On Piping Layoutpuru55980No ratings yet

- Competency Assessment FormDocument2 pagesCompetency Assessment FormLielet MatutinoNo ratings yet

- Long Quiz For Week 12345Document26 pagesLong Quiz For Week 12345Jerwyn Marie CayasNo ratings yet

- Pallet Truck wp3000 Spec1 GBDocument6 pagesPallet Truck wp3000 Spec1 GBEjaz EjazNo ratings yet

- BiometricsDocument10 pagesBiometricsKrishna Murthy PNo ratings yet

- Stsgroup 1Document13 pagesStsgroup 1Wenalyn Grace Abella LlavanNo ratings yet