Professional Documents

Culture Documents

Rtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement Operations

Uploaded by

Emad JamshidiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement Operations

Uploaded by

Emad JamshidiCopyright:

Available Formats

LEVEL 1 CAPABILITY

WELLBORE | Level |2 Retrievable

SERVICE TOOLS Capability (if

Tools

applicable)

RTTS® Packer

SIMPLE, VERSATILE MEANS FOR TESTING, TREATING AND

SQUEEZE CEMENT OPERATIONS

FEATURES & BENEFITS

»» Full opening design of the packer

mandrel bore allows large volumes of

fluid to pump through the tool

»» Tubing-type guns and other

wireline tools can be run through

the packer

»» Packer can be set and relocated as

many times as necessary

»» Tungsten carbide slips provide greater

holding ability and improved wear

resistance in high-strength casing

»» Optional integral circulating valve locks

into open or closed position during

OVERVIEW squeezing or treating operations and

opens easily to allow circulation above

The RTTS® packer has been one of the most used and well known service

the packer

packers in the industry for over 60 years. These Halliburton packers have been run

successfully in over a hundred thousand jobs in just about every country oil and

OPERATION

gas is produced. Reliability and durability is what makes operators ask for them by

name - some are still in wellbores that have been working continuously for as long The tool is run slightly below the desired

as 29 years. setting position to set the packer and

is then picked up and rotated several

HOW IT WORKS turns. If the tool is on the bottom,

only a quarter-turn is actually required.

The RTTS packer is a full-opening, hookwall packer used for testing, treating, and

However, in deep or deviated holes,

squeeze cementing operations. In most cases, the tool runs with a circulating valve

several turns with the rotary may be

assembly. The packer body includes a J-slot mechanism, mechanical slips, packer

necessary. To maintain position, the

elements, and hydraulic slips. Large, heavy-duty slips in the hydraulic holddown

right-hand torque must be held until the

mechanism help prevent the tool from being pumped up the hole. Drag springs

mechanical slips on the tool are set and

operate the J-slot mechanism on ≤ 3 1/2-in. (88.9-mm) packer bodies, while larger

can start taking weight.

packer sizes ≥ 4-in. (101.6 mm) use drag blocks. Automatic J-slot sleeves are

standard equipment on all Halliburton packer bodies. The pressure must be equalized across

the packer to unset it. As the tubing is

The circulating valve, if used, is a locked-open/locked-closed type that serves as

picked up, the circulating valve remains

both a circulating valve and bypass. The valve automatically locks in the closed

closed, establishing reverse circulation

position when the packer sets. During testing or squeezing operations, the lock

around the lower end of the packer.

prevents the valve from being pumped open. A straight J-slot in the locked-

The circulating valve is opened so it can

open position matches with a straight J-slot (optional) in the packer body. This

come out of the hole when the tubing is

combination eliminates the need to turn the tubing to close the circulating valve

lowered, rotated to the right, and

or reset the packer after the tubing has been displaced with cement, thus saving

picked up.

valuable rig time.

LEVEL 1 CAPABILITY

WELLBORE | Level |2 Retrievable

SERVICE TOOLS Capability (if

Tools

applicable)

RTTS® Packers

Packer Nominal

Minimum Maximum Tensile Max working

Casing Size Main Body Packer ID Casing Length in.

Casing ID Casing ID Rating* lb pressure

in. OD in. (cm) Weight (cm)

in. (mm) in. (mm) (kg) psi (MPa)

in. (cm) lb/ft

1.81 0.60 1.930 2.029 35.45 28,700 10,000

2 3/8 4.6

(4.60) (1.52) (49.02) (51.54) (90.04) (13,018) (68.95)

2.22 0.75 2.372 2.493 28.44 38,300 10,000

6.5

(5.64) (1.91) (60.25) (63.32) (72.24) (17,373) (68.95)

2 7/8

2.10 0.60 2.172 2.353 35.46 54,463 10,000

7.9 - 8.7

(5.33) (1.52) (55.17) (59.77) (90.07) (24,704) (68.95)

2.93 0.62 3.150 3.197 32.53 63,800 10,000

5.7

(7.44) (1.57) (80.01) (81.20) (82.63) (28,940) (68.95)

2.70 0.62 2.842 3.037 32.53 63,800 10,000

3 1/2 9.2 - 10.2

(6.86) (1.57) (72.19) (77.14) (82.63) (28,940) (68.95)

2.50 0.62 2.668 2.809 32.53 63,800 10,000

13.3

(6.35) (1.57) (67.77) (71.35) (82.63) (28,940) (68.95)

3.18 1.12 3.350 3.599 52.68 73,959 10,000

9.5 - 11.6

(8.08) (2.84) (85.09) (91.41) (133.81) (33,584) (68.95)

4

3.06 0.875 3.144 3.441 50.30 63,200 10,000

12.5 - 15.7

(7.77) (2.22) (79.86) (87.40) (127.76) (28,667) (68.95)

3.89 1.80 3.941 4.154 51.85 77,077 10,000

9.5

(9.88) (4.57) (100.10) (105.51) (131.70) (34,962) (68.95)

3.75 1.80 3.852 4.041 51.85 77,077 10,000

4 1/2 11.6 - 13.5

(9.53) (4.57) (97.85) (102.64) (131.70) (34,962) (68.95)

3.55 1.50 3.657 3.903 49.27 107,059 10,000

15.1 - 17.1

(9.02) (3.81) (92.89) (99.14) (125.15) (48,562) (68.95)

4.25 1.80 4.430 4.560 48.10 84,649 10,000

11.5 - 13

(10.80) (4.57) (112.52) (115.82) (122.17) (38,397) (68.95)

4.06 1.80 4.194 4.486 48.35 86,026 10,000

15 - 18

(10.31) (4.57) (106.53) (113.94) (122.81) (39,021) (68.95)

5

3.89 1.80 4.031 4.219 51.85 77,077 10,000

21.4

(9.88) (4.57) (102.38) (107.15) (131.70) (34,962) (68.95)

3.78 1.80 3.945 4.145 51.85 77,077 10,000

23.2

(9.53) (4.57) (100.20) (105.28) (131.70) (34,962) (68.95)

4.55 1.90 4.694 5.102 48.61 142,344 10,000

13 - 20

(11.56) (4.83) (119.23) (129.59) (123.47) (64,567) (68.95)

4.40 1.80 4.577 4.867 48.10 84,649 10,000

5 1/2 20 -23

(11.18) (4.57) (116.25) (123.62) (122.17) (38,397) (68.95)

4.25 1.90 4.444 4.765 48.10 84,649 10,000

23 - 26

(10.79) (4.83) (112.87) (121.02) (122.17) (38,397) (68.95)

4.89 1.90 5.100 5.365 48.61 133,208 10,000

5 3/4 14 - 18

(12.42) (4.83) (129.54) (136.27) (123.47) (60,423) (68.95)

5.06 1.90 5.151 5.599 48.61 142,344 10,000

15 - 23

(12.85) (4.83) (130.84) (142.21) (123.47) (64,567) (68.95)

6

4.89 1.90 5.034 5.388 48.61 133,200 10,000

20 - 26

(12.42) (4.83) (127.85) (136.86) (123.47) (60,419) (68.95)

5.65 2.38 5.799 6.551 54.22 160,810 10,000

17 - 20

(14.35) (6.03) (147.29) (166.40) (137.72) (72,943) (68.95)

6 5/8

5.43 1.90 5.567 5.980 48.62 133,208 10,000

24 - 32

(13.79) (4.83) (141.40) (151.89) (123.49) (60,423) (68.95)

These ratings are guidelines only. * High-Expansion Packer

Table continued on next page

LEVEL 1 CAPABILITY

WELLBORE | Level |2 Retrievable

SERVICE TOOLS Capability (if

Tools

applicable)

RTTS® Packers

Packer Nominal

Minimum Maximum Tensile Max working

Casing Size Main Body Packer ID Casing Length in.

Casing ID Casing ID Rating* lb pressure

in. OD in. (cm) Weight (cm)

in. (mm) in. (mm) (kg) psi (MPa)

in. (cm) lb/ft

5.65 2.38 5.799 6.551 54.22 160,810 10,000

17 - 38

(14.35) (6.03) (147.29) (166.40) (137.72) (72,943) (68.95)

7

5.25 2.00 5.384 5.701 48.61 133,208 10,000

49.5

(13.34) (5.08) (136.76) (144.81) (123.47) (60,423) (68.95)

6.35 2.38 6.509 7.129 54.22 160,810 10,000

24 - 39

(16.13) (6.03) (165.32) (181.08) (137.72) (72,943) (68.95)

7 5/8

6.16 2.38 6.430 6.901 54.22 158,238 10,000

29.7 - 45.3

(15.64) (6.03) (163.32) (175.29) (137.72) (71,777) (68.95)

6.16 2.38 6.430 6.901 54.22 158,238 10,000

7 3/4 33.2 - 50

(15.64) (6.03) (163.32) (175.29) (137.72) (71,777) (68.95)

7.31 3.00 7.381 8.207 89.29 237,218 7,500

8 5/8 24 - 49

(18.57) (7.62) (187.48) (208.46) (226.80) (107,602) (51.71)

8.25 3.75 8.403 9.049 94.12 379,267 7,500

36 - 53.5

(20.96) (9.53) (213.43) (229.85) (239.06) (172,036) (51.71)

9 5/8

7.80 3.00 7.958 8.587 90.79 237,200 7,500

58.4 - 71.8

(19.81) (7.62) (202.13) (218.11) (230.61) (107,592) (51.71)

9.40 3.75 9.631 10.189 90.83 444,600 5,000

40.5 - 55.5

(23.88) (9.53) (244.63) (258.88) (230.71) (201,667) (34.48)

10 3/4

8.85 3.75 8.976 9.818 94.58 444,600 5,000

60.7 - 85.3

(22.48) (9.53) (228.00) (249.37) (240.23) (201,667) (34.48)

10.60 3.75 10.756 11.223 92.27 444,600 5,000

47 - 54

(26.92) (9.53) (273.20) (285.06) (234.37) (201,667) (34.48)

11 3/4

10.10 3.75 10.438 10.934 96.27 444,600 5,000

60 - 71

(25.65) (9.53) (265.13) (277.72) (244.53) (201,667) (34.48)

11.10 3.75 11.500 11.884 92.27 444,600 3,000

12 3/4 57 - 81

(28.19) (9.53) (292.10) (301.85) (234.37) (201,667) (20.69)

11.94 3.75 12.203 12.783 132.29 651,300 5,000

54.5 - 72

(30.33) (9.53) (309.96) (324.69) (336.02) (295,425) (34.48)

13 3/8

11.50 3.75 11.760 12.403 101.36 651,300 5,000

72 - 98

(29.21) (9.53) (298.70) (315.04) (257.45) (295,425) (34.48)

12.25 3.75 12.449 13.067 103.36 651,300 5,000

14 82.5 - 98

(31.12) (9.53) (316.20) (331.90) (262.53) (295,425) (34.48)

14.43 3.75 15.115 15.564 113.93 651,300 2,500

55 - 65

(36.65) (9.53) (383.92) (395.33) (289.38) (295,425) (17.24)

14.18 3.75 14.509 15.215 113.93 651,300 2,500

16 84 - 109

(36.02) (9.53) (368.53) (386.46) (289.38) (295,425) (17.24)

13.62 3.75 13.968 14.688 113.93 651,300 2,500

109 - 146

(34.59) (9.53) (354.79) (373.07) (289.38) (295,425) (17.24)

These ratings are guidelines only. * High-Expansion Packer

Table continued on next page

LEVEL 1 CAPABILITY

WELLBORE | Level |2 Retrievable

SERVICE TOOLS Capability (if

Tools

applicable)

RTTS® Packers

Packer Nominal

Minimum Maximum Tensile Max working

Casing Size Main Body Packer ID Casing Length in.

Casing ID Casing ID Rating* lb pressure

in. OD in. (cm) Weight (cm)

in. (mm) in. (mm) (kg) psi (MPa)

in. (cm) lb/ft

16.87 3.75 17.257 17.980 122.71 651,300 2,500

18 5/8 78 - 118

(42.85) (9.53) (438.33) (456.69) (311.68) (295,425) (17.24)

18.535 19.213 114.71 1,000,000 2,500

17.87 (45.39) 3.75 (9.53) 94 - 133

(470.79) (488.01) (291.36) (453,592) (17.24)

17.257 17.980 209.72 1,000,000 2,500

20 17.25* (43.82) 4.14 (10.25) 133 - 187

(438.33) (456.69) (532.69) (453,592) (17.24)

17.951 18.650 122.71 1,000,000 2,500

17.25 (43.82) 3.75 (9.53) 169 - 204

(455.96) (473.71) (311.68) (453,592) (17.24)

These ratings are guidelines only. * High-Expansion Packer

For more information, contact your local Halliburton representative

or visit us on the web at www.halliburton.com

Sales of Halliburton products and services will be in accord solely with the terms and conditions

contained in the contract between Halliburton and the customer that is applicable to the sale.

H08344 8/17 © 2017 Halliburton. All Rights Reserved.

You might also like

- CHAMP® XHP PackerDocument2 pagesCHAMP® XHP PackerservicemenruNo ratings yet

- Hydraquaker: Hydraulic Drilling Jar Delivers High ImpactDocument4 pagesHydraquaker: Hydraulic Drilling Jar Delivers High ImpactPavin PiromNo ratings yet

- PPE I PR 005Document11 pagesPPE I PR 005MahanderOadNo ratings yet

- Casing Running and Drilling ToolsDocument33 pagesCasing Running and Drilling Toolsfffggg777No ratings yet

- Successfully Drills Through Total Losses Zones, Saves 17.6 DaysDocument2 pagesSuccessfully Drills Through Total Losses Zones, Saves 17.6 DaysAriel Della TorreNo ratings yet

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocument15 pagesPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806No ratings yet

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- 4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description FeaturesDocument1 page4 - in and 5-In. Posiset Thru-Tubing Plug (1 - In. Od) : Description Featureshamed1725No ratings yet

- Halliburton: VR Safety JointDocument2 pagesHalliburton: VR Safety Jointsaeed65No ratings yet

- Alternate Path Technology: Higher Production From Gravel-Packed WellsDocument8 pagesAlternate Path Technology: Higher Production From Gravel-Packed WellsNatasha Perez EscobarNo ratings yet

- The Most Accurate Whipstock OrientationDocument2 pagesThe Most Accurate Whipstock OrientationSaeed AraNo ratings yet

- Champ Ion PackerDocument2 pagesChamp Ion PackerCHO ACHIRI HUMPHREYNo ratings yet

- ElastiCem Resilient Slurry SystemsDocument2 pagesElastiCem Resilient Slurry Systemsbagus918No ratings yet

- Preparation For Running CasingDocument3 pagesPreparation For Running CasingYougchu LuanNo ratings yet

- Tdas West Shell 091602Document15 pagesTdas West Shell 091602amin peyvandNo ratings yet

- Fs2 Isolation Barrier ValveDocument12 pagesFs2 Isolation Barrier Valvehamed66652No ratings yet

- C 2 Hipstock Ystems: HapterDocument16 pagesC 2 Hipstock Ystems: HapterRazvan Radu100% (1)

- Seal Assemblies (Locator, Anchor, Latch)Document2 pagesSeal Assemblies (Locator, Anchor, Latch)Yougchu LuanNo ratings yet

- Cement PlugDocument7 pagesCement PlugJayesh ChavanNo ratings yet

- 9 1/2" Autotrak RCLS: Technical Data SheetDocument2 pages9 1/2" Autotrak RCLS: Technical Data SheetTamer Hesham AhmedNo ratings yet

- Radial Cutting Torch 070415Document4 pagesRadial Cutting Torch 070415Carlos Alberto Aguilera MendezNo ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- Packer Technology: Joshua BeierDocument75 pagesPacker Technology: Joshua BeierOctopus100% (1)

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Inspection Casing On Location Procedure22222222Document11 pagesInspection Casing On Location Procedure22222222hamdi hamdiNo ratings yet

- Trackmaster OhcDocument5 pagesTrackmaster OhcCharles DesmazuresNo ratings yet

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Posiset Ds PDFDocument2 pagesPosiset Ds PDFariosabzNo ratings yet

- Properties of Drilling FluidDocument3 pagesProperties of Drilling FluidAnsell EwemeNo ratings yet

- DST Slip Joint PDFDocument8 pagesDST Slip Joint PDFcrni rokoNo ratings yet

- Davis Stage Cementing Collar and Equipment PDFDocument5 pagesDavis Stage Cementing Collar and Equipment PDFPdax FirdausNo ratings yet

- Uses of PackersDocument13 pagesUses of Packersmohamed_sahnoun_enisNo ratings yet

- Sidetracking PrinciplesDocument3 pagesSidetracking PrinciplesDon BraithwaiteNo ratings yet

- Trackmaster CH - DesbloqueadoDocument19 pagesTrackmaster CH - DesbloqueadoPaola SamoNo ratings yet

- Seal Bore Packer System - RetrievableDocument8 pagesSeal Bore Packer System - RetrievableFabio ParceroNo ratings yet

- 5in 18ppf SLHT S-Timed PDFDocument1 page5in 18ppf SLHT S-Timed PDFBunda AntieNo ratings yet

- Wellbore Integrity Restoration Services Brochure PDFDocument8 pagesWellbore Integrity Restoration Services Brochure PDFDavid LuhetoNo ratings yet

- Maintenance Steps of Mud Gas SeparatorDocument1 pageMaintenance Steps of Mud Gas SeparatorNumbWong100% (1)

- Auto Fill Float Casing RunningDocument3 pagesAuto Fill Float Casing RunningtxcrudeNo ratings yet

- Drilling With Casing Promises Major BenefitsDocument12 pagesDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaNo ratings yet

- Cavins Double Action Tubing PumpDocument2 pagesCavins Double Action Tubing PumpHassan KhalidNo ratings yet

- CTD Liner Running & CementingDocument6 pagesCTD Liner Running & CementingAdel Ahmed AlkhaligyNo ratings yet

- Training Report Down HoleDocument36 pagesTraining Report Down HolePulkit GururaniNo ratings yet

- Freeing Stuck Pipe Probability and FishingDocument7 pagesFreeing Stuck Pipe Probability and Fishingvelayati_aNo ratings yet

- Homco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealDocument8 pagesHomco Casing Patch: Restoring Casing Integrity With A Permanent Steel SealHamed NazariNo ratings yet

- Shts & RPSB, HPSRDocument8 pagesShts & RPSB, HPSRAyman100% (1)

- Introduction To Cementing ClientsDocument59 pagesIntroduction To Cementing ClientsSlim.BNo ratings yet

- Deep Workover Challenges of An HP:HT Sour Gas Well - Case History of Mutriba 12Document14 pagesDeep Workover Challenges of An HP:HT Sour Gas Well - Case History of Mutriba 12Erdal AYDIN100% (1)

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- Well CommanderDocument6 pagesWell Commanderrichard_1219No ratings yet

- PackerDocument9 pagesPackerMahesh sinhaNo ratings yet

- Tam Anulus Casing PackersDocument20 pagesTam Anulus Casing Packersallan_lennoxNo ratings yet

- Casing Wear: Causes, Prediction and PreventionDocument13 pagesCasing Wear: Causes, Prediction and PreventionPegasus Vertex, Inc.No ratings yet

- Drilling Tools - 1Document269 pagesDrilling Tools - 1berrouiNo ratings yet

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Document21 pagesFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- AC-0049 Well Design RulesDocument5 pagesAC-0049 Well Design RulesairlinemembershipNo ratings yet

- ExPro Well - Intervention - Brochure PDFDocument20 pagesExPro Well - Intervention - Brochure PDFNaveed HasanNo ratings yet

- Field Test Procedures Chemical Injection ValveDocument2 pagesField Test Procedures Chemical Injection ValveHua Tien Dung100% (1)

- CV - Emad Jamshidi: P Date of Birth Gender Citizenship E-Mail Phone Work Mobile Telephone Current ProfessionDocument1 pageCV - Emad Jamshidi: P Date of Birth Gender Citizenship E-Mail Phone Work Mobile Telephone Current ProfessionEmad JamshidiNo ratings yet

- DS-1 Cat 5 Inspection Program For Drill PipeDocument1 pageDS-1 Cat 5 Inspection Program For Drill PipeEmad Jamshidi100% (1)

- Cementing Equipment and Plugs: Running & Drillout ProcedureDocument3 pagesCementing Equipment and Plugs: Running & Drillout ProcedureEmad JamshidiNo ratings yet

- JobAdvertisement 203031Document3 pagesJobAdvertisement 203031Emad JamshidiNo ratings yet

- PracticalPetro DemoDocument15 pagesPracticalPetro DemoEmad JamshidiNo ratings yet

- 9-5/8" RTTS Packer Assembly: 4-1/2" IF BOXDocument1 page9-5/8" RTTS Packer Assembly: 4-1/2" IF BOXEmad JamshidiNo ratings yet

- Kopr Kote Oilfield SdsDocument10 pagesKopr Kote Oilfield SdsEmad JamshidiNo ratings yet

- Performances Levels: Elfmatic J6Document1 pagePerformances Levels: Elfmatic J6Emad JamshidiNo ratings yet

- 8 5 Drill Collar (8-Jnts) - Full InspDocument2 pages8 5 Drill Collar (8-Jnts) - Full InspEmad JamshidiNo ratings yet

- Mahan Air Tower Azadegan ST., Tehran, Iran Tel: +98 21 48384848, Fax: +98 21 48381450 Reserv Ations@mahan - AeroDocument2 pagesMahan Air Tower Azadegan ST., Tehran, Iran Tel: +98 21 48384848, Fax: +98 21 48381450 Reserv Ations@mahan - AeroEmad Jamshidi0% (1)

- 2-Basic Engineering Calculations - (AMOCO) Drilling Fluids ManDocument48 pages2-Basic Engineering Calculations - (AMOCO) Drilling Fluids ManEmad JamshidiNo ratings yet

- Engieering Standars For FIFI Vessel PDFDocument32 pagesEngieering Standars For FIFI Vessel PDFEmad JamshidiNo ratings yet

- Pasargad-100 RIL 2019-8-10Document233 pagesPasargad-100 RIL 2019-8-10Emad JamshidiNo ratings yet

- Yalda-02 - Prognosis Chart, 8.5 SectionDocument1 pageYalda-02 - Prognosis Chart, 8.5 SectionEmad JamshidiNo ratings yet

- Cement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Document7 pagesCement Slurry Volume (BBL) Cement Plug Height (M) - Cement Plug Height (M)Emad JamshidiNo ratings yet

- Dynamic Bridge Plugs WL and MechDocument2 pagesDynamic Bridge Plugs WL and MechEmad JamshidiNo ratings yet

- Liner Lap TestingDocument1 pageLiner Lap TestingEmad JamshidiNo ratings yet

- Inflatable Bridge Plugs & Cement Retainer PDFDocument4 pagesInflatable Bridge Plugs & Cement Retainer PDFEmad JamshidiNo ratings yet

- Magnum Composite Plug Catalog 06-30-10 PDFDocument21 pagesMagnum Composite Plug Catalog 06-30-10 PDFEmad JamshidiNo ratings yet

- Magnum Composite Plug Catalog 06-30-10Document21 pagesMagnum Composite Plug Catalog 06-30-10Emad JamshidiNo ratings yet

- Steps To Assemble A PCDocument4 pagesSteps To Assemble A PCTiana HaynesNo ratings yet

- LUXEN SERIES 3 158.75 120cells 325-340w MONOFACIAL ALL BLACKDocument2 pagesLUXEN SERIES 3 158.75 120cells 325-340w MONOFACIAL ALL BLACKServicios Ingeniería Test LabNo ratings yet

- Hydraulic Block Pilot Oil D3 Atw 5KDocument8 pagesHydraulic Block Pilot Oil D3 Atw 5KSteven Y.MNo ratings yet

- Asl - Ga11vsd Aii140337 - 30141203Document46 pagesAsl - Ga11vsd Aii140337 - 30141203manuel barberoNo ratings yet

- ASR 9006 PowerDocument5 pagesASR 9006 PowerrenuNo ratings yet

- Buton Cheie SS 077Document1 pageButon Cheie SS 077CameliaNo ratings yet

- MST 5 S Series Product PresentationDocument67 pagesMST 5 S Series Product PresentationNelson Andrade Velasquez100% (1)

- Figure 2: Wiring Diagram: Van'S Aircraft, IncDocument1 pageFigure 2: Wiring Diagram: Van'S Aircraft, IncMark Evan SalutinNo ratings yet

- Parts and Accessories Installation Instructions: Auxiliary Connector Retrofit For External Audio SourcesDocument12 pagesParts and Accessories Installation Instructions: Auxiliary Connector Retrofit For External Audio SourcesFernando MuñozNo ratings yet

- Control Valve SpoolDocument3 pagesControl Valve SpoolManuel felipe PalmaNo ratings yet

- Air Leakage ReportDocument5 pagesAir Leakage Reporthari kurniawanNo ratings yet

- With ASME ' U ' StampDocument4 pagesWith ASME ' U ' StampOSWALINFRA HEDNo ratings yet

- Grade 1 Types of ComputingDocument4 pagesGrade 1 Types of ComputinggrannyNo ratings yet

- AJ-1800 AJ-2000: Colour Inkjet PrinterDocument48 pagesAJ-1800 AJ-2000: Colour Inkjet PrinterGeorge Cristian CatunaNo ratings yet

- Deckhand 40 For Use With "P" Serial Numbers 2-Year WarrantyDocument3 pagesDeckhand 40 For Use With "P" Serial Numbers 2-Year WarrantyДима СелютинNo ratings yet

- Siemens MXL MXLV Operation Installation ManualDocument366 pagesSiemens MXL MXLV Operation Installation ManualHenryGalt100% (1)

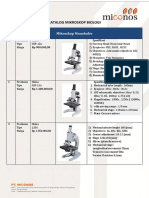

- Katalog MikroskopDocument14 pagesKatalog MikroskopDewi Endar YatunNo ratings yet

- Tex32 PDFDocument5 pagesTex32 PDFragkaraNo ratings yet

- Valvula Check C2-835 VickersDocument2 pagesValvula Check C2-835 VickersDaniel GómezNo ratings yet

- Ved New Sep 320 Ok ReportDocument44 pagesVed New Sep 320 Ok ReportRaj YadavNo ratings yet

- Dpi 821 822 Datasheet English PDFDocument4 pagesDpi 821 822 Datasheet English PDFmaxbigosNo ratings yet

- Manual sg2500mvDocument104 pagesManual sg2500mvDung Vu DinhNo ratings yet

- Model 1266 A/R Sepex: Separately Excited Electronic Motor Speed ControllerDocument4 pagesModel 1266 A/R Sepex: Separately Excited Electronic Motor Speed ControllermbgprsmsNo ratings yet

- Manual - Panel Board - Tablero de Control RTQ RIELLOtech PrimeDocument20 pagesManual - Panel Board - Tablero de Control RTQ RIELLOtech PrimeLuis Fernando OrtigozaNo ratings yet

- (To Be Filled by The Applicant and Empanelled Contractor) : A NN E X Ur E - Vi I IDocument3 pages(To Be Filled by The Applicant and Empanelled Contractor) : A NN E X Ur E - Vi I Isingla.nishant1245No ratings yet

- ONRAM 1500: Diamond Core Drill Technical SpecificationDocument7 pagesONRAM 1500: Diamond Core Drill Technical SpecificationFedericoButronNo ratings yet

- PHE Indent (1) Tracker1Document9 pagesPHE Indent (1) Tracker1Prashanth PawarNo ratings yet

- Fanuc Oi-M Keep RelaysDocument3 pagesFanuc Oi-M Keep Relayskarthik kNo ratings yet

- PSK SERIES MANUAL - Feb 2012 Rev K PDFDocument24 pagesPSK SERIES MANUAL - Feb 2012 Rev K PDFSamuel MuendaneNo ratings yet

- Sbs 260 001 en C 2Document2 pagesSbs 260 001 en C 2Giap Ngoc LeNo ratings yet