Professional Documents

Culture Documents

Mx3 Tool Registration Alarm 240

Uploaded by

anthony solizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mx3 Tool Registration Alarm 240

Uploaded by

anthony solizCopyright:

Available Formats

1.

Set mode switch to manual

2. Press DGN button, enter 8600 by using the DATA key.

3. Press the CURSOR down key.

4. Record the tool number of the magazine pocket at the tool change position.

5. Record the spindle tool number(diagnosis # 8620)

6. Set the NC system switch ( SETTING #6219) to 1.

7. Insert the tools removed after emergency stop, into the spindle and the magazine

pocket in accordance with the tools numbers on the screen.

8. Set the NC system switch (setting #6219) to 0.

9. Reset the NC unit.

I don't think you need to reset the table, if that doesn't work I'll scan a couple

pages on re setting the table.

On the MX3 does one still need to

T6

G91 G28 Z0

M06

as I do on my MX2?

It cost me 500 dollars for Methods to stop by my place and teach me how to teach my

Matsuura where tools are.

It was well worth,the gent was fist class worker,smart.

He also showed me how to use a larger screw driver to move tool pot back and

forth ,which by

the way, gets done every couple months when I have a stupid attack,

.I dont know if the MX3 is the same but I still have the teach method written

down,its in the barn, if you need it,hollar.

Gw

more info, I got my manual fron Yasnacs site,printed here for the cost of printing

That's not a Yaskawa/Yasnac issue, that is a MTB (machine tool builder) error.

These errors are generated in the ladder software, on the machine side. If you

can't find it in a Matsuura maintenance or operator manual, it will have to be

found in the ladder diagram. If you don't have that or are unfamiliar with reading

them, call Methods and ask for their help.

Just in general for tool changers like that on a VMC, there will be parameters that

track the tool number in the spindle, the tool in the waiting pot (the next tool to

change) and which pot is empty. If you have a 20-tool magazine, for instance, one

pot or the spindle should be empty. If one parameter says the empty pot is 7, and

the parameter for Pot 7 says it has a tool in it, there is a conflict, and an error

will result. Clearing the error can't take place until revising the numbers in the

params so they don't conflict. This is an example, but gives you an idea of what

can occur in a tool table that would cause an error. Again, this machine behavior

is determined by the MTB, so is a general description, but can vary between brands.

You might also like

- Backlash ProgramDocument32 pagesBacklash ProgramCristopher Entena50% (2)

- CNC Turning Guide for BeginnersDocument23 pagesCNC Turning Guide for Beginnersmiguel187No ratings yet

- 12.machine MaintenanceDocument5 pages12.machine MaintenanceThoi CoNo ratings yet

- Tajima Embroidery Machine Error Code GuideDocument5 pagesTajima Embroidery Machine Error Code GuideHeroe AP0% (1)

- Ticket Eater - User Manual 2006Document24 pagesTicket Eater - User Manual 2006tokio2424No ratings yet

- Clean Unable 46Document3 pagesClean Unable 46Alya AtizaNo ratings yet

- Vortech Operating ManualDocument10 pagesVortech Operating ManualDoug LaursenNo ratings yet

- Lantek Expert ManualDocument111 pagesLantek Expert ManualИлияИванов100% (1)

- User Manual: Second EditionDocument15 pagesUser Manual: Second EditionDennis XenosNo ratings yet

- 808D OP Turning 0113 en PDFDocument118 pages808D OP Turning 0113 en PDFemir_delic2810100% (1)

- M32 Operating ManualDocument322 pagesM32 Operating ManualLuis Enrique Garduño Landazuri100% (9)

- CNCDesign Coil Winder Software Manual V1 2Document46 pagesCNCDesign Coil Winder Software Manual V1 2DeaferrantNo ratings yet

- Coil Winding Software ManualDocument46 pagesCoil Winding Software ManualDeaferrant50% (2)

- Magner 22 User ManualDocument10 pagesMagner 22 User ManualtheatresonicNo ratings yet

- Lathe Tutorial: Step-by-Step Guide to Creating Toolpaths in Mastercam X5Document8 pagesLathe Tutorial: Step-by-Step Guide to Creating Toolpaths in Mastercam X5lionlionsherNo ratings yet

- Canon MP280/MP287/MP288 MP495/MP497/MP498 Service ManualDocument10 pagesCanon MP280/MP287/MP288 MP495/MP497/MP498 Service Manualniceboy797No ratings yet

- Service Tool V3400 For Resetting Canon Printers CounterDocument9 pagesService Tool V3400 For Resetting Canon Printers CounterSheen Quinto100% (1)

- Tennant p6080 NaDocument128 pagesTennant p6080 Nagaraguainamo11No ratings yet

- Rapidcount T SerieDocument140 pagesRapidcount T Seriefyla99No ratings yet

- Millimar - 3757450 - BA - EN - 2007-02-01 - C1216Document89 pagesMillimar - 3757450 - BA - EN - 2007-02-01 - C1216OkaNo ratings yet

- MACH3 USB 6040Z ManualDocument33 pagesMACH3 USB 6040Z Manual아이디어창작소 도깨비No ratings yet

- fx-570 991EX ENDocument46 pagesfx-570 991EX ENEmanuel GabrielNo ratings yet

- Bystronic Basic Applications ManualDocument37 pagesBystronic Basic Applications ManualThomas Smith70% (10)

- An Introduction To Programming The HP 48G/48GX Calculator: Thiel CollegeDocument25 pagesAn Introduction To Programming The HP 48G/48GX Calculator: Thiel Collegebogus1234No ratings yet

- MACH3 CNC 6040 ManualDocument36 pagesMACH3 CNC 6040 Manual아이디어창작소 도깨비No ratings yet

- BMW MSD80 DiagnosticsDocument26 pagesBMW MSD80 DiagnosticshoffspringNo ratings yet

- MAGNER 75 User ManualDocument34 pagesMAGNER 75 User ManualFritz BukowskyNo ratings yet

- MACH3 CNC 6090マニュアルのダウンロードDocument30 pagesMACH3 CNC 6090マニュアルのダウンロードLeonardo Eladio Vergara GuillenNo ratings yet

- CNC MillingDocument19 pagesCNC MillingRafiqNo ratings yet

- Software Troubleshooting Guide: Multifunctional Digital Color Systems / Multifunctional Digital SystemsDocument82 pagesSoftware Troubleshooting Guide: Multifunctional Digital Color Systems / Multifunctional Digital SystemslkjcfsdñklfjgsdkNo ratings yet

- Installing The Tangential Knife System For Desktop ToolsDocument6 pagesInstalling The Tangential Knife System For Desktop ToolsIsrael caballero Caballero DiazNo ratings yet

- Lanner Group WITNESS Hints & Tips Service SummaryDocument13 pagesLanner Group WITNESS Hints & Tips Service SummaryVC Chua Yee LeongNo ratings yet

- CG60ST Operation D200417 V1.5Document32 pagesCG60ST Operation D200417 V1.5Perita BotelloNo ratings yet

- Reset 2100P Turbidimeter to Factory CalibrationDocument1 pageReset 2100P Turbidimeter to Factory CalibrationbanexeNo ratings yet

- Mach3 Setup TutorialDocument14 pagesMach3 Setup TutorialFederico Santinelli100% (1)

- BX305/BX525/BX620/BX625/BX635, WF7015/WF7515/WF7525: Box ContentDocument2 pagesBX305/BX525/BX620/BX625/BX635, WF7015/WF7515/WF7525: Box ContentNani GangNo ratings yet

- Sensei 406-135MO 406-131MODocument28 pagesSensei 406-135MO 406-131MOmurNo ratings yet

- Documentation Masso PDFDocument239 pagesDocumentation Masso PDFELIEZERMANUELNo ratings yet

- Tennant 8300 Parts ManualDocument360 pagesTennant 8300 Parts ManualUmar ShamsudinNo ratings yet

- LPKF Calibration Procedures: Tool AdjustmentsDocument2 pagesLPKF Calibration Procedures: Tool Adjustmentspetrusz1No ratings yet

- Canon Service Tool GuideDocument11 pagesCanon Service Tool GuideJames GonzagaNo ratings yet

- Instruction of Using VSoft Viscometer Data Collection, Analysis and Graphing Software-USBDocument11 pagesInstruction of Using VSoft Viscometer Data Collection, Analysis and Graphing Software-USBBe FluentNo ratings yet

- CNC Design Coil Winder Software Manual ARM MKII V1 0Document51 pagesCNC Design Coil Winder Software Manual ARM MKII V1 0waldo100100% (1)

- Manual EngDocument4 pagesManual EngZim_256No ratings yet

- 6040 mini Numerical Control Carving Machine manual - DSP versionDocument36 pages6040 mini Numerical Control Carving Machine manual - DSP versiongoyox15882100% (1)

- How To Report Data in Alternate Units of MeasureDocument27 pagesHow To Report Data in Alternate Units of MeasurePiedone64No ratings yet

- MasterCAM X5 TutorialDocument7 pagesMasterCAM X5 Tutorialtedfill100% (1)

- English Mau Al For CNC RouterDocument38 pagesEnglish Mau Al For CNC RouterMX100No ratings yet

- Uso 302 IngDocument24 pagesUso 302 IngJose Luis PulidoNo ratings yet

- SAP Smartforms Tutorial - Table Calculations Using Sum TotalDocument6 pagesSAP Smartforms Tutorial - Table Calculations Using Sum Totalemisto100% (1)

- How To Reset Error Code E08 in Canon MP287Document78 pagesHow To Reset Error Code E08 in Canon MP287Jeffrey Salazar Albania100% (1)

- Mastercam To Mazatrol Post-Processor Tutorial: Section 1. Programming A Mill Part Section 2. Programming A Lathe PartDocument77 pagesMastercam To Mazatrol Post-Processor Tutorial: Section 1. Programming A Mill Part Section 2. Programming A Lathe PartabelNo ratings yet

- M-32-Parameters and AlarmsDocument231 pagesM-32-Parameters and AlarmsArvin Darwin67% (6)

- Your World 60D: The Still Photographer's Guide to Operation and Image Creation with the Canon EOS 60DFrom EverandYour World 60D: The Still Photographer's Guide to Operation and Image Creation with the Canon EOS 60DNo ratings yet

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- 41-NC Maint PDFDocument510 pages41-NC Maint PDFakirenaviNo ratings yet

- Ge Fanuc Alpha Series PDFDocument73 pagesGe Fanuc Alpha Series PDFAnonymous yovhaUQNo ratings yet

- Control Warranty-Contract RegistrationDocument4 pagesControl Warranty-Contract Registrationanthony solizNo ratings yet

- Determine Fanuc 0 CNC Control Model TypeDocument1 pageDetermine Fanuc 0 CNC Control Model Typeanthony solizNo ratings yet

- Atc Adjust InstructionsDocument1 pageAtc Adjust Instructionsanthony solizNo ratings yet

- FanucDocument12 pagesFanucDuta Narendratama100% (1)

- Determine Fanuc 0 CNC Control Model TypeDocument1 pageDetermine Fanuc 0 CNC Control Model Typeanthony solizNo ratings yet

- 41-NC Maint PDFDocument510 pages41-NC Maint PDFakirenaviNo ratings yet

- FanucDocument12 pagesFanucDuta Narendratama100% (1)

- Atc Adjust InstructionsDocument1 pageAtc Adjust Instructionsanthony solizNo ratings yet

- ATC recovery procedure for MV-35 ~ 55 with MX-2 controlDocument2 pagesATC recovery procedure for MV-35 ~ 55 with MX-2 controlanthony solizNo ratings yet

- PCA2 Desktop Wireless BT Audio Amplifier FeaturesDocument4 pagesPCA2 Desktop Wireless BT Audio Amplifier Featuresanthony solizNo ratings yet

- ATC recovery procedure for MV-35 ~ 55 with MX-2 controlDocument2 pagesATC recovery procedure for MV-35 ~ 55 with MX-2 controlanthony solizNo ratings yet

- Fanuc Alarm PDFDocument72 pagesFanuc Alarm PDFcardoso5286% (7)

- ATC recovery procedure for MV-35 ~ 55 with MX-2 controlDocument2 pagesATC recovery procedure for MV-35 ~ 55 with MX-2 controlanthony solizNo ratings yet

- Mx3 Tool Registration Alarm 240Document1 pageMx3 Tool Registration Alarm 240anthony solizNo ratings yet

- ATC recovery procedure for MV-35 ~ 55 with MX-2 controlDocument2 pagesATC recovery procedure for MV-35 ~ 55 with MX-2 controlanthony solizNo ratings yet

- PCA2 Desktop Wireless BT Audio Amplifier FeaturesDocument4 pagesPCA2 Desktop Wireless BT Audio Amplifier Featuresanthony solizNo ratings yet

- Claim SubmissionDocument2 pagesClaim Submissionanthony solizNo ratings yet

- Claim SubmissionDocument2 pagesClaim Submissionanthony solizNo ratings yet

- LMB Chassis Boxes and Enclosures Mouser ElectronicsDocument1 pageLMB Chassis Boxes and Enclosures Mouser Electronicsanthony solizNo ratings yet

- Repair Report - 0450072924-1000Document2 pagesRepair Report - 0450072924-1000anthony solizNo ratings yet

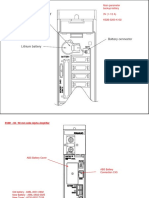

- Main Parameter Backup Battery 3V (1-1/2 A) K02B-0200-K102Document4 pagesMain Parameter Backup Battery 3V (1-1/2 A) K02B-0200-K102anthony solizNo ratings yet

- LMB Chassis Boxes and Enclosures Mouser ElectronicsDocument1 pageLMB Chassis Boxes and Enclosures Mouser Electronicsanthony solizNo ratings yet