Professional Documents

Culture Documents

Clamping: Clamping Forces Dry Cycle Time

Uploaded by

schaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Clamping: Clamping Forces Dry Cycle Time

Uploaded by

schaCopyright:

Available Formats

1.

Clamping

Prior to the injection of the material into the mold, the two halves of the mold must first be securely closed

by the clamping unit..

Each half of the mold is attached to the injection molding machine and one half is allowed to slide.

The hydraulically powered clamping unit pushes the mold halves together and exerts sufficient force to

keep the mold securely closed while the material is injected.

The time required to close and clamp the mold is dependent upon the machine - larger machines (those

with greater clamping forces) will require more time.

This time can be estimated from the dry cycle time of the machine

2. Injection

The raw plastic material, usually in the form of pellets, is fed into the injection molding machine, and

advanced towards the mold by the injection unit

During this process, the material is melted by heat and pressure

The molten plastic is then injected into the mold very quickly and the buildup of pressure packs and holds

the material..

The amount of material that is injected is referred to as the shot.

The injection time is difficult to calculate accurately due to the complex and changing flow of the molten

plastic into the mold

However, the injection time can be estimated by the shot volume, injection pressure, and injection power

3. Cooling

The molten plastic that is inside the mold begins to cool as soon as it makes contact with the interior mold

surfaces

As the plastic cools, it will solidify into the shape of the desired part. However, during cooling

some shrinkage of the part may occur

The packing of material in the injection stage allows additional material to flow into the mold and reduce

the amount of visible shrinkage.

The mold can not be opened until the required cooling time has elapsed.

The cooling time can be estimated from several thermodynamic properties of the plastic and

the maximum wall thickness of the part.

4. Ejection

After sufficient time has passed, the cooled part may be ejected from the mold by the ejection system,

which is attached to the rear half of the mold.

When the mold is opened, a mechanism is used to push the part out of the mold.

Force must be applied to eject the part because during cooling the part shrinks and adheres to the mold.

In order to facilitate the ejection of the part, a mold release agent can be sprayed onto the surfaces of the

mold cavity prior to injection of the material..

The time that is required to open the mold and eject the part can be estimated from the dry cycle time of

the machine and should include time for the part to fall free of the mold

Once the part is ejected, the mold can be clamped shut for the next shot to be injected

You might also like

- Final Report-Plastic Injection MoldingDocument40 pagesFinal Report-Plastic Injection MoldingAnant Sharma86% (42)

- Report Plastic Injection MoldingDocument40 pagesReport Plastic Injection Moldingابو حنيف100% (3)

- Final Report Plastic Injection MoldingDocument48 pagesFinal Report Plastic Injection MoldingGunjan Trivedi0% (1)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Kertas Arahan Makmal: Bbm40501 Amali KejuruteraanDocument6 pagesKertas Arahan Makmal: Bbm40501 Amali KejuruteraanschaNo ratings yet

- Anemia PDFDocument11 pagesAnemia PDFRegieLimos100% (1)

- Clamping: Clamping Forces Dry Cycle TimeDocument1 pageClamping: Clamping Forces Dry Cycle TimeschaNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection MoldingelectroternalNo ratings yet

- Injection MouldingDocument4 pagesInjection MouldinganipcatalyzerNo ratings yet

- Plastic Injection MoldingDocument24 pagesPlastic Injection Moldingmechhandbook100% (1)

- Plastic Injection MouldingDocument28 pagesPlastic Injection MouldingDavid StefanNo ratings yet

- Injection Moulding Defects: BlisterDocument10 pagesInjection Moulding Defects: BlisterAmith S KaratkarNo ratings yet

- A Brief Study On Plastic Injection Molding ProcessDocument42 pagesA Brief Study On Plastic Injection Molding ProcessDinesh arNo ratings yet

- INDUSTRIAL TRANING SEMINAR - PPTX AnshuDocument31 pagesINDUSTRIAL TRANING SEMINAR - PPTX Anshuanshu rajNo ratings yet

- Injection MouldingDocument23 pagesInjection MouldingPrathmeshBhokari100% (1)

- Summer Training Project ReportDocument28 pagesSummer Training Project ReportSaurav GabaNo ratings yet

- Injection Moulding: Points CoveredDocument14 pagesInjection Moulding: Points Coveredanilkolekar0% (1)

- IMM - Write UpDocument5 pagesIMM - Write UpvanmanNo ratings yet

- Advances in Injection MoldingDocument15 pagesAdvances in Injection MoldingPranav PatilNo ratings yet

- Injection MouldingDocument33 pagesInjection MouldingArpit S SavarkarNo ratings yet

- Injection Moulding Lab ReportDocument27 pagesInjection Moulding Lab ReportErnie Yana IINo ratings yet

- Components of An Injection Molding Machine R1Document11 pagesComponents of An Injection Molding Machine R1Cesar GarciaNo ratings yet

- Procedure For Investment CastingDocument4 pagesProcedure For Investment CastingRAJARAMNo ratings yet

- 3 03 Design PrinciplesDocument15 pages3 03 Design Principlesphạm minh hùngNo ratings yet

- Jadavpur Univrsity: Department of Mechanical Engineering A Report On CastingDocument18 pagesJadavpur Univrsity: Department of Mechanical Engineering A Report On CastingfirdoshansariNo ratings yet

- Setup Operator ResponsibilitiesDocument4 pagesSetup Operator Responsibilitiessaadbinsadaqat123456No ratings yet

- I/ Reading 1 1. What Is Plastic Injection Molding?Document5 pagesI/ Reading 1 1. What Is Plastic Injection Molding?Hieu Nguyen TrungNo ratings yet

- Transfer MouldingDocument3 pagesTransfer MouldingGirishNo ratings yet

- Injection mouldingCH2Document8 pagesInjection mouldingCH2prasanna_326avanthiNo ratings yet

- Manual Injection MoldingDocument5 pagesManual Injection MoldingM. AhmadNo ratings yet

- Flow Lines Description: Flow Lines Are Streaks, Patterns, or Lines - Commonly Off-TonedDocument5 pagesFlow Lines Description: Flow Lines Are Streaks, Patterns, or Lines - Commonly Off-TonedMadhab BeraNo ratings yet

- In Jection MouldingDocument21 pagesIn Jection MouldingAbhinandan PatilNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Final Report Plastic Injection MoldingDocument38 pagesFinal Report Plastic Injection MoldingshriNo ratings yet

- Ae 301 Injection Moulding ProcessDocument15 pagesAe 301 Injection Moulding ProcessschaNo ratings yet

- Injection Molding Machine SnopsisDocument6 pagesInjection Molding Machine Snopsisrajinder kutaalNo ratings yet

- Molding Process PDFDocument7 pagesMolding Process PDFSreedhar PugalendhiNo ratings yet

- Injection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarsDocument37 pagesInjection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarslakhancipetNo ratings yet

- Processes Encountered in Plastic IndustriesDocument16 pagesProcesses Encountered in Plastic IndustriesdebdeepNo ratings yet

- Nanyang Technological University School of Mechanical and Aerospace Engineering AY2011/2012Document13 pagesNanyang Technological University School of Mechanical and Aerospace Engineering AY2011/2012TibbercesNo ratings yet

- Gear Type Injection Moulding MachineDocument4 pagesGear Type Injection Moulding MachineJeya KumarNo ratings yet

- EXP 4 Injection MoldingDocument18 pagesEXP 4 Injection MoldingJasmine NguNo ratings yet

- ASWIN MANOJ PresentationDocument13 pagesASWIN MANOJ PresentationAswin MNo ratings yet

- Injection MouldingDocument2 pagesInjection MouldingVinayakNo ratings yet

- Designing For Injection MoldingDocument28 pagesDesigning For Injection Moldingnado100% (2)

- Moulding InjectionDocument5 pagesMoulding InjectionAmit JainNo ratings yet

- Polymer Processing Operation: "Sheet Extruding Machine"Document9 pagesPolymer Processing Operation: "Sheet Extruding Machine"zarqullah javaidNo ratings yet

- Injection Molding MachineDocument4 pagesInjection Molding MachineAsif Khan NiaziNo ratings yet

- Injection Moulding MachineDocument4 pagesInjection Moulding MachinescbrajaNo ratings yet

- Lab Report Injection MoldingDocument4 pagesLab Report Injection MoldingMuzamil RazaNo ratings yet

- Injection MoldingDocument5 pagesInjection MoldingFAIZ RASOOLNo ratings yet

- Plastics Molded ProblemsDocument11 pagesPlastics Molded ProblemsJaynie Lee VillaranNo ratings yet

- Gear Type Injection MouldingDocument47 pagesGear Type Injection MouldingJohn Ajish50% (2)

- Part 4 - 2 - Polymers Processing TechsDocument42 pagesPart 4 - 2 - Polymers Processing TechsAlemu MergaNo ratings yet

- High Speed Blow Molding MachineDocument64 pagesHigh Speed Blow Molding MachineSandip LadNo ratings yet

- Ejercicios Mold and Die DesignDocument6 pagesEjercicios Mold and Die DesignEl VictorNo ratings yet

- Plasting ProcessingDocument19 pagesPlasting Processingnethumini GunawardanaNo ratings yet

- Oguz Canturk Internship Report 66819 1537471972Document15 pagesOguz Canturk Internship Report 66819 1537471972oğuz cantürkNo ratings yet

- Se - Experiment 6Document12 pagesSe - Experiment 6Manoj DohaleNo ratings yet

- Plastic Moulding ProcessDocument4 pagesPlastic Moulding Processkeerthi939No ratings yet

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.From EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.No ratings yet

- Meat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingFrom EverandMeat & Potatoes of Plastic Injection Moulding, Explanation & Guides TroubleshootingNo ratings yet

- Interactive - Intuitive - Incredible: Lechal InitiativeDocument9 pagesInteractive - Intuitive - Incredible: Lechal InitiativeschaNo ratings yet

- 1 - Tool Design MethodDocument16 pages1 - Tool Design MethodschaNo ratings yet

- Augmented Reality in Teaching and Learning Process: April 2020Document16 pagesAugmented Reality in Teaching and Learning Process: April 2020schaNo ratings yet

- Symmetry: Real-Time Projection-Based Augmented Reality System For Dynamic Objects in The Performing ArtsDocument11 pagesSymmetry: Real-Time Projection-Based Augmented Reality System For Dynamic Objects in The Performing ArtsschaNo ratings yet

- Projection-Based Augmented Reality in Engineering ApplicationsDocument9 pagesProjection-Based Augmented Reality in Engineering ApplicationsschaNo ratings yet

- Ae 301 Injection Moulding ProcessDocument15 pagesAe 301 Injection Moulding ProcessschaNo ratings yet

- Placement of Plant AND Layout EquipmentDocument18 pagesPlacement of Plant AND Layout EquipmentschaNo ratings yet

- Science Pharma-PlayfulDocument14 pagesScience Pharma-PlayfulschaNo ratings yet

- Abstract Design Circle Bubble PowerPoint Templates StandardDocument3 pagesAbstract Design Circle Bubble PowerPoint Templates StandardschaNo ratings yet

- Change Is Good, Disruptive Change Is Better: Focus On FitnessDocument3 pagesChange Is Good, Disruptive Change Is Better: Focus On FitnessschaNo ratings yet

- Bluetooth 2Document2 pagesBluetooth 2schaNo ratings yet

- Binomial Expansion With Negative Fraction Jun 2014Document13 pagesBinomial Expansion With Negative Fraction Jun 2014schaNo ratings yet

- Approximation NotesDocument14 pagesApproximation NotesschaNo ratings yet

- Illinois Winning Essay-JOURNALDocument2 pagesIllinois Winning Essay-JOURNALschaNo ratings yet

- HIDRAULIK MOBIL BAB 5 - EnglishDocument23 pagesHIDRAULIK MOBIL BAB 5 - EnglishschaNo ratings yet

- Ch2 - BBM 10103 Material StructureDocument82 pagesCh2 - BBM 10103 Material StructureschaNo ratings yet

- Chapter 5Document17 pagesChapter 5schaNo ratings yet

- Chapter 2Document37 pagesChapter 2schaNo ratings yet

- Chapter 1 - Production PlanningDocument29 pagesChapter 1 - Production PlanningschaNo ratings yet

- Chapter 4 Quality Assurance (QA)Document19 pagesChapter 4 Quality Assurance (QA)schaNo ratings yet

- Ch3 - BBM 10103 Phase DiagramDocument86 pagesCh3 - BBM 10103 Phase DiagramschaNo ratings yet

- Your Electronic Ticket ReceiptDocument2 pagesYour Electronic Ticket ReceiptTuty Alawiyah LubisNo ratings yet

- Letter: Flight of An Aeroplane With Solid-State PropulsionDocument8 pagesLetter: Flight of An Aeroplane With Solid-State PropulsionMuhammad Faiz BaihaqiNo ratings yet

- Academic PressureDocument7 pagesAcademic PressureJohn Mark MontillaNo ratings yet

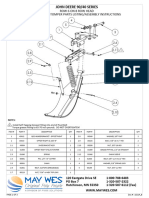

- JD 90 - 40 Rows 3 - 6 On 8 RowDocument7 pagesJD 90 - 40 Rows 3 - 6 On 8 Rowalaynnastaabx786No ratings yet

- Sps. Ermino v. Golden VillageDocument2 pagesSps. Ermino v. Golden Villagejanine nenaria50% (2)

- UTStarcom B820 DSLAM Product DescriptionDocument116 pagesUTStarcom B820 DSLAM Product DescriptionSanjeev GargNo ratings yet

- Chapter 2Document2 pagesChapter 2Ahmed HossainNo ratings yet

- Challenges and Solutions For Tunnel ConsDocument29 pagesChallenges and Solutions For Tunnel ConsAfomiya ZelalemNo ratings yet

- Assignment-CA SIC2002Document6 pagesAssignment-CA SIC2002Baginda RamleeNo ratings yet

- Unidad 1 Samrt Choice ResueltoDocument7 pagesUnidad 1 Samrt Choice ResueltoSandry JiménezNo ratings yet

- A Healthy Man Is A Happy ManDocument2 pagesA Healthy Man Is A Happy ManYan KyawNo ratings yet

- 1-S2.0-S1877042812020769-Main - Rail LogisticDocument4 pages1-S2.0-S1877042812020769-Main - Rail LogisticDodi Julianto فاصلNo ratings yet

- Fluido Barrera SeleccionDocument20 pagesFluido Barrera Seleccionmartin.rubenNo ratings yet

- Aluminium Rail CoachDocument7 pagesAluminium Rail CoachdselvakuuNo ratings yet

- The Mathematical Gazette Volume 59 Issue 407 1975 (Doi 10.2307 - 3616804) Crockett Johnson - A Construction For A Regular HeptagonDocument6 pagesThe Mathematical Gazette Volume 59 Issue 407 1975 (Doi 10.2307 - 3616804) Crockett Johnson - A Construction For A Regular HeptagonEduardo CostaNo ratings yet

- Lesson Plan Monster GeneticsDocument2 pagesLesson Plan Monster Geneticsapi-312959802No ratings yet

- Astm D 4221 99 Doble Hidrometro PDFDocument3 pagesAstm D 4221 99 Doble Hidrometro PDFHayatoNo ratings yet

- Safed MusliDocument8 pagesSafed Muslimetro1cupidNo ratings yet

- Site of The First MassDocument39 pagesSite of The First MassCherry Mae PalilioNo ratings yet

- Jurnal Non Sirotic VEDocument21 pagesJurnal Non Sirotic VEDheajeng Intan MutiarasariNo ratings yet

- 165: 21-23 Neville Street, Abergavenny. Archaeological EvaluationDocument175 pages165: 21-23 Neville Street, Abergavenny. Archaeological EvaluationAPAC LtdNo ratings yet

- Bechelor ThesisDocument71 pagesBechelor ThesisLê KiênNo ratings yet

- Tunnel Diode 87Document23 pagesTunnel Diode 87Rudra BhartiNo ratings yet

- Female Sex HormonesDocument30 pagesFemale Sex HormonesMagdy El-GammalNo ratings yet

- Edinburgh Festival RockDocument27 pagesEdinburgh Festival RockguerramarNo ratings yet

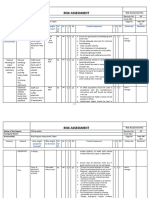

- RA-05-Office SafetyDocument5 pagesRA-05-Office Safetyamritha n krishnaNo ratings yet

- Operation and Maintenance Manual For Urban Water Utilities PDFDocument182 pagesOperation and Maintenance Manual For Urban Water Utilities PDFKrischaEverNo ratings yet

- Biomaterials Based Sensors Recent Advances and ApplicationsDocument416 pagesBiomaterials Based Sensors Recent Advances and Applicationshenry.a.peraltaNo ratings yet

- NewTiger3 U4 TestDocument6 pagesNewTiger3 U4 TestMAIALEN AGIRRENo ratings yet