Professional Documents

Culture Documents

No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTD

Uploaded by

ubraghuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTD

Uploaded by

ubraghuCopyright:

Available Formats

TOP

RUN

AUT

OMO

TIVE

INDIA

PVT

LTD

TOPRUN AUTOMOTIVE INDIA PVT LTD

WORK INSTRUCTION

DOC NO : TRAI/PD/MWI/71

WOR

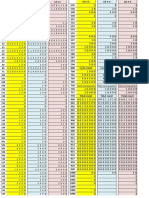

K Product Machine Resin / Part Assembly / Subparts

OPE

CUSTOMER

RATI CAR MODEL DRIVE PART DESCRIPTION / PART NUMBER TONNAGE DESCRIPTION Item No Drier Temp

Part WeightAssemb Part Description Item No Qty

ON

SHEE

T Material PP

Grade HP310SU2I

As Per

SHIELD COVER FR SEAT INR, LH(MNL)/RH(H/ADJ) Color NNB/RBD

HTL - SU2I - 450T - Control

88030-BV000/88040-BV100

Eo.No Plan

Eo Date

No Description / Explanation PICTURE / SKETCH

1 INJECTION MOLDING

2 PICK THE PART FROM MACHINE FOR ROBO AND KEPT IN THE PART FOR THE CONVEYOR

3 GATE POINT TRIMMING THE PART

4 100% VISUAL INSPECTION WITH SAMPLE PART

2. PICK THE PART FROM MACHINE 3. GATE POINT TRIMMING THE

1.INJECTION MOLDING FOR ROBO AND KEPT IN THE PART

5 DATE AND SHIFT CODE MENTION IN PART FOR THE CONVEYOR

PART

6 PACK THE PART AS PER PACKING STANDARD

6. PACK THE PART AS PER 5. DATE AND SHIFT CODE 4. 100% VISUAL INSPECTION

PACKING STANDARD MENTION IN PART WITH SAMPLE PART

CAUTION POINTS Q-ALERT POINTS CAUTION AREAS

1 Every machine stop isolate the first 2 pcs for QA verifcation to setup

bin (yellow bin or trolley)

2 Confirmed rejects should be moved to red bin or trolley for QA Verification

3 Check all the caution points for flash, shortfill and any other defects

Hole flash

e

4 Any abnormalities or high rejection , escalate to supervisor

Flow mark

Front side e

e

Preparation

1 Arrange packaging cover as per lot qty Shortfill

2 Use Pen knife for deflashing e

Rear side Sink Mark

e

`

00 12.02.2019 Initial Released Rajesh Satheesh Magesh

Rev Date History / Change of content Prepared By Reviewed By Approved By

TRAI/PD/002 Page 1 of 2 Rev 00/21.02.2018

TOP

RUN

AUT

OMO

TIVE

INDIA

PVT

LTD

TOPRUN AUTOMOTIVE INDIA PVT LTD

WORK INSTRUCTION

DOC NO : TRAI/PD/MWI/71

WOR

K Product Machine Resin / Part Assembly / Subparts

OPE

CUSTOMER

RATI CAR MODEL DRIVE PART DESCRIPTION / PART NUMBER TONNAGE DESCRIPTION Item No Drier Temp

Part WeightAssemb Part Description Item No Qty

ON

SHEE

T Material PP

Grade HP310SU2I

As Per

SHIELD COVER FR SEAT INR, RH(MNL)/LH(H/ADJ) Color NNB/RBD

HTL - SU2I - 450T - Control

88040-BV000/88030-BV100

Eo.No Plan

Eo Date

No Description / Explanation PICTURE / SKETCH

1 INJECTION MOLDING

2 PICK THE PART FROM MACHINE FOR ROBO AND KEPT IN THE PART FOR THE CONVEYOR

3 GATE POINT TRIMMING THE PART

4 100% VISUAL INSPECTION WITH SAMPLE PART

2. PICK THE PART FROM MACHINE 3. GATE POINT TRIMMING THE

1.INJECTION MOLDING FOR ROBO AND KEPT IN THE PART

5 DATE AND SHIFT CODE MENTION IN PART FOR THE CONVEYOR

PART

6 PACK THE PART AS PER PACKING STANDARD

6. PACK THE PART AS PER 5. DATE AND SHIFT CODE 4. 100% VISUAL INSPECTION

PACKING STANDARD MENTION IN PART WITH SAMPLE PART

CAUTION POINTS Q-ALERT POINTS CAUTION AREAS

1 Every machine stop isolate the first 2 pcs for QA verifcation to setup

bin (yellow bin or trolley)

Flow mark

2 Confirmed rejects should be moved to red bin or trolley for QA Verification

e

3 Check all the caution points for flash, shortfill and any other defects

Hole flash

e

4 Any abnormalities or high rejection , escalate to supervisor

Front side

e

Preparation Sink Mark

1 Arrange packaging cover as per lot qty Shortfill

2 Use Pen knife for deflashing e

Rear side

e

`

00 12.02.2019 Initial Released

Rev Date History / Change of content Prepared By Reviewed By Approved By

TRAI/PD/002 Page 2 of 2 Rev 00/21.02.2018

You might also like

- Process Parameter SheetDocument1 pageProcess Parameter SheetCATALINANo ratings yet

- Single Machine - Multiple Parts (OEE Reporting)Document2 pagesSingle Machine - Multiple Parts (OEE Reporting)Vergence Business Associates100% (1)

- Instructions For Completion of Piece Cost Breakdown WorksheetDocument9 pagesInstructions For Completion of Piece Cost Breakdown WorksheetfranciscoNo ratings yet

- Injection Molding Cost AnalysisDocument21 pagesInjection Molding Cost AnalysisIams MuhammadNo ratings yet

- Dissertation Report HYUNDAI MARUTIDocument23 pagesDissertation Report HYUNDAI MARUTIAkhil Suneja100% (1)

- Chevrolet Europe Case StudyDocument5 pagesChevrolet Europe Case StudyBonnie SalamatosNo ratings yet

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YDocument2 pagesHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuNo ratings yet

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 pagesPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Injection Mould Component Cost EstimationDocument7 pagesInjection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- Inj Mold CalculateDocument9 pagesInj Mold CalculateGiap NguyenNo ratings yet

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocument4 pagesInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNo ratings yet

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Document1 pageInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNo ratings yet

- CBI Export Coaching Programme for Moulds and Dies ManufacturersDocument4 pagesCBI Export Coaching Programme for Moulds and Dies Manufacturersprasad_kcpNo ratings yet

- 8 D For ShrinkageDocument6 pages8 D For ShrinkageSachin KumbharNo ratings yet

- D10369520ADocument4 pagesD10369520AQUALITY ControlNo ratings yet

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 pagesProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanNo ratings yet

- CM InjectDocument21 pagesCM InjectTiago CerqueiraNo ratings yet

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Document10 pagesNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreNo ratings yet

- Specific Gravity in Rubber CompoundingDocument1 pageSpecific Gravity in Rubber CompoundingBharat ChatrathNo ratings yet

- QAF-160 Supplier Quality Survey 3-5-18Document9 pagesQAF-160 Supplier Quality Survey 3-5-18Gábor MonokNo ratings yet

- Master Kaizen (Sample)Document7 pagesMaster Kaizen (Sample)avinashbatra1No ratings yet

- ICAS - Initial Capacity Assessment Sheet - 2010-12-09Document15 pagesICAS - Initial Capacity Assessment Sheet - 2010-12-09pchakkrapaniNo ratings yet

- Injctmld F03Document2 pagesInjctmld F03prasad_kcpNo ratings yet

- Total Productive Effectiveness Calculation/ Tính Toán Năng Suất Thực Tế Của Máy (Oee)Document15 pagesTotal Productive Effectiveness Calculation/ Tính Toán Năng Suất Thực Tế Của Máy (Oee)PhuNguyenVanNo ratings yet

- Rubber Grommet Cost Estimation SheetDocument1 pageRubber Grommet Cost Estimation SheetVenkateswaran venkateswaran100% (1)

- Process FMEA for Farm Equipment SectorDocument1 pageProcess FMEA for Farm Equipment SectorBALACHANDAR SNo ratings yet

- WI Mold HandlingDocument5 pagesWI Mold HandlingAnonymous dS56HONo ratings yet

- FMEA Base Roof 7779-617Document19 pagesFMEA Base Roof 7779-617RidwanNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Process SheetDocument8 pagesProcess SheetSuraj RawatNo ratings yet

- Moulding TroubleshootingDocument22 pagesMoulding TroubleshootingPiousPatialaNo ratings yet

- PT Vs SOP 17 Tooling RepairDocument7 pagesPT Vs SOP 17 Tooling RepairRidwanNo ratings yet

- Tool Development PlanDocument3 pagesTool Development PlanTrivesh SharmaNo ratings yet

- 195 CasingDocument14 pages195 Casingsasi10000No ratings yet

- Past defect history details root cause analysis formatDocument10 pagesPast defect history details root cause analysis formatRahulNo ratings yet

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- Setup & Inprocess Inspection Report CaseDocument19 pagesSetup & Inprocess Inspection Report CaseMURALIDHRANo ratings yet

- Abs - Injection Mould Component Cost EstimationDocument7 pagesAbs - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- 6W2H For Side Wrinkles MY17 - RearDocument4 pages6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghNo ratings yet

- Technical Specification MatrixDocument1 pageTechnical Specification MatrixPriyaprasad PandaNo ratings yet

- Moudling Operation GSIC Process: MouldingDocument13 pagesMoudling Operation GSIC Process: MouldingBalakumaran MurugesanNo ratings yet

- Fmea Data&PlanDocument5 pagesFmea Data&PlanLaerteBessaMatias1No ratings yet

- Perancangan PengajaranDocument16 pagesPerancangan PengajaranMohammad Farihan100% (1)

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- QA Assistant Studio PFMEA ExampleDocument1 pageQA Assistant Studio PFMEA ExampleIqraYounasNo ratings yet

- 4M Change Monitoring SheetDocument1 page4M Change Monitoring SheetDinesh KumarNo ratings yet

- pure cotton pvt ltd final inspection reportDocument4 pagespure cotton pvt ltd final inspection reportTarun PariharNo ratings yet

- Dis 6 W 2 HDocument14 pagesDis 6 W 2 HBalachandar SathananthanNo ratings yet

- IMM Process SetupsDocument25 pagesIMM Process Setupslam nguyen100% (1)

- Injctmld F03Document3 pagesInjctmld F03Šetkić SemirNo ratings yet

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocument8 pagesMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNo ratings yet

- Plant Lean Assessment Reveals Opportunities for 5S Workplace OrganizationDocument19 pagesPlant Lean Assessment Reveals Opportunities for 5S Workplace OrganizationLeontin LeonNo ratings yet

- Lead Time - 001Document18 pagesLead Time - 001Purushothama Nanje GowdaNo ratings yet

- Cost Weighted OEE TemplateDocument10 pagesCost Weighted OEE TemplateSAMGPRONo ratings yet

- Routsis Injection Molding ReferenceDocument176 pagesRoutsis Injection Molding ReferenceRupesh PillaiNo ratings yet

- AM FormatDocument73 pagesAM Formathisham_eyesNo ratings yet

- Fr-scm-085 Packaging StandardDocument3 pagesFr-scm-085 Packaging StandardKaramjit SinghNo ratings yet

- Histogram X-Bar Chart: Company NameDocument1 pageHistogram X-Bar Chart: Company NameSachin RamdurgNo ratings yet

- Capacity Verification Run at Rate IpaDocument4 pagesCapacity Verification Run at Rate IpaIram ChaviraNo ratings yet

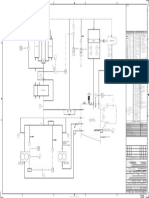

- Instrument Diagram W20V32 WartsilaDocument24 pagesInstrument Diagram W20V32 WartsilaMuhammad IkramNo ratings yet

- Aa 036638 002Document1 pageAa 036638 002hai sunNo ratings yet

- Kannada WordsDocument16 pagesKannada WordsubraghuNo ratings yet

- Apqp - Layered Process Audit-1594636097 SAMPLE 4Document9 pagesApqp - Layered Process Audit-1594636097 SAMPLE 4ubraghuNo ratings yet

- January 2020 Calendar LandscapeDocument1 pageJanuary 2020 Calendar LandscapeAmit ParchakeNo ratings yet

- 1537 Minutes of MeetingDocument2 pages1537 Minutes of MeetingubraghuNo ratings yet

- January 2019: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDocument1 pageJanuary 2019: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayVega AditamaNo ratings yet

- Iso/Ts 16949 WorkshopDocument115 pagesIso/Ts 16949 WorkshopubraghuNo ratings yet

- B515 TempDocument4 pagesB515 TempubraghuNo ratings yet

- December 2021: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayDocument1 pageDecember 2021: Sunday Monday Tuesday Wednesday Thursday Friday SaturdayubraghuNo ratings yet

- Govt Jobs in IndiaDocument10 pagesGovt Jobs in IndialakshmilavanyaNo ratings yet

- Managing Change at Daejung Mo PartsDocument4 pagesManaging Change at Daejung Mo PartsubraghuNo ratings yet

- Apqp 2017Document124 pagesApqp 2017ubraghuNo ratings yet

- My Favourite Animal Is COW Reason: 1.giving Milk 2.harm Less 3.urine and Featal Have Medicinal Characteristic SDocument2 pagesMy Favourite Animal Is COW Reason: 1.giving Milk 2.harm Less 3.urine and Featal Have Medicinal Characteristic SubraghuNo ratings yet

- Complete Injection Molding Process: As Summarized in Fig. 1-2, Injection MoldDocument27 pagesComplete Injection Molding Process: As Summarized in Fig. 1-2, Injection MoldFedericoNo ratings yet

- Toprun Automotive India PVT LTD Work Instruction: Lever FR Seat Recl, LH/RH 88016/26-BV000 NNB/RBDDocument1 pageToprun Automotive India PVT LTD Work Instruction: Lever FR Seat Recl, LH/RH 88016/26-BV000 NNB/RBDubraghuNo ratings yet

- SU2I Ins STDDocument10 pagesSU2I Ins STDubraghuNo ratings yet

- Major Difference ISODocument1 pageMajor Difference ISOubraghuNo ratings yet

- Rubber Mixing Unit As A, Shift Incharge. Service Engineer-Furniture and Interior GroupDocument2 pagesRubber Mixing Unit As A, Shift Incharge. Service Engineer-Furniture and Interior GroupubraghuNo ratings yet

- Book IRCTC ticket onlineDocument2 pagesBook IRCTC ticket onlineHimanshu GuptaNo ratings yet

- Tuvnord Payment ScreenshotDocument1 pageTuvnord Payment ScreenshotubraghuNo ratings yet

- Grinding Machine ParametterDocument19 pagesGrinding Machine ParametterubraghuNo ratings yet

- Govt Jobs in IndiaDocument10 pagesGovt Jobs in IndialakshmilavanyaNo ratings yet

- Ojt For Air CleaningDocument1 pageOjt For Air CleaningubraghuNo ratings yet

- Book IRCTC ticket onlineDocument2 pagesBook IRCTC ticket onlineHimanshu GuptaNo ratings yet

- IATF 16949:2016 vs. ISO/TS 16949:2009 MatrixDocument26 pagesIATF 16949:2016 vs. ISO/TS 16949:2009 MatrixP.NAVEENAN50% (2)

- ISO/TS 16949 Quotation QuestionnaireDocument2 pagesISO/TS 16949 Quotation QuestionnaireubraghuNo ratings yet

- Thickness Gauge Usage Standard: SL - No OK Not Ok Not OkDocument1 pageThickness Gauge Usage Standard: SL - No OK Not Ok Not OkubraghuNo ratings yet

- Q Alert GrindingDocument1 pageQ Alert GrindingubraghuNo ratings yet

- D GTH-4010 AU.2 Australian From SN 16125Document112 pagesD GTH-4010 AU.2 Australian From SN 16125sixin93551No ratings yet

- Volvo s40 Wiring Diagram 2005 19v16662Document20 pagesVolvo s40 Wiring Diagram 2005 19v16662minnie100% (53)

- Freelander 2: Maintenance Check Sheet A B Main Service (Vehicle Interior) A B Main Service (Under Vehicle)Document2 pagesFreelander 2: Maintenance Check Sheet A B Main Service (Vehicle Interior) A B Main Service (Under Vehicle)LuizHenriqueAraujoNo ratings yet

- Active Height Control Suspension and Adaptive Variable SuspensionDocument9 pagesActive Height Control Suspension and Adaptive Variable SuspensionEgoro Kapito100% (2)

- FMX 440 6x4T RSS - 2014Document2 pagesFMX 440 6x4T RSS - 2014limyisyuenNo ratings yet

- Golf Vi BrochureDocument36 pagesGolf Vi BrochureRichard J FloydNo ratings yet

- K Lite Catalogue 2Document126 pagesK Lite Catalogue 2Walter Antezano CasalloNo ratings yet

- Ford Ranger 1993-2005Document8 pagesFord Ranger 1993-2005hasnol_othmanNo ratings yet

- Honda Fit 2013 AbsDocument4 pagesHonda Fit 2013 AbsSpeedoshop RobertoNo ratings yet

- Parts Manual Reach Stacker Rs 45 31 CH (C222e) H PM Uk en (08 2014)Document826 pagesParts Manual Reach Stacker Rs 45 31 CH (C222e) H PM Uk en (08 2014)Thawan100% (2)

- Jinan Qingong International Trade Co.,Ltd.: Item Part Number Part Name Specifications Price PhotoDocument16 pagesJinan Qingong International Trade Co.,Ltd.: Item Part Number Part Name Specifications Price PhotoMoges AberaNo ratings yet

- New CRSP 2020 Effective 7TH July 2020.Document116 pagesNew CRSP 2020 Effective 7TH July 2020.isaacNo ratings yet

- Tatra t815-7z0r9t enDocument2 pagesTatra t815-7z0r9t enPaul Damian100% (1)

- Peças Hangcha RW 1,0-1,8T - 2017Document360 pagesPeças Hangcha RW 1,0-1,8T - 2017Eldelson BaggetoNo ratings yet

- Catalog Airtech 2013 PDFDocument335 pagesCatalog Airtech 2013 PDFAtmosferaNo ratings yet

- Deed of Sale Motor Vehicle Helen Odoño MoranteDocument2 pagesDeed of Sale Motor Vehicle Helen Odoño MoranteAnonymous r1cRm7FNo ratings yet

- Pdfmanualsmaserati2018 Maserati Levante S PDFDocument410 pagesPdfmanualsmaserati2018 Maserati Levante S PDFRasheed MuhammedNo ratings yet

- PEUGEOT Diagnostics ListDocument74 pagesPEUGEOT Diagnostics ListEko hari PrasetyoNo ratings yet

- Products Truck VT Hd65 Cargo SpecDocument10 pagesProducts Truck VT Hd65 Cargo SpecAlexey KolmakovNo ratings yet

- Colt Ralliart BrochureDocument8 pagesColt Ralliart BrochureHarry UrioNo ratings yet

- Autonomous CarsDocument7 pagesAutonomous CarssantiagoNo ratings yet

- ETKA Skoda Transmission CodesDocument16 pagesETKA Skoda Transmission CodesglistridaNo ratings yet

- Tesla Electrical Vehicle Design TechnologyDocument15 pagesTesla Electrical Vehicle Design TechnologyNagendra Babu NaiduNo ratings yet

- Driving Lessons Need Not Be ExpensiveDocument4 pagesDriving Lessons Need Not Be ExpensiveClint M. MaratasNo ratings yet

- Telematics Position Paper v11Document14 pagesTelematics Position Paper v11Anshul DyundiNo ratings yet

- AVDI DiagnosticsDocument7 pagesAVDI DiagnosticsFlorin MoneaNo ratings yet

- Atlas Copco Rocket Boomer: Diagrams and DrawingsDocument165 pagesAtlas Copco Rocket Boomer: Diagrams and DrawingsAlejandro 187No ratings yet

- Fiat Models Tacho Programming GuideDocument12 pagesFiat Models Tacho Programming GuideligiaNo ratings yet