Professional Documents

Culture Documents

Capacity Verification Run at Rate Ipa

Uploaded by

Iram ChaviraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capacity Verification Run at Rate Ipa

Uploaded by

Iram ChaviraCopyright:

Available Formats

IPA Form No.

EE517 Issue 1

IPA

1 2 3 7 8

Interconnect Product Assembly AS

CAPACITY VERIFICATION (Production Readiness Review / RUN@RATE)

4 5

Part Number Part Description XXX Annual Capacity Planning Volume pcs/year Process Step Process Description Units hours shifts days weeks hours % pcs/hour % % pcs/hour pcs/year % X hour pcs pcs % pcs pcs/ hour pcs/ hour hour text % X STEP 1 STEP 2

Run@Rate Date Supplier Name Supplier Location STEP 3 STEP 4 STEP 5 STEP 6

I - Supplier Working Standards

9 10 11 12 13 14

Working hours/shift Shifts/ day Days/ week Weeks/ year Total hours/year (9*10*11*12) % of line for XXX parts (Allocation %) Quoted Production Rate (part # item 1) Quoted % scrap Quoted % line efficiency Adjusted production rate (15*(1-16)*17) Available capacity (15*14*(1-16)*17)*13 Utilization % (3/19) Bottleneck operation Trial run duration Total parts produced Number of bad parts First time capability % ((23-24)/24)*100 Number of good parts (23-24) Net output (26/22) Takt Time Rate (Target) (3/13*14) Downtime Reason

II - Supplier Capacity Data III - RUN@RATE Results

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30 31 32

Run-Off utilization % (3/(27*13*14)) Bottleneck operation

SHADED CELLS ARE CALCULATED and protected

34

SUMMARY

35

RUN@RATE results are acceptable and meet XXX capacity planning volume requirements:

33

The attached capability study results meet XXX requirements: Corrective actions are required: New production readiness trial run is required: Date: Date:

Overall Process Utilization % 0.00%

Status Acceptable

Auditor Information Name: Company: Location:

36

Supplier representative signature:

Auditor signature:

IPA Form No. EE517 Issue 1

IPA

1 2 3 7 8

Interconnect Product Assembly AS

CAPACITY VERIFICATION (Production Readiness Review / RUN@RATE)

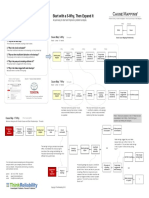

30301458B Inflator retainer bracket pcs/year Process Step Process Description Units hours shifts days weeks hours % pcs/hour % % pcs/hour pcs/year % X hour pcs pcs % pcs pcs/ hour pcs/ hour hour text % X 28.1% 700,000 STEP 1 Stamp Part 7.5 3 5 48 5400 100% 720.0 2% 97% 684 3,695,933 19% 2.00 929 5 99.46% 924 462 130 STEP 2 CNC #1 8.5 2 5 48 4080 87% 210.0 2% 94% 193 686,677 102% X 1.00 249 2 99.20% 247 247 197 0.5 Reprogramming 79.8% 97.1% X 34 SUMMARY 72.3% 70.3%

35 4 5 6

Part Number Part Description XXX Annual Capacity Planning Volume

Run@Rate Date Supplier Name Supplier Location STEP 3 CNC #2 7.0 3 5 48 5040 100% 164.0 5% 95% 148 745,970 94% 2.00 290 4 98.62% 286 143 139 STEP 4 Weld Fasteners 7.0 3 5 48 5040 100% 240.0 9% 92% 201 1,012,677 69% 1.25 252 12 95.24% 240 192 139

February 14, 2004 Acme Machining Cleveland, OH STEP 5 Paint 10.5 1 5 48 2520 50% 1200.0 5% 95% 1,083 1,364,580 51% 1.00 794 4 99.50% 790 790 556 STEP 6

I - Supplier Working Standards

9 10 11 12 13 14

Working hours/shift Shifts/ day Days/ week Weeks/ year Total hours/year (9*10*11*12) % of line for XXX parts (Allocation %) Quoted Production Rate (part # item 1) Quoted % scrap Quoted % line efficiency Adjusted production rate (15*(1-16)*17) Available capacity (15*14*(1-16)*17)*13 Utilization % (3/19) Bottleneck operation Trial run duration Total parts produced Number of bad parts First time capability % ((23-24)/24)*100 Number of good parts (23-24) Net output (26/22) Takt Time Rate (Target) (3/13*14) Downtime Reason

II - Supplier Capacity Data III - RUN@RATE Results

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

30 31 32

Run-Off utilization % (3/(27*13*14)) Bottleneck operation

SHADED CELLS ARE CALCULATED and protected

RUN@RATE results are acceptable and meet XXX capacity planning volume requirements:

33

The attached capability study results meet XXX requirements: Corrective actions are required: New production readiness trial run is required: Date: Date: April 1, 2404 May 16, 2004

Overall Process Utilization % 97.13%

Status Acceptable

Auditor Information Name: Gerald Biggs Company: XXX Location: Mesa, AZ

36

Supplier representative signature:

Tom Alison

Auditor signature:

Gerald Biggs

IPA

Interconnect Product Assembly AS

IPA Form No. EE518 Issue 1

SUPPLIER PROCESS CAPABILITY

Sample Size Critical and Signficant? Note: If no USL/LSL, then leave cell blank

SECTION 1 -SPECIFICATION DATA AND MEASUREMENT RESULTS

Part Number

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

Lower Specification Limit

PpK

1 2 3 4 5 6 7

Part Number

Sample Size Critical and Signficant?

Note: If no USL/LSL, then leave cell blank Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

PpK

1 2 3 4 5 6 7

Part Number

Sample Size Critical and Signficant?

Note: If no USL/LSL, then leave cell blank Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

PpK

1 2 3 4 5 6 7

Part Number

Sample Size Critical and Signficant?

Note: If no USL/LSL, then leave cell blank Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

PpK

1 2 3 4 5 6 7

Part Number

Sample Size Critical and Signficant?

Note: If no USL/LSL, then leave cell blank Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

PpK

1 2 3 4 5 6 7

IPA Form No. EE518 Issue 1

IPA

Interconnect Product Assembly AS

SUPPLIER PROCESS CAPABILITY

30301458B Critical and Signficant? Sample Size 30 Note: If no USL/LSL, then leave cell blank

SECTION 1 -SPECIFICATION DATA AND MEASUREMENT RESULTS

Part Number

Characteristic or Specification

Average

Standard Deviation

Upper Specification Limit

3.5500 6.8200 0.5100 0.0550

Lower Specification Limit

3.4500 6.7800 0.4950 0.0450

PpK

1 2 3 4 5 6 7

Hole Diameter 3.5 mm 6.8 mm dimension .5 radius .05 chamfer

3.4800 6.7900 0.4990 0.0510

0.0300 0.0500 0.0100 0.0010

0.333 0.067 0.133 1.333

Part Number Critical and Signficant?

Sample Size

Note: If no USL/LSL, then leave cell blank Upper Specification Limit Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

PpK

1 2 3 4 5 6 7

Part Number Critical and Signficant?

Sample Size

Note: If no USL/LSL, then leave cell blank Upper Specification Limit Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

PpK

1 2 3 4 5 6 7

Part Number Critical and Signficant?

Sample Size

Note: If no USL/LSL, then leave cell blank Upper Specification Limit Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

PpK

1 2 3 4 5 6 7

Part Number Critical and Signficant?

Sample Size

Note: If no USL/LSL, then leave cell blank Upper Specification Limit Lower Specification Limit

Characteristic or Specification

Average

Standard Deviation

PpK

1 2 3 4 5 6 7

You might also like

- Consumer Reports Buying Guide 2021Document227 pagesConsumer Reports Buying Guide 2021fatso68100% (1)

- Key combinations in Fusion 360Document4 pagesKey combinations in Fusion 360marccerdan9828No ratings yet

- TVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRDocument5 pagesTVS MOTOR COMPANY Audit Date Check Sheet for Significant Production Trial Run (SPTRSAKTHIVEL ANo ratings yet

- Capacity Verification Run at Rate IpaDocument4 pagesCapacity Verification Run at Rate IpaBES100% (1)

- Teamcenter Compatibility MatrixDocument3 pagesTeamcenter Compatibility MatrixIram ChaviraNo ratings yet

- Mri BrainDocument74 pagesMri Brainagithia100% (1)

- LPA Procedure2Document6 pagesLPA Procedure2Iram ChaviraNo ratings yet

- Neil Strauss - The Annihilation Method - Style's Archives - Volume 1 - The Origin of Style - How To Transform From Chump To Champ in No TimeDocument132 pagesNeil Strauss - The Annihilation Method - Style's Archives - Volume 1 - The Origin of Style - How To Transform From Chump To Champ in No TimeDaniel Nii Armah Tetteh100% (2)

- Measurement System Analysis: VARIABLE STUDY (Average-Range Method)Document1 pageMeasurement System Analysis: VARIABLE STUDY (Average-Range Method)Iram ChaviraNo ratings yet

- S ApqpDocument15 pagesS ApqpIram ChaviraNo ratings yet

- 5.2 Process Capability Analysis Rev2ADocument8 pages5.2 Process Capability Analysis Rev2APollyNo ratings yet

- Gauge Repeatability & Reproduceability Report (MSA Study)Document2 pagesGauge Repeatability & Reproduceability Report (MSA Study)Karan MalhiNo ratings yet

- Process Flow Chart Ext. RotorDocument6 pagesProcess Flow Chart Ext. RotorVasile MarculescuNo ratings yet

- Supplier Control Plan: Audit SummaryDocument2 pagesSupplier Control Plan: Audit SummaryRay ManNo ratings yet

- Advanced Process CapabilityDocument11 pagesAdvanced Process Capabilitycheqjieja100% (1)

- FC/CP WorksheetDocument4 pagesFC/CP WorksheetVu NguyenNo ratings yet

- Manual MSA.3.Ingles PDFDocument240 pagesManual MSA.3.Ingles PDFIram ChaviraNo ratings yet

- Documents - Pub Cqi 15 Welding Worksheets Process Tables 2Document55 pagesDocuments - Pub Cqi 15 Welding Worksheets Process Tables 2amirkhakzad498No ratings yet

- GM FMEA DoneDocument12 pagesGM FMEA DoneSuraj RawatNo ratings yet

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocument2 pagesNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNo ratings yet

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 pagesPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Statistical Process Control Study: SampleDocument23 pagesStatistical Process Control Study: SampleRizwanAli100% (2)

- 195 CasingDocument14 pages195 Casingsasi10000No ratings yet

- Exedy India Ltd. APQP Process DocumentsDocument3 pagesExedy India Ltd. APQP Process Documentssam1hi5No ratings yet

- Benutzerhandbuch QTR Online Englische Version PDFDocument34 pagesBenutzerhandbuch QTR Online Englische Version PDFBrian BoruNo ratings yet

- Continental GQA 150429Document22 pagesContinental GQA 150429dywonNo ratings yet

- INGFRT-11 Run at RateDocument3 pagesINGFRT-11 Run at RateMarisol RubioNo ratings yet

- APQP FormDocument103 pagesAPQP FormJERFSON AUGUSTONo ratings yet

- CQI-9 - 2a. Edicion - Ingles PDFDocument69 pagesCQI-9 - 2a. Edicion - Ingles PDFIram Chavira100% (1)

- ISO 14644 Presentation PDFDocument35 pagesISO 14644 Presentation PDFSandy Piccolo100% (1)

- Training in MSA PQ Systems Training Material PDFDocument109 pagesTraining in MSA PQ Systems Training Material PDFsaby aroraNo ratings yet

- CPK GuidelinesDocument2 pagesCPK GuidelinesNavnath Tamhane100% (1)

- Ejc-M13 - FN953205Document203 pagesEjc-M13 - FN953205JoséNo ratings yet

- Enter and analyze data using statistical process control chartDocument6 pagesEnter and analyze data using statistical process control chartAhmed TeranNo ratings yet

- Bartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentDocument146 pagesBartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentMars Mar100% (1)

- CAPS LESSON PLAN, KAHOOT QUIZ, PPT VIDEODocument3 pagesCAPS LESSON PLAN, KAHOOT QUIZ, PPT VIDEOMandisa MselekuNo ratings yet

- FMEA analysis of flywheel casting process failuresDocument7 pagesFMEA analysis of flywheel casting process failuresSuraj RawatNo ratings yet

- Structure Analysis (3) Function AnalysisDocument6 pagesStructure Analysis (3) Function Analysisprasathm873900No ratings yet

- (World of Art) John Boardman - Athenian Black Figure Vases-Thames and Hudson (1974)Document128 pages(World of Art) John Boardman - Athenian Black Figure Vases-Thames and Hudson (1974)Karen SantosNo ratings yet

- Attribute Gauge R&RDocument5 pagesAttribute Gauge R&Rhel2905No ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Statistic ProcessDocument39 pagesStatistic ProcessxredjokerxNo ratings yet

- GRR Study MSA TemplateDocument21 pagesGRR Study MSA TemplaterajarajanNo ratings yet

- Measure Science AccuratelyDocument41 pagesMeasure Science AccuratelyAnthony QuanNo ratings yet

- Supplier Controlled - Safe Launch PlanDocument6 pagesSupplier Controlled - Safe Launch PlanMario RojasNo ratings yet

- Airport Design GuidelinesDocument408 pagesAirport Design Guidelinesnickolololo67% (9)

- Apqp (1) (VBS)Document111 pagesApqp (1) (VBS)MR KonarengineeringNo ratings yet

- Kaizen Report Sheet Template for Mechanical Engineering DepartmentDocument1 pageKaizen Report Sheet Template for Mechanical Engineering DepartmentSaravana VigneshNo ratings yet

- CP / CPK Calculation Sheet: SpecificationDocument6 pagesCP / CPK Calculation Sheet: Specificationjulian12345No ratings yet

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Document2 pages5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemNo ratings yet

- Advanced Product Quality Planning and Control Plan PDFDocument13 pagesAdvanced Product Quality Planning and Control Plan PDFCesarNo ratings yet

- Lean FormsDocument103 pagesLean FormsWashington Fonseca100% (1)

- Destructive R&RDocument19 pagesDestructive R&RKalyan SrinivasNo ratings yet

- Quality ControlDocument2 pagesQuality ControlKumar AshutoshNo ratings yet

- VDA Product-Process AuditDocument1 pageVDA Product-Process AuditYo GoldNo ratings yet

- PPAP PriruckaDocument10 pagesPPAP PriruckaKin MattNo ratings yet

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityNo ratings yet

- Ppap Review ChecklistDocument8 pagesPpap Review ChecklistVipin RanaNo ratings yet

- 8DDocument8 pages8DRomie CubalNo ratings yet

- SRG Global PPAP ChecklistDocument61 pagesSRG Global PPAP Checklistanamika tripathiNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- Cqi 9 Errata AIAGDocument5 pagesCqi 9 Errata AIAGRafael AlvesNo ratings yet

- Leather Testing StandardizationDocument8 pagesLeather Testing StandardizationDaniel MoralesNo ratings yet

- QA Assistant Studio PFMEA ExampleDocument1 pageQA Assistant Studio PFMEA ExampleIqraYounasNo ratings yet

- 5 Why WeldingRobot ToyotaDocument1 page5 Why WeldingRobot ToyotaMickloSoberanNo ratings yet

- Automotive Quality Management Systems A Complete Guide - 2020 EditionFrom EverandAutomotive Quality Management Systems A Complete Guide - 2020 EditionNo ratings yet

- PIR Motion Sensor: User ManualDocument1 pagePIR Motion Sensor: User ManualIram ChaviraNo ratings yet

- Piano SyllabusDocument2 pagesPiano SyllabusIram ChaviraNo ratings yet

- Stage Telescopic ActuatorsDocument4 pagesStage Telescopic ActuatorsIram ChaviraNo ratings yet

- Structural analysis beam element forcesDocument18 pagesStructural analysis beam element forcesIram ChaviraNo ratings yet

- RRDocument1 pageRRIram ChaviraNo ratings yet

- Catalogo Mangueras ParkerDocument308 pagesCatalogo Mangueras ParkerrubenlrtqNo ratings yet

- Step Inside Design Jan/Feb 2007 23, 1 Proquest Arts ModuleDocument9 pagesStep Inside Design Jan/Feb 2007 23, 1 Proquest Arts ModuleIram ChaviraNo ratings yet

- RaDocument1 pageRaIram ChaviraNo ratings yet

- Voyage 200Document1,008 pagesVoyage 200Iram ChaviraNo ratings yet

- Z18 Um V2Document66 pagesZ18 Um V2Iram ChaviraNo ratings yet

- DesignDocument189 pagesDesignumashankaresNo ratings yet

- Fy13 01Document41 pagesFy13 01Iram ChaviraNo ratings yet

- Unlock ExcelDocument1 pageUnlock ExcelIram ChaviraNo ratings yet

- Bend Calculation - DIN 6935Document2 pagesBend Calculation - DIN 6935Iram Chavira100% (1)

- Contingency Plan 25.07.12Document14 pagesContingency Plan 25.07.12Iram ChaviraNo ratings yet

- NX OS CertificationDocument1 pageNX OS CertificationIram ChaviraNo ratings yet

- Ch16 Aggregate PlanningDocument3 pagesCh16 Aggregate PlanningPutri Rizky DwisumartiNo ratings yet

- Nut Case AbcDocument7 pagesNut Case AbcTruong Minh RangNo ratings yet

- Chengdu Finalva Report 2013Document3 pagesChengdu Finalva Report 2013Iram ChaviraNo ratings yet

- This Is Solution of Problem 4 of Homework Set 4 That Deals With A Multiple Product Inventory Problem With (In This Case) A Space ProblemDocument4 pagesThis Is Solution of Problem 4 of Homework Set 4 That Deals With A Multiple Product Inventory Problem With (In This Case) A Space ProblemIram ChaviraNo ratings yet

- Graphics Certification TableDocument10 pagesGraphics Certification TableIram ChaviraNo ratings yet

- 2 Blazejewski PDFDocument15 pages2 Blazejewski PDFIram ChaviraNo ratings yet

- Williamstown Cannabis Cultivation PlanDocument48 pagesWilliamstown Cannabis Cultivation PlanOltion JaupajNo ratings yet

- Document Revision TableDocument11 pagesDocument Revision Tableseva1969No ratings yet

- Taxation Management AssignmentDocument11 pagesTaxation Management AssignmentniraliNo ratings yet

- Orca Share Media1463138182934 PDFDocument167 pagesOrca Share Media1463138182934 PDFJhon Raphael JimenezNo ratings yet

- Kristine Jane T. Zipagan Assignment: 1. Parts of InfographicsDocument2 pagesKristine Jane T. Zipagan Assignment: 1. Parts of InfographicsChristyNo ratings yet

- Mordaunt Short ms907w User ManualDocument12 pagesMordaunt Short ms907w User ManualiksspotNo ratings yet

- Vaping in Preganacy A Systematic ReviewDocument8 pagesVaping in Preganacy A Systematic ReviewMia LouwNo ratings yet

- Folktalesofkeral 00 MenoDocument124 pagesFolktalesofkeral 00 Menoreena sudhirNo ratings yet

- 2020会社案内(英語版)Document18 pages2020会社案内(英語版)DAC ORGANIZERNo ratings yet

- Lyrics: Original Songs: - JW BroadcastingDocument56 pagesLyrics: Original Songs: - JW BroadcastingLucky MorenoNo ratings yet

- Philippine Christian University Graduate School of Business and Management Integrated Syllabi ModuleDocument5 pagesPhilippine Christian University Graduate School of Business and Management Integrated Syllabi ModuleRoselle Anne Luna GuatatoNo ratings yet

- Chapter 3 Week 1 Inductive and Deductive ReasoningDocument57 pagesChapter 3 Week 1 Inductive and Deductive ReasoningDiane Agcaoili Edra50% (6)

- WordPress Introduction: CMS BasicsDocument21 pagesWordPress Introduction: CMS BasicsNgô Ngọc Hải phươngNo ratings yet

- UFD/MMC/SD Controller Flash Support Limitation and Interconnection NoteDocument5 pagesUFD/MMC/SD Controller Flash Support Limitation and Interconnection Noteمہرؤآنہ آبہرآهہيہمہNo ratings yet

- CN Assignment 1 COE-540Document5 pagesCN Assignment 1 COE-540Ghazanfar LatifNo ratings yet

- Analysis of Security Issues in Web Applications Through Penetration TestingDocument7 pagesAnalysis of Security Issues in Web Applications Through Penetration Testingabdel_lakNo ratings yet

- GogikavofobifigukidonDocument2 pagesGogikavofobifigukidonMd. Bepul HossainNo ratings yet

- Unit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivesDocument18 pagesUnit IV - CPU Scheduling and Algorithm Section 4.1 Scheduling Types Scheduling ObjectivessmsaranyaNo ratings yet

- SP Manual Addendum For OS 3 - 03Document2 pagesSP Manual Addendum For OS 3 - 03kevmac88No ratings yet

- Weap - ModflowDocument20 pagesWeap - Modflowguive3No ratings yet