Professional Documents

Culture Documents

Shafts

Uploaded by

Jim Lester AmodiaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shafts

Uploaded by

Jim Lester AmodiaCopyright:

Available Formats

SCHOOL OF ENGINEERING

DEPARTMENT OF MECHANICAL AND MANUFACTURING ENGINEERING

ME 3122L MACHINE DESIGN I LABORATORY

PLATE NO.2 SHAFTS

Design Problem No.1:

Design a machinery shaft using ASME Code. It is to transmit 82 hp at a speed of 1150 rpm with

mild shock. The shaft is subjected to a maximum bending moment of 7500 in-lb. and an axial thrust

load of 15,000 lb. The material is AISI 3150, OQT 1000 F.

Design Problem No. 2:

A cold-rolled transmission shaft, made of annealed AISI C1050, is to transmit a torque of 27 in-

kips with a maximum bending moment of 43 in-kips. What should be the diameter according to the

Code for a mild shock load?

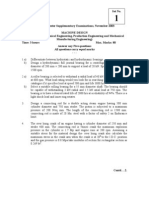

Design Problem No. 3:

A short stub shaft, made of SAE 1035, as rolled, receives 30 hp at 300 rpm via a 12-in. spur gear,

the power being delivered to another shaft through a flexible coupling. The gear is keyed midway

between the bearings and its pressure angle φ = 20o . See figure below. (a) Neglecting the radial

component of the tooth load, determine the shaft diameter for a mild shock load. (b) Considering

both tangential and radial components, compute the shaft diameter.

You might also like

- 17.1 Diesel - Hydro PowerDocument11 pages17.1 Diesel - Hydro PowerJim Lester AmodiaNo ratings yet

- 19.1 Steam Plant Accessories SolutionsDocument9 pages19.1 Steam Plant Accessories SolutionsJim Lester AmodiaNo ratings yet

- 18.1 Steam Power SolutionsDocument6 pages18.1 Steam Power SolutionsJim Lester AmodiaNo ratings yet

- MECH 344 - Final Exam (Winter 2021)Document4 pagesMECH 344 - Final Exam (Winter 2021)Puneet Rudhar100% (1)

- Project ProblemsDocument9 pagesProject Problemsvivek geddamNo ratings yet

- Design Work 9 - Shaft Design Under Combined LoadingsDocument22 pagesDesign Work 9 - Shaft Design Under Combined LoadingsEngr Ghulam MustafaNo ratings yet

- Problem Sets Shafts Keys and CouplingDocument4 pagesProblem Sets Shafts Keys and CouplingJay Ann TondoNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- Machine Design - Sample ProblemDocument10 pagesMachine Design - Sample ProblemMiss RozuNo ratings yet

- Dme Model QPDocument3 pagesDme Model QPCody LeeNo ratings yet

- nr321401 Principles of Machine DesignDocument2 pagesnr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Design of Transmission Systems - Department of Mechanical EngineeringDocument10 pagesDesign of Transmission Systems - Department of Mechanical EngineeringDesejo SozinandoNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- 0326 Me 2303 Design of Machine ElementsDocument3 pages0326 Me 2303 Design of Machine ElementsSaravanan MathiNo ratings yet

- TUTORIAL 3 Design of Shaft Key and CouplingDocument2 pagesTUTORIAL 3 Design of Shaft Key and Couplingrip111176100% (1)

- Deisgn of Machine Elements (MTE2202 - 2)Document3 pagesDeisgn of Machine Elements (MTE2202 - 2)MeghaNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- Machine Design-II EME602 2012-13Document4 pagesMachine Design-II EME602 2012-13nitin_johriNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Week 1Document14 pagesWeek 1Mohammed AlryaniNo ratings yet

- Machine Element II Worksheet 1Document2 pagesMachine Element II Worksheet 1Hanan ShayiboNo ratings yet

- ME-6503 Design of Machine Elements - 16 MarksDocument12 pagesME-6503 Design of Machine Elements - 16 MarksMadhu MithaNo ratings yet

- NR 320301 Machine DesignDocument8 pagesNR 320301 Machine DesignSrinivasa Rao GNo ratings yet

- Dme 2 QP CombinedDocument9 pagesDme 2 QP CombinedPrasinNo ratings yet

- 15A03602 Design of Machine Members - IIDocument2 pages15A03602 Design of Machine Members - IIJagannath CherkuNo ratings yet

- Worksheet 1Document2 pagesWorksheet 1dagimawgchew777No ratings yet

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- Dome-Model-2 QuestionDocument2 pagesDome-Model-2 QuestionPraba KaranNo ratings yet

- DME Unit 2 33Document35 pagesDME Unit 2 33Chandrasekhar PrabhakaranNo ratings yet

- Question Paper Code:: Reg. NoDocument3 pagesQuestion Paper Code:: Reg. NoSURESH KUMAR APNo ratings yet

- Code: 13A03505: (Mechanical Engineering)Document2 pagesCode: 13A03505: (Mechanical Engineering)MrHEMAMAHEHNo ratings yet

- rr321401 Principles of Machine DesignDocument8 pagesrr321401 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- ME 352 - All Problem Class - 14-18 BatchDocument125 pagesME 352 - All Problem Class - 14-18 BatchEntertainment GamingNo ratings yet

- Question PapersDocument89 pagesQuestion PapersDreamer ChavanNo ratings yet

- DESIGN OF MACHINE ELEMENTS Question PaperDocument4 pagesDESIGN OF MACHINE ELEMENTS Question PaperL RevathiNo ratings yet

- Me 7 Sem Subject Design of Mechanical Drives Jun 2017Document2 pagesMe 7 Sem Subject Design of Mechanical Drives Jun 2017djniksthehearteditorNo ratings yet

- Slip Test DMEDocument3 pagesSlip Test DMERyan GomezNo ratings yet

- MD2 Model QuestionsDocument2 pagesMD2 Model Questionsmanish sharmaNo ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailNo ratings yet

- Engine and Drive Line DesignDocument2 pagesEngine and Drive Line DesignMinnuNo ratings yet

- Docs MEDMMIAssignments2013 PDFDocument13 pagesDocs MEDMMIAssignments2013 PDFHafiz Mahar28No ratings yet

- Set No: 1: Code No: V3203/R07Document50 pagesSet No: 1: Code No: V3203/R07Polireddi Gopala KrishnaNo ratings yet

- B Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1Document6 pagesB Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1suneel kumar rathoreNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Me 331Document5 pagesMe 331arumugam_rNo ratings yet

- Diploma Board Examination - December 2020Document2 pagesDiploma Board Examination - December 2020Pradeep AppuNo ratings yet

- Design of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Document3 pagesDesign of Mechanical Drives: B.E. (Mechanical Engineering / Power Engineering) Seventh Semester (CBS)Komal HingeNo ratings yet

- Assignment 7221 MD-IIIDocument2 pagesAssignment 7221 MD-IIIkalikaNo ratings yet

- Dmm2 Mar2006Document8 pagesDmm2 Mar2006Abdul Saleem MohammedNo ratings yet

- Shaft Design AbduaDocument16 pagesShaft Design AbduaLIBRE MAXIME S.No ratings yet

- Me8593 - Dme - Model QPDocument3 pagesMe8593 - Dme - Model QPChandrasekhar PrabhakaranNo ratings yet

- ShaftsDocument73 pagesShaftsponcatoeraNo ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- Tut6 - Shaft Design - MemoDocument11 pagesTut6 - Shaft Design - MemoVincent SibandaNo ratings yet

- DesignDocument21 pagesDesignmeindyaNo ratings yet

- Analysis of Simple StressesDocument39 pagesAnalysis of Simple StressesEduCartNo ratings yet

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- BSME - Students CLEARANCE-4Document1 pageBSME - Students CLEARANCE-4Jim Lester AmodiaNo ratings yet

- Student Clearance AmodiaDocument1 pageStudent Clearance AmodiaJim Lester AmodiaNo ratings yet

- 3 AutosavedDocument21 pages3 AutosavedJim Lester AmodiaNo ratings yet

- Input Process OutputDocument15 pagesInput Process OutputJim Lester AmodiaNo ratings yet

- Lab Activity 1: Faraday'S Law: ObjectivesDocument5 pagesLab Activity 1: Faraday'S Law: ObjectivesJim Lester AmodiaNo ratings yet