Professional Documents

Culture Documents

Hydro-Pneumatic Water Pressure Systems

Uploaded by

Haidee Hernandez0 ratings0% found this document useful (0 votes)

33 views2 pagesThe document is a brochure describing SKS hydro-pneumatic water pressure systems. It summarizes that the systems:

- Automatically maintain building water pressure through use of close-coupled pumps, tanks, valves and controls.

- Come pre-assembled and pre-wired in simplex (one pump) and duplex (two pump) configurations to supply flows up to 80 GPM and heads up to 160 feet.

- Utilize end suction centrifugal pumps from 1.5 to 5 HP and a 132 gallon hydro-pneumatic tank to separate air and water without needing recharging.

Original Description:

Original Title

SKS_brochure[1]

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a brochure describing SKS hydro-pneumatic water pressure systems. It summarizes that the systems:

- Automatically maintain building water pressure through use of close-coupled pumps, tanks, valves and controls.

- Come pre-assembled and pre-wired in simplex (one pump) and duplex (two pump) configurations to supply flows up to 80 GPM and heads up to 160 feet.

- Utilize end suction centrifugal pumps from 1.5 to 5 HP and a 132 gallon hydro-pneumatic tank to separate air and water without needing recharging.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views2 pagesHydro-Pneumatic Water Pressure Systems

Uploaded by

Haidee HernandezThe document is a brochure describing SKS hydro-pneumatic water pressure systems. It summarizes that the systems:

- Automatically maintain building water pressure through use of close-coupled pumps, tanks, valves and controls.

- Come pre-assembled and pre-wired in simplex (one pump) and duplex (two pump) configurations to supply flows up to 80 GPM and heads up to 160 feet.

- Utilize end suction centrifugal pumps from 1.5 to 5 HP and a 132 gallon hydro-pneumatic tank to separate air and water without needing recharging.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Brochure # 0710

T Y PE

••••••••••• H YD RO -PN EUMAT I C

SKS

WATER PRESSU RE SYST E MS

Flows to 80 GPM/pump, Heads to

160 feet. simplex and duplex inits.

horsepower range 1 1/2 thru 5,

3450 RPM operation.

H IG H LIG H T S

• • Automatic maintenance of building water pressure

• • Factory assembled and wired

• • Simplex and duplex systems available

• • Cushion-Stop tank with 132 gallon nominal capacity

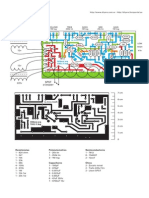

F E AT U R E S Selection Table

GPM Pump Pump Heade Tank Nom.

SKS WATER PRESSURE SYSTEMS: Type System Pump Motor Motor Connection

Each Head Head Size Cap.

Number Model H.P. R.P.M Size Simplex

Pump Lbsl. Feet Duplex Gallons

SKS systems are pre-assembled and

pre-wired units which provide steady SKS-4020-2 20 45 1.25CC-1.5-2 1.5 3450

water pressure boosting for all types of SKS-4030-2 30 70 1.25CC-1.5-2 1.5 3450

buildings. The system includes close- SKS-4040-2 40 95 1.25CC-1.5-2 1.5 3450

40 2 2.5 132

coupled pumps, copper suction and SKS-4050-2 50 115 1CG-3-2 3 3450

discharge headers, pressure gauge, SKS-4060-2 60 140 1CG-5-2 5 3450

b ro nze p u m p iso l atio n va lve s a n d SKS-4070-2 70 160 1CG-5-2 5 3450

check valves, a steel base, a hydro-

SKS-6020-2 20 45 1.5CC-1.5-2 1.5 3450

pne umatic tank , a pressure switch

SKS-6030-2 30 70 1.5CG-2-2 2 3450

for each pump, a fusible disconnect

SKS-6040-2 40 95 1.5CG-3-2 3 3450

switch and magnetic starter (HOA) 60 2 2.5 132

for each motor (plus an automatic SKS-6050-2 50 115 1.5CG-5-2 5 3450

alternator for duplex units.). SKS-6060-2 60 140 1.5CG-5-2 5 3450

SKS-6070-2 70 160 1.5CK-5-2 5 3450

SKS PUMP AND MOTOR UNITS: Type

S KS water pressure systems are SKS-8020-2 20 45 1.5CC-1.5-2 1.5 3450

built with Federal Type CC , CG and SKS-8030-2 30 70 1.5CC-3-2 3 3450

80 2 2.5 132

C K c l o s e - c o u p l e d , b r o n ze - f i t te d , SKS-8040-2 40 95 1.5CG-5-2 5 3450

end suction, centrifugal pumps. The SKS-8050-2 50 115 1.5CG.5-5-2 5 3450

pumps are back pull-out style with

center-line discharge, and are fitted

with leakless mechanical shaft seals.

They are driven by standard Type JM S U G G E S T E D S P E C I F I C AT I O N S

close-coupled motors. DUPLEX SKS WATER PRESSURE SYSTEM

Furnish and install, as shown on plans, a Federal Pump Corporation Duplex Type SKS

SKS HYDRO-PNEUMATIC TANKS: The

factor y-assemble d and f actor y-wire d hydro - pne umatic water pressure syste m to

standard SKS hydro-pneumatic tank provide steady water pressure boosting for the building. Pumps shall be rated as shown

has a 132 gallon nominal capacity and in the pump schedule.

is rated for 150 psi maximum working The system shall include close-coupled pumps, copper suction and discharge headers,

pressure. The tank has a sealed inert a discharge pressure gauge, a bronze isolation valve on the suction and discharge

connection of each pump, a check valve in the discharge line of each pump, a hydro-

flexible water chamber to separate pneumatic tank, a pressure switch for each pump and a control panel.

the water and the air, and, therefore,

The SKS pumps shall be close-coupled, bronze-fitted, end suction, centrifugal type,

no periodic recharging is required. of the back pulll-out design, with centerline discharge and leakless mechanical shaf t

seal. Each pump shall be driven by a standard JM-shaf t-close-coupled pump motor of

SIMPLEX SYSTEM OPERATION: The the horsepower shown in the pump schedule.

pump operates continuously to satisfy

The SKS hydro-pneumatic tank shall have a 132 gallon nominal capacity and be rated

the water demand. When the demand for 150 psi maximum working pressure. The tank shall have a sealed inert flexible water

decreases, the discharge header chamber to separate the water and air and eliminate periodic tank recharging.

p re s s u re i n c re a s e s a n d th e p u m p The SKS control panel shall include a fusible disconnect switch, a magnetic starter

control pressure switch shuts down and an HOA selector switch for each pump, plus an automatic alternator and shall be

mounted and wired on the unit.

the pump. The tank then continues

to satisf y the small wate r de mand Furnish and install a stainless steel braided hose connection for the ends of the suction

and discharge headers, of the size shown in the pump schedule.

u ntil th e ta n k p ressu re d ro ps to a

pre-determined low point. The pump The Duplex SKS System shall operate as follows: The lead pump operates continuously to

satisf y the water demand. When the demand decreases, the discharge header pressure

control pressure switch then turns on increases and the lead pump pressure switch shuts down the lead pump. The tank then

the pump to refill the tank and satisfy continues to satisf y the small water demand until the tank pressure drops to a pre-

the building demand. determined low point. The lead pump pressure switch then turns on the lead pump to

re-fill the tank and satisf y the building demand. If the lead pump is unable to satisf y

D U P L E X SYS T E M O P E R AT I O N : A the demand alone, the pressure in the discharge header will drop to a second low level

and the lag pump pressure switch will turn on the lag pump to operate simultaneously

duplex system operates in the same with the lead pump. The automatic alternator will interchange the lead pump and lag

manner as a simplex system except pump on each operating cycle.

that a second pump control pressure

PUMP SCHEDULE:

switch is provided to allow both pumps

to o p e r a te s i m u l t a n e o u s l y d u r i n g No. of Pumps: 2 , System No.: SKS-

periods of very high water demand. G.P.M. per Pump: , TDH: f t.

A n a l te r n a to r i s a l s o p rov i d e d to

automatically interchange the lead Motor H.P.: , R.P.M.: 3450 , Phase: 3 , Cycles: 60 , Volts:

pump and the lag pump on each Flexible hose size: ins. x ins.

operating cycle.

ADDRESS: 1144 Utica Avenue, Brooklyn, NY 1 1 203 TEL: (718) 451-2000 URL: fed era lp u m p s .co m

2 All images and information contained in this booklet are the sole property of The Federal Pumps Corporation, and may not be reproduced without written permission.

You might also like

- PSV SizingDocument3 pagesPSV SizingpavanNo ratings yet

- 210-S637UUT-200FH-HA - Baylor MotorsGenerators Instruction and Service Manual PDFDocument49 pages210-S637UUT-200FH-HA - Baylor MotorsGenerators Instruction and Service Manual PDFCarlos Antonio Fontalvo Carrascal100% (4)

- Pre-Amp Marshall JCM800Document2 pagesPre-Amp Marshall JCM800jailsondelimaNo ratings yet

- Condensate Return Boiler Feed Pumps G Series-TI-5-302-USDocument2 pagesCondensate Return Boiler Feed Pumps G Series-TI-5-302-US呂仲書No ratings yet

- 50PVB ProductDocument29 pages50PVB Producthakimmunas100% (1)

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionDocument8 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionHai NguyenNo ratings yet

- The Source of Hydraulic PowerDocument16 pagesThe Source of Hydraulic Powersekar507100% (1)

- P 271 B - Doc 2 - Part D - Sec - HVAC - BOQ Priced Rev.001 Subcontractor WorksDocument55 pagesP 271 B - Doc 2 - Part D - Sec - HVAC - BOQ Priced Rev.001 Subcontractor WorksAdmire MuvunzwiNo ratings yet

- Denison HydraulicsDocument48 pagesDenison HydraulicsPartagon PowNo ratings yet

- LKS 160Document10 pagesLKS 160SamulaNo ratings yet

- LKS 160 - en 1Document10 pagesLKS 160 - en 1shoppingmehdi9No ratings yet

- Series Features: Two-Stage Preset ValveDocument2 pagesSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosNo ratings yet

- Enquiry - Plumbing PumpDocument9 pagesEnquiry - Plumbing Pumprkpatel40No ratings yet

- SB373AR2Document8 pagesSB373AR2GiovaniBalzaniNo ratings yet

- Brochure GPAC70-210 Air CooledDocument10 pagesBrochure GPAC70-210 Air CooledAva AlonserNo ratings yet

- Operating Manual Consolidated - 02.01.2017Document133 pagesOperating Manual Consolidated - 02.01.2017Jyoti Tecno PowerNo ratings yet

- VSD PDFDocument20 pagesVSD PDFJovanny MarquezNo ratings yet

- Modified Hydraulic System in Bokaro Steel Plant: OutlookDocument4 pagesModified Hydraulic System in Bokaro Steel Plant: Outlooksurya325kiranNo ratings yet

- 72PM 2GNM110001 NewDocument2 pages72PM 2GNM110001 NewmorrissubhashNo ratings yet

- Preset Valve Ocv Model Sheet 115 - 25 Aviation 2020Document2 pagesPreset Valve Ocv Model Sheet 115 - 25 Aviation 2020varadarajck893No ratings yet

- Commercial ComponentsDocument0 pagesCommercial ComponentsChevronelleNo ratings yet

- NH3 Compressor UnitDocument1 pageNH3 Compressor UnitdzungNo ratings yet

- TCCC 1 SD 439 0001 R0Document11 pagesTCCC 1 SD 439 0001 R0Luis Angel PatiñoNo ratings yet

- HVAC Tender BOQ 24.12.17Document22 pagesHVAC Tender BOQ 24.12.17yohannes haileNo ratings yet

- Cable ListDocument2 pagesCable Listmd.muneerNo ratings yet

- YORK Marine Screw Chiller Units: Type MCSH-SDocument2 pagesYORK Marine Screw Chiller Units: Type MCSH-SMike ErftmierNo ratings yet

- BAQUABIIDocument16 pagesBAQUABIIAnonymous 7xHNgoKE6eNo ratings yet

- JPCE Issue 01-drwgsDocument22 pagesJPCE Issue 01-drwgsasswipeNo ratings yet

- Johnsons ActuatorDocument16 pagesJohnsons ActuatorTibe HoubrixNo ratings yet

- Clint Cha k726p 36012p Brochure 0325 enDocument2 pagesClint Cha k726p 36012p Brochure 0325 enDorin100% (1)

- External Fire Fighting WorksDocument28 pagesExternal Fire Fighting WorksSaurabh Kumar Sharma100% (1)

- Disjuntor 123-160 KV - ABBDocument2 pagesDisjuntor 123-160 KV - ABBdmezzavillaNo ratings yet

- Hvac Boq - R0Document17 pagesHvac Boq - R0Avik Biswas67% (3)

- Circulator Pumps: Hot & Cold Water CirculatorsDocument4 pagesCirculator Pumps: Hot & Cold Water Circulatorstvshow zeeNo ratings yet

- Til/v/: "GY, RV H Rr+doaa, O)Document15 pagesTil/v/: "GY, RV H Rr+doaa, O)Bimal DeyNo ratings yet

- PG Spec 12V4000DS1250 1250kW 3D T2 60Hz 50CDocument4 pagesPG Spec 12V4000DS1250 1250kW 3D T2 60Hz 50CMark Louies Mago VillarosaNo ratings yet

- Experience of Commissioning The AES 2006 V 392M ST - 2017 - Nuclear Energy andDocument8 pagesExperience of Commissioning The AES 2006 V 392M ST - 2017 - Nuclear Energy andAhmed KamelNo ratings yet

- BB Condensate Return Systems Apr11Document4 pagesBB Condensate Return Systems Apr11fauzi endraNo ratings yet

- Instantaneous - DHW - Production Heat ExchangerDocument4 pagesInstantaneous - DHW - Production Heat ExchangerMoutaz IsmailNo ratings yet

- Enquiry - Hvac Pump SetDocument6 pagesEnquiry - Hvac Pump Setrkpatel40No ratings yet

- Datamate Parts ManualDocument20 pagesDatamate Parts Manualdesto2100% (1)

- ERP Material List 01.18.19Document23 pagesERP Material List 01.18.19Wellmorc AgetroNo ratings yet

- Circuit DiagramsDocument120 pagesCircuit DiagramsCarlos Andrés Sánchez VargasNo ratings yet

- 2759 - Carrier 30 HK 060Document25 pages2759 - Carrier 30 HK 060Pop-Coman SimionNo ratings yet

- Price List of Electronic Load Control (Elc-Pme) 2014Document9 pagesPrice List of Electronic Load Control (Elc-Pme) 2014Yan NaingNo ratings yet

- Section 6A - Closed Cooling SystemDocument48 pagesSection 6A - Closed Cooling SystemJorge SoberanoNo ratings yet

- FF Comparison BOQDocument9 pagesFF Comparison BOQsyed yaqubNo ratings yet

- Motor Denison M6 FijoDocument25 pagesMotor Denison M6 FijoEdwin Quispe CarlosNo ratings yet

- XCT7 SEA SD 4-5HP) Service Manual 20210506Document56 pagesXCT7 SEA SD 4-5HP) Service Manual 20210506BCINo ratings yet

- eSV + REFLEX CatalogueDocument37 pageseSV + REFLEX CatalogueFARAZamuNo ratings yet

- E C T K - L C: Lectric Ounter Ilting Ettle Eft OnsoleDocument2 pagesE C T K - L C: Lectric Ounter Ilting Ettle Eft OnsoleSergio HernandezNo ratings yet

- Control Ball ValvesDocument44 pagesControl Ball ValvesAleksandar PetrusevskiNo ratings yet

- Actualización SIZERDocument2 pagesActualización SIZERmpensador2No ratings yet

- Centrifugal Pumps: Cast Iron & Bronze ModelsDocument8 pagesCentrifugal Pumps: Cast Iron & Bronze Modelsudrogono2No ratings yet

- Hydraulic Power Pack: Q 0.5 - 50 L/min - P 250 Bar - P 7.5 KWDocument8 pagesHydraulic Power Pack: Q 0.5 - 50 L/min - P 250 Bar - P 7.5 KWPradeep RavalNo ratings yet

- VSD05M Service ManualDocument4 pagesVSD05M Service ManualMario Javier Serrano100% (1)

- Operation and Mainetance Manual of Dongfang 300mw Steam Turbine Generator Unit-1Document728 pagesOperation and Mainetance Manual of Dongfang 300mw Steam Turbine Generator Unit-1Adeta GitaNo ratings yet

- Omplaint: High TCC Slip RPM at Increasing LoadDocument1 pageOmplaint: High TCC Slip RPM at Increasing Loadalex5101No ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Scroll Decent PowerDocument5 pagesScroll Decent PowerMauricioNo ratings yet

- CHAPTER 1 - Fire Technology and Arson InvDocument32 pagesCHAPTER 1 - Fire Technology and Arson InvjhasonNo ratings yet

- Kcj467hag BXXXDocument4 pagesKcj467hag BXXXMohammad ZakoutNo ratings yet

- Siemens Industrial Steam Turbine SST 400 BrochureDocument8 pagesSiemens Industrial Steam Turbine SST 400 Brochurewintermutte100% (1)

- Cengel Fluid Mechanics PDFDocument34 pagesCengel Fluid Mechanics PDFHafiz YusufNo ratings yet

- OSOGF12009 MergedDocument2 pagesOSOGF12009 Mergedwaad mellitiNo ratings yet

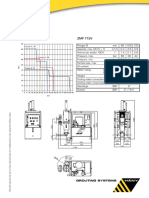

- Data Sheet: ZMP 712VDocument2 pagesData Sheet: ZMP 712VJulian FraileNo ratings yet

- CompAir L23 - L29 - RS Compressor Brochure PDFDocument8 pagesCompAir L23 - L29 - RS Compressor Brochure PDFbulentbulutNo ratings yet

- New Ecowill - A New Generation Gas Engine Micro-ChpDocument13 pagesNew Ecowill - A New Generation Gas Engine Micro-ChpBibek JoshiNo ratings yet

- Exercise 2Document6 pagesExercise 2adeelsnNo ratings yet

- Energy BooksDocument4 pagesEnergy BooksEngr. Nazia BaigNo ratings yet

- Wankel Engine PresentationDocument15 pagesWankel Engine PresentationHarish TalluriNo ratings yet

- Subject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerDocument19 pagesSubject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerSuraj KambleNo ratings yet

- Client ListDocument18 pagesClient ListEngr Irfan AkhtarNo ratings yet

- Parameters of Different Heat ExchangersDocument2 pagesParameters of Different Heat ExchangersCuando la dictadura es un hecho, la Revolución es un derechoNo ratings yet

- HVAC and Refrigeration SystemDocument36 pagesHVAC and Refrigeration Systemranveer100% (1)

- Fuel Pump CavitationDocument3 pagesFuel Pump Cavitationstergios meletisNo ratings yet

- The Bataan Nuclear Power PlantDocument7 pagesThe Bataan Nuclear Power PlantJustin Cebrian100% (1)

- H2B2!21!013-MW Scale TechEconProp.0Document57 pagesH2B2!21!013-MW Scale TechEconProp.0ReenNo ratings yet

- E82 DataSheet EnglishDocument2 pagesE82 DataSheet EnglishIvan MedranoNo ratings yet

- PART 1 Solved Problems Cooling TowerDocument11 pagesPART 1 Solved Problems Cooling TowerPETER PENNo ratings yet

- Safety Valve StandardsDocument2 pagesSafety Valve StandardsA.YOGAGURUNo ratings yet

- Compressed Air Generation Using Speed BreakerDocument36 pagesCompressed Air Generation Using Speed BreakerRaja ManeNo ratings yet

- F - 155 - Esempio Di Calcolo IdraulicoDocument5 pagesF - 155 - Esempio Di Calcolo Idraulicokikohassan123No ratings yet

- A320 - 49 Apu - GFC-1Document20 pagesA320 - 49 Apu - GFC-1belinda koyaiyeNo ratings yet

- Refrigeration NotesDocument9 pagesRefrigeration NotesMechanical EngineeringNo ratings yet

- Daily Air Compressor ChecklistDocument4 pagesDaily Air Compressor ChecklistSuraj S DixitNo ratings yet

- Oxygen Generation SystemDocument3 pagesOxygen Generation SystemMandeep SthaNo ratings yet