Professional Documents

Culture Documents

Mail Your Order Today! Sale Ends September 30,1986

Uploaded by

michealOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mail Your Order Today! Sale Ends September 30,1986

Uploaded by

michealCopyright:

Available Formats

THREE-YEAR WARRANTY ON

ALL EMPEROR MOVEMENTS

INGS EMPEROR MOVEMENTS AND DIAL FOR

NEWPORT MODEL 120-K

MADE OF SOLID BRASS•ONE-WEEK•WEIGHT-DRIVEN•WESTMINSTER CHIMES

SELF-ADJL STING MOVEMENTS MAKE BEALITIFULLY CRAFTED

CLOCK-LEVELING UNNECESSARY SOLID BRASS DIAL FACES

Emperor Model 101-M movements are Emperor Model 101-M dial faces are

manufactured by Hermle Black Forest Clock manufactured in West Germany by Johann

Company, owned and operated by the family Jackie, the world's largest dial-making firm

of Franz Hermle, Gosheim, West Germany. specializing in brass. Each dial is a quality

The Hermle family is the world's largest man product and is made exclusively of solid

ufacturer of fine quality grandfather clock brass. Emperor does not sell steel or alumi

movements, and each Model 101-M move num dial faces coated to look like brass.

ment is a precision quality timepiece, Choose from two dial versions: Tempus

renowned for accuracy and dependability. Fugit(Time Flies) and Moving Moon with

The Model 101-M movement features a self- classic lunar calendar. The solid brass dial

regulating escapement, which means the ring has a silver finish with solid brass raised a. 101-M Movement with Tempus Fugit

movement adjusts itself to tick smoothly and Arabic numerals. Antique spandrels frame the Dial $169.50

accurately so you never have to level your dial ring, and the center inlay is texture- b. 101-M Movement with Moving Moon

clock. Dial $184.50

finished brass.

Each movement is made of solid brass QUALITY TESTED AND INSPECTED MOVEMENTS CARRY A

with pinions of hardened steel and comes All Emperor movements are thoroughly 3-YEAR WARRANTY

complete with weights, solid brass weight inspected and tested before being shipped to

shells, brass-finished bob, pendulum and you. We proudly stand behind our name LYRE

chimes. 100%. Emperor movements are known and PENDULUM

The chimes con valued everywhere for lasting accuracy and With Solid

The cost ofoak is rising,

sist of two sets dependability. Don't risk buying anything less. Brass Rods

so buy now before it

goes higher! of musically $^00 EXTRA

tuned rods. One INSTALLATION AND Rased Arabic

set sounds the historic Westminster chimes: ADJUSTMENT ARE Nym^rals

four notes on the quarter-hour, eight on the SIMPLE.FOLLOWING EXTRA

half-hour, twelve on the three-quarter-hour STEP-BY-STEP FREE With Purchase of

and sixteen on the hour. The other set counts Clock Kit and Movement

INSTRUCTIONS SUPPLIED.

each hour with a Big Ben tone.

MAIL YOUR ORDER TODAY!SALE ENDS SEPTEMBER 30,1986

ORDER DIRECT WITH THIS FORM•ORDERS SHIPPED 2 TO 3 WEEKS•SHIPPING CHARGES COLLECT

EMPEROR CLOCK COMPANY, Dept.133 CREDIT CARD TELEPHONE ORDERS WELCOME Please Check: New Customer □

Emperor Industrial Park, Fairhope, Alabama 36532 CALL 1-205-928-2316 Previous Customer □

PRODUCT REG.

QTY. NUMBER DESCRIPTION WT. PRICE SALE EXTENSION

DO-IT-YOURSELF CASE KIT:

# 103 Newport Model 120-K. Solid 3/4" Oak Do-lt-Yourself Case Kit

(Movement Priced Separately Below) 55 $239.50 $139.50

# 103 Same As Above, Without Purchase of Movement 55 $239.50 $159.50

YOUR CHOICE OF MOVEMENTS TO COMPLETE KIT:

# 202 Model 101-M Self-Adjusting Movement Complete with Westminster Chimes,

Moving Moon Dial, Arabic Numerals for Model 120-K 30 $184.50

# 207 Model 101-M Self-Adjusting Movement Complete with Westminster Chimes,

Tempus Fugit Dial, Arabic Numerals for Model 120-K 30 $169.50

COMPLETELY ASSEMBLED AND FINISHED GRANDFATHER CLOCK:

#40701 Newport Model 120-A in Solid 3/4" Oak with Self-Adjusting Movement,

Westminster Chimes, Moving Moon Dial, Arabic Numerals too $899.50

TOTAL $_

Enclosed $_ _□ Check

Alabama residents, add 4% sales tax;

OA, GA, NO, TN. Wl residents,

Charge to my; □ MasterCard □ VISA add applicable sales tax $_

□ Diners Club □ American Express

Card No -Expires. GRAND TOTALS.

PLEASE SEND FREE COLOR BROCHURE TO: Please ship this order; □ UPS □ Parcel Post □ Motor Freight

Emperor reserves the right to select method of shipment, if necessary.

ItAWE . NAME .

STREET. STREET .

STATE. ZIP. CITY, STATE, ZIP.

TELEPHONE NUMBER. TELEPHONE NUMBER.

(PLEASE PRINT) (PLEASE PRINT)

VISIT OUR FACTORY SHOWROOMS MONDAY-SATURDAY, EMPEROR INDUSTRIAL PARK, FAIRHOPE, ALABAMA

ALSO IN ORLANDO, FLORIDA, CHATTANOOGA, TENNESSEE, AND ASHEVILLE, NORTH CAROUNA

K

l4^rdrobe wail system

doubles storage space

Walter C. Crocco

When our 56 year old home, was built, ends of solid stock joined by a front were cut from 5/4 stock (1-1/4 in., usually

people had fewer clothes than we have framing. The edges of the top and bot netting out at 1-1/8 in. thick). A 1/4 x 3/8

today, so the bedroom closet simply is tom frames are profiled, or molding is in. rabbet is cut on the back edges of

not adequate. To create sufficient storage attached. No back was used on the orig each front, then the face of each front is

space we designed and built a wardrobe inal base cabinet, but a sheet of plywood profiled as shown. This creates drawer

wall system that is twice the size of the could be used, fitted in rabbets cut on the fronts with a bold projection of about 7/8

existing closet. Additionally, it can be inner edges of the top frame, bottom and in. Considering the 6 ft. length of the

disassembled and moved to another loca ends. The center frame would have to be cabinet, drawers of lighter material sim

tion if that ever is necessary. shortened front to back by the thickness ply would not look suitably massive.

The three upper cabinets can be sep of the plywood used for the back. Make the slides, as detailed, and mount

arated from each other, and removed Two vertical supports at the back of the one to the bottom of each drawer.

from the base. The free standing base cabinet fit between the top and bottom Drawer guides are made for each of

then also can be transported. Once in a web frames, and in notches in the center the six openings, and fastened fairly

new location, the upper cabinets are frame. While sheets of 3/4 in. plywood tightly at the center of the front of each

placed on the base cabinet, then joined could be used in place of the web frames, opening with one countersunk flathead

together with the molding strips across with molding on the ends and fronts of screw. Each drawer is slipped into its

the upper edges. the top and bottom pieces, the additional opening all the way,then carefully pulled

Start construction by building the base weight could cause problems if the cab back out a couple of inches. This action

cabinet which, like almost all cabinets, inet is ever moved to another location. will locate the position of the back end

basically is a box. In this case the box Drawers are fairly standard construc of the guide. Drive a screw through the

consists of three web frames, and two tion, as shown in the drawing. The fronts back end of each guide into the frame.

2 WORKBENCH, July-August 1986 Continued on page 6

You might also like

- Model Railroad January 2017Document92 pagesModel Railroad January 2017marcos100% (3)

- VastuDocument19 pagesVastuutsav khatri100% (1)

- StewMac Catalog 145Document104 pagesStewMac Catalog 145Feli AlfonsoNo ratings yet

- Pickup Guide PDFDocument2 pagesPickup Guide PDFSemmi HemmiNo ratings yet

- National Geographic History 2018 November (Sistine Splendor)Document100 pagesNational Geographic History 2018 November (Sistine Splendor)ポール ジラサック100% (1)

- Instant Download Ebook PDF Entrepreneurship The Practice and Mindset by Heidi M Neck PDF ScribdDocument41 pagesInstant Download Ebook PDF Entrepreneurship The Practice and Mindset by Heidi M Neck PDF Scribdjohn.brandt885100% (47)

- Prosthetic Aspects of Dental Implants - IIDocument73 pagesProsthetic Aspects of Dental Implants - IIKomal TalrejaNo ratings yet

- VW Aircraft Engine Building - Bob HooverDocument133 pagesVW Aircraft Engine Building - Bob Hooverjwzumwalt100% (4)

- Lone Star Shopper: Grocery Auction 903-896-2000Document12 pagesLone Star Shopper: Grocery Auction 903-896-2000CoolerAdsNo ratings yet

- National Geographic History - July 2019Document102 pagesNational Geographic History - July 2019AbdraieNo ratings yet

- A Mobile Horr : - Ori R Patio: How You Can Tvvo Projects You Beautify Can Create For YourDocument2 pagesA Mobile Horr : - Ori R Patio: How You Can Tvvo Projects You Beautify Can Create For YourmichealNo ratings yet

- Be06d85d 1Document32 pagesBe06d85d 1Michell Vasconcelos SiqueiraNo ratings yet

- Desert Magazine 1970 SeptemberDocument52 pagesDesert Magazine 1970 Septemberdm1937No ratings yet

- National Geographic HistoryDocument100 pagesNational Geographic Historykapshere7100% (2)

- FRN Book Poultry PDFDocument206 pagesFRN Book Poultry PDFErgatisGisNo ratings yet

- Website Details1Document2 pagesWebsite Details1priyankasuryaneniNo ratings yet

- Frequency NSWDocument2 pagesFrequency NSWPig SeventyfiveNo ratings yet

- Vastu ShastraDocument37 pagesVastu ShastraAr Amit MehtaNo ratings yet

- Vastu ShastraDocument37 pagesVastu ShastraAr Amit MehtaNo ratings yet

- Workshop ManualDocument272 pagesWorkshop Manualpiedrahec100% (1)

- A/C Check-Up: RatingDocument32 pagesA/C Check-Up: RatingCoolerAdsNo ratings yet

- LSS09072010 PG 1Document1 pageLSS09072010 PG 1lonestarshopperNo ratings yet

- They Thought I Was Crazy To Ship Live Lobsters - PDF AdDocument1 pageThey Thought I Was Crazy To Ship Live Lobsters - PDF Adpostbox90No ratings yet

- Monogramas 1912 PDFDocument70 pagesMonogramas 1912 PDFNuestra Manera100% (1)

- National Geographic History - September 2020Document102 pagesNational Geographic History - September 2020Love SharmaNo ratings yet

- Lone Star Shopper: Tunnell Real Estate - 149 West Main - Van 75790Document12 pagesLone Star Shopper: Tunnell Real Estate - 149 West Main - Van 75790CoolerAdsNo ratings yet

- 2005 - Discovery 3, Ranger 4, Pageant 5, Senator 5Document16 pages2005 - Discovery 3, Ranger 4, Pageant 5, Senator 5AlfonsoNo ratings yet

- Superior Tone, Balanced Action, and Extreme Portability. - Cascio PDFDocument16 pagesSuperior Tone, Balanced Action, and Extreme Portability. - Cascio PDFAlfredo Olias AragónNo ratings yet

- Programme From 1947 - The Gypsy Rover, An Operetta in Three ActsDocument23 pagesProgramme From 1947 - The Gypsy Rover, An Operetta in Three ActsART'S PLACE100% (1)

- PlextortionDocument2 pagesPlextortionRod LissNo ratings yet

- Wilsons Guide To Avalon and CatalinaDocument30 pagesWilsons Guide To Avalon and CatalinaVoid o'ClockNo ratings yet

- 13 - ShiphandlingDocument54 pages13 - Shiphandlinglu_kiteNo ratings yet

- Perfection, Stoves, Ranges and Furnaces Catalog by The James Smart MFG Co.Document164 pagesPerfection, Stoves, Ranges and Furnaces Catalog by The James Smart MFG Co.Wolf100% (1)

- VastuDocument37 pagesVastushrutichauhan664No ratings yet

- Nut - FlangeDocument26 pagesNut - FlangeBrianNo ratings yet

- Fast, Same Day Shipping:: TOLL-FREE FAX: 800-535-8414 - DALLAS PHONE: 214-421-5171Document132 pagesFast, Same Day Shipping:: TOLL-FREE FAX: 800-535-8414 - DALLAS PHONE: 214-421-5171Anonymous UcmNTu6rNo ratings yet

- Palloys My Dream Ring CatalogueDocument152 pagesPalloys My Dream Ring CatalogueSrimurugan ViswakarmaNo ratings yet

- Turkish Shotguns Pt.2Document3 pagesTurkish Shotguns Pt.2Patrick100% (1)

- Granite Bay View - May 2011Document48 pagesGranite Bay View - May 2011GCMediaNo ratings yet

- The Super Shopper 0210Document20 pagesThe Super Shopper 0210WolfRiverMediaNo ratings yet

- Full Catalog (11.9mb)Document165 pagesFull Catalog (11.9mb)Blaster Web ServicesNo ratings yet

- Boston Theatre Bab 00 Un SeDocument28 pagesBoston Theatre Bab 00 Un SesetblygkwmxvmiuqtbNo ratings yet

- Series 3: MovementDocument1 pageSeries 3: MovementAPR7No ratings yet

- Series 4: MovementDocument1 pageSeries 4: MovementAPR7No ratings yet

- 2018-05-17 Re1 (Old Format) TheDock Food Menu-ETC PageDocument24 pages2018-05-17 Re1 (Old Format) TheDock Food Menu-ETC PageThammachart SeafoodNo ratings yet

- CLA Cattle Market Report August 08, 2012Document1 pageCLA Cattle Market Report August 08, 2012Clovis Livestock AuctionNo ratings yet

- Lone Star Shopper: Grocery Auction 903-896-2000Document12 pagesLone Star Shopper: Grocery Auction 903-896-2000CoolerAdsNo ratings yet

- PlazasenayanmenuDocument10 pagesPlazasenayanmenuArs SyfaNo ratings yet

- Tata Pravesh Doors PDFDocument10 pagesTata Pravesh Doors PDFanadinathNo ratings yet

- Quays: Healy Power Quarries LTDDocument38 pagesQuays: Healy Power Quarries LTDmwmccarthyNo ratings yet

- Vietnam - October 2016 PDFDocument68 pagesVietnam - October 2016 PDFXeanoai100% (1)

- Breedlove Catalog PDFDocument22 pagesBreedlove Catalog PDFwisniewski.maciekNo ratings yet

- Lone Star Shopper: Discount Grocery 903-896-2000Document12 pagesLone Star Shopper: Discount Grocery 903-896-2000CoolerAdsNo ratings yet

- Archaeology - February 2024 USADocument72 pagesArchaeology - February 2024 USAOscar Valladares100% (1)

- ThrillingWesternV08n011936 01 IfcibcDocument130 pagesThrillingWesternV08n011936 01 Ifcibcchucks001No ratings yet

- Lonestarshopperaug 82410 PG 2 ADocument1 pageLonestarshopperaug 82410 PG 2 AlonestarshopperNo ratings yet

- Lone Star Shopper: Johnnie StoneDocument8 pagesLone Star Shopper: Johnnie StoneCoolerAdsNo ratings yet

- Lone Star Shopper: Johnnie StoneDocument8 pagesLone Star Shopper: Johnnie StoneCoolerAdsNo ratings yet

- Samples Split Feb 23Document11 pagesSamples Split Feb 23joasevNo ratings yet

- K18 50 60 80 BrochureDocument6 pagesK18 50 60 80 BrochureIan ChoongNo ratings yet

- American Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883From EverandAmerican Antique Weather Vanes: The Complete Illustrated Westervelt Catalog of 1883Rating: 3 out of 5 stars3/5 (1)

- 10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgeDocument8 pages10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgemichealNo ratings yet

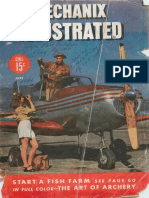

- MechanixDocument2 pagesMechanixmichealNo ratings yet

- 10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgeDocument8 pages10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgemichealNo ratings yet

- 10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgeDocument8 pages10 New Ways To Make Your Fortune .4: THE Terrible Teredo-Underseas ScourgemichealNo ratings yet

- ATM BrochuresDocument5 pagesATM Brochuresगुंजन सिन्हाNo ratings yet

- Dua e Mujeer Arabic English Transliteration PDFDocument280 pagesDua e Mujeer Arabic English Transliteration PDFAli Araib100% (2)

- Moonage Daydream From Ziggy StardustDocument18 pagesMoonage Daydream From Ziggy StardustTin SmajlagićNo ratings yet

- MAraguinot V Viva Films DigestDocument2 pagesMAraguinot V Viva Films DigestcattaczNo ratings yet

- TRIAD: A Sustainable Approach To ForestryDocument25 pagesTRIAD: A Sustainable Approach To ForestryInstitut EDSNo ratings yet

- Precontraint 502S2 & 702S2Document1 pagePrecontraint 502S2 & 702S2Muhammad Najam AbbasNo ratings yet

- Modern America Study Guide With Answers 2020 21Document2 pagesModern America Study Guide With Answers 2020 21maria smithNo ratings yet

- May 11-Smart LeadersDocument28 pagesMay 11-Smart LeaderstinmaungtheinNo ratings yet

- IAD 2023 Camporee Information Sheet - CARU - UPDATED 08.09.2022Document8 pagesIAD 2023 Camporee Information Sheet - CARU - UPDATED 08.09.2022Evelyn SaranteNo ratings yet

- Peer Pressure and Academic Performance 1Document38 pagesPeer Pressure and Academic Performance 1alnoel oleroNo ratings yet

- Engg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Document24 pagesEngg 135 Design of Reinforced Concrete Structures: Bond and Bar Development Reading: Wight and Macgregor Chapter 8Manuel MirandaNo ratings yet

- Ansr Definitionofex Gay PDFDocument10 pagesAnsr Definitionofex Gay PDFAlexandria Firdaus Al-farisyNo ratings yet

- Max3080 Max3089Document21 pagesMax3080 Max3089Peter BirdNo ratings yet

- Marcos v. CADocument2 pagesMarcos v. CANikki MalferrariNo ratings yet

- Research EssayDocument8 pagesResearch Essayapi-509696875No ratings yet

- Pengaruh Suhu Pengeringan Terhadap Karakteristik Kimia Dan Aktivitas Antioksidan Bubuk Kulit Buah Naga MerahDocument9 pagesPengaruh Suhu Pengeringan Terhadap Karakteristik Kimia Dan Aktivitas Antioksidan Bubuk Kulit Buah Naga MerahDika CodNo ratings yet

- Sourabh ResumeDocument2 pagesSourabh ResumeVijay RajNo ratings yet

- Sir Phillip Manderson SherlockDocument1 pageSir Phillip Manderson SherlockSkyber TeachNo ratings yet

- Week 5 Class 2Document33 pagesWeek 5 Class 2ppNo ratings yet

- Taxation During Commonwealth PeriodDocument18 pagesTaxation During Commonwealth PeriodLEIAN ROSE GAMBOA100% (2)

- Unit f663 Paradise Lost Book 9 John Milton Introduction and Guided ReadingDocument17 pagesUnit f663 Paradise Lost Book 9 John Milton Introduction and Guided ReadingChristopher Pickett100% (1)

- Econ 281 Chapter02Document86 pagesEcon 281 Chapter02Elon MuskNo ratings yet

- Unit 1 Revision PDFDocument2 pagesUnit 1 Revision PDFИлья ЕвстюнинNo ratings yet

- HeLa B Cell LineDocument3 pagesHeLa B Cell LineAhnaph RafinNo ratings yet

- Temario de Oposiciones De: InglésDocument25 pagesTemario de Oposiciones De: Inglésvanesa_duque_3100% (1)

- The Book of Mark: BY Dr. R. Muzira Skype: Pastorrobertmuzira Cell: 0782 833 009Document18 pagesThe Book of Mark: BY Dr. R. Muzira Skype: Pastorrobertmuzira Cell: 0782 833 009Justice MachiwanaNo ratings yet

- Barber ResumeDocument6 pagesBarber Resumefrebulnfg100% (1)