Professional Documents

Culture Documents

System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HR

Uploaded by

Lea Rebeca Tuesta Gonzales ZuñigaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HR

Uploaded by

Lea Rebeca Tuesta Gonzales ZuñigaCopyright:

Available Formats

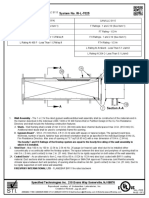

System No.

W-L-2458

September 22, 2005

F Ratings — 1 and 2 Hr (See Item 1)

T Rating — 0 Hr

1. Wall Assembly — The 1 or 2 hr fire-rated gypsum wallboard/stud wall assembly shall be constructed of the materials

and in the manner specified in the individual U300, U400 or V400 Series Wall and Partition Designs in the UL Fire

Resistance Directory and shall include the following construction features:

A. Studs — Wall framing may consist of either wood studs or steel channel studs. Wood studs

to consist of nom 2 by 4 in. (51 by 102 mm) lumber spaced 16 in. OC (406 mm). Steel studs to

be min 2-1/2 in. (64 mm) wide and spaced max 24 in. OC (610 mm).

B. Gypsum Board* — The gypsum board type, thickness, number of layers and orientation

shall be, as specified in the individual Wall and Partition Design. Max diam of opening is 3 in.

(76 mm).

The hourly F Ratings of the firestop system are equal to the hourly fire rating of the wall

assembly.

2. Nonmetallic Pipe — One nom 2 in. (51 mm) diam (or smaller) SDR 13.5 Chlorinated Polyvinyl Chloride (CPVC) pipe to

be installed concentrically or eccentrically within the firestop system. The annular space shall be min 0 (point contact) to

max 5/8 in. (16 mm). Pipe to be rigidly supported on both sides of wall assembly.

3. Firestop System — The firestop system shall consist of the following:

A. Packing Material — (Optional)— For 2 hr wall assemblies, foam backer rod firmly packed

into opening as a permanent form. Packing material to be recessed from each surface of the

wall to accommodate the required thickness of fill material.

B. Fill Void or Cavity Materials* - Caulk — Min 5/8 in. (16 mm) thickness of fill material

applied within the annulus on both surfaces of the wall assembly. A min 1/2 in. (13 mm) diam

bead of caulk shall be applied to the pipe/gypsum board interface at the point contact location

on both sides of wall.

RECTORSEAL — Metacaulk 350i

*Bearing the UL Classification Mark

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- System No. W-L-2199Document2 pagesSystem No. W-L-2199DatNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- System No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDocument2 pagesSystem No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDatNo ratings yet

- Firestopping System Applications AND Standard Application - Ul ListedDocument5 pagesFirestopping System Applications AND Standard Application - Ul ListedAry TubagusNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- M2 - Manual PDFDocument0 pagesM2 - Manual PDFFlorinHanu100% (1)

- HW D 0187Document2 pagesHW D 0187Luiggi Zuñiga BarahonaNo ratings yet

- w-j-2094 - PVC CPVC, ABS 2 Hr.Document2 pagesw-j-2094 - PVC CPVC, ABS 2 Hr.DatNo ratings yet

- System No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-2346: F Rating - 3 HR T Rating - 0 HRArulNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- Bandeja - Concreto - W-J-4031Document2 pagesBandeja - Concreto - W-J-4031cesar walter salazar garciaNo ratings yet

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- Ks1150 TC 100 Ipn Fire Resistance Classification ProtocolDocument8 pagesKs1150 TC 100 Ipn Fire Resistance Classification ProtocolBinh HuynhNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- C Aj 2294Document2 pagesC Aj 2294vhin84No ratings yet

- Fire Resistance Bulletin: Fire Resistance Ratings For Exterior Walls U. L. Tested and Classified For 1 and 2 HoursDocument4 pagesFire Resistance Bulletin: Fire Resistance Ratings For Exterior Walls U. L. Tested and Classified For 1 and 2 HoursbzakriaNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- BXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqDocument4 pagesBXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqEmanuel Ciprian CiucurNo ratings yet

- W L 1054Document2 pagesW L 1054shama093No ratings yet

- CEJ114PDocument2 pagesCEJ114PGauri Calderon TrujilloNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2320Document1 pageSystem PDF Files - 1. UL and cUL Systems - fc2320Emanuel PastlNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Cellecta Sound Proofing Solutions GuideDocument24 pagesCellecta Sound Proofing Solutions Guidejamiecellecta2012No ratings yet

- Rockwool Fire Barrier SystemsDocument8 pagesRockwool Fire Barrier Systemsaag0475No ratings yet

- Revised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsDocument6 pagesRevised Minimum Performance Standards/ Specifications (By Technical Committee) I. Governing Codes and SpecificationsBendaña KHayeNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- DEPED Revised Minimum Performance StandardsDocument6 pagesDEPED Revised Minimum Performance StandardsrubydelacruzNo ratings yet

- Attachment #6 1 - Schedule of Quantities FDC 22.09.21Document119 pagesAttachment #6 1 - Schedule of Quantities FDC 22.09.21El Charasquiada CharroNo ratings yet

- Rockwool Intumescent PillowsDocument3 pagesRockwool Intumescent PillowsBobana AdamovicNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- Tek 07-03a1 PDFDocument4 pagesTek 07-03a1 PDFJustin UyarNo ratings yet

- Suspended Ceilings Construction GuideDocument4 pagesSuspended Ceilings Construction GuideHassan RahilNo ratings yet

- SECTION 15081: Ductwrap - Doc 1Document2 pagesSECTION 15081: Ductwrap - Doc 1geverett2765No ratings yet

- Detailed Specification PE Casing Jacket With Standard UIP System 1) GeneralDocument3 pagesDetailed Specification PE Casing Jacket With Standard UIP System 1) GeneralMina MagdyNo ratings yet

- SoundStop Guidespec BRDocument5 pagesSoundStop Guidespec BRRaj BharaliNo ratings yet

- Proposed Three Bedroom ResidentialDocument5 pagesProposed Three Bedroom ResidentialMel FNo ratings yet

- WL7223Document1 pageWL7223Juvenal GutierrezNo ratings yet

- Ductwork SystemDocument8 pagesDuctwork SystemrkssNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurNo ratings yet

- Gyprock 512 Cinema Wall 201306Document12 pagesGyprock 512 Cinema Wall 201306Jane SweetNo ratings yet

- GRP Enclosures For PAckage SubstationDocument12 pagesGRP Enclosures For PAckage SubstationjoseNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemNo ratings yet

- MP HALL - Speci-DDocument3 pagesMP HALL - Speci-DAbdul RahumanNo ratings yet

- Fire Barrier & Cavity Systems Stop Fires!: KillerDocument4 pagesFire Barrier & Cavity Systems Stop Fires!: KillerMedhat ElhagrasiNo ratings yet