Professional Documents

Culture Documents

Fire Resistance Ratings for Metal Building Exterior Walls

Uploaded by

bzakriaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire Resistance Ratings for Metal Building Exterior Walls

Uploaded by

bzakriaCopyright:

Available Formats

Fire Resistance

Bulletin 2

Fire Resistance Ratings for Exterior Walls

U. L. Tested and Classified For 1 and 2 Hours

Insurance Bulletin No. 5 explains how insurance The same requirement is in the Standard Building

rates for metal buildings are affected by exterior Code published by the Southern Building Code

wall construction. Fire Resistive Bulletin #1 (for- Congress International, Inc. (Table 600, note i).

merly listed as Insurance Bulletin #6) explains U.L. Design No. U425 details the wall construction

how insurance rates can be improved by using U.L. and gypsum wallboard protection. U.L. Design

tested and classified 1, 1 ½ and 2-hour fire protect- U425 is also included in this bulletin.

ed columns.

As with the fire rated columns, MBMA considers

Through meetings and discussions with Insurance this a breakthrough in fire protection research of

Services Office headquarters and through field great importance to the designers and users of eco-

experience it was determined that although the pro- nomical light steel frame buildings.

tected columns were providing an improved insur-

ance rate, they were still not producing rates that Design No. U489

would be directly competitive with buildings with Bearing Wall Rating - 1, 1 ½ and 2 Hr.

concrete block exterior walls. Therefore, the

MBMA Committee on Fire Protection and Related

Insurance Matters undertook an engineering analy-

sis and testing program to establish fire resistant

rated exterior walls.

These walls are listed by Underwriters

Laboratories, Inc. in the 1996 Fire Resistance

Directory as U.L. Design No. U489.

In addition to improving fire insurance rates, fire

resistant exterior rated walls are helpful in meeting

building code requirements, including lot line sep-

aration and set-back requirements. The BOCA

National Building Code published by the Building

Officials and Code Administrators International,

Inc. require that exterior walls having a 5 foot or

less fire separation to the closest interior lot line, to

the centerline of a street or public way or to an

imaginary line between two buildings on the same

property, be rated for exposure to fire from both

sides. Where the fire separation distance is greater

than 5 feet, the exterior wall needs only be rated

from the inside (Section 705.2). Continued on next page

Note: This bulletin was previously released as Insurance Bulletin #16

Metal Building Manufacturers Association

MBMA.com

Fire Resistance

Bulletin 2

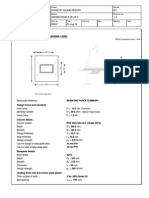

1. Column Protection - See Design Nos. X524 Design No. U425

and X530 for column protection. (For Exterior Walls, Ratings Applicable For

Exposure To Fire On Interior Face Only)

2. Girts - "Z" or "C" shape girts fabricated from (See Items 4 and 5)

0.056 to 0.120 in. thick steel. Girts shall be 6 to Bearing Wall Rating - 45 Min., 1, 1 ½ or 2 HR.

10 in. deep with 2 ½ to 3 in. flanges.

3. Girt Clips - Fabricated from min. 0.115 in.

thick steel, angles may be bolted to columns

with ½ by 1 ½ in. bolts and nuts or may be

plates shop-welded to columns.

4. Steel Wall Panels - No. 26 MSG min. coated

steel.

5. Wall Construction - See Design No. U425 for

details.

a. Top of the wall shall be against the underside

of roof deck.

b. All openings between top of wall and roof

deck are to be filled with UL Classified miner-

al wool or glass fiber insulation.

c. Steel studs in accordance with the specifica-

tions in Design No. U425.

HORIZONTAL SECTION

6. Subgirts - Min. 0.020 in. (25 gauge) thick gal-

vanized steel, 1 5/16 in. wide on top and 1. Steel Floor and Ceiling Tracks (Not Shown)

2 ¾ in. wide at bottom by 7/8 in. deep (hat sec- - Top and bottom tracks of wall assemblies

tion), spaced 48 in. O.C. max. shall consist of steel members, min. No. 20

GSG (0.036 in. thick) galvanized steel or No.

20 MSG (0.033 in. thick) primed steel, that

*Bearing the UL Classification Marking provide a sound structural connection between

steel studs, and to adjacent assemblies such as

a floor, ceiling, and/or other walls. Attached to

floor and ceiling assemblies with steel fasten-

ers spaced not greater than 24 in. O.C.

Continued on next page

Metal Building Manufacturers Association

MBMA.com

Fire Resistance

Bulletin 2

2. Steel Studs - Corrosion-protected steel studs, both sides of studs or by welded or bolted con-

min. 3 ½ in. wide, min. No. 20 GSG (0.036 in. nections designed in accordance with the AISI

thick) galvanized steel or No. 20 MSG (0.033 specifications.

in. thick) primed steel, cold-formed, shall be

designed in accordance with the current edition Lateral Support Members (Not shown) -

of the Specification for the Design of Cold- Where required for lateral support of studs,

Formed Steel Structural Members by the support may be provided by means of steel

American Iron and Steel Institute. All design straps, channels or other similar means as spec-

details enhancing the structural integrity of the ified in the design of a particular steel stud wall

wall assembly, including the axial design load system.

of the studs, shall be as specified by the steel

stud designer and/or producer, and shall meet Wallboard, Gypsum* - Gypsum wallboard

the requirements of all applicable local code bearing the UL Classification Marking as to

agencies. The max. stud spacing of wall assem- Fire Resistance. Applied vertically with joints

blies shall not exceed 24 in. O.C. (or 16 in. between layers staggered. Outer layer of 3

O.C. - See Item 5c). Studs attached to floor and layer construction may be applied horizontally.

ceiling tracks with ½ in. long Type S-12 pan The thickness and number of layers and per-

head, self-drilling, self-tapping steel screws on cent of design load for the 45 min., 1 hr., 1 ½

hr and 2 hr ratings are as follows:

Interior Walls (Wallboard Protection Both Sides of Wall)

Number of Layers and

Rating Thickness of Boards in Each Layer Percent of Design Load

45 min. * 1 layer, ½ in. thick 100

1 hour * 1 layer, 5/8 in. thick 100

1 ½ hr. * 2 layers, ½ in. thick 100

2 hours * 2 layers, 5/8 in. thick 80

* 3 layers, ½ in. thick or 100

* 2 layers, ¾ in. thick 100

*Ratings applicable to assemblies serving as exterior walls where Classified fire resistive gypsum sheathing type

wallboard is substituted on the exterior face.

Exterior Walls (Wallboard Protection On Interior Side of Wall)

Number of Layers and

Rating Thickness of Boards in Each Layer Percent of Design Load

45 min. * 1 layer, 5/8 in. thick 100

1 hour * 2 layers, 1/2 in. thick 100

1 ½ hr. * 2 layers, 5/8 in. thick 100

2 hours * 3 layers, 1/2 in. thick or 100

* 2 layers, 3/4 in. thick 100

*Bearing the UL Classification Marking Continued on next page

Metal Building Manufacturers Association

MBMA.com

Fire Resistance

Bulletin 2

See Wallboard Gypsum (CKNX) Category for C. Cementitious Backer Units* - ½ or 5/8 in.

names of Classified Companies of ½ in. or 5/8 in thick, square edge boards, attached to steel

thick wallboard. See below for Classified company studs over gypsum sheathing with 1 5/8 in.

of ¾ in. thick wallboard long, Type S-12, corrosion resistant, self-tap-

ping wafer head steel screws, spaced 8 in. O.C.

United States Gypsum Co. – Studs spaced a max. of 16 in. O.C. Joints cov-

ULTRACODE or Type IP-X3 ered with glass fiber mesh tape.

4. Wallboard, Gypsum* (As an alternate to sid- United States Gypsum Co. -

ing, steel siding, brick veneer, or 5/8 in. thick Durock Exterior Cement Board or

wallboards in Item 4) - Nom. ¾ in. thick. Durock Cement Board

TEC Inc. - Type TEC

United States Gypsum Co. - Type AR

United States Gypsum Co. - Type WSX 6. Fasteners (Not Shown) - Screws used to

attached wallboard to studs: self-tapping bugle

5. Gypsum Sheathing - For exterior walls, X or head sheet steel type, spaced 12 in. O.C. First

5k in. thick exterior regular gypsum sheathing layer Type S- 12 by 1 in. long for ½ and 5/8 in.

applied vertically and attached to studs and thick wallboard and 1 ¼ in. long for ¾ in. thick

runner tracks with 1 in. long type S-12 bugle wallboard. Second layer Type S-12 by 1 5/8 in.

head screws spaced 12 in. O.C. along studs long for ½ in. and 5/8 in. thick wallboards and

and tracks. One of the following exterior fac- 2 ¼ in. long for ¾ in. thick wallboard. Third

ings are to be applied over the gypsum sheath- layer Type S-12 by 1 7/8 in. long.

ing.

7. Batts and Blankets* - Placed in stud cavities

A. Siding, Brick, or Stucco – Aluminum sid-

of all exterior walls. May or may not be used in

ing, steel siding, brick veneer, or stucco

interior walls. Any glass fiber or mineral wool

attached to studs over gypsum sheathing and

batt material bearing the UL Classification

meeting the requirements of local code agen-

Marking as to Fire Resistance, of a thickness to

cies. When a min. 3 ¾ in. thick brick veneer

completely fill stud cavity. See Batts and

facing is used, the Exterior Wall Rating is

Blankets (BZJZ) Category for names of

applicable with exposure on either face. Brick

Classified Companies.

veneer wall attached to studs with corrugated

metal wall ties attached to each stud with steel

8. Joint Tape and Compound (Not Shown) -

screws, not more than each sixth course of

Vinyl or casein, dry or premixed joint com-

brick.

pound applied in two coats to joints and screw-

B. Mineral and Fiber Boards* - Exterior heads of out layer. Perforated paper tape, 2 in.

hardboard paneling, chemically treated over wide, embedded in first layer of compound

gypsum sheathing with primed or finished over all joints of outer layer.

face, 7/16 in. thick by 48 in. wide. Attached to

studs over gypsum sheathing with 1 7/8 in. *Bearing the UL Classification Marking

long bugle head TEK fasteners 16 in. O.C. at

the intermediate supports. Or, exterior lap sid-

Additional Information:

ing, chemically treated, 7/16 in. thick by 8 in.

Metal Building Manufacturers Association, Inc.

or 12 in. wide. Attached to studs with 1 7/8 in.

1300 Sumner Avenue • Cleveland, Ohio 44115-2851

long, bugle head Type TEK fasteners at each

216-241-7333 • 216-241-0105 (fax)

lap. Panels lapped minimum 1 in.

Email: mbma@mbma.com

Masonite Corp. - Type FT Website: www.mbma.com

Metal Building Manufacturers Association

MBMA.com

You might also like

- AWC DCA5 PostFrameBuildings 1012 PDFDocument5 pagesAWC DCA5 PostFrameBuildings 1012 PDFDylan BoltonNo ratings yet

- CSA S16 09 Example 001Document7 pagesCSA S16 09 Example 001thanzawtun1981No ratings yet

- Foam Concrete: A Lightweight Building MaterialDocument36 pagesFoam Concrete: A Lightweight Building MaterialamitNo ratings yet

- Quotation For Industrial BuildingDocument3 pagesQuotation For Industrial BuildingSingh Gurpreet0% (2)

- Tray and Ladder Practice GuideDocument73 pagesTray and Ladder Practice GuidemariusrotaruNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Peb Technical SpecificationDocument4 pagesPeb Technical Specificationalankar ambwadeNo ratings yet

- Technical Specification Main WarehouseDocument4 pagesTechnical Specification Main Warehouseadr_kharisma100% (2)

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- CFSEI Shear Wall Design GuideDocument23 pagesCFSEI Shear Wall Design GuideJaypee Chang100% (1)

- Seminar On Pre-Engineered Metal Buildings BY Kavitha Maharaj M.Tech. (P.T.P.G) 5 SemesterDocument38 pagesSeminar On Pre-Engineered Metal Buildings BY Kavitha Maharaj M.Tech. (P.T.P.G) 5 SemestermaheshbandhamNo ratings yet

- Fire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard ProtectionDocument8 pagesFire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard Protectionjbatista_njg4152No ratings yet

- Lintel DesignDocument7 pagesLintel DesignDan AielloNo ratings yet

- WBSDocument7 pagesWBSmonisaniNo ratings yet

- NF P 18 710 UhpcDocument136 pagesNF P 18 710 UhpcKashif Naukhez100% (2)

- U.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTDocument15 pagesU.S. ARMY CORPS OF ENGINEERS DESIGN CHECKLISTSankar CdmNo ratings yet

- AASHTO - LRFD - Construction Specs-2nd Edition-2 PDFDocument664 pagesAASHTO - LRFD - Construction Specs-2nd Edition-2 PDFSharfaraz Hossain100% (1)

- R.C. Building Design and Analysis FundamentalsDocument33 pagesR.C. Building Design and Analysis FundamentalsAmzarNo ratings yet

- Technical Note Cold-Formed SteelDocument8 pagesTechnical Note Cold-Formed SteelIshwarya SrikanthNo ratings yet

- RCC Cantilever Slab DesignDocument1 pageRCC Cantilever Slab DesigndaxeshNo ratings yet

- Promat PFPH Chapter 3 Structural SteelDocument71 pagesPromat PFPH Chapter 3 Structural SteelRamiAl-fuqahaNo ratings yet

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurNo ratings yet

- Fire resistance of steel columns protected by gypsum wallboardDocument5 pagesFire resistance of steel columns protected by gypsum wallboardPrakash BharatiNo ratings yet

- 1 and 1 Hour Fire Rated MBMA Roof SystemsDocument7 pages1 and 1 Hour Fire Rated MBMA Roof SystemsPrakash BharatiNo ratings yet

- Pages From SpecsDocument30 pagesPages From SpecsEricNo ratings yet

- BXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqDocument4 pagesBXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqEmanuel Ciprian CiucurNo ratings yet

- Technical Note: Introduction To Curtain Wall Design Using Cold-Formed SteelDocument10 pagesTechnical Note: Introduction To Curtain Wall Design Using Cold-Formed SteelalbertoxinaNo ratings yet

- SCI ED012 Light Steel Framed HousingDocument4 pagesSCI ED012 Light Steel Framed HousingTiago CastelaniNo ratings yet

- AISI Section 092600 - Metal Framing For Gypsum Board AssembliesDocument6 pagesAISI Section 092600 - Metal Framing For Gypsum Board AssembliesĐường Nguyễn ThừaNo ratings yet

- ProSTUD UL V477Document8 pagesProSTUD UL V477K PreitoNo ratings yet

- 1 and 2 HR Wall Assemblies PDFDocument9 pages1 and 2 HR Wall Assemblies PDFaNo ratings yet

- 05315Document4 pages05315Adnan ColoNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- Legacy Report: ICC Evaluation Service, IncDocument9 pagesLegacy Report: ICC Evaluation Service, IncArvind AnchliyaNo ratings yet

- Section 09111 Non-Load-Bearing Steel Framing Part 1Document94 pagesSection 09111 Non-Load-Bearing Steel Framing Part 1jacksondcplNo ratings yet

- Park House 1001Document6 pagesPark House 1001IvanBaptistaSegoviaNo ratings yet

- Wall ConstructionDocument22 pagesWall ConstructionJohn Michael CastilloNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemNo ratings yet

- Roof Deck SpecificationsDocument2 pagesRoof Deck SpecificationsVictor IkeNo ratings yet

- Steel Floor Decking InstallationDocument4 pagesSteel Floor Decking InstallationRal GLNo ratings yet

- Modular Homes: Technical InformationDocument18 pagesModular Homes: Technical InformationBrian NiessenNo ratings yet

- FRAME SUPPORTED MEMBRANE STRUCTUREDocument13 pagesFRAME SUPPORTED MEMBRANE STRUCTUREloc nguyenNo ratings yet

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- SCI ED019 Thermal Performance of Light Steel ConstructionDocument4 pagesSCI ED019 Thermal Performance of Light Steel ConstructionTiago CastelaniNo ratings yet

- Civil & Structural Design Report for Springfield AcademyDocument10 pagesCivil & Structural Design Report for Springfield AcademyElilragiGanasanNo ratings yet

- LGS Fire Rating PDFDocument8 pagesLGS Fire Rating PDFNabeel SheikhNo ratings yet

- Section 08630 Metal-Framed SkylightDocument4 pagesSection 08630 Metal-Framed SkylightMØhãmmed ØwięsNo ratings yet

- Fire Containment in Wood Construction Doesn't Just HappenDocument12 pagesFire Containment in Wood Construction Doesn't Just HappenaNo ratings yet

- Steel Reinforcement For WallsDocument7 pagesSteel Reinforcement For WallsSurinderPalSinghGillNo ratings yet

- Cold-Formed Steel Shear Wall DesignDocument8 pagesCold-Formed Steel Shear Wall DesignjmiguelmenaNo ratings yet

- Wall Panel DetailsDocument20 pagesWall Panel Detailsdebbie89_myloves100% (1)

- Government of India Addendum No. 1 for Construction ProjectDocument9 pagesGovernment of India Addendum No. 1 for Construction ProjectAbhay KumarNo ratings yet

- Composite Panel SpecificationDocument6 pagesComposite Panel SpecificationracvilleNo ratings yet

- Roof Specialties for Alamein Downtown TowersDocument6 pagesRoof Specialties for Alamein Downtown TowersWENDING HUNo ratings yet

- Uninterrupted Height of Masonry Cladding To Light Steel FramingDocument4 pagesUninterrupted Height of Masonry Cladding To Light Steel FramingmgmccarthyNo ratings yet

- Clark Dietrich AB ClipDocument8 pagesClark Dietrich AB ClipChanduthewilderNo ratings yet

- SECTION 05 21 00 Steel Joist FramingDocument5 pagesSECTION 05 21 00 Steel Joist FramingJuanPaoloYbañezNo ratings yet

- 05 31 00milDocument7 pages05 31 00milJerico NamucoNo ratings yet

- Good Acoustic Performance: Steel Industry Guidance NotesDocument2 pagesGood Acoustic Performance: Steel Industry Guidance Noteschernl2004No ratings yet

- TN28B Brick Veneer Steel Stud WallsDocument15 pagesTN28B Brick Veneer Steel Stud WallsKen SuNo ratings yet

- AIJ Standard for Structural Design of Reinforced Concrete Box-Shaped Wall StructuresDocument80 pagesAIJ Standard for Structural Design of Reinforced Concrete Box-Shaped Wall StructureshbookNo ratings yet

- Steel Floor Decking 05 31 13Document6 pagesSteel Floor Decking 05 31 13Taher AmmarNo ratings yet

- F 826 - 94 R99 - Rjgyng - PDFDocument5 pagesF 826 - 94 R99 - Rjgyng - PDFRománBarciaVazquezNo ratings yet

- Metal Doors and Frames - MSTDocument14 pagesMetal Doors and Frames - MSTwafikmh4No ratings yet

- Prototype For Earthquake-Resistant Residential Buildings Combining Steel Frames With Local MaterialsDocument10 pagesPrototype For Earthquake-Resistant Residential Buildings Combining Steel Frames With Local MaterialsIZPNo ratings yet

- ACP SpecsDocument8 pagesACP SpecsJana jerodyNo ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- Pre-Engineered Buildings: Technology Park Pilot ProjectDocument8 pagesPre-Engineered Buildings: Technology Park Pilot ProjectPradip Tapan BanerjeeNo ratings yet

- Research Proposal F (X)Document8 pagesResearch Proposal F (X)I-Chie PlacidoNo ratings yet

- Screening Phase Structural ChecklistsDocument119 pagesScreening Phase Structural ChecklistsSameh EidNo ratings yet

- Management of Ageing of Major: Nuclear Power Plant Components Important To Safety: Concrete Containment BuildingsDocument162 pagesManagement of Ageing of Major: Nuclear Power Plant Components Important To Safety: Concrete Containment BuildingsbzakriaNo ratings yet

- Combined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationDocument9 pagesCombined Gradation of Aggregates Project Consultant Contractor Mix Identification No. Sample Deasription Sampling Method Test Method LocationAndrew MwambaNo ratings yet

- "Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionDocument6 pages"Stiffner" - Steel Beam Web Stiffener Analysis: Program DescriptionGustavo PaganiniNo ratings yet

- Design of Hollow Block Slabs: Dr. Hamed HadhoudDocument19 pagesDesign of Hollow Block Slabs: Dr. Hamed HadhoudFady Abdel AzizNo ratings yet

- Balochistan Building Control and Town Planning Rules, 2022Document142 pagesBalochistan Building Control and Town Planning Rules, 2022baloch47No ratings yet

- Rapid Hardening Concrete Research ReportDocument28 pagesRapid Hardening Concrete Research ReportLil jommthiiNo ratings yet

- Yield Line Analysis - 1Document19 pagesYield Line Analysis - 1Ahmed NabilNo ratings yet

- 2021-22 Copo V Sem Cv2302 Advanced Structural Analysis VNMDocument68 pages2021-22 Copo V Sem Cv2302 Advanced Structural Analysis VNMHAsNo ratings yet

- PCA Chapter 15 - Specify, Design, ProportionDocument91 pagesPCA Chapter 15 - Specify, Design, Proportiongreat_triskelionNo ratings yet

- ERRATA - December 2020: Design Guide On The ACI 318 Building Code Requirements For Structural ConcreteDocument8 pagesERRATA - December 2020: Design Guide On The ACI 318 Building Code Requirements For Structural ConcreteBabrak Khan NoorzoiNo ratings yet

- Beam Force Detail Summary: Axial Shear Torsion Bending Beam L/C D FX Fy FZ MX My MZDocument23 pagesBeam Force Detail Summary: Axial Shear Torsion Bending Beam L/C D FX Fy FZ MX My MZsnoariNo ratings yet

- General Construction SpecificationsDocument6 pagesGeneral Construction SpecificationsCOMPASS LanguageAndskillsTrainingNo ratings yet

- FINAL Design - of - RCC Two Way Slab S2Document5 pagesFINAL Design - of - RCC Two Way Slab S2sujit naikwadiNo ratings yet

- Apollo Bill 2Document3 pagesApollo Bill 2NNAWUIHE MARTINSNo ratings yet

- Consultant Expert DR Mohamed Seif Al Den TahaDocument107 pagesConsultant Expert DR Mohamed Seif Al Den Tahaconsultant expert dr mohamed seif al den tahaNo ratings yet

- Vertikal Cement MillDocument8 pagesVertikal Cement MillMohamad Taufik (abang topek)No ratings yet

- Report Example ColumnDocument46 pagesReport Example ColumnvirgoknNo ratings yet

- EN 1993-1-1: 2005 Global Analysis and StabilityDocument9 pagesEN 1993-1-1: 2005 Global Analysis and StabilitySengthai TolaNo ratings yet

- GITC 4th Floor C N D Repairs BOQDocument4 pagesGITC 4th Floor C N D Repairs BOQAbhisheK MishrANo ratings yet

- NZS 3404-1997 Example 002Document5 pagesNZS 3404-1997 Example 002Mohamed Abo-ZaidNo ratings yet

- IPITS S2 Struktur DTS ITSDocument39 pagesIPITS S2 Struktur DTS ITSyou foolNo ratings yet

- Peri Domino 300 PDFDocument36 pagesPeri Domino 300 PDFThanos TsirkosNo ratings yet