Professional Documents

Culture Documents

3D Laser Calibration Technology Safely Calibrates Fuel Tanks in Under 40 Minutes

Uploaded by

Mahmoud GaberOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3D Laser Calibration Technology Safely Calibrates Fuel Tanks in Under 40 Minutes

Uploaded by

Mahmoud GaberCopyright:

Available Formats

Technical Specifications*

• -0,6 mm ±0,1 mm accuracy in distance measurements

• -0,2° ±0,3° accuracy in pan measurements

• -0,6° ±0,1° accuracy in tilt measurements

• -0,1° ±0,1° accuracy in inclination measurements

• ±%0,2-0,5 accuracy in volume calculations

*According to VSL Dutch Metrology Institute and NMi evaluation results

Security and Safety

All system components are designed and certificated according to

international safety regulations.

ZONE 2

ZONE 1

ZONE 0

KE06/0516/R01

CalibeX

3D Laser Calibration Technology

Calibrating fuel tanks with high accuracy, safely in a short period of time

using 3D laser technology.

ASIS Automation and Fueling Systems Inc.

Tatlısu, Akif İnan Sk. No:14 Ümraniye, Istanbul - Turkey

P: +90 216 540 64 64 F: +90 216 540 64 54 info@asis.com.tr www.asis.com.tr www.asis.com.tr First in The World

CalibeX

3D Laser Calibration Technology

3DCalibeX is one of the most comprehensive technological projects developed by

Asis to date. It is a system composed of advanced robot mechanics, mechatronics,

state-of-the-art electronic circuit designs, on-board LEL device design, laser and

optical applications, etc. and applications consisting of 3D modeling algorithms

and data analysis software involving advanced mathematics.

One of the most important features of the system is its capability of completing

the calibration processes within a short time such as 25-40 minutes, owing to the

specially developed laser-measurement technology applied through the 2”

coupling, which is the smallest inlet of fuel tank covers.

The system creates a SPATIAL POINT PATTERN for the tank volume using the 3D

algorithms, ultimately creating the 3 dimensional mathematical model of the

underground fuel tanks. All internal and external dimensions of the underground

tanks, tank volume, length, inclination angle, radius of tank heads, as well as any

other data can be obtained digitally and visually using the modeling data

generated from the spatial point pattern. Then, the calibration table is created

based on the mathematical model.

Basic Features of the System

• Measures the internal dimensions of • It is reliable and all risk factors are

the tanks on a 3D spatial point taken under control (ATEX).

First in The World pattern. • Application and operation of the

• Calculates the inclination of the tank system fully meets the Occupational

(Angular) Health and Safety and Environmental

• Calculates the direction and position criteria (OHSE).

of the tank. • Calibration process does not cause

• Computes the diameter of the tank. downtime.

• Calculates the internal dimensions of • It does not require the tanks to be full.

the tank (Depth and length, etc.). The emptier tank, the higher accuracy

• Calculates the diameters of the tank of the system.

heads. • It generates highly accurate and

• Creates mathematical model of the tank. reliable calibration tables compared to

• Usable in all horizontal, cylindrical any other systems.

underground and aboveground tanks. • Ensures prompt and definite results

• One tank can be calibrated within from the tank automation system.

maximum 30 minutes and calibration

of all tanks at a filling station can be

completed only within a few hours.

You might also like

- Truck CamDocument8 pagesTruck CamPietro JúniorNo ratings yet

- Cameron - CAMCHEC Riser Inspection - TC1484Document4 pagesCameron - CAMCHEC Riser Inspection - TC1484jahehe2000No ratings yet

- Intertek Tank Calibration 2021Document4 pagesIntertek Tank Calibration 2021david montoyaNo ratings yet

- Atos Scanbox: Optical 3D Coordinate Measuring MachineDocument24 pagesAtos Scanbox: Optical 3D Coordinate Measuring Machinesarawut praneetponkrangNo ratings yet

- RCS Brochure Tcm533-1172411Document8 pagesRCS Brochure Tcm533-1172411Ronald OsorioNo ratings yet

- Calibration Service Provider Works Faster and Smarter To Create More RevenueDocument3 pagesCalibration Service Provider Works Faster and Smarter To Create More Revenuekamala nandulaNo ratings yet

- Laser Profiler System: Features & BenefitsDocument6 pagesLaser Profiler System: Features & BenefitsJuanNo ratings yet

- SCADADocument66 pagesSCADAADLURI SRIKARNo ratings yet

- ATOS Triple Scan en RevADocument12 pagesATOS Triple Scan en RevAm2ryusNo ratings yet

- Project Presentation (CS499) - Albert MairaDocument30 pagesProject Presentation (CS499) - Albert Mairakingunge100% (1)

- LaserQC BrochureDocument4 pagesLaserQC BrochurejesszeusNo ratings yet

- AP Instruments RheolabQCDocument6 pagesAP Instruments RheolabQCAndrés MárquezNo ratings yet

- UT of Pressure Vessel Construction WeldsDocument30 pagesUT of Pressure Vessel Construction WeldsKashif KaziNo ratings yet

- About TESCO EquipmentsDocument24 pagesAbout TESCO EquipmentsfilbryantNo ratings yet

- ATOS Core EN RevD PDFDocument10 pagesATOS Core EN RevD PDFAlickNo ratings yet

- SigQC BearingDocument2 pagesSigQC Bearingpavlestepanic9932No ratings yet

- Sitrans CV Ap01 Us 2016Document10 pagesSitrans CV Ap01 Us 2016muggle1357No ratings yet

- Sitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVDocument6 pagesSitrans CV: Accurate, Cost-Saving and Reliable Natural Gas Analyzer SITRANS CVpkbijuNo ratings yet

- System Accuracy - Test: Shutdown SIS Previous ScreenDocument23 pagesSystem Accuracy - Test: Shutdown SIS Previous ScreenEshop ManualNo ratings yet

- Gom Brochure Atos Core enDocument12 pagesGom Brochure Atos Core enquoctuanNo ratings yet

- Scan CompressionDocument20 pagesScan CompressionJai Kiran RNo ratings yet

- Leica TCA1800Document6 pagesLeica TCA1800glee_401528No ratings yet

- Evaluate Measurement Data With jBEAMDocument4 pagesEvaluate Measurement Data With jBEAMRodrigo MargaritNo ratings yet

- Leica Absolute Tracker AT401 White Paper enDocument16 pagesLeica Absolute Tracker AT401 White Paper enGeorge AcostaNo ratings yet

- Worldwide Technical Centers and Production Facilities: 5. Umicore Autocat USA IncDocument1 pageWorldwide Technical Centers and Production Facilities: 5. Umicore Autocat USA IncprabhjotbhangalNo ratings yet

- Experiment 4Document13 pagesExperiment 4shawon_darkNo ratings yet

- Project Final PDF - PagenumberDocument35 pagesProject Final PDF - PagenumberB00GeY manNo ratings yet

- CMMDocument26 pagesCMMSanjeev kumar Verma100% (1)

- Research On Logistics Simulation and OptimizationDocument10 pagesResearch On Logistics Simulation and OptimizationNguyễn Ngọc QuangNo ratings yet

- CNC MachineDocument18 pagesCNC MachineRajeev Ranjan100% (1)

- 3D Data CaptureDocument19 pages3D Data Capturem_925No ratings yet

- Cobra Scan InspectionDocument58 pagesCobra Scan InspectionMohsin Iam100% (2)

- Indian Railways PDFDocument13 pagesIndian Railways PDFTsogjavkhlan TumurbaatarNo ratings yet

- Geosense Brochure 2011 V1.2Document46 pagesGeosense Brochure 2011 V1.2jnfNo ratings yet

- Robot Vision: Automating Automation With Machine VisionDocument8 pagesRobot Vision: Automating Automation With Machine Visionshehan2008No ratings yet

- Evaluation Kit Texas Instruments CC2400EMKDocument3 pagesEvaluation Kit Texas Instruments CC2400EMKGeneration GenerationNo ratings yet

- CNC Part ProgramingDocument129 pagesCNC Part ProgramingKavan PanneerselvamNo ratings yet

- BH34196 Advanced Inspection ServicesDocument24 pagesBH34196 Advanced Inspection ServicesTh NattapongNo ratings yet

- CE PresentationDocument8 pagesCE PresentationÁSädKHänNo ratings yet

- DC 240 - DC250 Max Set UpDocument36 pagesDC 240 - DC250 Max Set Uprenfag83% (6)

- Proposal Purchasing New Equipment Mictrack Series 4000Document8 pagesProposal Purchasing New Equipment Mictrack Series 4000joni Mart SitioNo ratings yet

- Study of Plcs and CNC Machines at Bhel,: Register No: 15bec1172 Name: V Ajay KumarDocument33 pagesStudy of Plcs and CNC Machines at Bhel,: Register No: 15bec1172 Name: V Ajay KumarTanmay RaiNo ratings yet

- Vmat QaDocument31 pagesVmat QaJoseLuisDumontNo ratings yet

- IA800 Brochure 04072021Document8 pagesIA800 Brochure 04072021Danielle SilvaNo ratings yet

- FAQ - EMCview V1 - 8Document33 pagesFAQ - EMCview V1 - 8Michael MayerhoferNo ratings yet

- TS 240 BrochureDocument2 pagesTS 240 BrochureSharon SunasseeNo ratings yet

- Altera Scantek5 CMMDocument8 pagesAltera Scantek5 CMMJorge OliveiraNo ratings yet

- Metering Units B048 Bro GB Rev0Document16 pagesMetering Units B048 Bro GB Rev0andi bangsawanNo ratings yet

- Custody Transfer SystemDocument8 pagesCustody Transfer SystempriyoNo ratings yet

- HVAC Design & Drafting Training for Construction IndustryDocument25 pagesHVAC Design & Drafting Training for Construction IndustryMuhammad Noman100% (1)

- HVAC Design & Drafting Training for Construction IndustryDocument25 pagesHVAC Design & Drafting Training for Construction IndustryAdil49No ratings yet

- A Heartful Thank You For Giving OpportunityDocument30 pagesA Heartful Thank You For Giving Opportunityzeeshan khanNo ratings yet

- Titan ADX DatasheetDocument4 pagesTitan ADX Datasheetmiguelrccosta100% (1)

- IC Layout Design-SaadDocument51 pagesIC Layout Design-SaadMuhammad SaadNo ratings yet

- Honeywell Smart Position SensorDocument8 pagesHoneywell Smart Position SensorRaymund GatocNo ratings yet

- Metering Units SatamDocument16 pagesMetering Units Satamhesam asgariNo ratings yet

- Atm Facilities and EquipmentDocument24 pagesAtm Facilities and EquipmentPritam ChattopadhyayNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- 2017MR1 BeginnersGuide Tank ENDocument20 pages2017MR1 BeginnersGuide Tank ENMahmoud GaberNo ratings yet

- User Manuals For The Focus3D X 130 or 130 HDRDocument2 pagesUser Manuals For The Focus3D X 130 or 130 HDRMahmoud GaberNo ratings yet

- Pressure Gage Const 211Document1 pagePressure Gage Const 211Mahmoud GaberNo ratings yet

- Report Tank CY3DRDocument52 pagesReport Tank CY3DRMahmoud GaberNo ratings yet

- Mohamedshaaban Abu El-Hassan: Career ObjectivesDocument3 pagesMohamedshaaban Abu El-Hassan: Career ObjectivesMahmoud GaberNo ratings yet

- 3D 301 Header AnalysisDocument19 pages3D 301 Header AnalysisMahmoud GaberNo ratings yet

- Lifting Lug Design B 01Document17 pagesLifting Lug Design B 01Mahmoud GaberNo ratings yet

- Offcon DNV Zorro SkidDocument6 pagesOffcon DNV Zorro SkiddakidofdaboomNo ratings yet

- Offcon DNV Zorro SkidDocument6 pagesOffcon DNV Zorro SkiddakidofdaboomNo ratings yet

- It Is With Great Sense of GratitudeDocument2 pagesIt Is With Great Sense of GratitudeehasayinNo ratings yet

- Storage Tank Calibration MethodsDocument4 pagesStorage Tank Calibration MethodsMuhammadShabbirNo ratings yet

- API 653 Study PlanDocument7 pagesAPI 653 Study PlanJeganeswaranNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- Offcon DNV Zorro SkidDocument6 pagesOffcon DNV Zorro SkiddakidofdaboomNo ratings yet

- Manual UT 1Document129 pagesManual UT 1Mahmoud Gaber100% (1)

- Total Ut Gan 2003Document108 pagesTotal Ut Gan 2003Mahmoud Gaber100% (1)

- Design of Padeye CalcDocument3 pagesDesign of Padeye CalcBolarinwa89% (9)

- API 653 - The "Who DAT?"Document1 pageAPI 653 - The "Who DAT?"Mahmoud GaberNo ratings yet

- Non-Destructive Testing Acceptance Standards for API 1104Document6 pagesNon-Destructive Testing Acceptance Standards for API 1104WillykateKairu75% (4)

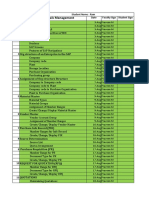

- Quality Control Plan for Storage TankDocument6 pagesQuality Control Plan for Storage TankShiva KumarNo ratings yet

- Ytujens 2018 36 4.4222Document14 pagesYtujens 2018 36 4.4222Mahmoud GaberNo ratings yet

- Iso 12917 1 2017Document15 pagesIso 12917 1 2017Mahmoud GaberNo ratings yet

- FARO Focus X 130: High-Speed 3D Laser ScannerDocument2 pagesFARO Focus X 130: High-Speed 3D Laser ScannerMahmoud GaberNo ratings yet

- Storage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksDocument42 pagesStorage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksMahmoud GaberNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Section 2 API-653 Practice QuestionsDocument56 pagesSection 2 API-653 Practice QuestionsAliDadKhan100% (4)

- Modeling of Storage Tank Settlement Based On The United States StandardsDocument7 pagesModeling of Storage Tank Settlement Based On The United States StandardsRktBatamNo ratings yet

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjNo ratings yet

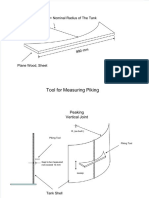

- Peaking BandingDocument4 pagesPeaking BandingMahmoud GaberNo ratings yet

- بالطو وفانله وتاب أحمد عاطف #فور - ريدDocument254 pagesبالطو وفانله وتاب أحمد عاطف #فور - ريدMahmoud GaberNo ratings yet

- Regulations 1-6 of 13Document2 pagesRegulations 1-6 of 13Leonardo RivasNo ratings yet

- Building C# Applications: Unit - 2Document25 pagesBuilding C# Applications: Unit - 2mgsumaNo ratings yet

- 03board of Directors Resolution For AGRONetBIZ ENGLISHDocument1 page03board of Directors Resolution For AGRONetBIZ ENGLISHyuswirdaNo ratings yet

- Improved Line Maze Solving Algorithm For PDFDocument2 pagesImproved Line Maze Solving Algorithm For PDFRaja Joko MusridhoNo ratings yet

- Ram SAP MM Class StatuscssDocument15 pagesRam SAP MM Class StatuscssAll rounderzNo ratings yet

- Schedule LIII Form No. 376 CommutationDocument3 pagesSchedule LIII Form No. 376 Commutationbkrawat2008No ratings yet

- MCMT 2 eDocument461 pagesMCMT 2 eRonNo ratings yet

- C-TECC Principles Guide TECC EducationDocument4 pagesC-TECC Principles Guide TECC EducationDavid Sepulveda MirandaNo ratings yet

- Data Protection Act (DPA)Document14 pagesData Protection Act (DPA)Crypto SavageNo ratings yet

- The Prosecutor's HandbookDocument162 pagesThe Prosecutor's HandbooksamuelNo ratings yet

- Engine Tune-UpDocument43 pagesEngine Tune-UpЮра ПетренкоNo ratings yet

- Physical security system essentialsDocument5 pagesPhysical security system essentialsLindo Gondales Jr.No ratings yet

- Quiz ME 1Document4 pagesQuiz ME 1Radytia BimantaraNo ratings yet

- Spirax-Sarco - Boiler Controls and SystemsDocument8 pagesSpirax-Sarco - Boiler Controls and SystemstpqnhatNo ratings yet

- PKG Materials Standards IIP A A JoshiDocument45 pagesPKG Materials Standards IIP A A JoshiDeepak VermaNo ratings yet

- Workplace 2017Document8 pagesWorkplace 2017Vesign MediaNo ratings yet

- Gliffy Public Diagram - ATM FlowchartDocument3 pagesGliffy Public Diagram - ATM Flowchartmy nNo ratings yet

- Water Supply NED ArticleDocument22 pagesWater Supply NED Articlejulie1805No ratings yet

- GPU, A Gnutella Processing UnitDocument27 pagesGPU, A Gnutella Processing UnitMengotti Tiziano FlavioNo ratings yet

- Treehouse Avatar Technologies v. TurbineDocument5 pagesTreehouse Avatar Technologies v. TurbinePriorSmart0% (1)

- Proposed Rule: Employment: Adverse ActionsDocument4 pagesProposed Rule: Employment: Adverse ActionsJustia.comNo ratings yet

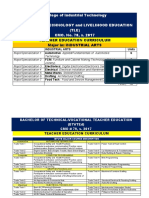

- College of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Document5 pagesCollege of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Industrial TechnologyNo ratings yet

- The Sssessential List of Microsoft Outlook Keyboard ShortcutsDocument3 pagesThe Sssessential List of Microsoft Outlook Keyboard Shortcutsabidaliabid1No ratings yet

- Senate Bill 365Document5 pagesSenate Bill 365samtlevinNo ratings yet

- Modern History Notes (Sample Notes For JPSC Mains Exam)Document21 pagesModern History Notes (Sample Notes For JPSC Mains Exam)Ijhar AhmadNo ratings yet

- Complete HSE document kit for ISO 14001 & ISO 45001 certificationDocument8 pagesComplete HSE document kit for ISO 14001 & ISO 45001 certificationfaroz khanNo ratings yet

- PRINCIPLES OF MANAGEMENT Model Questions - ADocument4 pagesPRINCIPLES OF MANAGEMENT Model Questions - ALionel MintsaNo ratings yet

- Toaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRDocument33 pagesToaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRma celine villoNo ratings yet

- Fnce 220: Business Finance: Lecture 6: Capital Investment DecisionsDocument39 pagesFnce 220: Business Finance: Lecture 6: Capital Investment DecisionsVincent KamemiaNo ratings yet

- Subhasis Patra CV V3Document5 pagesSubhasis Patra CV V3Shubh SahooNo ratings yet