Professional Documents

Culture Documents

Energy Consumption of Chosen Spinning Mill - Textile School

Uploaded by

Muhammad Bilal Qadir0 ratings0% found this document useful (0 votes)

13 views8 pagesOriginal Title

Energy consumption of chosen spinning mill - Textile School

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views8 pagesEnergy Consumption of Chosen Spinning Mill - Textile School

Uploaded by

Muhammad Bilal QadirCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Home Yarn

YARN AIR-JET SPINNING OPEN-END SPINNING

Energy consumption of chosen spinning mill

In order to obtain the necessary information about energy consumption of a speci c spinning mill, one which is able to spin every

kind of staple ber (i.e. cotton, linen, polyester, viscose) in a wide count range using both ring and open-end systems to be

chosen.

By Textile School Last updated Mar 13, 2018

Table of Contents

Accumulating the power consumption data

In order to obtain the necessary information about energy consumption of a speci c spinning mill, one which is able to

spin every kind of staple ber (i.e. cotton, linen, polyester, viscose) in a wide count range using both ring and open-end

systems were chosen. This spinning mill included not only machines used for manufacturing (blowing room, carding,

combing, drawing, roving, spinning, winding), but also included 5 air conditioning systems, 2 compressors and 2555

lamps for illumination. Besides this, the chosen spinning mill used only electrical energy.

Energy consumption on various machines

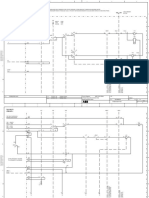

The unit power needed for corresponding machines in production line and power for the air conditioning system,

compressors and lamps can be seen in Table. Installed power is a power needed for each equipment if there is no energy

loss; the actual power was calculated taking into consideration energy loss or energy e ciency. The total installed and

actual power needed for each equipment given in the table was obtained by multiplying the number of machines with the

unit power required. The subtotal of each equipment group is also shown, i.e. subtotal of actual power necessary for

carding machines is 229.5 kW. In addition, the last column of the table shows the share of actual power required for each

equipment group in the total actual power consumption, i.e. carding machines form 9.44% of the total actual power

consumption. The amount of total actual power in the chosen spinning mill was determined as 2432.8 kW in which

machines, air conditioning, compressors, and illumination were included and the machines consumed energy which

formed 78% of the total energy consumption alone.

For unit machine For total

Number of Installed Actual Installed Actual Share of each in otal

Equipment Type machines power,kW power, kW power,kW power, kW actual power, %

Blow Room (Cot- 1 36.00 22.00 36.00 22.00 8.10

Linen Line)

Blow Room 1 64.00 42.00 64.00 42.00

(Automatic)

Blow Room 6 16.30 8.00 97,75 48.00

(Manuel1)

Blow Room 3 7.15 4.00 21,45 12.00

(Manuel2)

Blow Room 4 26.10 10.75 104,50 43.00

(Poly/vis)

For unit machine For total

Number of Installed Actual Installed Actual Share of each in otal

Equipment Type machines power,kW power, kW power,kW power, kW actual power, %

Vertical Opener 5 9.40 6.00 47.00 30.00

SUB TOTAL – 158.95 92.75 370,70 197.00

Carding M. (Saco- 5 4.00 3.30 20.00 16.50 9.44

Lowell)

Carding M.(C10) 8 13.25 8.50 106.00 68.00

Carding M.(Rieter) 10 20.70 14.50 207.00 145.00

SUB TOTAL 37.95 26.30 333.00 229.50

Drawing Machines 14 10.00 7.50 140.00 105.00 4.30

Combing Machines 4 6.53 5.50 26.12 22.00 0.90

Lap Machine 1 13.00 11.00 13.00 11.00 0.45

Roving Machines 12 17.30 11.40 207.50 136.80 5.60

Ring Spinning 33 40.00 34.00 1320.00 700.00 28.80

Machines

Ring Traveler 10 0.497 0.30 4.97 3.00 0.10

Robots

Open-end Spinning 5 81.60 60.00 408.00 300.00 15.10

Machines 1

For unit machine For total

Number of Installed Actual Installed Actual Share of each in otal

Equipment Type machines power,kW power, kW power,kW power, kW actual power, %

Open-end Spinning 1 100.00 67.50 100.00 67.50

Machines 2

Winding Machine 15.50 13.50 155.00 135.00 5.60

10

SUBTOTAL OF MACHINES 3078.29 1906.80 78.40

Compressor 1 1 58.00 40.00 58.00 40.00 2.63

Compressor 2 1 45.00 24.00 45.00 24.00

SUBTOTAL OF COMPRESSORS 103.00 64.00 103.00 64.00

Air Conditioning 1 110.00 55.00 110.00 55.00 16.00

System 1

Air Conditioning 1 147.10 91.00 147.10 91.00

System 2

Air Conditioning 1 147.10 116.00 147.10 116.00

System 3

Air Conditioning 1 126.00 73.00 126.00 73.00

System 4

Air Conditioning 1 81.50 55.00 81.50 55.00

System 5

SUBTOTAL OF AIR CONDITIONING 611.70 390.00 611.70 390.00

For unit machine For total

Number of Installed Actual Installed Actual Share of each in otal

Equipment Type machines power,kW power, kW power,kW power, kW actual power, %

LAMPS 2555 0.04 – 102.00 72.00 2.98

TOTAL 3894.99 2432.80 100

Energy consumption for a chosen spinning mill in May

The chosen spinning mill operated in 3 shifts a day which consisted of 8 hours and also works 25 days a month.

Considering the monthly operating time and number of machines, the monthly (May) energy consumption of the chosen

spinning mill was calculated and all the data are shown in the following table. The actual total monthly energy

consumption of the spinning mill was 1459680 kWh/month in May as shown. 78.4% of this energy was consumed by the

machines, see Figure 1.a and 37% of the monthly energy consumed by the machines was due to the ring spinning

machines (Figure 1.b).

In order to determine the unit energy consumption of unit yarn mass which is known as speci c energy consumption, the

monthly energy consumption of the investigated mill was divided by monthly production quantity and the variation

obtained is demonstrated in Figure. The amount of speci c energy consumption changed between 3.23 and 3.76 kWh/kg

in the chosen mill among the selected months. These values were the average which changed depending on the yarn

properties.

Hourly energy Daily energy Monthly energy

Equipment Type consumption, kWh consumption, kWh consumption, kWh

Blow Room (Cot-Linen 22 528.0 13200

Line)

Blow Room (Automatic) 42 1008.0 25200

Blow Room (Manuel1) 48 1152.0 28800

Blow Room (Manuel2) 12 288.0 7200

Blow Room (Poly/vis) 43 1032.0 25800

Vertical Opener 30 720.0 18000

SUB TOTAL 197 4728.0 118200

Hourly energy Daily energy Monthly energy

Equipment Type consumption, kWh consumption, kWh consumption, kWh

Carding M.(Sacolowell) 16.5 396.0 9900

Carding M.(C10) 68 1632.0 40800

Carding M.(Rieter) 145 3480.0 87000

SUB TOTAL 229.5 5508.0 137700

Drawing Machines 105 2520.0 63000

Combing + Lap Machines 33 792.0 19800

Roving Machines 136.8 3283.2 82080

Ring Spinning Machines + 703 16872.0 421800

Robots

Open-end Spinning 367.5 8820.0 220500

Machines

Winding Machines 135 3240.0 81000

MACHINE TOTAL 1906.8 45763.2 1144080

AIR CONDITIONING 390 9360.0 234000

SYTEMS

ILLUMINATION 72 1728.0 43200

COMPRESSORS 64 1536.0 38400

TOTAL 2432.8 58387.2 1459680

energy consumption spinning spinning machine

Textile School - 393 Posts - 0 Comments

1 Comment

Shiva Says 6 months ago

The information shared by you is very useful but can you please tell me the number of spindles that you have taken under consideration?

This site uses Akismet to reduce spam. Learn how your comment data is processed.

FIBER YARN FABRIC FINISHING APPAREL SPECIALTY

TEXTILES RSS Q&A

© 2021 - Textile School. All Rights Reserved.

Advertise with us

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- B18 American National Standards For Bolts, Nuts, Rivets, Screws, Washers, and Similar FastenersDocument1 pageB18 American National Standards For Bolts, Nuts, Rivets, Screws, Washers, and Similar FastenerskarthegreNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- GSX1300RAL5Document156 pagesGSX1300RAL5jaspal59No ratings yet

- Well Control Manual: Chapter 3 - Tripping ProceduresDocument6 pagesWell Control Manual: Chapter 3 - Tripping ProceduresMahrouz MadoNo ratings yet

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- Rexroth AA4VGDocument64 pagesRexroth AA4VGSedin MurtićNo ratings yet

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjNo ratings yet

- Photoelectrochemical Complexes For Solar EnergyDocument8 pagesPhotoelectrochemical Complexes For Solar EnergyMuhammad Bilal QadirNo ratings yet

- IMPROVED DYE-SENSITIZED SOLAR CELLDocument8 pagesIMPROVED DYE-SENSITIZED SOLAR CELLMuhammad Bilal QadirNo ratings yet

- Surface Treatment of Dye-Sensitized Solar Cell Using Dielectric BarrierDocument6 pagesSurface Treatment of Dye-Sensitized Solar Cell Using Dielectric BarrierMuhammad Bilal QadirNo ratings yet

- Enhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmDocument8 pagesEnhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmMuhammad Bilal QadirNo ratings yet

- Perovskite-Based Solar Cells Impact of Morphology and Device Architecture On Device PerformanceDocument85 pagesPerovskite-Based Solar Cells Impact of Morphology and Device Architecture On Device PerformanceMuhammad Bilal QadirNo ratings yet

- Journal of Energy StorageDocument13 pagesJournal of Energy StorageMuhammad Bilal QadirNo ratings yet

- Fabrication of Flexible Dye Sensitized Solar Cells On Plastic SubstratesDocument16 pagesFabrication of Flexible Dye Sensitized Solar Cells On Plastic SubstratesMuhammad Bilal QadirNo ratings yet

- Photocurrent Enhancement by Surface Plasmon Resonance of Silver Nanoparticles in Highly Porous Dye-Sensitized Solar CellsDocument6 pagesPhotocurrent Enhancement by Surface Plasmon Resonance of Silver Nanoparticles in Highly Porous Dye-Sensitized Solar CellsMuhammad Bilal QadirNo ratings yet

- Effect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthDocument9 pagesEffect of Elastane Plating On Physical Thermal Comfort Properties of Lyocell Single Jersey Knit Fabric With Different Loop LengthMuhammad Bilal QadirNo ratings yet

- Controlled Porosity TiO2 Beads Boost Sb2S3 Solar Cell Efficiency 15Document33 pagesControlled Porosity TiO2 Beads Boost Sb2S3 Solar Cell Efficiency 15Muhammad Bilal QadirNo ratings yet

- 2020-Development of KapokRecycled-PET Blended Needle-Punched Thermal WaddingsDocument10 pages2020-Development of KapokRecycled-PET Blended Needle-Punched Thermal WaddingsMuhammad Bilal QadirNo ratings yet

- Energy Efficiency and Analysis of Motors in Spinning MillDocument9 pagesEnergy Efficiency and Analysis of Motors in Spinning MillMuhammad Bilal QadirNo ratings yet

- MIT 3.071 Amorphous Materials: Juejun (JJ) HuDocument36 pagesMIT 3.071 Amorphous Materials: Juejun (JJ) HuMuhammad Bilal QadirNo ratings yet

- 2020-Effect of Elastane Parameters On The Dimensional and Mechanical Properties of Stretchable Denim FabricsDocument15 pages2020-Effect of Elastane Parameters On The Dimensional and Mechanical Properties of Stretchable Denim FabricsMuhammad Bilal QadirNo ratings yet

- 2021-Thermodynamic and Kinetic Study of Adsorptive Removal of Lead by The Nanocomposite Loaded NanofibersDocument39 pages2021-Thermodynamic and Kinetic Study of Adsorptive Removal of Lead by The Nanocomposite Loaded NanofibersMuhammad Bilal QadirNo ratings yet

- MIT 3.071 Amorphous Materials: Juejun (JJ) HuDocument35 pagesMIT 3.071 Amorphous Materials: Juejun (JJ) HuMuhammad Bilal QadirNo ratings yet

- MIT 3.071 Amorphous Materials: Juejun (JJ) HuDocument22 pagesMIT 3.071 Amorphous Materials: Juejun (JJ) HuMuhammad Bilal QadirNo ratings yet

- Influence of Spinneret Polarity in Needleless ElectrospinningDocument9 pagesInfluence of Spinneret Polarity in Needleless ElectrospinningMuhammad Bilal QadirNo ratings yet

- 2021 - Synthesis of The Novel Binary Composite of Self-Suspended Polyaniline (S-PANI) and Functionalized Multi-Walled Carbon Nanotubes For High-Performance SupercapacitorsDocument13 pages2021 - Synthesis of The Novel Binary Composite of Self-Suspended Polyaniline (S-PANI) and Functionalized Multi-Walled Carbon Nanotubes For High-Performance SupercapacitorsMuhammad Bilal QadirNo ratings yet

- MIT 3.071 Amorphous Materials: Juejun (JJ) HuDocument25 pagesMIT 3.071 Amorphous Materials: Juejun (JJ) HuMuhammad Bilal QadirNo ratings yet

- SBP Financing Scheme For Renewable Energy: RE-1 Refinance Application FormDocument10 pagesSBP Financing Scheme For Renewable Energy: RE-1 Refinance Application FormMuhammad Bilal QadirNo ratings yet

- Irjet V5i3368 PDFDocument7 pagesIrjet V5i3368 PDFGobu SKNo ratings yet

- 2021-Development and Characterization of Biodegradable Starch-Based Fibre by Wet ExtrusionDocument13 pages2021-Development and Characterization of Biodegradable Starch-Based Fibre by Wet ExtrusionMuhammad Bilal QadirNo ratings yet

- MIT 3.071 Amorphous Materials: Juejun (JJ) HuDocument21 pagesMIT 3.071 Amorphous Materials: Juejun (JJ) HuMuhammad Bilal QadirNo ratings yet

- An Investigation of Energy Usage in Yarn ProductionDocument8 pagesAn Investigation of Energy Usage in Yarn ProductionMuhammad Bilal QadirNo ratings yet

- Requision of Refinance Limit Under Renewable Energy Refinance Scheme For FY 20xx Yy Category IDocument3 pagesRequision of Refinance Limit Under Renewable Energy Refinance Scheme For FY 20xx Yy Category IMuhammad Bilal QadirNo ratings yet

- Textile Progress 2019Document43 pagesTextile Progress 2019Muhammad Bilal QadirNo ratings yet

- Energy Harvesting From Piezoelectric Textile Fibers: SciencedirectDocument4 pagesEnergy Harvesting From Piezoelectric Textile Fibers: SciencedirectMuhammad Bilal QadirNo ratings yet

- Dhayaneswaran-Ashokkumar2013 Article AStudyOnEnergyConservationInTe PDFDocument8 pagesDhayaneswaran-Ashokkumar2013 Article AStudyOnEnergyConservationInTe PDFMuhammad NabeelNo ratings yet

- Parts Guide Manual: HD-514 A1RmDocument17 pagesParts Guide Manual: HD-514 A1RmmemetNo ratings yet

- Improving weld test pass rates for stainless to mild steel jointsDocument4 pagesImproving weld test pass rates for stainless to mild steel jointscarlospalacioeNo ratings yet

- Tech guide for replacing centrifuges locksDocument7 pagesTech guide for replacing centrifuges locksAbdalazeez AlsayedNo ratings yet

- Cat - Mang y Acoples. Eaton-Winner PDFDocument12 pagesCat - Mang y Acoples. Eaton-Winner PDFGiovannyNo ratings yet

- Intrerupator 110kv Actionare Trifazata - 1HSB543260-AADDocument10 pagesIntrerupator 110kv Actionare Trifazata - 1HSB543260-AADMaria MirceaNo ratings yet

- Spring/Summer: Catalog 2014Document76 pagesSpring/Summer: Catalog 2014tekijacNo ratings yet

- Final TT-End Sem - Spring Sem2022-23 - 13.04.2023Document4 pagesFinal TT-End Sem - Spring Sem2022-23 - 13.04.2023Ritwik NandiNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Patented Oct. 27, 1896.: Gas Operated Magazine GunDocument14 pagesPatented Oct. 27, 1896.: Gas Operated Magazine GunСлэйтер Строительная компанияNo ratings yet

- CG 2020004 01 CHEMGUARD OscillatingMonitorsDocument4 pagesCG 2020004 01 CHEMGUARD OscillatingMonitorsbhima irabattiNo ratings yet

- Reg No: SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL DEPARTMENT OF MECHANICAL ENGINEERING ASSIGNMENT – IIDocument2 pagesReg No: SELVAM COLLEGE OF TECHNOLOGY, NAMAKKAL DEPARTMENT OF MECHANICAL ENGINEERING ASSIGNMENT – IISelvaraj GNo ratings yet

- 5 Cross Section Plastic Resistance (Plastic Hinge)Document15 pages5 Cross Section Plastic Resistance (Plastic Hinge)Imran SaikatNo ratings yet

- Parts List: JTR-MOL254/LBADocument74 pagesParts List: JTR-MOL254/LBAJoseNo ratings yet

- 9282Document13 pages9282Frank StephensNo ratings yet

- Curso Toby Pugh PDFDocument13 pagesCurso Toby Pugh PDFPresident PCNo ratings yet

- PDF Lecture 04 - Design of Doubly Reinforced BeamDocument7 pagesPDF Lecture 04 - Design of Doubly Reinforced BeamTrisha de OcampoNo ratings yet

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- Machine Friction and ElementsDocument94 pagesMachine Friction and ElementsParkunam RandyNo ratings yet

- Pneufit C Composite - Pneufit M MetricDocument11 pagesPneufit C Composite - Pneufit M MetricSonthi MooljindaNo ratings yet

- Clivet Toplotne PumpeDocument15 pagesClivet Toplotne PumpeSean ThomasNo ratings yet

- KEP-22-23-01 Lifting Price ListDocument25 pagesKEP-22-23-01 Lifting Price ListShekhar Pratap SinghNo ratings yet

- How to Use a Thread Die for Cutting ThreadsDocument2 pagesHow to Use a Thread Die for Cutting ThreadsSulthan WildanNo ratings yet

- Process Control Plan Excel TemplateDocument13 pagesProcess Control Plan Excel TemplateTalal NajeebNo ratings yet

- Hungary Pilgrim CenterDocument1 pageHungary Pilgrim Centerzain deen0% (1)