Professional Documents

Culture Documents

Lab 3

Uploaded by

Mi LengCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 3

Uploaded by

Mi LengCopyright:

Available Formats

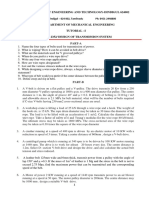

Laboratory work №3.

«Conceptual/Preliminary design of the Roller Module for cargo hold and

container compartment».

The aim of the laboratory work: Skill mastering in the designing Equipment for

cargo hold and container compartment floor.

The objectives of the laboratory work:

- Study of the modern designs of the Roller Floor Modules.

- Development of the procedures for the preliminary design of the Roller

modules for the cargo or passenger aircraft.

Terms, definitions and examples.

Try to formulate your own definition of the Roller Module

The proposed procedure.

1. Define the number of Roller Modules installed on one m2 in the selected

aircraft.

This selected airplane is An-26, in this laboratory work, I will design the roller

system for the An-26.

The parameters of An-26 cargo hold.

Length :11.2m

Width :2.25m

Height:1.65m

The length of the roller system: 10.2m

The numbers of the roller tracks: 3, they are on the left, right, and center

respectively.

The number of roller modules installed on 1 m2

In the longitudinal direction, there are 6 rollers, and in the horizontal direction,

there are 3 rollers.

In the 2.25 m2, there are 18 rollers.

On the 1m2, there are

18

n= =8 rollers/m2

2.25

The roller tray will be designed 10.2m, between two frames, there are 3 rollers

will be installed.

The numbers of roller in one tray

10.2

z= ×3 ≈ 61

0.5

2. Define the preliminary dimensions of one Roller Module.

3. Load on one Roller Module.

For the An-26, the max area load is 400kg /m2;

There are 6 rollers/m2;

The load on one roller is equal:

400

the load on one roller= =50 kg /m 2

8

4. Constructional material for Roller Module Components.

In China, for the roller axis, we use 30CrMnSIA that is alloy steel. It is

widely used as shaft for aircraft. The mechanical properties are as follows:

For the rollers, I select the aluminum 2024-T3. The 2024-T3 is mainly used

for making various high load parts and components.

For the installation tray, I think the aluminum alloy is better, so I use the

7A04, which is Super-hard aluminum alloy, widely is used for main load bearing

elements.

5. The dimensions of primary components.

The diameter of the axis can be calculated according to the formula:

4∙ S 4 ×500

d=

√ √ =

( π ∙i∙ z ∙ τ cp ) ( 3.14 ×2 ×1 ×250 ×106 )

=1.2 mm

We can get if the diameter of axis more than 1.2mm, this axis can bear the

load of the cargo. Then we choose the diameter of axis is 12mm.

Select bearings

the load to the axis is radial load which is subjected from max area load, and

axial load that is subjected from tray. we can use double row angular contact ball

bearing

The we can get the load from the radial is light, I use the ball bearing.

The internal diameter of the bearing is 12mm, that suit for axis.

6. Select method for the lubrication.

There is contact between the bearing rings and rolling element when the

bearing rotates. This contact will lead to friction and wear. To prevent this, we

should use lubrication

For the rollers, the load is low-speed rotation, and consider the sealing

device, I think the grease lubrication is great.

The method of lubrication is that put the grease fills the bearing. Then the

grease is filled into the grease sector inside the house through the grease nipple,

following into the inside of the bearing,

Supplementary material can be found in the presentation of the lecture

“Aircraft Roller Systems”

You might also like

- Task2 PDFDocument11 pagesTask2 PDFÁngel José Fernández MuiñosNo ratings yet

- Chapter Wise Questions Bank MD-iiDocument6 pagesChapter Wise Questions Bank MD-iiinderpreet singhNo ratings yet

- Design of Machine Element IIDocument41 pagesDesign of Machine Element IIYohanis AgumaseNo ratings yet

- mODULE #3. Machine Elements .FinalsDocument21 pagesmODULE #3. Machine Elements .FinalsRocsNo ratings yet

- Tutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringDocument2 pagesTutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringSrimanthula SrikanthNo ratings yet

- Gearless Transmission System MD-08Document20 pagesGearless Transmission System MD-08Sameer AhmadNo ratings yet

- Lunar Rover Stress Analysis PDFDocument21 pagesLunar Rover Stress Analysis PDFVirtual Station100% (1)

- Med2601 ProjectDocument15 pagesMed2601 ProjectLungah MaShamase DumaNo ratings yet

- Pipe Inspection RobotDocument19 pagesPipe Inspection RobotJeevan Landge PatilNo ratings yet

- CH 01 PDFDocument7 pagesCH 01 PDFRalphAramburuNo ratings yet

- Artigo - Study On Bridge Structure of Bridge Crane - ICCET 2015 - Li Hai-Ying and Wu Hua-Iiang PDFDocument4 pagesArtigo - Study On Bridge Structure of Bridge Crane - ICCET 2015 - Li Hai-Ying and Wu Hua-Iiang PDFKaique CavalcanteNo ratings yet

- DTS Question BankDocument21 pagesDTS Question BankSam TirshathNo ratings yet

- Me1036 Dts Tutorial Note BookDocument176 pagesMe1036 Dts Tutorial Note BookSachi DhanandamNo ratings yet

- Mvjce Me 6 SemDocument101 pagesMvjce Me 6 SemAkash AkuNo ratings yet

- Perencanan Ulang Transmisi Daya Mekanik Mesin Penghancur Es Balok Di Pasar Bina Usahakota MeulabohDocument9 pagesPerencanan Ulang Transmisi Daya Mekanik Mesin Penghancur Es Balok Di Pasar Bina Usahakota MeulabohSyibbran MulaesyiNo ratings yet

- Group B3Document24 pagesGroup B3Atalelew ZeruNo ratings yet

- Spring TestDocument5 pagesSpring Testmohanadymt50% (2)

- Chapter 1 - IntroductionDocument7 pagesChapter 1 - IntroductionErik Alejandro Velazquez PinedaNo ratings yet

- MD ShaftDocument18 pagesMD Shaftiftikhar ahmedNo ratings yet

- IJSRDV9I50222Document7 pagesIJSRDV9I50222Abhijeet SableNo ratings yet

- Lab Chi ML EngDocument7 pagesLab Chi ML EngHilmy MuhammadNo ratings yet

- Winch DesignDocument132 pagesWinch Designzeek7767% (3)

- MD Tut PDFDocument6 pagesMD Tut PDFNelsan PatelNo ratings yet

- 7.1.theory Questions and Answers: 1) What Is A Bearing? State The Functions of A BearingDocument12 pages7.1.theory Questions and Answers: 1) What Is A Bearing? State The Functions of A BearingKunal ShindeNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- Me6601 QB 4 PDFDocument15 pagesMe6601 QB 4 PDFpremgmech762No ratings yet

- ME374 - Module 4 (Updated)Document36 pagesME374 - Module 4 (Updated)VinNo ratings yet

- Unit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesDocument15 pagesUnit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesM Rasyid RidhoNo ratings yet

- Design of FlywheelDocument15 pagesDesign of FlywheelGujar SnehaNo ratings yet

- Tutorial 6 PDFDocument2 pagesTutorial 6 PDFkalirajgurusamyNo ratings yet

- D MDocument9 pagesD MMuthu KumarNo ratings yet

- r05321403 Principles of Machine DesignDocument8 pagesr05321403 Principles of Machine DesignSRINIVASA RAO GANTANo ratings yet

- Shaft Design (Mini Project 2) Machine Design ProjectDocument26 pagesShaft Design (Mini Project 2) Machine Design ProjectMohammad Tahir100% (5)

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- Design, Analysis and Safety Norms of Transmission Systems in SubmarinesDocument29 pagesDesign, Analysis and Safety Norms of Transmission Systems in SubmarinesASHUTOSH CHAURASIANo ratings yet

- 5 - Machine Tool SpindleDocument23 pages5 - Machine Tool SpindleOkan ÖzelNo ratings yet

- Soran University 1Document23 pagesSoran University 1Hadi Bapir SlemanNo ratings yet

- Car Chasis Analysis Using Abaqus SoftwarDocument15 pagesCar Chasis Analysis Using Abaqus SoftwarSoufianeNo ratings yet

- Ring Spinning MachineDocument11 pagesRing Spinning MachinePradip Gupta100% (1)

- 730 itleAssignMaster 1107202309265366011848Document1 page730 itleAssignMaster 1107202309265366011848ajay2011.jsrsharmaNo ratings yet

- Training Report at Al Shakhsheer Company: Hashemite University College of Engineering Civil Engineering DepartmentDocument21 pagesTraining Report at Al Shakhsheer Company: Hashemite University College of Engineering Civil Engineering DepartmentSalah100% (1)

- Swapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTDocument5 pagesSwapnil (2016) - Design of Components Used in Hoisting Mechanism of An EOTGogyNo ratings yet

- Question Bank SoMDocument3 pagesQuestion Bank SoMarunsunderNo ratings yet

- Analysis of Powered Roller Conveyor UsinDocument5 pagesAnalysis of Powered Roller Conveyor UsinVăn Tuấn NguyễnNo ratings yet

- rr320305 Design of Machine Members IIDocument8 pagesrr320305 Design of Machine Members IISrinivasa Rao GNo ratings yet

- Exp 2Document3 pagesExp 2Devendra P. SinghNo ratings yet

- At 6602 ACCD Imp Qns 2by2resultsDocument3 pagesAt 6602 ACCD Imp Qns 2by2resultsKarthickNo ratings yet

- Training Report - 1466958477542Document24 pagesTraining Report - 1466958477542Anuj JainNo ratings yet

- 7 Dts Question Bank-1Document22 pages7 Dts Question Bank-1Placements DhaanishNo ratings yet

- Power ScrewDocument21 pagesPower Screwjethro ganeloNo ratings yet

- TT 601practicalsDocument18 pagesTT 601practicalsHiba EjazNo ratings yet

- Dts Tutorial - IDocument1 pageDts Tutorial - IRama SamyNo ratings yet

- Shaft DesignDocument16 pagesShaft DesignOgunsina AdebayoNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- TRASCO ES Couplings PDFDocument16 pagesTRASCO ES Couplings PDFAlvaro Felipe CharlinNo ratings yet

- Road SafetyDocument6 pagesRoad SafetySabitah AhmadNo ratings yet

- Using Caterpillar Monitoring System To Determine Diagnostic CodesDocument6 pagesUsing Caterpillar Monitoring System To Determine Diagnostic CodesAtaa AssaadNo ratings yet

- Combined Homework 8 PDFDocument16 pagesCombined Homework 8 PDFAnsh SrivastavaNo ratings yet

- Life Cycle Costs of Pumps in Chemical IndustryDocument6 pagesLife Cycle Costs of Pumps in Chemical Industryarguri2006No ratings yet

- BSC (Hons) Financial Engineering: School of Innovative Technologies and EngineeringDocument7 pagesBSC (Hons) Financial Engineering: School of Innovative Technologies and EngineeringEddingtonNo ratings yet

- UK BIM Alliance, BSI & CDBB Launch UK BIM FrameworkDocument2 pagesUK BIM Alliance, BSI & CDBB Launch UK BIM FrameworkInuyashahanNo ratings yet

- Patterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsDocument7 pagesPatterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsFirli FarhatunnisaNo ratings yet

- The Old Struggle For Human Rights, New Problems Posed by SecurityDocument6 pagesThe Old Struggle For Human Rights, New Problems Posed by SecurityLen TaoNo ratings yet

- Franklin 1988Document16 pagesFranklin 1988Verônica VieiraNo ratings yet

- Venture Building, A New Model For Entrepreneurship and Innovation - LinkedInDocument16 pagesVenture Building, A New Model For Entrepreneurship and Innovation - LinkedInkhaledhassangamal9516No ratings yet

- Turn It inDocument32 pagesTurn It inFretz aaron BacongaNo ratings yet

- Module 9 Gestalt PsychologyDocument14 pagesModule 9 Gestalt PsychologyAnna Liese100% (6)

- EMCO WinNC GE Series Fanuc 21Document98 pagesEMCO WinNC GE Series Fanuc 21PHONG2790% (1)

- Effect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsDocument5 pagesEffect of Microcrystalline Cellulose From Banana Stem Fiber On Mechanical Properties and Cystallinity of PLA Composite FilmsHubby Mukaffa Al-JauzyNo ratings yet

- Linear RegressionDocument967 pagesLinear RegressionPeuli DasNo ratings yet

- 5.foundations of AIDocument17 pages5.foundations of AITariqMalikNo ratings yet

- Exterminate, RegenerateDocument2 pagesExterminate, Regeneratekafka47caNo ratings yet

- BISE MCQs-I (Microsoft Forms)Document3 pagesBISE MCQs-I (Microsoft Forms)Ghulam FaridNo ratings yet

- Comparison of Oman Seismic Code For Buildings With International CounterpartsDocument12 pagesComparison of Oman Seismic Code For Buildings With International CounterpartskarlNo ratings yet

- Soal Usbn Kelas Xii Bahasa InggrisDocument80 pagesSoal Usbn Kelas Xii Bahasa InggrisDANKNo ratings yet

- Hydraulic TestDocument3 pagesHydraulic TestSaurabh BarangeNo ratings yet

- 04mindset2 Unit3 Test OralProductionDocument2 pages04mindset2 Unit3 Test OralProductionAndrea David MartínezNo ratings yet

- NRS EZ0302 StandardSpecificationDocument40 pagesNRS EZ0302 StandardSpecificationArifNo ratings yet

- Cement and Concrete CompositesDocument7 pagesCement and Concrete CompositessattiricNo ratings yet

- Investigatory ProjectDocument65 pagesInvestigatory Projectnica pidlaoanNo ratings yet

- Group 2 - Gendered Family and Gendered Education (Notes) PDFDocument6 pagesGroup 2 - Gendered Family and Gendered Education (Notes) PDFMarlon C. ManaloNo ratings yet

- 2.0 Cegeotech2 Lec m1 (Intro)Document19 pages2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaNo ratings yet

- درجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةDocument26 pagesدرجة تضمين مهارات الاقتصاد المعرفي في مقررات الدراسات الاجتماعية للمرحلة الابتدائية بالمملكة العربية السعوديةAbdallah HamedNo ratings yet

- Final Test Series For NEET 2023 XII & RM Code A Phase 01 1Document2 pagesFinal Test Series For NEET 2023 XII & RM Code A Phase 01 1Ansh PathakNo ratings yet