Professional Documents

Culture Documents

Approval Document ASSET DOC LOC 524

Approval Document ASSET DOC LOC 524

Uploaded by

aOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Document ASSET DOC LOC 524

Approval Document ASSET DOC LOC 524

Uploaded by

aCopyright:

Available Formats

S IFI

FWD 1021

AS

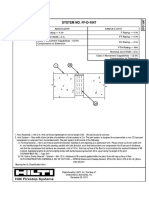

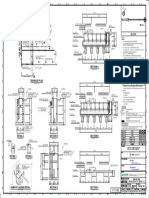

System No. FW-D-1021

CL

ED

C US Assembly Rating—3 Hr

Classified by

Underwriters Laboratories, Inc.

Nominal Joint Width—3 In.

to UL 2079 and CAN/ULC-S115 Class II Movement Capabilities - 25% Compression or Extension

3B

2 3A

1. Wall Assembly — Min 5 in. (127 mm) thick reiforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) structural concrete. Wall may

also be constructed of any UL Classified Concrete Blocks*.

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Floor Assembly — Min 5 in. (127 mm) thick reinforced lightweight or normal weight (100 - 150 pcf or 1600-2400 kg/m3) structural concrete.

3. Joint System — Max separation between edge of floor and face of wall (at time of installation of joint system) is 3 in. (76 mm). The joint system is

designed to accommodate a max 25 percent compression or extension from its installed width. The joint system shall consist of the following:

A. Packing Material — Min 4 pcf (64 kg/m3) mineral wool batt insulation installed in joint opening as a permanent form. Pieces of batt cut to min

width of 4-3/4 in. (121 mm) and installed edge-first into joint opening, parallel with joint direction, such that batt sections are compressed min

50% and batt sections are recessed from top surface of the floor as required to accommodate the required thickness of fill material. Adjoining

lengths of batt to be tightly butted with butted seams spaced min 16 in. apart along the length of the joint.

B. Fill, Void or Cavity Material*—Sealant — Min 1/4 in. (6 mm) wet thickness of fill material applied within the joint, flush with top surface of floor

and lapping a min 3/4 in. (19 mm) onto the surface of the floor and wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP672 Firestop Spray or CFS-SP WB Firestop Joint Spray

*Bearing the UL Classification Mark

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

June 04, 2010

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- Keystone Retaining WallsDocument98 pagesKeystone Retaining WallsWorld Outdoor Emporium100% (1)

- Engineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisFrom EverandEngineer's Report: Seismic Performance Evaluation and Tire Construction AnalysisNo ratings yet

- One Steel ReoDataDocument40 pagesOne Steel ReoDatapete0980100% (1)

- Approval Document ASSET DOC LOC 523Document1 pageApproval Document ASSET DOC LOC 523aNo ratings yet

- Firestop Application Handbook (Macau) - Part-8 PDFDocument30 pagesFirestop Application Handbook (Macau) - Part-8 PDFSharoon S raoNo ratings yet

- HW D 0097 WB JuntaDocument1 pageHW D 0097 WB JuntaLibardoNo ratings yet

- Approval Document ASSET DOC LOC 522Document1 pageApproval Document ASSET DOC LOC 522aNo ratings yet

- 3H Expansion DesignDocument2 pages3H Expansion DesignMd Farid AhmedNo ratings yet

- BXUV.P264 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P264 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Bridge Deck ProtectionDocument7 pagesBridge Deck ProtectionJirachai LaohaNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- System No. HW-D-0403Document1 pageSystem No. HW-D-0403Daniel Soaloon SibaraniNo ratings yet

- AMERICAN SpiralWeld Pipe - Linings and CoatingsDocument6 pagesAMERICAN SpiralWeld Pipe - Linings and CoatingsLudi D. LunarNo ratings yet

- 5 Johnny Choi PresentationDocument11 pages5 Johnny Choi PresentationSirisha AdepuNo ratings yet

- Approval Document ASSET DOC LOC 99Document1 pageApproval Document ASSET DOC LOC 99Amir IqbalNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- r1Document1 pager1jlledwinestebanNo ratings yet

- 9 October 1975: Us. Government I++Inting Omce: 1981-703-02316682 MDocument4 pages9 October 1975: Us. Government I++Inting Omce: 1981-703-02316682 MКонстантин КорнеевNo ratings yet

- Design of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Document9 pagesDesign of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Vishal Parashuram MiskinNo ratings yet

- AirForceBlastDesignGuideforURM PDFDocument38 pagesAirForceBlastDesignGuideforURM PDFFelipe Cisneros AsianNo ratings yet

- Foam Fillers Tapes Sealants BrochureDocument8 pagesFoam Fillers Tapes Sealants BrochureAppavoo DeelenNo ratings yet

- HW-D-1010 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-1010 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- UniplanxDocument12 pagesUniplanxbiik0076153No ratings yet

- FAQ 11-14 - ASTM C90 CommentaryDocument16 pagesFAQ 11-14 - ASTM C90 Commentarymido_20067581No ratings yet

- C-AJ-2813 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2813 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- Flat Plate Final For CanvaDocument9 pagesFlat Plate Final For CanvaRick SarazaNo ratings yet

- Kingspan 20insulation Thermaroof 20tr22Document8 pagesKingspan 20insulation Thermaroof 20tr22Ady SasuNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- Unispan BrochureDocument12 pagesUnispan Brochurebiik0076153No ratings yet

- NORMA UL - L565 - Armoroc 1 - Hour - FloorDocument5 pagesNORMA UL - L565 - Armoroc 1 - Hour - FloorLAWNo ratings yet

- Design and Construction of Brick Fin WallsDocument5 pagesDesign and Construction of Brick Fin Wallschoriya007No ratings yet

- P739Document7 pagesP739brauliosopasNo ratings yet

- MGI INDIA LGSF Technical SpecificationDocument60 pagesMGI INDIA LGSF Technical SpecificationAshkan Ranjbar MoshfeghiNo ratings yet

- Woodframemultistory Article PDFDocument19 pagesWoodframemultistory Article PDFLouis AndersonNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- Chapter Three: 3.0 Lightweight ConcreteDocument10 pagesChapter Three: 3.0 Lightweight ConcreteFahad UmarNo ratings yet

- Slim Floor ConstructionDocument18 pagesSlim Floor ConstructionFrankie ChanNo ratings yet

- Fireclad System BoralDocument8 pagesFireclad System BoralSuciul E ViuNo ratings yet

- Background: 3610 Commerce Drive, Suite 817 Baltimore, MD 21227 USA O: +1 410-737-8677 F: +1 410-737-8688Document14 pagesBackground: 3610 Commerce Drive, Suite 817 Baltimore, MD 21227 USA O: +1 410-737-8677 F: +1 410-737-8688Sanjay GhejiNo ratings yet

- 2006 Texas Revisions To The 2006 International Building CodeDocument9 pages2006 Texas Revisions To The 2006 International Building CodeEltigani HamadNo ratings yet

- Exterior Cladding DetailsDocument13 pagesExterior Cladding DetailsMuhammad irfan javaidNo ratings yet

- Bison Hollow Core Floors March 2007Document15 pagesBison Hollow Core Floors March 2007walshceNo ratings yet

- ASME B31.4 Design Minimum Wall ThicknessDocument6 pagesASME B31.4 Design Minimum Wall ThicknessAlfredo BravoNo ratings yet

- Development of Creep Model For Structural Insulated Timber-Foam Sandwich Walls Under Sustained Soil Pressure in Basements of Residential BuildingsDocument12 pagesDevelopment of Creep Model For Structural Insulated Timber-Foam Sandwich Walls Under Sustained Soil Pressure in Basements of Residential Buildingseli700No ratings yet

- System No. HW-D-0441Document1 pageSystem No. HW-D-0441kirollos HabibNo ratings yet

- 5313ub Usg Boral Sheet Ceiling SystemsDocument5 pages5313ub Usg Boral Sheet Ceiling SystemsJessie Jr CuisonNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemShanmuga SundaramNo ratings yet

- Anchorage of Wood Shear Walls To Concrete For Tension and Shear PDFDocument6 pagesAnchorage of Wood Shear Walls To Concrete For Tension and Shear PDFIonFlorentaNo ratings yet

- Department of Public Works and HighwaysDocument6 pagesDepartment of Public Works and HighwaysFaustino AbadNo ratings yet

- Lightweight Concrete - Types, Classification, Uses and AdvantagesDocument6 pagesLightweight Concrete - Types, Classification, Uses and AdvantagesJustin MusopoleNo ratings yet

- Er-5414 (2001)Document7 pagesEr-5414 (2001)m0172No ratings yet

- Composite PC Slabs and SCI P287 Release Note PDFDocument3 pagesComposite PC Slabs and SCI P287 Release Note PDFRobert GilbertNo ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123No ratings yet

- Joint Filler & Bearing Pads - Sparkton Const. Supplies, IncDocument2 pagesJoint Filler & Bearing Pads - Sparkton Const. Supplies, IncKaren IsananNo ratings yet

- FlameOFF Fire Barrier PaintDocument2 pagesFlameOFF Fire Barrier PaintmurdicksNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Approval Document ASSET DOC LOC 2179580Document4 pagesApproval Document ASSET DOC LOC 2179580aNo ratings yet

- Approval Document ASSET DOC LOC 537Document4 pagesApproval Document ASSET DOC LOC 537aNo ratings yet

- Approval Document ASSET DOC LOC 518Document1 pageApproval Document ASSET DOC LOC 518aNo ratings yet

- Approval Document ASSET DOC LOC 523Document1 pageApproval Document ASSET DOC LOC 523aNo ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- Approval Document ASSET DOC LOC 338Document3 pagesApproval Document ASSET DOC LOC 338aNo ratings yet

- Approval Document ASSET DOC LOC 522Document1 pageApproval Document ASSET DOC LOC 522aNo ratings yet

- Approval Document ASSET DOC LOC 333Document2 pagesApproval Document ASSET DOC LOC 333aNo ratings yet

- Approval Document ASSET DOC LOC 319Document5 pagesApproval Document ASSET DOC LOC 319aNo ratings yet

- PstoDocument32 pagesPstoaNo ratings yet

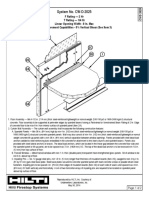

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Document2 pagesSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aNo ratings yet

- Approval Document ASSET DOC LOC 328Document2 pagesApproval Document ASSET DOC LOC 328aNo ratings yet

- Stopping StuffDocument28 pagesStopping StuffaNo ratings yet

- PtosDocument31 pagesPtosaNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- Hot StopDocument30 pagesHot StopaNo ratings yet

- StoppingDocument45 pagesStoppingaNo ratings yet

- QMM RP 000 Pat 00004Document85 pagesQMM RP 000 Pat 00004TASNEEMNo ratings yet

- Gantt Chart-Project Design LDocument9 pagesGantt Chart-Project Design LHaymanAHMEDNo ratings yet

- Question Paper CDocument3 pagesQuestion Paper ChassanNo ratings yet

- Schedule of Quantity For Industrial BuildingDocument4 pagesSchedule of Quantity For Industrial BuildingShashankSinghNo ratings yet

- First Floor Plan-Week 8Document1 pageFirst Floor Plan-Week 8HAhaNo ratings yet

- Building Schedule 050721Document6 pagesBuilding Schedule 050721Parth DaxiniNo ratings yet

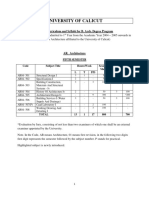

- Fifth Semester B.arch 2004 Syllabus Calicut UniversityDocument12 pagesFifth Semester B.arch 2004 Syllabus Calicut UniversityshemiNo ratings yet

- Steel Fabrikation PT Beton Perkasa WijaksanaDocument12 pagesSteel Fabrikation PT Beton Perkasa WijaksanaMohammad QoirulNo ratings yet

- Eeu BoqDocument12 pagesEeu BoqSisay chaneNo ratings yet

- 1ns20at001 MMBCDocument11 pages1ns20at001 MMBCblessyNo ratings yet

- LUYỆN NGHE TOEIC PART 1 - PHẦN 1Document6 pagesLUYỆN NGHE TOEIC PART 1 - PHẦN 1ptrang010921No ratings yet

- CA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21Document7 pagesCA No. GE (I) (CG) /KOCHI/ OF 2022-2023 Schedule 'A' Ser Page No.21sajanjoseNo ratings yet

- Can I Use Galvanized Sheet Metal For Kitchen TabletopDocument2 pagesCan I Use Galvanized Sheet Metal For Kitchen TabletopmarketingNo ratings yet

- Visual Interpretation of The: Tair Uilding ODEDocument16 pagesVisual Interpretation of The: Tair Uilding ODEadhithyaNo ratings yet

- Building Technology ResearchDocument10 pagesBuilding Technology ResearchBlyne ComilangNo ratings yet

- Industrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaDocument59 pagesIndustrial Building: by Tausif Kauswala Adit College V.V. Nagar, Anand, Gujarat, IndiaPhuong ThaoNo ratings yet

- Es 19 565214Document2 pagesEs 19 565214Rodney ZephaniaNo ratings yet

- 9th Monthly Summary TLE 7Document14 pages9th Monthly Summary TLE 7rajpreet kaurNo ratings yet

- Cement Manufacturing 1Document56 pagesCement Manufacturing 1Kian MoradosNo ratings yet

- Construction of A Superadobe Dome: Marco Aurelio López-Gómez M de Las Nieves González-GarcíaDocument13 pagesConstruction of A Superadobe Dome: Marco Aurelio López-Gómez M de Las Nieves González-Garcíamarimark77No ratings yet

- Parameter Critical Dimension: Apr/21 May/21 Jun/21 Jul/21 Aug/21 Sep/21 Oct/21 Nov/21 Dec/21 Jan/22 Feb/22 Mar/22Document2 pagesParameter Critical Dimension: Apr/21 May/21 Jun/21 Jul/21 Aug/21 Sep/21 Oct/21 Nov/21 Dec/21 Jan/22 Feb/22 Mar/22Prakash kumarTripathiNo ratings yet

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VM100% (1)

- Jaisalmer: Case StudyDocument27 pagesJaisalmer: Case Studyhudco kaamNo ratings yet

- QT1-0-C-UZR-01-00027 - 2 - Trestle Pier Drainage Plan & SectionDocument1 pageQT1-0-C-UZR-01-00027 - 2 - Trestle Pier Drainage Plan & SectionĐỨC ĐOÀN NGỌCNo ratings yet

- MAH Sahu: Modular Air Handling UnitsDocument28 pagesMAH Sahu: Modular Air Handling UnitsAhmad SalahNo ratings yet

- Drive Way 5800 Wide: DN From Ground FloorDocument1 pageDrive Way 5800 Wide: DN From Ground FloorEram HashmiNo ratings yet

- PWT Residential User Guide 2021-10-13Document24 pagesPWT Residential User Guide 2021-10-13Pradeep Kumar TKNo ratings yet

- PLC3PS8221 & 8229 Rev.01Document7 pagesPLC3PS8221 & 8229 Rev.01isan.structural TjsvgalavanNo ratings yet

- DMW 3305 30116 1 3305 602 - Is00Document1 pageDMW 3305 30116 1 3305 602 - Is00nuramirah2023No ratings yet