Professional Documents

Culture Documents

Electrical Isolation

Uploaded by

ABDUL GHAFOORCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Isolation

Uploaded by

ABDUL GHAFOORCopyright:

Available Formats

Standard Operating Procedure

Title: Page:

Electrical Isolation 1 of 8

Reference: Revision: Revision Date:

1

Table of Contents

Section Topic

1.0 Purpose 2

2.0 Scope 2

3.0 Definitions 2

4.0 Assignment and responsibilities 3

5.0 Electrical Isolation Certificates 3

6.0 Isolation Initiation Procedure 4

7.0 Procedure for Part A Electrical Isolation by Operations 4

8.0 Procedure for Part B Electrical Isolation by Electrical Authority

and Issuing Authority 5

9.0 Responsibility of Performing Authority 6

10.0 Procedure for Amendment to Isolation 6

11.0 Close Out 7

12.0 Exceptions 7

13.0 Revision Record and Approval Log 8

14.0 Certificates 8

Appendix 1: Electrical Isolation Certificate Part A 8

Appendix 2: Electrical Isolation Certificate Part B 8

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 2 of 8

Reference: Revision: Revision Date:

1

1.0 Purpose

Establish the minimum procedures necessary to provide personnel safety

while performing maintenance on electrically powered equipment and to

prevent unexpected release of electrical energy or operation of equipment.

Ensure all electrical energy sources are isolated prior to beginning work.

Ensure effective control of isolation devices is maintained.

Ensure that only qualified personnel operate Medium voltage equipment.

The Electrical Isolation SOP shall be implemented in conjunction with

applicable standards, Permits and existing procedures for equipment

shutdown, purging, blinding etc.

2.0 Scope

Electrical isolation and de-isolation for Margham, GCS, Jebel Ali Terminal,

LNG Jetty and Pipeline installations.

3.0 Definitions

Issuing Authority refers to the Operations Supervisor and Superintendent

or their immediate designates.

Electrical Authority refers to an authorized plant electrician (not a

contractor).

Operator refers to the plant Operator / Controller unless otherwise stated.

Performing Authority refers to the personnel taking PTW for work on

electrically isolated equipment.

Isolated refers to a condition of being electrically separated from the

Electrical Source.

Lockout/Tagout (LOTO) Installation of lock(s) and tag(s) on the Electrical

isolating device to ensure that the equipment(s) they isolate or control,

cannot be operated until the lock(s) and tag(s) are removed.

Tag refers to warning device affixed to isolating device.

De-isolated refers to restoration of Electrical power

Medium Voltage ( M.V) refers to voltages above 600 volts up to and

including 11kV

Breaker rackout refers to positioning the Breaker in its enclosure cubicle

from power connected position to the power disconnected position.

AC refers to frequency based alternating current/ voltage power.

DC refers to zero frequency current flow in one direction.

4.0 Assignment and responsibilities

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 3 of 8

Reference: Revision: Revision Date:

1

The Engineers/Supervisors/Managers are responsible for

Implementation of this procedure in their area of responsibility.

Ensuring staff conformance to the requirements of this procedure.

The Operations and Electrical Authority are responsible for complying with the

requirements of this procedure and ensure they are not placing themselves or

others at risk or injury.

5.0 Electrical Isolation Certificates

DUSUP has 2 types of Electrical isolation Certificates: Part A and Part B.

(Refer Appendix 1 and 2)

5.1 Electrical Isolation Certificate Part A is to be used for isolation of :

a) AC power up to a maximum of 415 volt.

b) 3.3kV power at Motor Starter Cubicles.

c) DC circuit up to a maximum of 120v (includes DC back up Lube

Oil pump motor starters).

Part A isolation shall be performed by Operations only if a ‘Simple

Isolation’ is required for Process Equipment only, in the form of the

electrical breaker/switch being placed into the off/opened position,

locked off and tagged externally without opening the power cubicle.

Notes:

Any other electrical isolations for Margham or Jebel Ali terminal

e.g. panel feeder to be completed by Electrical Authority -

Certificate Part B

For GCS only – the Electrical Authority for the GCS shall

perform Low Voltage isolations required by Electrical Isolation

Certificate Part A.

5.2 Electrical Isolation Certificate Part B is to be used for isolation of :

a) AC circuit up to maximum of 415 volt requiring electrical

disconnection or removal of power fuses or racking out of

Breaker.

b) 11 kV Breaker/Switch isolation.

c) 3.3kV Circuit breaker requiring rack out or fuse disconnections.

d) 120v/230v Direct Current (DC) circuit requiring electrical

disconnection or removal of fuses. ( 230V DC for UPS Battery

Banks )

Part B isolation will be completed by Issuing Authority and Electrical

Authority.

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 4 of 8

Reference: Revision: Revision Date:

1

The Electrical Isolation Certificate can be valid for more than one

permit. This allows a piece of equipment to have different jobs and

Performing Authorities all protected by the same Electrical Isolation

Certificate. All Permit numbers must be quoted on the original Electrical

Isolation Certificate.

If any of the jobs are not completed by the end of the workday and are to

be carried over into the next day, the Electrical Isolation Certificate will

remain valid and be posted on the Permit Board and logged in the

Supervisor's log.

The Shift Supervisor responsible for the electrical work being carred out on

his shift shall validate the Electrical Isolation Certificate.

6.0 Isolation Initiation Procedure

A Hot or Cold Work Permit may be initiated ( but not issued ) prior to any

action being taken to electrically isolate by lock-out and tagging of

switches, circuit breakers etc. However there is no separate Work Permit

issued for Electrical Isolation, the Electrical Isolation Certificate Part-A or

Part-B itself serves as the Work Permit.

The Issuing Authority will ensure that the Electrical Isolation is appropriate

for the work to be performed and initiate the isolation by completing

Sections 1, 2 and appropriate details of Section 3 of the Electrical

Isolation Certificate Part A or Part B (attached).

7.0 Procedure for Part A Electrical Isolation by Operations

The Issuing Authority will authorize the Operator to perform the

requested isolation for Process Equipment only.

The Operator, or the Electrical Authority at GCS, will electrically isolate

the equipment, lockout/tagout with a hasp and suitably numbered

Operations Padlock and attach a "DANGER - DO NOT OPERATE" tag to

the hasp with his Name, Date and Isolation Certificate Number.

For Process Isolated Equipment, as a further precaution to confirm the

equipment is not starting:

- The Operator, or the Electrical Authority at GCS, in the presence of

the technican requesting the work will attempt to start the equipment

at the local Start/Stop station.

- The local STOP button shall be activated. ‘Locked-off’ (where

applicable) and Tagged ‘Do Not Operate’ along with his Name, Date

and Isolation Certificate Number.

Records the details of isolation performed in Section 3 of Electrical

Isolation Certificate.

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 5 of 8

Reference: Revision: Revision Date:

1

The Issuing Authority will verify and certify (Section 4) completion of

Electrical isolation.

The Issuing Authority will ensure:

a) Details of isolation are recorded in the Isolation Log book (‘Lock

Register’ at Margham) located in the Control Room.

b) Post the Electrical Isolation Certificate on the Permit Board.

Prior to the issue of a Permit to Work, ALL Performing Authorities shall

attach their own Isolation locks at the point of Isolation.

The Issuing Authority shall confirm the Performing Authority has installed

their own Isolation lock.

Permit to Work numbers shall be entered in Section 5 of the Isolation

Certificate.

8.0 Procedure for Part B Electrical Isolation by Electrical

Authority and Issuing Authority

The Issuing Authority will request assistance from Electrical Authority

to perform the Electrical isolation.

The Issuing Authority will arrange an Operator to Lockout /Tag out the

isolated Equipment with a hasp and suitably numbered Operations

Padlock and attach a "DANGER - DO NOT OPERATE" tag to the hasp

with his Name, Date and Isolation Certificate Number.

The Electrical Authority shall perform the Electrical isolation, verify

isolation integrity and confirm requested isolated circuit is de-energized

and dead. The Electrical Authority will record details of isolation

performed including disconnections, power fuses removed or Grounding

done in Section 3 of the Electrical Isolation Certificate and will also certify

the isolation verification (Section 4).

The Issuing Authority will verify and certify (Section 4) completion of

Electrical isolation.

The Electrical Authority shall attach his own Isolation lock to this isolation

only if working as a Performing Authority on equipment related to this

isolation.

The Issuing Authority will ensure details of isolation are recorded in the

isolation Log book (‘Lock Register’ at Margham) located in the Control

Room and post the Electrical Isolation Certificate on the Permit Board.

For every permit issued on the electrically isolated Equipment the Issuing

Authority shall confirm the Performing Authority has put their own

Isolation lock and the details of the Work permit shall be entered in

Section 5 of the Isolation Certificate.

9.0 Responsibility of Performing Authority

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 6 of 8

Reference: Revision: Revision Date:

1

The Performing Authority (before start of work) shall:

Attach a numbered padlock to the Operations hasp, locking out

equipment.

Obtain authorized, signed Permit to start work from the Operations

Department together with copy of the Electrical Isolation Certificate Part A

or Part B.

The Performing Authority on completion or suspension of work or at end of

shift shall remove Performing Authority padlock from the Electrical isolation.

Performing Authority will then close out the work permit clearly indicating the

completed or uncompleted status of the job and return this to the Control

Room. Only the Performing Authorities originally attaching the lock and tag is

(are) authorized to remove the lock and tag

10.0 Procedure for Amendment to Isolation

A Cold or Hot Work Permit is issued for the test work.

All related Work Permits are suspended for the period of the test.

The issuing Authority will complete the "Sanction to Test" section of the

Electrical Isolation Certificate.

The Operator or Electrical Authority de-isolates as required and records

the change in the Amendment to Isolation section of the Electrical

Isolation Certificate.

After the tests are complete, the isolations are again completed and the

change recorded on the Amendment to isolation section of the Certificate

before the related Work Permits are re-validated.

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 7 of 8

Reference: Revision: Revision Date:

1

11.0 Close Out

The Issuing Authority will ensure all associated work is complete, permits

are closed, signed off and equipment is safe to be energized. Issuing

Authority will then complete the de-isolation request section 6 of the

Electrical Isolation Certificate and arrange the removal of the final

Operation’s padlock hasp and tag before the equipment is re-energized.

For Electrical isolation Part A the Operator, or Electrical Authority at GCS,

will restore power to the process equipment and sign Section 3 of the

Electrical Isolation Certificate Part A as de-isolated.

For Electrical isolation Part B the Electrical Authority will restore power to

the equipment and will sign the Section 3 and Section 7 of the Electrical

Isolation certificate Part B as de-isolated.

The Issuing Authority will verify the de-isolation and sign section 7, De-

isolation verification of the Electrical Isolation Certificate Part A or Part B.

The Issuing Authority will approve the de-isolation verification of the

Isolation Certificate and sign off the entry in the Isolation Log Book (Lock

Register at Margham) as de-isolated.

12.0 Exceptions

For repairs to Lighting and Air-conditioning units, requiring repeated

isolation and deisolation for testing, the Electrical Authority can be

permitted to isolate and deisolate the Circuit with their own single lock

and with isolation approval of the Issuing Authority. Electrical Authority

will be fully responsible to ensure and maintain safe working conditions

on the job.

The Issuing Authority is permitted to isolate the Equipment under unit

shutdown or Plant shutdown conditions as a preparation for maintenance

or operational activities using an isolation Certificate without a Permit to

Work.

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

Standard Operating Procedure

Title: Page:

Electrical Isolation 8 of 8

Reference: Revision: Revision Date:

1

13.0 Revision Record and Approval Log

At the periodic review or for entire plan revisions assign a new revision

number and date. For minor wording or paragraph revisions make the

change in blue font and note the date at the end of the SOP. Incorporate the

changes at the next periodic review.

Paper Copies are Uncontrolled. 522964831.docx

This copy valid only at time of printing.

You might also like

- Homework Forcible Entry: Section A: Key TermDocument13 pagesHomework Forcible Entry: Section A: Key TermJoey Kirkland100% (2)

- 5 Why Incident Investigation ReportDocument4 pages5 Why Incident Investigation ReportShelley BattenNo ratings yet

- VV016036E User Manual CataRhex Easy VC820100CEDocument20 pagesVV016036E User Manual CataRhex Easy VC820100CEMuhammad Khizar100% (2)

- 9 Training PPT For Safety Standard On Positive IsolationDocument42 pages9 Training PPT For Safety Standard On Positive IsolationParth Patel100% (1)

- Control of Hazardous EnergyDocument31 pagesControl of Hazardous EnergyJennifer Quino100% (1)

- SDS Freezetone Degreaser Purple Lightning ENG 2020Document7 pagesSDS Freezetone Degreaser Purple Lightning ENG 2020Darwin Turcios100% (1)

- T370 2 PDFDocument4 pagesT370 2 PDFwilmar_tovar_1100% (1)

- UW Lockout Tagout Program: Controlling Hazardous EnergyDocument12 pagesUW Lockout Tagout Program: Controlling Hazardous EnergyVictorNo ratings yet

- Electrical Isolation Procedure for South Pars Gas FieldDocument12 pagesElectrical Isolation Procedure for South Pars Gas FieldJahel Looti100% (1)

- NFPA 70E Sample Lockout-Tagout ProgramDocument4 pagesNFPA 70E Sample Lockout-Tagout ProgramJesus MolinaNo ratings yet

- Arc FlashDocument41 pagesArc FlashSatya PrabhatNo ratings yet

- Plant Isolation, Safety Tag and Lockout ProceduresDocument8 pagesPlant Isolation, Safety Tag and Lockout ProceduresiuiuiooiuNo ratings yet

- Electrical Safe Work PracticeDocument138 pagesElectrical Safe Work PracticeIjaz HussainNo ratings yet

- Isolation Permit SafetyDocument2 pagesIsolation Permit SafetyMohammed KadhimNo ratings yet

- 5.2 - Isolation of Energy SourcesDocument16 pages5.2 - Isolation of Energy SourcesarunNo ratings yet

- LOTO - PSM Week 2019Document24 pagesLOTO - PSM Week 2019rizwanNo ratings yet

- 2014 Energized Electrical Work Permit - ByU-IdahoDocument2 pages2014 Energized Electrical Work Permit - ByU-Idahocarrot123456No ratings yet

- Isolation and Lockout - IEDocument25 pagesIsolation and Lockout - IEyuwantoniNo ratings yet

- Hip Plan - Hvac WorkDocument30 pagesHip Plan - Hvac WorksrisetNo ratings yet

- Safe Work Permit 1Document33 pagesSafe Work Permit 1Vikas SinghNo ratings yet

- Isolation Certificate DetailsDocument2 pagesIsolation Certificate DetailsAndrey Dariyenko100% (2)

- Lockout Tagout1Document10 pagesLockout Tagout1Jafar KhanNo ratings yet

- LOTO Policy and ProceduresDocument11 pagesLOTO Policy and ProcedurestintucinbNo ratings yet

- Lock Out Tag Out Procedure For - : TitleDocument12 pagesLock Out Tag Out Procedure For - : TitleerwinNo ratings yet

- Isolation PlantsDocument20 pagesIsolation Plantssuzan astyNo ratings yet

- Power Transformer Installation, Commissioning and Maintenance GuideDocument87 pagesPower Transformer Installation, Commissioning and Maintenance Guideramkumartanwar100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- SG11 Working Safely With Electricity Jun 09Document20 pagesSG11 Working Safely With Electricity Jun 09Anonymous iI88LtNo ratings yet

- LOTO StepsDocument1 pageLOTO StepsaravindappiNo ratings yet

- HSE-OCP-042 SRL - Access Control ProcedureDocument5 pagesHSE-OCP-042 SRL - Access Control ProcedureibrahimNo ratings yet

- Positive Isolation StandardDocument21 pagesPositive Isolation Standardmadhulika100% (2)

- Fire Prevention and Protection Plan-2Document22 pagesFire Prevention and Protection Plan-2Ashok sNo ratings yet

- Total Productive MaintenanceDocument31 pagesTotal Productive MaintenanceNo HopeNo ratings yet

- Standard Operating Procedure - COVID 19 Transport Infrastructure - May 4 - DraftDocument27 pagesStandard Operating Procedure - COVID 19 Transport Infrastructure - May 4 - DraftChandra Kumar100% (1)

- StandardOperating Procedure - Diesel Generator - V01-26082010Document6 pagesStandardOperating Procedure - Diesel Generator - V01-26082010Karthik MandyaNo ratings yet

- CEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTDocument6 pagesCEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTtanaNo ratings yet

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDocument25 pagesProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianNo ratings yet

- 03 DG Checklist DailyDocument1 page03 DG Checklist Dailyjohn rajNo ratings yet

- Scissor Lift - HseDocument4 pagesScissor Lift - HserassdriverNo ratings yet

- Electrical Isolation - De-Isolation PermitsDocument11 pagesElectrical Isolation - De-Isolation PermitsMuneeb Ur RehmanNo ratings yet

- Flagman TrainingDocument58 pagesFlagman TrainingIndermohan MehtaNo ratings yet

- Electrical Safety Hazards and PreventionDocument38 pagesElectrical Safety Hazards and PreventionYvonne TohNo ratings yet

- LOTO StandardsDocument13 pagesLOTO Standardshanabanana_yap100% (1)

- OSHAD-SF - TG - New and Expectant Mothers - A Guide For Employers - V3.1 EnglishDocument30 pagesOSHAD-SF - TG - New and Expectant Mothers - A Guide For Employers - V3.1 EnglishNiel Brian VillarazoNo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- Job Safety Analysis for Caustic and Sulfuric Acid UnloadingDocument2 pagesJob Safety Analysis for Caustic and Sulfuric Acid UnloadingifoodNo ratings yet

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Document255 pagesPDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNo ratings yet

- Hse Five Steps To Risk AssessmentDocument2 pagesHse Five Steps To Risk AssessmentNithish ShettyNo ratings yet

- Lockout Tagout GuideDocument63 pagesLockout Tagout GuideEdmund Yoong100% (1)

- Method Statement For UPSDocument12 pagesMethod Statement For UPSelbaraniNo ratings yet

- Lock Out Tag OutDocument13 pagesLock Out Tag OutsexyrustyNo ratings yet

- LOTO ProcedureDocument2 pagesLOTO ProcedureRitesh Dev MaityNo ratings yet

- Working Safe With ElectricityDocument68 pagesWorking Safe With ElectricityocernnNo ratings yet

- NA-5 Automatic Welding Systems: SVM131-ADocument152 pagesNA-5 Automatic Welding Systems: SVM131-AmaxNo ratings yet

- Procedure Safe Access To SubstationDocument14 pagesProcedure Safe Access To SubstationMohsin YasinNo ratings yet

- Electrical Safety Guidelines AZSPU-HSSE-DOC-00288-2Document44 pagesElectrical Safety Guidelines AZSPU-HSSE-DOC-00288-2El Khan100% (1)

- Energy Isolation: MS&L ProcedureDocument29 pagesEnergy Isolation: MS&L Procedureelias mwiineNo ratings yet

- Lockout Tagout TRNG GuideDocument7 pagesLockout Tagout TRNG GuideSyed Mujtaba Ali Bukhari100% (1)

- Understanding Oil and Gas HSE Management (37Document34 pagesUnderstanding Oil and Gas HSE Management (37Madhur ChopraNo ratings yet

- Hazardous Energy Control Procedure: Lockout/Tagout SheetDocument3 pagesHazardous Energy Control Procedure: Lockout/Tagout SheetPaul HymanNo ratings yet

- 500 KVA Generator Semi-AnnualDocument2 pages500 KVA Generator Semi-AnnualABDUL GHAFOORNo ratings yet

- Pt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsDocument1 pagePt100-Temperature-Relay Type TR250: Digital, 3 Sensors, 3 LimitsABDUL GHAFOORNo ratings yet

- Battery Charger or Battireis PMDocument4 pagesBattery Charger or Battireis PMABDUL GHAFOORNo ratings yet

- Governor and ActuatorDocument36 pagesGovernor and ActuatorPonraj Govindarajan100% (1)

- Neutral Grounding High VoltageDocument2 pagesNeutral Grounding High VoltageABDUL GHAFOORNo ratings yet

- Job Description: Job Purpose: Key HSE ResponsibilitiesDocument1 pageJob Description: Job Purpose: Key HSE ResponsibilitiesABDUL GHAFOORNo ratings yet

- Electrical LV Panelboards (Annual)Document3 pagesElectrical LV Panelboards (Annual)ABDUL GHAFOORNo ratings yet

- Industrial Electric HeatersDocument12 pagesIndustrial Electric Heatersmayukhguha88No ratings yet

- Quick QuoteDocument1 pageQuick QuoteABDUL GHAFOORNo ratings yet

- Compact SCP: Installation & MaintenanceDocument12 pagesCompact SCP: Installation & MaintenanceABDUL GHAFOORNo ratings yet

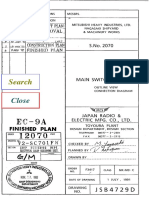

- EC-9A Main SwitchboardDocument130 pagesEC-9A Main SwitchboardABDUL GHAFOORNo ratings yet

- TemPower ACBsDocument56 pagesTemPower ACBsABDUL GHAFOORNo ratings yet

- Digest SchaniderDocument56 pagesDigest SchaniderSaka AdityaNo ratings yet

- Masterpact NT12 H1 User ManualDocument56 pagesMasterpact NT12 H1 User ManualSlaxNo ratings yet

- LVPED208001EN (Web) PDFDocument296 pagesLVPED208001EN (Web) PDFsupriNo ratings yet

- Installation: (High Resolution Adjustable Micro Distance)Document1 pageInstallation: (High Resolution Adjustable Micro Distance)ABDUL GHAFOORNo ratings yet

- Zelio Timer Relays - RE22R2QEMRDocument6 pagesZelio Timer Relays - RE22R2QEMRABDUL GHAFOORNo ratings yet

- Shnieder Electric PDFDocument616 pagesShnieder Electric PDFABDUL GHAFOORNo ratings yet

- Schneider Masterpact NT NW CatalogueDocument172 pagesSchneider Masterpact NT NW Cataloguel1f3b00kNo ratings yet

- Compact SCP: Plate Mounted Axial Flow FanDocument28 pagesCompact SCP: Plate Mounted Axial Flow FanABDUL GHAFOORNo ratings yet

- NSX Catalogue 2008Document256 pagesNSX Catalogue 2008ABDUL GHAFOORNo ratings yet

- Tesys D Green: Catalogue 2017Document48 pagesTesys D Green: Catalogue 2017SavaKrsticNo ratings yet

- Scope of Work MV Vishva VijetaDocument1 pageScope of Work MV Vishva VijetaABDUL GHAFOORNo ratings yet

- Risk Assessment: Client VesselDocument3 pagesRisk Assessment: Client VesselABDUL GHAFOORNo ratings yet

- Lvped208008en PDFDocument184 pagesLvped208008en PDFasmir_aganovic8119No ratings yet

- METHOD Statment MV VISHVA VIJETADocument1 pageMETHOD Statment MV VISHVA VIJETAABDUL GHAFOORNo ratings yet

- Novel Cornavirus - Self Reporting Form For Travelers Arriving From 2019-Ncov Affected CountriesDocument1 pageNovel Cornavirus - Self Reporting Form For Travelers Arriving From 2019-Ncov Affected CountriesManik JainNo ratings yet

- NEWAGE STAMFORD AvK Parts Manual A053J574 - I18 - 202006Document152 pagesNEWAGE STAMFORD AvK Parts Manual A053J574 - I18 - 202006ABDUL GHAFOOR100% (1)

- Intelligent Electromagnetic Flowmeter: Working PrincipleDocument20 pagesIntelligent Electromagnetic Flowmeter: Working PrincipleABDUL GHAFOORNo ratings yet

- Course: Manufacturing Science Lecture No.: 15 Arc Welding Power SourceDocument10 pagesCourse: Manufacturing Science Lecture No.: 15 Arc Welding Power SourcezombieNo ratings yet

- PHQ250 Jackleg Parts and Service ManualDocument41 pagesPHQ250 Jackleg Parts and Service ManualCSI_MIAMINo ratings yet

- Susol RMU - E - 180702Document28 pagesSusol RMU - E - 180702Sandeep Kr Arya0% (1)

- Transmission Removal & Installation - Metro & Firefly (Canadian)Document2 pagesTransmission Removal & Installation - Metro & Firefly (Canadian)Jose PichinteNo ratings yet

- Diluter operation guide for GX-8000 coal carrier gas detectorDocument2 pagesDiluter operation guide for GX-8000 coal carrier gas detectorpcatruongNo ratings yet

- ANT AMB4520R0 1433 DatasheetDocument2 pagesANT AMB4520R0 1433 DatasheetDeiz Sovie100% (1)

- Gear DesignDocument40 pagesGear DesignAshenafi KenaNo ratings yet

- Tabela de Códigos OBD-2Document4 pagesTabela de Códigos OBD-2RicardoNo ratings yet

- Specific Safety Rules Safety Warnings For Drill: 4) Power Tool Use and CareDocument7 pagesSpecific Safety Rules Safety Warnings For Drill: 4) Power Tool Use and CareAlif Rahmat FebriantoNo ratings yet

- Demo 8Document22 pagesDemo 8Kushal NNo ratings yet

- Major Aspects of Security & BarriersDocument3 pagesMajor Aspects of Security & BarriersgraciaNo ratings yet

- FH v1 PDFDocument114 pagesFH v1 PDFDan BirkenheadNo ratings yet

- ETG9 - Electrical Safety at WorkDocument4 pagesETG9 - Electrical Safety at WorkRahul RamachandranNo ratings yet

- 74LS244Document5 pages74LS244marcelloNo ratings yet

- Masurare Grosime Vopsea 1 - Fisa-tehnica-Extech-CG204Document1 pageMasurare Grosime Vopsea 1 - Fisa-tehnica-Extech-CG204RizzoRo1No ratings yet

- PGm304, PGm365-1 sGm304, sGm365, sGm466Document2 pagesPGm304, PGm365-1 sGm304, sGm365, sGm466MtHdJimNo ratings yet

- Shaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherDocument2 pagesShaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherBrad BorgesNo ratings yet

- Leon MK1 Cruise Control Guide - Pic Heavy - SEAT CupraDocument37 pagesLeon MK1 Cruise Control Guide - Pic Heavy - SEAT CupraProgramkoNo ratings yet

- BP 51defenderDocument4 pagesBP 51defenderMarianus Antimus BukuNo ratings yet

- Operator'S Manual: Ref - No. VOE21B1003320 English CSTDocument256 pagesOperator'S Manual: Ref - No. VOE21B1003320 English CSTCATALOGOS 83MNo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual PSDocument30 pages2003 Nissan Altima 2.5 Serivce Manual PSAndy DellingerNo ratings yet

- Basic Carburettor Circuits in Modern Carburettor: Float CircuitDocument38 pagesBasic Carburettor Circuits in Modern Carburettor: Float Circuitgaurav_juneja_4No ratings yet

- RISC-V Core RISC-V CoreDocument3 pagesRISC-V Core RISC-V CoreRajini KasalaNo ratings yet

- Lec# 8 The Addressing Modes of 8085 MicroprocessorDocument20 pagesLec# 8 The Addressing Modes of 8085 MicroprocessorSalva KhanNo ratings yet

- April 2016 - Naarva S23 Length Measuring and Automatic Drive 2016Document26 pagesApril 2016 - Naarva S23 Length Measuring and Automatic Drive 2016notitle91No ratings yet

- L32W831 L37W8311Document97 pagesL32W831 L37W8311Litman Bocanegra anguloNo ratings yet

- Ericsson Universal Cable EngDocument1 pageEricsson Universal Cable EngMuhammad Afrizal HidayatNo ratings yet