Professional Documents

Culture Documents

Enhancing Production of Bioisoprene Using Hybrid MVA Pathway and Isoprene Synthase in E ColiPLoS ONE

Uploaded by

Estefania GrisalesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enhancing Production of Bioisoprene Using Hybrid MVA Pathway and Isoprene Synthase in E ColiPLoS ONE

Uploaded by

Estefania GrisalesCopyright:

Available Formats

Enhancing Production of Bio-Isoprene Using Hybrid MVA

Pathway and Isoprene Synthase in E. coli

Jianming Yang1, Mo Xian1*, Sizheng Su2, Guang Zhao1, Qingjuan Nie3, Xinglin Jiang1, Yanning Zheng1,

Wei Liu1

1 Biomaterials Center, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences, Qingdao, China, 2 Department of Biochemistry, Beijing

Risun Chemical Technologies Institute, China Risun Coal Chemicals Group Limited, Beijing, China, 3 College English Office, Foreign Languages School, Qingdao

Agricultural University, Qingdao, China

Abstract

The depleting petroleum reserve, increasingly severe energy crisis, and global climate change are reigniting enthusiasm for

seeking sustainable technologies to replace petroleum as a source of fuel and chemicals. In this paper, the efficiency of the

MVA pathway on isoprene production has been improved as follows: firstly, in order to increase MVA production, the source

of the ‘‘upper pathway’’ which contains HMG-CoA synthase, acetyl-CoA acetyltransferase and HMG-CoA reductase to covert

acetyl-CoA into MVA has been changed from Saccharomyces cerevisiae to Enterococcus faecalis; secondly, to further enhance

the production of MVA and isoprene, a alanine 110 of the mvaS gene has been mutated to a glycine. The final genetic strain

YJM25 containing the optimized MVA pathway and isoprene synthase from Populus alba can accumulate isoprene up to

6.3 g/L after 40 h of fed-batch cultivation.

Citation: Yang J, Xian M, Su S, Zhao G, Nie Q, et al. (2012) Enhancing Production of Bio-Isoprene Using Hybrid MVA Pathway and Isoprene Synthase in E. coli. PLoS

ONE 7(4): e33509. doi:10.1371/journal.pone.0033509

Editor: Spencer J. Williams, University of Melbourne, Australia

Received December 5, 2011; Accepted February 15, 2012; Published April 27, 2012

Copyright: ß 2012 Yang et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits

unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Funding: No funding has supported the work.

Competing Interests: Sizheng Su is currently employed by China Risun Coal Chemicals Group Limited. There are no other relevant declarations relating to

employment, consultancy, patents, products in development or marketed products for Sizheng Su or any other authors. This does not alter the authors’

adherence to all the PLoS ONE policies on sharing data and materials.

* E-mail: xianmo@qibebt.ac.cn

Introduction archaebacteria, and cytosols of higher plants, while the MEP

pathway is used by many eubacteria, green algae, and chloroplasts

Isoprene (2-methyl-1,3-butadiene) was firstly discovered as a cell of higher plant [14,15]. MVA pathway has been studied

metabolite in the mid-1950s by Sanadze.[1,2]. It functions as a extensively for producing isoprenoids. The introduction of

thermoprotectant of plant membranes or as an antioxidant [3,4], heterologous MVA pathway genes into E. coli has been reported

or may have a signaling function, altering the flowering time in to improve the productivity of carotenoids or sesquiterpenes that

some plants [5]. As an important platform chemical, isoprene has are synthesized from DMAPP[16,17,18,19,20,21,22].

been used in industrial production of synthetic rubber for tires and Although MVA pathway has been studied comprehensively, the

coatings [6] or aviation fuel [7]. methylerythritol phosphate (MEP) pathway was merely discovered

Isoprene is the progenitor of the isoprenoid family of in the early 1990s by labeling experiments in bacteria and

compounds[8]. Many commercially relevant isoprenoids exist in plants[23,24], and till 2001 the genes of whole MEP pathway has

nature in small quantity and the yield produced from their natural been completely characterized [25]. This biosynthetic pathway,

organisms remains rather low. The depletion of fossil sources and made up of seven enzymatic steps, begins with the condensation of

the structural complexity of isoprenoids make it difficult or costly pyruvate and glyceraldehyde-3-phosphate to form 1-deoxy-D-

to produce isoprenoids by means of chemical synthesis. Isoprene is xylulose 5-phosphate (DXP) and ends with the formation of the

no exception since it is produced entirely from petrochemical isoprenoid precursors isopentenyl diphosphate (IPP) and dimethy-

sources through chemical synthesis method [9,10,11]. lallyl diphosphate (DMAPP) [26,27]. In spite of great efforts taken

Compared with conventional means, microbial synthesis of in isoprenoids production using MEP pathway[28,29,30], this

isoprene by fermentation should become a promising and approach still remains ineffective due to regulation mechanisms

attractive route mainly for environmental production, renewable present in the native host[18].

resources, sustainable development[12]. Additionally, isoprene In this paper, based on our previous experiments, the efficiency

could be collected from the gas phase of the fermentor, eliminating of the MVA pathway on isoprene production has largely been

the need for distillation. All isoprenoids are biosynthesized from improved as follows: firstly, in order to increase MVA production,

the same basic units, isopentenyl diphosphate (pyrophosphate; the source of the ‘‘upper pathway’’ which contains HMG-CoA

IPP), and its isomer dimethylallyl diphosphate (DMAPP), which synthase, acetyl-CoA acetyltransferase and HMG-CoA reductase

are synthesized from two different pathways including methyler- to covert acetyl-CoA into MVA has been changed from

ythritol 4-phosphate (MEP) pathway and mevalonate (MVA) Saccharomyces cerevisiae to Enterococcus faecalis; secondly, to further

pathway (Fig.1) [13]. MVA pathway mainly exists in eukaryotes, enhance the production of MVA and isoprene, a alanine 110 of

PLoS ONE | www.plosone.org 1 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

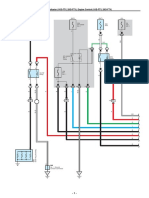

Figure 1. Production of isoprene via the MVA pathways used in this study. Gene symbols and the enzymes they encode (all genes marked

with white arrows were isolated from S. cerevisiae, the gene marked with light gray arrows derived from P. alba and all genes marked with gray

arrows were from Enterococcus faecalis). MVA pathway: ERG10, acetoacetyl-CoA thiolase; ERG13, HMG-CoA synthase; tHMGR, truncated HMG-CoA

reductase; MvaE, acetyl-CoA acetyltransferase/HMG-CoA reductase; MvaS, HMG-CoA synthase; ERG12, mevalonate kinase; ERG8, phosphomevalonate

kinase; ERG19, mevalonate pyrophosphate decarboxylase; IDI1, IPP isomerase; ispSPa, P. alba isoprene synthase was optimized to the preferred

codon usage of E. coli. Pathway intermediates. MVA pathway: A-CoA, acetyl-CoA; AA-CoA, acetoacetyl-CoA; HMG-CoA, hydroxymethylglutaryl-CoA;

Mev-P, mevalonate 5-phosphate; Mev-PP, mevalonate pyrophosphate. IPP, isopentenyl pyrophosphate; DMAPP, dimethylallyl pyrophosphate.

doi:10.1371/journal.pone.0033509.g001

the mvaS gene has been mutated to a glycine. The final genetic CATTTAAAATAG-39) and pGH/mvaE as a template. The

strain YJM25 containing the optimized MVA pathway and isolated mvaE gene fragment was excised using NcoI and BamHI,

isoprene synthase from P. alba can accumulate isoprene up to followed by insertion into the corresponding sites of pACYCDuet-

6.3 g/L after 40 h of fed-batch cultivation, which is approximately 1 or pYJM8 to create pYJM15 and pYJM18 respectively. The

a 12-fold increase in isoprene production compared with the mvaS gene was obtained by PCR using the primers mvaS-F (59-

previous data [25]. CCAGAGCTCAGGAGGTAAAAAAACATGACAATTGG G-

ATTGATAAAATTA-39) and mvaS-R (59-CAACTGCAGT-

Materials and Methods TAGTTTCGATAAGAGCGAA CG-39) and pGH/mvaS as a

template. The product of mvaS was introduced behind the mvaE

Bacterial Strains, Plasmids, and Growth Conditions gene of pYJM15 or pYJM18 after restriction with SacI and PstI to

All Strains and plasmids used in this study are listed in Table 1. create pYJM16 (Fig.2A) and pYJM20 (Fig.2C).

E. coli strains were grown in LB medium. For MVA or isoprene

production, recombinant strains were cultured in shake-flask or Construction of Plasmid for Lower Pathway of MVA

fed-batch fermentation with the medium containing glucose 20 g/ Plasmid pYJM14 was constructed on pTrcHis2B by introducing

l, K2HPO4 9.8 g/l, beef extract 5 g/l, ferric ammonium citrate the ERG8, ERG12, ERG19 and IDI1 from S. cerevisiae. The four

0.3 g/l, citric acid monohydrate 2.1 g/l, MgSO4 0.06 g/l and genes were ligated into the plasmid pTrcHis2B using the method

1 ml trace element solution which includes (NH4)6 Mo7O24?4H2O established in our lab [25,32] as follows: successive substrate

0.37 g/l, ZnSO4?7 H2O 0.29 g/l, H3BO4 2.47 g/l, Cu- fragments that designed to have long overlaps with each other

SO4?5H2O 0.25 g/l, and MnCl2?4H2O 1.58 g/l. If necessary, were mixed, denatured and annealed. Then a circle plasmid can

appropriate antibiotics were added to the culture medium at the form and be ready for transformation. The plasmid containing

following concentration: ampicillin (Amp, 100 mg/ml), kanamycin four genes (ERG12, ERG8, ERG19 and IDI1) was named pYJM14.

(Kan, 50 mg/ml), and chloramphenicol (Cm, 34 mg/ml). The correct insertions of these genes into vectors were confirmed

by PCR, restriction digestion and subsequent sequencing.

Plasmid Construction

Standard DNA manipulations were carried out as previously Mutation of mvaS Gene from Enterococcus Faecalis

described by Sambrook et al. [31]. Polymerase chain reaction The mutation PCR procedure was performed according to the

(PCR) was performed using Pfu DNA polymerase (TaKaRa, instruction of Fast Mutagenesis System purchased from TransGen

Dalian, China) according to the manufacturer’s instruction. Biotech (Beijing, China). Mutagenesis mixtures contained

106EasyPfu polymerase buffer 2.5 ml, 200 mM dNTPs, 1 ng/ul

Construction of Plasmid for Upper pathway of MVA template, 500 nM each primer, and 1 ml EasyPfu DNA polymer-

The mvaS (HMG-CoA synthase, GenBank No. AAG02439) and ase. The mutated mvaS gene as described by[33] (mvaSMT, A110G)

mvaE (acetyl-CoA acetyltransferase/HMG-CoA reductase, Gen- was obtained by PCR using the primers mvaSMT2F (mutation

Bank No. AAG02438) genes from E. faecalis were chemically underlined, 59-CTCTTTCGAAATCAAGGAAGGTTGT-

synthesized by Genray Company with plasmid pGH as vector TACGGAGC-39) and mvaSMT2R (59-CTTCCTTGATTTC-

(named pGH/mvaS, pGH/mvaE). The mvaE was obtained by GAAAGAGCGAGCGAAAG-39) and pGH/mvaS as a template.

PCR using the primers mvaE-F (59-CATGCCATGGAGGAGG- The product of mvaSMT was cloned into the plasmid pYJM15 or

TAAAAAAACATGAAAACAGTAGTTATTATTGATGC-39) pYJM18 behind the mvaE gene after restriction with SacI and PstI

and mvaE-R (59-CGCGGATCCTTATTGTTTTCTTAAAT- to create pYJM17 (Fig.2B) and pYJM21 (Fig.2D) respectively. The

PLoS ONE | www.plosone.org 2 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

Table 1. Strains, plasmids and Oligonucleotide primers used in this study.

Name Relevant characteristics References

Strains

E.coli BL21(DE3) F2 ompT hsdSB (rB2mB2) gal dcm rne131 l(DE3) Invitrogen

E.coli JM109(DE3) endA1 recA1 gyrA96 thi hsdR17 (rk2 mk+) relA1 TaKaRa

supE44 D(lac-proAB) [F9 traD36

proAB+ laqIqZDM15] l(DE3)

TM

E.coli BL21star (DE3) F2 ompT hsdSB (rB2mB2) gal dcm rne131 lon l(DE3) Invitrogen

Saccharomyces cerevisiae Type strain ATCC

YJM8 E.coli BL21(DE3)/pYJM8 [1]

YJM11 E.coli BL21(DE3)/pYJM13 [1]

YJM12 E.coli BL21(DE3)/pYJM8,pYJM14 [1]

YJM13 E.coli BL21(DE3)/pYJM8, pYJM13,pYJM14 [1]

YJM16 E.coli BL21(DE3)/pYJM16 This study

YJM17 E.coli BL21(DE3)/pYJM17 This study

YJM20 E.coli BL21(DE3)/pYJM20,pYJM14 This study

YJM21 E.coli BL21(DE3)/pYJM21, pYJM14 This study

YJM22 E.coli JM109(DE3)/pYJM20,pYJM14 This study

YJM23 E.coli JM109(DE3)/pYJM21,pYJM14 This study

TM

YJM24 E.coli BL21star (DE3)/pYJM20,pYJM14 This study

TM

YJM25 E.coli BL21star (DE3)/pYJM21,pYJM14 This study

Plasmids

pACYCDuet-1 P15A (pACYC184), Cmr Novagen

TM

pCOLADuet -1 ColA origin, Kanr Novagen

pTrcHis2B pBR322 origin, Ampr Invitrogen

pYJM8 pACYCDuet-1 carrying ispSPa from Populus alba [1]

pYJM13 pCOLADuetTM-1 carrying ERG10, ERG13 and tHMGR, from Saccharomyces cerevisiae [1]

pYJM14 pTrcHis2B carrying ERG12, ERG8, ERG19 and IDI1 from Saccharomyces cerevisiae [1]

pYJM15 pACYCDuet-1 carrying mvaE from Enterococcus faecalis This study

pYJM16 pACYCDuet-1 carrying mvaE and mvaS This study

from Enterococcus faecalis

pYJM17 pACYCDuet-1 carrying mvaE and mvaSMT from Enterococcus faecalis This study

pYJM18 pACYCDuet-1 carrying mvaE from This study

Enterococcus faecalis, ispSPa from Populus alba

pYJM20 pACYCDuet-1 carrying mvaE and mvaS from Enterococcus faecalis, ispSPa from Populus alba This study

pYJM21 pACYCDuet-1 carrying mvaE and mvaSMT This study

from Enterococcus faecalis, ispSPa from Populus alba

doi:10.1371/journal.pone.0033509.t001

pYJM17 and pYJM21 were transformed into the BL21(DE3) vial and dried by vacuum distillation. The residues were re-

competent cell for expression. dissolved in 1 ml of ethyl acetate and analyzed by GC.

GC analysis was performed on an Agilent 7890A equipped with

a flame ionization detector (FID) and a HP-AL/S column

MVA Quantification by Gas Chromatography (GC) (25 m6320 mm68 mm). N2 was used as carrier gas with a linear

The mevalonate produced by the engineered strains was velocity of 1 ml/min. The column temperature profile was 75uC

quantitatively analyzed by GC-FID as described previously [34]. for 0.5 min, 25uC/min to 150uC, 15uC/min to 200uC, 30uC/min

The E. coli strain was inoculated in 50 ml fermentation medium to 250uC, and 250uC for 5 min. The product was characterized by

containing 34 mg/ml Cm resistance and incubated at 37uC and direct comparison with an authentic standard (Sigma-Aldrich,

180 rpm. When OD600 of the bacterial culture reached 0.6, the USA). The peak area was converted to MVA concentration by

culture cells were induced by IPTG at a final concentration of comparing with a standard curve plotted with a set of known

0.5 mM for 24 h. After fermentation broth was centrifuged for concentration of MVA.

10 min at 12000 rpm at room temperature, the supernatant was

adjusted to pH 2.0 with 3 M HCl and incubated at 45uC for 1 h Shake-flask Cultures

to convert mevalonate to mevalonic acid lactone. Then this Shake-flask experiments were carried out in triplicate series of

solution was saturated with Na2SO4, and extracted with ethyl 600 ml sealed shake flasks containing 50 ml fermentation medium

acetate. The ethyl acetate phase was transferred to a clean glass as described above plus 34 mg/ml Cm and 100 mg/ml Amp. E. coli

PLoS ONE | www.plosone.org 3 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

Figure 2. Plasmids used in this study.

doi:10.1371/journal.pone.0033509.g002

strains were inoculated to the culture broth and incubated in a in 1 L with glucose (20 g/L) as the primary carbon source). These

gyratory shaker incubator at 37uC and 180 rpm. When OD600 cultures were used to inoculate a 5-L fermentor (BIOSTAT Bplus

reached 0.6, IPTG was added to final concentration of 0.5 mM, MO5L, Sartorius, Germany) containing 3 L fermentation medi-

and culture was further incubated at 30uC for 24 h. Then 1 ml gas um. The temperature was controlled at 30uC; the pH was

sample from the headspace of the sealed cultures was analyzed as maintained at 7.0 via automated addition of ammonia, and

described earlier [35] using a GC (Agilent 7890A, America) Antifoam 204 was used to prohibit foam development. The

equipped with a flame ionization detector (FID) and a HP-AL/S stirring speed was first set at 400 rpm and then associated with the

column (25 m6320 mm68 mm). To identify bacterial isoprene dissolved oxygen (DO) to maintain a DO concentration of 20%

production, peak retention times and mass spectra were compared saturation. The expression of plasmid-borne exogenous gene(s) for

with that of standard. Concentrations of isoprene produced by isoprene production was initiated at an OD600 of 12 by adding

bacterial cells were calculated by converting GC peak area to mg IPTG to the final concentration of 0.5 mM and inducer was

of isoprene via a calibration curve. Isoprene standard (TCI-EP, added every 8 h. During the course of fermentation, the residual

Tokyo, Japan) of various concentrations was added to 600 ml glucose was measured using a glucose analyzer (SBA-40D, China)

fermentation medium to make a calibration curve. and maintained below 0.5 g/l by feeding solution containing

800 g/L of glucose at appropriate rates. Then isoprene accumu-

Fed-batch Fermentation lation was measured every 15 min by GC as described [35]. At the

The strain was grown overnight at 37uC in 100 ml of M9 same time, the growth of the bacterial culture was determined by

minimal media (containing K2HPO4 1 g, Na2HPO4?12H2O measuring the OD600 with a spectrophotometer (Cary 50 UV-Vis,

15.3 g, KH2PO4 3 g, NH4Cl 1 g; NaCl 0.5 g, MgSO4 0.5 mmol Varian).

PLoS ONE | www.plosone.org 4 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

Results and Discussion Evaluation of Upper Pathway of MVA from Different

Origins

Characterization of the Rate-limiting Step of MVA To eliminate the limitation of upper pathway of MVA, alteration

Pathway of the origins of the ‘‘upper pathway’’ of MVA might be a promising

In our previous work, a novel pathway for production of way. In the previous report, the mass production of mevalonate of

isoprene was established by assembling the whole MVA pathway 47 g/L was achieved by fed-batch culture of recombinant E. coli

derived from S. cerevisiae and isoprene synthase (IspS) from Populus harboring mvaE and mvaS genes of E. faecalis [36]. Yoon also

alba in the E. coli BL21(DE3) strain. The final engineered strain demonstrated that the mvaE and mvaS genes of E. faecalis were the

YJM13 harboring the MVA pathway and ispSPa gene could most efficient for mevalonate production among the top MVA

accumulate isoprene up to 2.48 mg/L and 532 mg/L under the portions used in E. coli [22]. Therefore, the engineered strain YJM16

flask and fed-batch fermentation conditions, respectively [25]. containing mvaS and mvaE gene from E. faecalis instead of ‘‘upper

However, the yield of isoprene by the engineered strain YJM13 is pathway’’ from S. cerevisiae was constructed in this study. The strain

too low to meet the demand for industrial application. YJM16 was inoculated in 50 ml fermentation medium and

The low yield of isoprene might be primarily attributed to the incubated at 37uC. When OD600 of the bacterial culture reached

existing of rate-limiting step of MVA pathway. In the previous 0.6, IPTG was added to a final concentration of 0.5 mM, and the

study, the whole MVA pathway was divided into two parts and culture was further incubated for 24 h. MVA was isolated from

studied respectively: the ‘‘upper pathway’’, which catalyzed the fermentation broth as described method. The strain YJM16

acetyl-CoA to MVA; the ‘‘lower pathway’’, which converted MVA containing the mvaS and mvaE gene from E. faecalis could accumulate

into DMAPP, and then was catalyzed by isoprene synthase into MVA up to 1.31 g/L, which was about fifty-fold in contrast to the

isoprene. strain YJM11 containing S. cerevisiae’s upper pathway (0.026 mg/L).

As for the study of the efficiency of ‘‘lower pathway’’, the plasmids Obviously, the upper pathway from E. faecalis proves to be more

pYJM14 and pYJM8 were simultaneously transformed into the E. coli effective than that from S. cerevisiae.

strain. Todetermine the extent to which isopreneproduction could be

enhanced with increased availability of MVA, different concentra- The Effect of Mutation of mvaS Gene on MVA Production

tions of MVA were added to the culture broth. The maximum The mvaS gene encodes the HMG-CoA synthase, the second

isoprene productions of 57, 118, 213 mg/L were obtained with the enzyme in the MVA pathway, which catalyzes three molecules of

addition of 2.5 mM, 5 mM and 10 mM MVA, respectively. The cell acetyl-CoA to HMG-CoA and plays a key role in isoprenoid

growth has not been influenced significantly by the MVA additions formation in the eukaryotic cytosol and in Gram-positive bacteria

(Fig. 3). The results showed that the increased isoprene productivity [37]. Steussy has reported that the overall reaction rate of the

was in proportion to the content of mevalonate added. The maximum enzyme was increased 140-fold by mutating alanine 110 of HMG-

isoprene production of 213 mg/L was obtained with 10 mM CoA synthase from E. faecalis into a glycine [33]. Hence, a

mevalonate addition under flask condition. The results implied that hypothesis would be put forward that the engineered strain with

the ‘‘lower pathway’’ was very efficient. Meanwhile, the functionality the mutated mvaS gene and mvaE from E. faecalis could further

of the heterologous ‘‘upper pathway’’ was also under test. The results enhance the MVA production.

showed that overexpression of the synthetic operon of the ‘‘upper To verify the effect of mutation of mvaS gene on MVA

pathway’’ could only give a very low yield of MVA (0.026 mg/L). production, the recombinant strains YJM17 (E. coli harboring

Based on the above-mentioned data, a conclusion could be reached mvaSMT & mvaE) and YJM16 (E. coli containing mvaS & mvaE)

that the ‘‘upper pathway’’ is the rate- limiting step of the whole MVA were cultured in fermentation medium under shake-flask

pathway. conditions. The amount of MVA accumulated in the culture

media from different recombinant strains was calculated

according to a standard curve plotted with a set of known

concentrations of MVA. MVA concentration of the strain

YJM17 reached around 3.1 g/L after being induced by 0.5 mM

IPTG for 24 h, about 2.37 times higher than that of the strain

YJM16 (1.31 g/L)(Fig. 4). The result demonstrated that A110G

mutation of mvaS gene caused an appreciable increase in MVA

production.

The Effect of Optimized Upper Pathway on Isoprene

Production

To test the function of optimized upper pathway on isoprene

production, the plasmid pYJM14 containing the lower pathway

from S. cerevisiae was transformed into the strains (E. coli

harboring mvaSMT & mvaE, mvaS & mvaE), which formed the

recombinant strains YJM21 and YJM20, respectively. Both of

the strains YJM21 and YJM20 were inoculated into the

medium under the shake-flask conditions and the cultures were

induced with 0.5 mM IPTG when the OD600 reached 0.6–0.9.

As is shown in Fig. 5, isoprene produced by the strain YJM21

Figure 3. Isoprene production of Strain YJM12. The strain was

reached 760 mg/L, which was about 1.5 fold to the control

cultured supplemented with different concentrations of mevalonate strain YJM20 (500 mg/L). The result showed that the optimized

under flask conditions. The experiment was done in triplicate. upper pathway played an important role in improving the

doi:10.1371/journal.pone.0033509.g003 isoprene production.

PLoS ONE | www.plosone.org 5 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

Table 2. Isoprene production by different E. coli strains

harboring pYJM14 and pYJM20 or pYJM14 and pYJM21 under

flask conditions.

Host Plasmids

pYJM14, pYJM14,

pYJM20 pYJM21

E.coli BL21(DE3) 502 mg/L 760 mg/L

E.coli BL21 StartTM (DE3) 788 mg/L 1091 mg/L

E.coli JM109(DE3) 32 mg/L 55 mg/L

The experiment was done in triplicate.

doi:10.1371/journal.pone.0033509.t002

Figure 4. MVA production by strains with or without mutation minimize acetic acid accumulation. As is shown in Fig. 6, isoprene

of mvaS gene. The MVA isolated from cultural broth as described in was produced in a growth associated manner in the fed-batch

‘‘MVA quantification by gas chromatography (GC)’’. The experiment was phase to reach maximum concentration of 6.3 g l21 after 40 h of

performed in triplicate. cultivation. The conversion efficiency of glucose to isoprene in the

doi:10.1371/journal.pone.0033509.g004

metabolically engineered strain has attained 7%, reaching 28% of

the theoretical limit (25.2%). The theoretical yield was calculated

Comparison of Isoprene Production in Different E. coli according to the following formula [13]:

Host Strains 1.5C6H12O6+2NADPH+6NAD+RC5H8+4CO2+6NADH+2-

To choose a most efficient host strain for isoprene production, NADP++H2O+4[H].

plasmids pYJM20 and pYJM21 were transformed into E. coli host Expressing the optimized MVA pathway and isoprene synthase

TM

strains JM109 (DE3), BL21 (DE3) and BL21 star (DE3) carrying from P. alba resulted in approximately a 12-fold increase in

plasmid pYJM14, respectively. As shown in the Table 2, BL21 isoprene production compared with our previous data achieved by

TM

star (DE3) produced more isoprene than BL21 (DE3), while the expression of the MVA pathway from S. cerevisiae and isoprene

yield of isoprene produced by JM109 (DE3) was the lowest among synthase in the same host strain.

TM

three strains. Obviously, BL21 star (DE3) was the most suitable In spite of the great progress for isoprene production made in E. coli,

host to produce isoprene. No significant difference in cell growth some problems still remained unsolved and were expected to be

was observed for all these strains. tackled before commercial production. For instance, the instability of

the recombinant strain remains to be a severe problem due to the

Fed-batch Culture of Metabolically Engineered E. coli plasmid instability which in turn restricts the industrial application to

Strains a large extent. From metabolic engineering perspective, the stability

To further confirm the effectiveness of the optimized MVA of strain can be improved by genetic manipulation of chromosome

pathway on increasing isoprene production, fed-batch cultivation integration technique [38,39]. From the fermentation process aspect,

TM

was carried out using the recombinant E. coli BL21 (DE3) strain immobilization of microbial cells may enhance the stability of

simultaneously harboring plasmids pYJM21 and pYJM14. After engineered stain during the process of production [40,41].

depletion of the glucose added initially, glucose (800 g l21) was fed

and the residual glucose was maintained below 0.5 g/l to

Figure 6. The time course of isoprene production by YJM25.

Figure 5. Comparison of isoprene production from different Isoprene accumulation (&) and cell growth (D) in YJM25, Induction was

recombinant strains. The experiment was conducted under flask carried out at an OD600 of 12. Other experiment conditions were

conditions in triplicate. described in ‘Fed-batch fermentation’.

doi:10.1371/journal.pone.0033509.g005 doi:10.1371/journal.pone.0033509.g006

PLoS ONE | www.plosone.org 6 April 2012 | Volume 7 | Issue 4 | e33509

Production of Isoprene in E. coli

Conclusions metabolically engineered strain has attained 7%, reaching 28%

In this paper, the efficiency of the MVA pathway on isoprene of the theoretical limit. These results proved to be the highest

production has largely been improved by changing the source of isoprene productivity reported so far [7,29,42].

‘‘upper pathway’’ of MVA synthesis from S. cerevisiae to E. faecalis

and mutatingTMthe mvaS gene. In the final engineered strain YJM25 Author Contributions

(E. coli BL21 (DE3)/pYJM21, pYJM14) containing the optimized Conceived and designed the experiments: JY MX. Performed the

MVA pathway and isoprene synthase, it can accumulated isoprene experiments: JY. Analyzed the data: JY SS XJ YZ. Contributed

up to 6.3 g/L after 40 h fed-batch fermentation. The conversion reagents/materials/analysis tools: JY GZ WL. Wrote the paper: JY.

efficiency of glucose to isoprene (gram to gram) in the Refined the manuscript: QN.

References

1. Sanadze G (1956) Emission of Gaseous Organic Substances from Plants. 22. Yoon SH, Lee SH, Das A, Ryu HK, Jang HJ, et al. (2009) Combinatorial

Repertuar Akademiia Nauk Gruzinskoi SSR 17: 429–433. expression of bacterial whole mevalonate pathway for the production of [beta]-

2. Sanadze G (1957) Nature of Gaseous Substances from the Robinia pseudoacacia carotene in E. coli. Journal of biotechnology 140: 218–226.

Leaves. Rep Akad Nauk GruzSSR 19: 83̈ sC86. 23. Rohmer M, Knani M, Simonin P, Sutter B, Sahm H (1993) Isoprenoid

3. Loreto F, Velikova V (2001) Isoprene produced by leaves protects the biosynthesis in bacteria: a novel pathway for the early steps leading to

photosynthetic apparatus against ozone damage, quenches ozone products, isopentenyl diphosphate. Biochemical Journal 295: 517.

and reduces lipid peroxidation of cellular membranes. Plant Physiology 127: 24. Schwarz MK (1994) Terpen-Biosynthese in Ginkgo biloba:Eine überraschende

1781. Geschichte. PhD Thesis, ETH Zürich, Switzerland.

4. Peñuelas J, Llusia J, Asensio D, Munné-Bosch S (2005) Linking isoprene with 25. Rodrı?guez-Concepción M, Boronat A (2002) Elucidation of the methylery-

plant thermotolerance, antioxidants and monoterpene emissions. Plant, Cell & thritol phosphate pathway for isoprenoid biosynthesis in bacteria and plastids. A

Environment 28: 278–286. metabolic milestone achieved through genomics. Plant Physiology 130:

5. Terry G, Stokes N, Hewitt C, Mansfield T (1995) Exposure to isoprene 1079–1089.

promotes flowering in plants. Journal of experimental botany 46: 1629. 26. Eisenreich W, Bacher A, Arigoni D, Rohdich F (2004) Biosynthesis of

isoprenoids via the non-mevalonate pathway. Cellular and Molecular Life

6. Alianell GA, Derwitsch F, Wells D, Taylor T (2010) Isoprene compositions and

Sciences 61: 1401–1426.

methods of use. US2010/0099932 A1.

27. Rodriguez-Concepcion M (2004) The MEP pathway: A new target for the

7. Lindberg P, Park S, Melis A (2010) Engineering a platform for photosynthetic

development of herbicides, antibiotics and antimalarial drugs. Current

isoprene production in cyanobacteria, using Synechocystis as the model Pharmaceutical Design 10: 2391–2400.

organism. Metabolic Engineering 12: 70–79. 28. Kim SJ, Kim MD, Choi JH, Kim SY, Ryu YW, et al. (2006) Amplification of 1-

8. Sacchettini JC, Poulter CD (1997) Creating isoprenoid diversity. Science 277: deoxy-d-xyluose 5-phosphate (DXP) synthase level increases coenzyme Q 10

1788. production in recombinant Escherichia coli. Applied Microbiology and

9. Reis T (1972) Isoprene production.2. Synthesis based on isobutylene. Chem Biotechnology 72: 982–985.

Process Eng 53: 68–71. 29. Xue JF, Ahring BK (2011) Enhancing isoprene production by genetic

10. Ushio S (1972) Extract isoprene with DMF. Chem Eng Prog 79: 82–83. modification of the DXP pathway in Bacillus subtilis. Applied and environ-

11. DiGiacomo AA, Maerker JB, Schall JW (1961) Isoprene by Dehydrogenation. mental microbiology 77: 2399–2405.

Chem Eng Prog 57: 3540. 30. Ghimire GP, Lee HC, Sohng JK (2009) Improved Squalene Production via

12. Clomburg JM, Gonzalez R (2010) Biofuel production in Escherichia coli: the Modulation of the Methylerythritol 4-Phosphate Pathway and Heterologous

role of metabolic engineering and synthetic biology. Applied microbiology and Expression of Genes from Streptomyces peucetius ATCC 27952 in Escherichia

biotechnology 86: 419–434. coli. Applied and Environmental Microbiology 75: 7291.

13. Steinbuchel A (2003) Production of rubber-like polymers by microorganisms. 31. Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual, 3rd

Current Opinion in Microbiology 6: 261–270. edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor.

14. Seemann M, Campos N, Rodriguez-Concepción M, Ibañez E, Duvold T, et al. 32. Jiang X YJ, Zhang H, Zou H, Wang C (2012) In Vitro Assembly of Multiple

(2002) Isoprenoid biosynthesis in Escherichia coli via the methylerythritol DNA Fragments Using Successive Hybridization. PLoS ONE. e30267.

phosphate pathway: enzymatic conversion of methylerythritol cyclodiphosphate doi:30210.31371/journal.pone.0030267.

into a phosphorylated derivative of (E)-2-methylbut-2-ene-1, 4-diol. Tetrahedron 33. Steussy CN, Robison AD, Tetrick AM, Knight JT, Rodwell VW, et al. (2006) A

Letters 43: 1413–1415. structural limitation on enzyme activity: the case of HMG-CoA synthase.

15. Eroglu E, Melis A (2010) Extracellular terpenoid hydrocarbon extraction and Biochemistry 45: 14407–14414.

quantitation from the green microalgae Botryococcus braunii var. Showa. 34. Pfleger BF, Pitera DJ, Newman JD, Martin VJJ, Keasling JD (2007) Microbial

Bioresource technology 101: 2359–2366. sensors for small molecules: development of a mevalonate biosensor. Metabolic

16. Anthony JR, Anthony LC, Nowroozi F, Kwon G, Newman JD, et al. (2009) Engineering 9: 30–38.

Optimization of the mevalonate-based isoprenoid biosynthetic pathway in 35. Julsing MK, Rijpkema M, Woerdenbag HJ, Quax WJ, Kayser O (2007)

Escherichia coli for production of the anti-malarial drug precursor amorpha-4, Functional analysis of genes involved in the biosynthesis of isoprene in Bacillus

11-diene. Metabolic Engineering 11: 13–19. subtilis. Applied microbiology and biotechnology 75: 1377–1384.

36. Tabata K, Hashimoto SI (2004) Production of mevalonate by a metabolically-

17. Campos N, Rodriguez-Concepcion M, Sauret-Gueto S, Gallego F, Lois L, et al.

engineered Escherichia coli. Biotechnology letters 26: 1487–1491.

(2001) Escherichia coli engineered to synthesize isopentenyl diphosphate and

37. Steussy CN, Vartia AA, Burgner JW, Sutherlin A, Rodwell VW, et al. (2005) X-

dimethylallyl diphosphate from mevalonate: a novel system for the genetic

ray crystal structures of HMG-CoA synthase from Enterococcus faecalis and a

analysis of the 2-C-methyl-d-erythritol 4-phosphate pathway for isoprenoid

complex with its second substrate/inhibitor acetoacetyl-CoA. Biochemistry 44:

biosynthesis. Biochemical Journal 353: 59.

14256–14267.

18. Martin VJJ, Pitera DJ, Withers ST, Newman JD, Keasling JD (2003) 38. Kuhlman TE, Cox EC (2010) Site-specific chromosomal integration of large

Engineering a mevalonate pathway in Escherichia coli for production of synthetic constructs. Nucleic Acids Research 38: e92.

terpenoids. Nature biotechnology 21: 796–802. 39. Chen HT, Lin MS, Hou SY (2008) Multiple-copy-gene integration on

19. Newman JD, Marshall J, Chang M, Nowroozi F, Paradise E, et al. (2006) High- chromosome of Escherichia coli for beta-galactosidase production. Korean

level production of amorpha-4, 11-diene in a two-phase partitioning bioreactor Journal of Chemical Engineering 25: 1082–1087.

of metabolically engineered Escherichia coli. Biotechnology and bioengineering 40. Chen X, Xu Z, Cen P, Wong W (2006) Enhanced plasmid stability and

95: 684–691. production of hEGF by immobilized recombinant E. coli JM101. Biochemical

20. Pitera DJ, Paddon CJ, Newman JD, Keasling JD (2007) Balancing a engineering journal 28: 215–219.

heterologous mevalonate pathway for improved isoprenoid production in 41. Kilonzo P, Margaritis A, Bergougnou M (2009) Airlift-driven fibrous-bed

Escherichia coli. Metabolic Engineering 9: 193–207. bioreactor for continuous production of glucoamylase using immobilized

21. Rodriguez-Villalon A, Perez-Gil J, Rodriguez-Concepcion M (2008) Carotenoid recombinant yeast cells. Journal of biotechnology 143: 60–68.

accumulation in bacteria with enhanced supply of isoprenoid precursors by 42. Zhao Y, Yang J, Qin B, Li Y, Sun Y, et al. (2011) Biosynthesis of isoprene in

upregulation of exogenous or endogenous pathways. Journal of biotechnology Escherichia coli via methylerythritol phosphate (MEP) pathway. Applied

135: 78–84. microbiology and biotechnology. pp 1–8.

PLoS ONE | www.plosone.org 7 April 2012 | Volume 7 | Issue 4 | e33509

You might also like

- Microbial Sensing in FermentationFrom EverandMicrobial Sensing in FermentationSatinder K. BrarNo ratings yet

- Plant Carotinoids BiochemistryDocument14 pagesPlant Carotinoids Biochemistrypaul WongNo ratings yet

- 2011 - Biosci. Biotechnol. Biochem - Enzymatic Total Synthesis of Gibberellin A4 From Acetate 3.16.48 PMDocument8 pages2011 - Biosci. Biotechnol. Biochem - Enzymatic Total Synthesis of Gibberellin A4 From Acetate 3.16.48 PMranukahewageNo ratings yet

- CurrPharmDesign2007 DXR InhibitorsDocument18 pagesCurrPharmDesign2007 DXR InhibitorsVincent GeruszNo ratings yet

- Rossoni 2015Document10 pagesRossoni 2015JPBCNo ratings yet

- BiotekDocument11 pagesBiotekMaria Bachdim RadcliffeNo ratings yet

- Metabolic Engineering of Escherichia Coli For The Biosynthesis of Alpha PineneDocument10 pagesMetabolic Engineering of Escherichia Coli For The Biosynthesis of Alpha PineneMaruf MuhammadNo ratings yet

- Improving Monoterpene Geraniol Production Through Geranyl Diphosphate Synthesis Regulation in Saccharomyces Cerevisiae PDFDocument11 pagesImproving Monoterpene Geraniol Production Through Geranyl Diphosphate Synthesis Regulation in Saccharomyces Cerevisiae PDFSilvia Juliana Sanabria UribeNo ratings yet

- Liu 2015Document9 pagesLiu 2015Aline HunoNo ratings yet

- Efficient Production of Mycosporine-Like Amino Acids, Natural Sunscreens, in YarrowiaDocument13 pagesEfficient Production of Mycosporine-Like Amino Acids, Natural Sunscreens, in YarrowiaaikimbotNo ratings yet

- Microbial Production of Biodegradable Polymers and Their Role in Cardiac Stent DevelopmentDocument11 pagesMicrobial Production of Biodegradable Polymers and Their Role in Cardiac Stent Development2begeniusNo ratings yet

- Rational Engineering of Kluyveromyces of Aromatic Products: Marxianus To Create A Chassis For The ProductionDocument19 pagesRational Engineering of Kluyveromyces of Aromatic Products: Marxianus To Create A Chassis For The ProductionsakuraNo ratings yet

- Producción de Antibióticos Mediante Mutagenesis Por UV e Ingeniería Ribosomal en BacteriasDocument11 pagesProducción de Antibióticos Mediante Mutagenesis Por UV e Ingeniería Ribosomal en BacteriasBryan Yair Gonzalez RodriguezNo ratings yet

- Engineered Saccharomyces Cerevisiae For The de Novo Biosynthesis of (?) - MentholDocument11 pagesEngineered Saccharomyces Cerevisiae For The de Novo Biosynthesis of (?) - MentholSlovodanNo ratings yet

- 1 s2.0 S2589014X19301586 MainextDocument10 pages1 s2.0 S2589014X19301586 MainextDouglas FariaNo ratings yet

- Labdanes of Natural Origin-Biological ActivitiesDocument24 pagesLabdanes of Natural Origin-Biological Activitiestheyuri@tlen.plNo ratings yet

- Producing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingDocument11 pagesProducing Malonate in Saccharomyces Cerevisiae Via The Alanine Pathwaysystems Microbiology and BiomanufacturingWendy SarmientoNo ratings yet

- tmp1611 TMPDocument11 pagestmp1611 TMPFrontiersNo ratings yet

- Yang 2018Document28 pagesYang 2018Josue Ortigoza BermudezNo ratings yet

- Ijms 22 04779Document15 pagesIjms 22 04779Sofiya -No ratings yet

- Gu 2019Document8 pagesGu 2019RamlahNo ratings yet

- Research Project: Prof. Dr. Rehab HamedDocument13 pagesResearch Project: Prof. Dr. Rehab HamedHassaninElaradyNo ratings yet

- Yarrowia Lipolytica - Art. ScienceDirect - Kuttuvan Valappil Sanja,... Ashok Pandey (2015)Document19 pagesYarrowia Lipolytica - Art. ScienceDirect - Kuttuvan Valappil Sanja,... Ashok Pandey (2015)Regi RGNo ratings yet

- ATPS2Document8 pagesATPS2Nicoly SilvaNo ratings yet

- Características Del Aceite Extraído Con Fosfatasa Recombinante LIS KATERINEDocument6 pagesCaracterísticas Del Aceite Extraído Con Fosfatasa Recombinante LIS KATERINEYury MartinezNo ratings yet

- Production of Resveratrol From Tyrosine in Metabolically Engineered Saccharomyces CerevisiaeDocument6 pagesProduction of Resveratrol From Tyrosine in Metabolically Engineered Saccharomyces CerevisiaeMaría Angélica Otálora MartínezNo ratings yet

- Metabolic Engineering of Yeast For The Production of Plant Secondary MetabolitesDocument4 pagesMetabolic Engineering of Yeast For The Production of Plant Secondary MetabolitesGung De RypNo ratings yet

- Phosphomannose Isomerase and Phosphomannomutase Gene Disruptions inDocument8 pagesPhosphomannose Isomerase and Phosphomannomutase Gene Disruptions inLuisa Fernanda Zapata OchoaNo ratings yet

- Retinoid Production Using Metabolically Engineered Escherichia Coli With A Two-Phase Culture SystemDocument12 pagesRetinoid Production Using Metabolically Engineered Escherichia Coli With A Two-Phase Culture SystemMellysaNo ratings yet

- Retinoid Production Using Metabolically Engineered Escherichia Coli With A Two-Phase Culture SystemDocument12 pagesRetinoid Production Using Metabolically Engineered Escherichia Coli With A Two-Phase Culture SystemMellysaNo ratings yet

- Nature 04640Document4 pagesNature 04640774hzz9zd8No ratings yet

- Hoffmann 2018Document52 pagesHoffmann 2018Andi DarmawanNo ratings yet

- Microbial Production of Fatty Acid Via Metabolic Engineering and Synthetic BiologyDocument18 pagesMicrobial Production of Fatty Acid Via Metabolic Engineering and Synthetic BiologyAnggaNo ratings yet

- Ncomms 1327Document9 pagesNcomms 1327Chandra ShekharNo ratings yet

- 2011 Basheer Et Al Aspergillus Awamori Lipase ProductionDocument12 pages2011 Basheer Et Al Aspergillus Awamori Lipase ProductiontigapeptindonesiaNo ratings yet

- Thermophilic Biohydrogen Production From Optimized Enzymatic Pretreatment of Palm Oil Mill Effluent Via Box-Behnken DesignDocument8 pagesThermophilic Biohydrogen Production From Optimized Enzymatic Pretreatment of Palm Oil Mill Effluent Via Box-Behnken DesignosuolaleNo ratings yet

- Jimb 0055Document11 pagesJimb 0055thiagoNo ratings yet

- Engineering Terpene Biosynthesis in StreDocument7 pagesEngineering Terpene Biosynthesis in StreANDREA VALENTINA MAYORGA LOPEZNo ratings yet

- 2019.maidana SA. Production of An Endopolygalacturonase From Wickerhanomyces AnomalusDocument7 pages2019.maidana SA. Production of An Endopolygalacturonase From Wickerhanomyces AnomalusluisbrumovskyNo ratings yet

- Carbohydrate Polymers: A B C A B A A CDocument10 pagesCarbohydrate Polymers: A B C A B A A CRaquel FernandesNo ratings yet

- Westfall 2011Document8 pagesWestfall 2011Jose VelascoNo ratings yet

- K. - Marxianus - Revised - Manuscript - (24-1-2021) - (Without - Track - Chang Es)Document35 pagesK. - Marxianus - Revised - Manuscript - (24-1-2021) - (Without - Track - Chang Es)黃優人No ratings yet

- Poly L Lysine and Poly L Diaminopropionic Acid Co Produced From Spent Mushroom Substrate Fermentation Potential Use As Food PreservativesDocument12 pagesPoly L Lysine and Poly L Diaminopropionic Acid Co Produced From Spent Mushroom Substrate Fermentation Potential Use As Food PreservativesSolgema LópezNo ratings yet

- Analysis of Zein by Matrix-Assisted Laser Desorption/Ionization Mass SpectrometryDocument6 pagesAnalysis of Zein by Matrix-Assisted Laser Desorption/Ionization Mass SpectrometrySabina BancilaNo ratings yet

- Talanta: SciencedirectDocument12 pagesTalanta: SciencedirectBianca AndreeaNo ratings yet

- A Novel Electroporation Procedure For Highly Efficient Transformation of Lipomyces StarkeyiDocument7 pagesA Novel Electroporation Procedure For Highly Efficient Transformation of Lipomyces Starkeyifilemon jaluNo ratings yet

- Andlar Et Al-2017-Journal of Chemical Technology and BiotechnologyDocument10 pagesAndlar Et Al-2017-Journal of Chemical Technology and BiotechnologyGary Kiel Palacios EspinozaNo ratings yet

- Ajikumar 2010Document6 pagesAjikumar 2010Jonathan DiasNo ratings yet

- (MB) Ortiz-Tena2016 Monosaccharides in CVDocument9 pages(MB) Ortiz-Tena2016 Monosaccharides in CVSacra PsyntergiaNo ratings yet

- Enzymatic Resolution of Diltiazem Intermediate by Serratia and Its Industrial ApplicationDocument9 pagesEnzymatic Resolution of Diltiazem Intermediate by Serratia and Its Industrial ApplicationDiky Okta Yudha PutraNo ratings yet

- Bertrand, 2016. Surface YeastDocument14 pagesBertrand, 2016. Surface YeastMarisol BravoNo ratings yet

- Differences in Hydrolytic Abilities of Two Crude Lipases From Geotrichum Candidum 4013Document13 pagesDifferences in Hydrolytic Abilities of Two Crude Lipases From Geotrichum Candidum 4013Rodolfo RibasNo ratings yet

- Ajol File Journals - 413 - Articles - 203082 - Submission - Proof - 203082 4921 508128 1 10 20210126Document12 pagesAjol File Journals - 413 - Articles - 203082 - Submission - Proof - 203082 4921 508128 1 10 20210126iqra sadiqNo ratings yet

- PavllovaDocument5 pagesPavllovalucia_bregNo ratings yet

- En Zima Conserva Ça oDocument7 pagesEn Zima Conserva Ça oJonas TeixeiraNo ratings yet

- High-Throughput Strategies For Penicillin G Acylase Production in Re. Coli Fed-Batch CultivationsDocument13 pagesHigh-Throughput Strategies For Penicillin G Acylase Production in Re. Coli Fed-Batch CultivationsMaruf MuhammadNo ratings yet

- Disertasi Hegar PramastyaDocument172 pagesDisertasi Hegar PramastyaAhmad Bayquni BayquniNo ratings yet

- Energies 09 00685Document12 pagesEnergies 09 00685Shampa SenNo ratings yet

- Kamarudin 2016Document8 pagesKamarudin 2016Jose perezNo ratings yet

- International Journal of Biological MacromoleculesDocument13 pagesInternational Journal of Biological MacromoleculesLuana FagundesNo ratings yet

- Relation of Phanerozoic Stable Isotope Excursions To Climate, Bacterial Metabolism, and Major ExtinctionsDocument5 pagesRelation of Phanerozoic Stable Isotope Excursions To Climate, Bacterial Metabolism, and Major ExtinctionsEstefania GrisalesNo ratings yet

- Origins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsDocument11 pagesOrigins and Transformations of Dissolved Organic Matter in Large Arctic RiversScientific ReportsEstefania GrisalesNo ratings yet

- Oral Assessment RubricDocument6 pagesOral Assessment RubricEstefania GrisalesNo ratings yet

- Inglés 3y 4Document5 pagesInglés 3y 4Estefania GrisalesNo ratings yet

- Taller de Inglés Grado 11 Periodo 2Document7 pagesTaller de Inglés Grado 11 Periodo 2Estefania GrisalesNo ratings yet

- Reading Log #1: AuthorDocument2 pagesReading Log #1: AuthorEstefania GrisalesNo ratings yet

- READING LOG Luisa Barrios MancoDocument3 pagesREADING LOG Luisa Barrios MancoEstefania GrisalesNo ratings yet

- ECT and A/T Indicator (1KD-FTV, 2KD-FTV), Engine Control (1KD-FTV, 2KD-FTV)Document33 pagesECT and A/T Indicator (1KD-FTV, 2KD-FTV), Engine Control (1KD-FTV, 2KD-FTV)Erick Lizana Neyra100% (4)

- Etiqa MozGuard Dengue Mosquito Insurance BrochureDocument3 pagesEtiqa MozGuard Dengue Mosquito Insurance BrochureHihiNo ratings yet

- Case-Friedland Timbers CompanyDocument2 pagesCase-Friedland Timbers Companytalented guy0% (1)

- Ayaz Ahmed SoomroDocument9 pagesAyaz Ahmed SoomroNoman RathoreNo ratings yet

- International Journal of Transportation Science and TechnologyDocument11 pagesInternational Journal of Transportation Science and TechnologyIrvin SmithNo ratings yet

- Steel Fence CatalogDocument4 pagesSteel Fence CatalogtempfencingNo ratings yet

- Oil and Gas - Black Gold!Document32 pagesOil and Gas - Black Gold!tabithapangNo ratings yet

- Bipolar MembraneDocument3 pagesBipolar MembranepriyaNo ratings yet

- Company Profile of Twenty First Century Communications, Howrah (20.4.12)Document55 pagesCompany Profile of Twenty First Century Communications, Howrah (20.4.12)Anindya NandiNo ratings yet

- 2nd Year Physics Full NotesDocument24 pages2nd Year Physics Full NotesmursiNo ratings yet

- Critical Issue Leisha CavallaroDocument8 pagesCritical Issue Leisha Cavallaroapi-216287146No ratings yet

- Sharp+Lc c6554u+Difference+Lc 65d64uDocument30 pagesSharp+Lc c6554u+Difference+Lc 65d64uNicholas RileyNo ratings yet

- Lesson Plan Ordinal NumbersDocument5 pagesLesson Plan Ordinal Numbersapi-329663096No ratings yet

- Assignment On I.T & Pharma IndustryDocument11 pagesAssignment On I.T & Pharma IndustryGolu SinghNo ratings yet

- Product Selector Guide Marine Protective Coatings en 196830Document1 pageProduct Selector Guide Marine Protective Coatings en 196830wilberizquierdo1No ratings yet

- English Year 3 - Midterm ExaminationDocument8 pagesEnglish Year 3 - Midterm Examinationsuhaini abidinNo ratings yet

- E-Katalog Warna - FullDocument43 pagesE-Katalog Warna - Fullarend alfiyantoNo ratings yet

- ACS 2000AD APPL SW Troubleshooting ManualDocument71 pagesACS 2000AD APPL SW Troubleshooting ManualFarhan Sattar0% (1)

- Abaqus Tutorial Axi-Symmetric UpsettingDocument4 pagesAbaqus Tutorial Axi-Symmetric Upsettingdeepak_dce_meNo ratings yet

- OTPBank Securities SI 20210217Document6 pagesOTPBank Securities SI 20210217bdsourav0No ratings yet

- Union Feb. 10, 2016Document16 pagesUnion Feb. 10, 2016Your News. When You Want It.No ratings yet

- Arihant 9 Years JEE MainDocument666 pagesArihant 9 Years JEE MainPG 么 SUSHANTH REDDYNo ratings yet

- DalmaDocument2 pagesDalmaSatish MishraNo ratings yet

- UntitledDocument42 pagesUntitledDiana JacquelineNo ratings yet

- Easy Pinjaman Ekspres PDSDocument4 pagesEasy Pinjaman Ekspres PDSFizz FirdausNo ratings yet

- Investigatory Project in Science ViDocument21 pagesInvestigatory Project in Science Vijasperrheyhuera100% (2)

- Final CV-Europass-20190916-MezakMatijević-EN (2) - Kopija PDFDocument4 pagesFinal CV-Europass-20190916-MezakMatijević-EN (2) - Kopija PDFMirela Mezak StastnyNo ratings yet

- TitanicDocument3 pagesTitanicJaap van DuynNo ratings yet

- Thesis On Cybercrime in IndiaDocument8 pagesThesis On Cybercrime in Indiakarinathomasdenver100% (2)

- GaugesDocument33 pagesGaugesUsman ansarNo ratings yet